Assembling the Turntable Bevel Gears for a REV Motor

Tags: design and innovatePersonhours: 4

Task: Assemble the bevel gears to the turntable to fit a rev motor

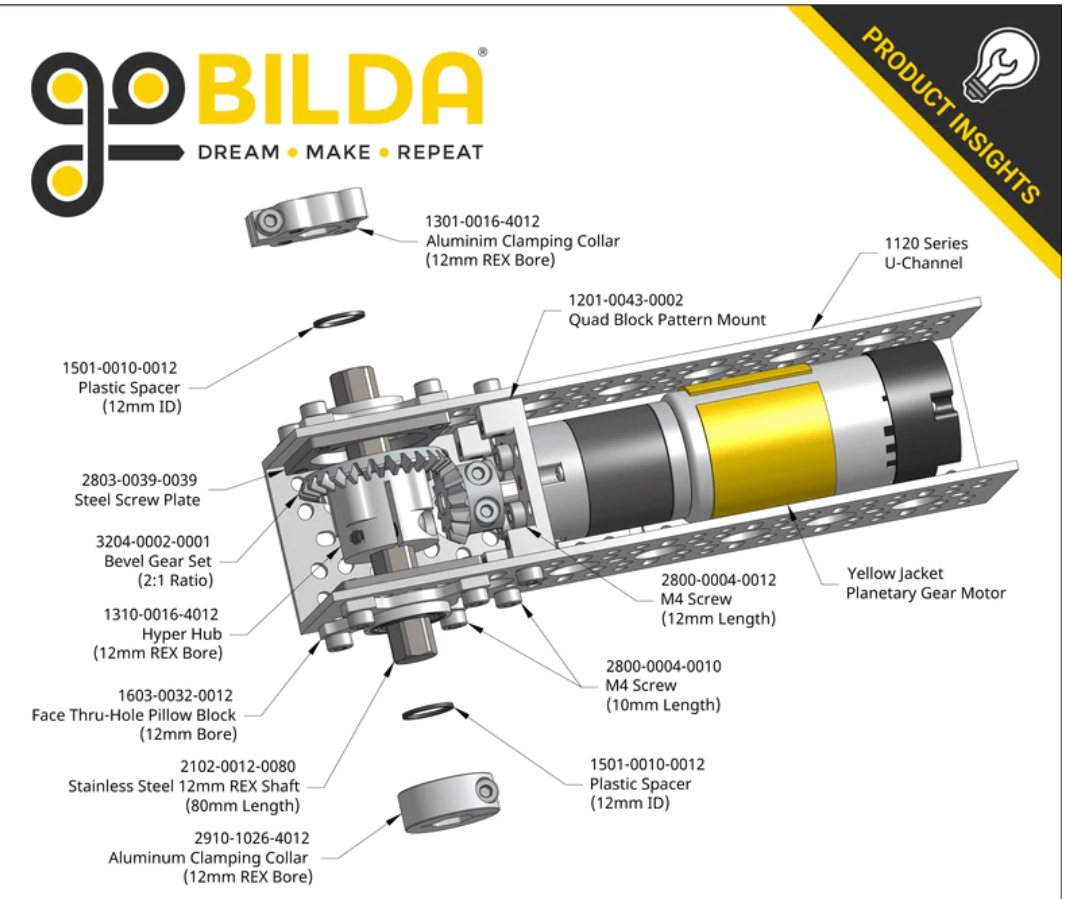

Today we assembled a second version of our bevel gear assembly for the turntable. Our previous design used an Andymark motor, which was very fast but couldn't provide enough torque for precise movement. The custom geared REV motors allow us to power the turntable with our desired torque. This is further explained in our Calculating Torque at the Turntable post dated 2020-01-01 . The Gobilda motor mount was designed to fit motors wit 6 evenly spaced mounting holes, while the new REV motors have 8. We decided that the most efficient solution was to mount a rev rail motor mount to the Gobilda channel. First we had to make sure the holes lined up and the motor shaft was centered in the channel; the holes lined up perfectly and centered the shaft in the channel. The sides of the motor mount were too wide and had to be cut to allow the mount to slide in the channel enough to line up the mounting holes. Due to the apparent standardization of mounting holes, we could easily mount our new motor to the gears. The rest of the assembly was just following the Gobilda instructions for assembling the bevel gears and bearings. We were ready mount the new motor assembly to the turntable.

Next Steps

Next we will remove the old motor assembly and replace it with the new one. We also need to test the strength of the mounting plate under the load of the turntable. We should also use the time with the turntable off to inspect the nylon gears for any wear.