CNC Machine Rehab 1

Tags: journalPersonhours: 10

Task: Refurbish an Apple II CNC Mill and Lathe Set

We were helping our school's FRC team clean out their parts closet, which hadn't been cleaned in 10-ish years. Under the layers and layers of FRC junk, we found an Apple II-operated Patterson/Paxton CNC Milling Set. These were meant to run off of a long-since-gone Apple II in a classroom setting. But, it had long been auctioned off, leaving the set useless. But, Iron Reign, as a collective of hoarders, decided to bring these machines over to the house to refurbish.

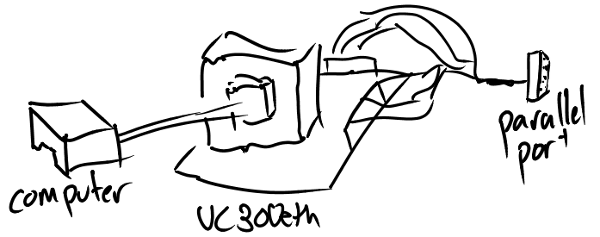

The first idea we looked at was emulating the Apple II with an Arduino, as seen here. However, this implementation didn't have the response rate needed for an accurate CNC machine, so we scrapped it. Then, we found this post. The problem that people mainly encounter is that, for some strange reason, Paxton\Patterson used a proprietary parallel port pinout, and deviating from that pinout (read: using a standard parallel cord) would fry the optidriver board in the machine. So, we bought a ethernet-to-parallel port jumper box (UC300eth).

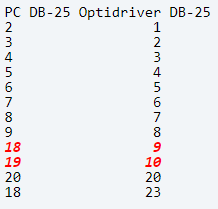

We then sliced a parallel cable in half, and rewired the wires to the pins, treating the left column of that of the port numbers on the board and the right as the pin numbers of the cables.

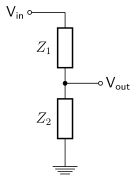

We then made a power supply for the UC300eth. We attempted to use a 10V DC power supply, and use a voltage splitter. Unfortunately, the power spiked, and probably fried the UC300.

Next Steps

We need to buy a new UC300 board and hook it up to a laptop with Mach3 to test the power.