Chassis Mark Two Planning

Tags: think, design, and innovatePersonhours: 1

Task: Plan a new BigWheel chassis

Our next tournament is a while away, in about two months. So, we have a little bit of time to redesign. And, our current chassis has plenty of faults.

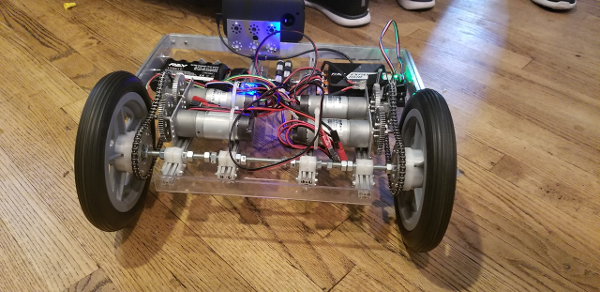

First and foremost, our chassis was built for a testing competition, not to be a full fledged competition robot. As such, it's a little lacking in features that would be normal on such a robot such as mounting points for other components, durability, and free space. So, we need a redesign that allows for greater modularity and functionality.

We're starting from the ground up; our current base is a square metal frame with a polycarb bottom. While this is a good start, it has some issues: the base seems to be a little wobbly due to the polycarb, there's only one level of construction, so our motor mounts, REV hubs, and supports compete for space, and we have to add all the counting points ourselves.

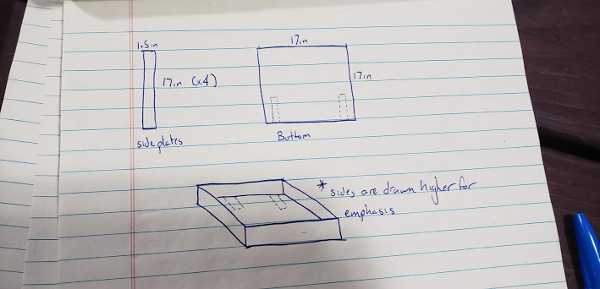

The main way to prevent the wobbliness is by replacing the polycarb with something sturdier, as well as not having everything simply bolted together. Thus, we're going to dive headfirst into the next step - welding. We plan to cut a base out of aluminum as well as four side plates to create a dish-like shape. Then, we plan to TIG weld these plates together (TIG welding uses a tungsten electrode in contact with two separate metal plates in combination with a filler metal that melts and joins the two plates together).

Next Steps

We plan to cut the aluminium next week, and TIG weld the pieces together the week after that. We're beginning to train a few of our members on TIG welding and we already have some of the safety equipment to do so.