Gearkeepers

Tags: think, design, and innovatePersonhours: 6

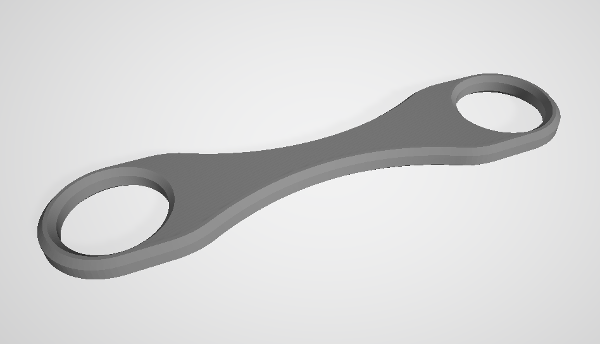

Task: Create and install gearkeepers to reduce slippage

We need to install gearkeepers on the Superman arm to prevent gear skippage which damages gears over time. We designed a simple rectangle in PTC Creo and cut holes to fit bearings, 3D-printed them, and attached them.

Now it was time to test for gear skippage. Unfortunately, we had one or two gear skips with every attempt of rotating the wheel mount. We tried using string to see if tensioning the gear holders would work but that also failed.

We went back to the drawing board and checked for a sizing error. To calculate this we take the module of the gear and multiply it by the amount of teeth the gear has, then dividing by two to get the gear's radius. We do this for both gears and add them together. The module of the REV plastic gears is 0.75. This resulted to be (15×0.75/2)+(125×0.75/2) or 52.5 mm. And the original gear holders were 53 mm long, a slight error but at least we found the reason for error. We also noticed that there was some give in the plastic inserts for the REV bearings so we decided to tighten it down to 52mm.

We changed the length of the inside of the gear holders from 53mm to 52mm and 3D printed them. This resulted in a complete fit where the gears were firmly engaged.

Next Steps

This is good for now but in the future, we need to watch the nylon of the gearkeepers for wear and tear as well as stretching - even a millimeter will allow the gears to slip.