Rotational Nylon Wear Test

Tags: think and designPersonhours: 2

Task: Test the amount of wear on a moving nylon part over time

After our last tournament, we noticed several 3D-printed sprockets that had worn down significantly. So, we wanted to measure how much wear one of our nylon sprockets takes per second.

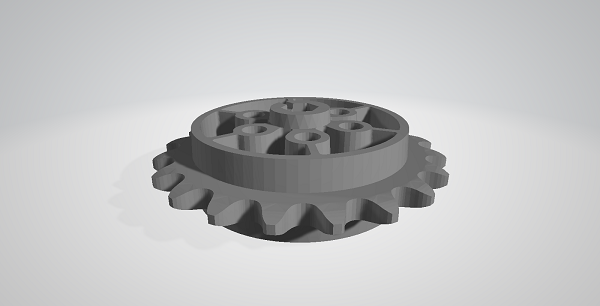

First, we printed out a model of one of the REV sprockets, using the STEP file here. We printed it with ~45% infill, our average for sprockets and other parts. Then, we attached a REV Core motor to an extrusion, then mounted the nylon sprocket on the other side. Then, we measured the length on one of the teeth. We ran the motor for 1:05:45, and then measured the length afterwards.

So, the tooth length before was 5.3mm, and after, it was 5.23mm, for a difference of 0.07mm. Then, we ran the system for 1:05:45. This results in a wear rate of 1.77*10^5 mm/sec. So, given that we use our robot for about an hour, cumulatively, in a tournament, 0.0638mm, or 1.2% of the sprocket. This is enough to be noticeable under loose-chain conditions and indicates that we should keep extra sprockets at tournaments so that we can do a quick replacement if needed.

Next Steps

We plan to perform more materials testing in the future; in particular, we'd like to determine the wear rate of the regular REV sprockets as well, but this requires a more rigorous experiment.