Materials Testing Planning

Tags: think and designPersonhours: 1

Task: Design a lab to test nylon properties

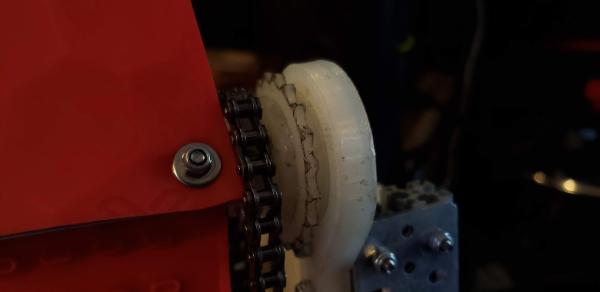

So, Iron Reign is used to using off-the-shelf materials on our robot: silicone oven gloves, ice cube trays, nylon 3D-printed parts, and more. But, we've never actually done a thorough investigation on the durability and efficacy of these parts. Because of this, we've had some high-profile failures: our silicone blocks breaking on contact with beacons in RES-Q, our nylon sprockets wearing down in Relic Recovery, our gears grinding down in Rover Ruckus. So, we're going to do an investigation of various materials to find their on-robot properties.

Nylon Testing

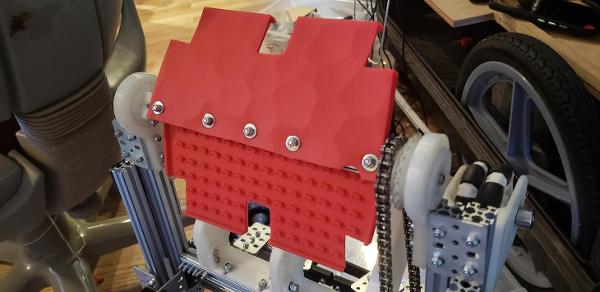

A majority of the 3D-printed parts on BigWheel are nylon - we find it to be stronger than any other material save ABS, but much less prone to shattering. Still, we still deal with a substantial amount of wear, and we want to find the conditions under which damage happens.

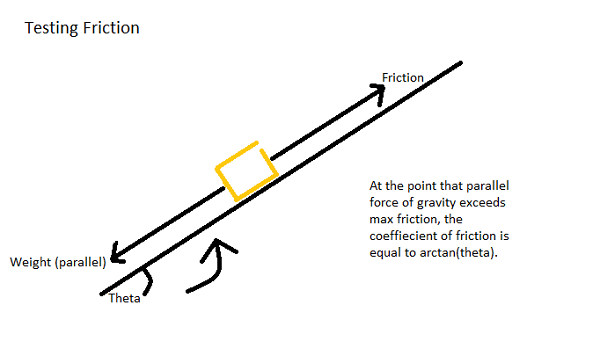

So, to start, we are printing a 4.5" x 1.5" block with a thickness of 4mm with an infill of 60% out of nylon. We chose these values as our average part is about 4mm thick, and our high-strength nylon pieces are about 60% infill. Then, we are going to test it under a variety on conditions meant to simulate stressful operation. As well, we're going to measure other values such as coefficient of friction using angle calculations.

Silicone Testing

Similarly, we use the silicone oven mitts on our intake; we find that they grip the particles pretty well. The main thing that we want to test is the amount of energy they have while rotating and then the amount of energy they lose upon collision. We plan to test this through video-analysis. In addition, we wish to test the coefficient of friction of the mitts to see if a better material can be found.

Next Steps

We are going to perform these labs so that we can compare the constants we receive to commonly accepted constants to test our accuracy.