Spool Joint

Tags: 3Dprinter, parts, mechanical, and ThingiversePersonhours: 1

Task: Leverage synergies as a team so as to look towards the horizon in the new tomorrow by implementing binomial+ access

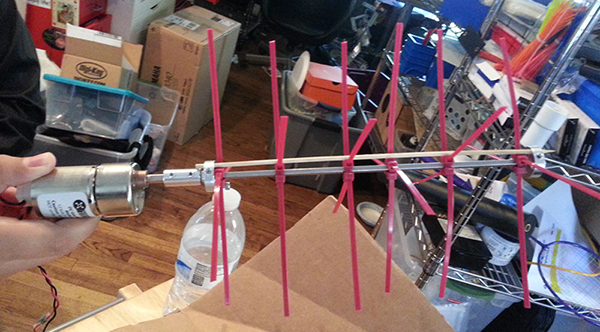

Today we 3D-printed a new version of the tube joint made to hold a spool (which we also made and printed) to put on the very ends of the SVAU (Spheroid Vertical Acceleration Unit) that are not connected to other segments by the normal joint. The piece that attaches directly to the tube has two long tabs instead of three, and they are far apart enough to house the spool. Additionally, we added onto both this and the original joint model by smoothing out the inside face and adding a bevelled edge to the bottom inside lip to make getting the joints onto the tubes easier, and made holes and sockets in the walls of each model that will hold a TETRIX-size NyLock nut snugly on the inside and have a hole for a bolt leading to the outer face, a very important addition because this allows us to finally attach the joints, and thus the entire SVAU, directly to the robot.

Reflections:

The walls of the joint piece had to be made thicker so that there would be enough material for a strong connection point for the bolts, and so the model was far bigger than the original tube joint. So, it took much longer to print. We compensated by increasing the print speed, which still gave it a print time of three and a half hours, with lower print quality. One of the effects of this is that the slots for the NyLock nuts sagged and ended up becoming somewhat shorter than planned. They will likely need to be sanded down to fit the nuts, and this may put the structural integrity of the piece at risk, considering the lower-resolution printing job caused by increasing the speed. The best solution for this will be to try to shear unnecessary material off of the model so that we can increase the accuracy of the print (by slowing the print speed) without extending the print time to death-by-starvation lengths.

Related Articles: