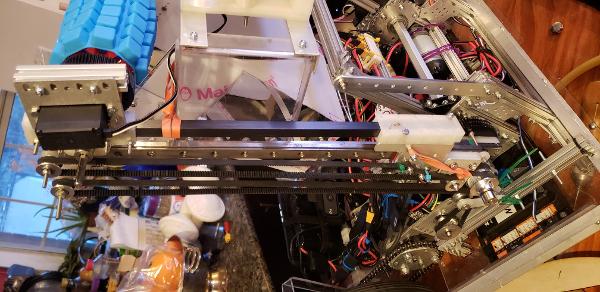

Belt Drive

Tags: think, design, and innovatePersonhours: 3

Task: Install a belt lift on our robot for depositing

The most recent addition to BigWheel has been the addition of a belt drive lift on either side of the linear slides. We chose a belt lift over a string and pulley lift because it is a much more secure, closed system, and doesn’t require stringing. For these reasons, we switched to belt drive. While more complicated to build, it requires no spool, only tension, no knots, and is super smooth in its motion. Our current design relies on the same time of belt drive used on 3D printers, something that we as a team are familiar with. The issues that come with using a belt drive lift include a more complicated setup and a more difficult time to repair in the pit, a lower ability to bear weight due to slippage of the teeth, and difficulties in tensioning.

Next Steps

So far the belt drive has experienced a bit of slippage, but with the intake redesign we are just about to start on, it should have a better time lifting the intake.