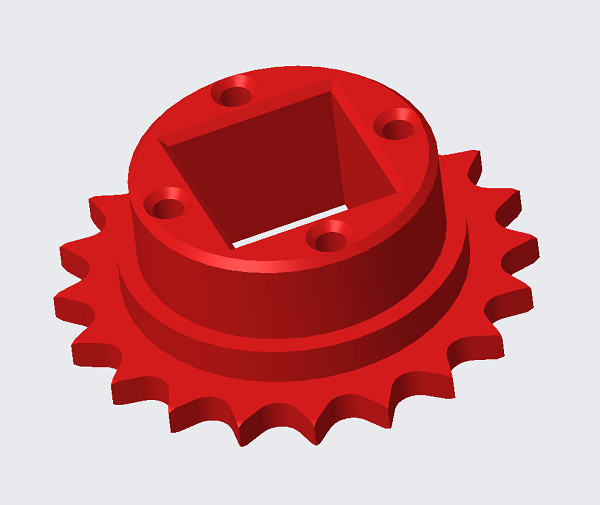

REVolution 15x20 Tooth Sprocket

Tags: Design, Innovate, Revolution, and thinkPersonhours: 1

Task: Power to the REVolution

This is our REV0lution 20 tooth sprocket for #25 chain. This took a lot of trial and error to get right, because it was the component most sensitive to our print settings. We had to inset the tooth profile quite a bit because any extra material created by perimeter settings would cause the gaps between teeth to be too small for the chain to fully engage, and because nylon is so slippery, this would radically increase the likelihood of the chain slipping. Or you would have to make the chain super-tight and that would increase the friction at the bearing. It still requires a pretty tight chain. And it requires a lot of post-print cleanup. The lip where the lowest layers spread out on the build plate have to be trimmed with a hobby knife - all the way around. And then the chamfers at the tip of the teeth have to be rebuilt. We used a reciprocating sander to do this. Nylon is one of the hardest materials to sand effectively, but fresh 220 grit paper will eventually do the job. We only need 2 sprockets for our new Glyph System, so it was worth the effort. This would be the first component that we would recommend replacing with a regular flat aluminum sprocket if you have the means to accurately broach a 15mm square hole in it. Or switch over to timing belts entirely - the timing pulley works fine right off the print bed.