Intake Iterations Summary

Tags: think, innovate, and designPersonhours: 12

Task: Go over our 5 intake iterations

This season, we experimented with 5 gripper models - both for our robot in three days project and for our competition bot. While we do not plan on using all 5 of these models, they allowed us to effectively implement the engineering process within our build season. Experimenting with each intake helped us to identify the potential of each design as well as how two individual designs could be combined to create a more efficient one. Each of these designs has its own article but this is just a summary of all of our intake designs so far.

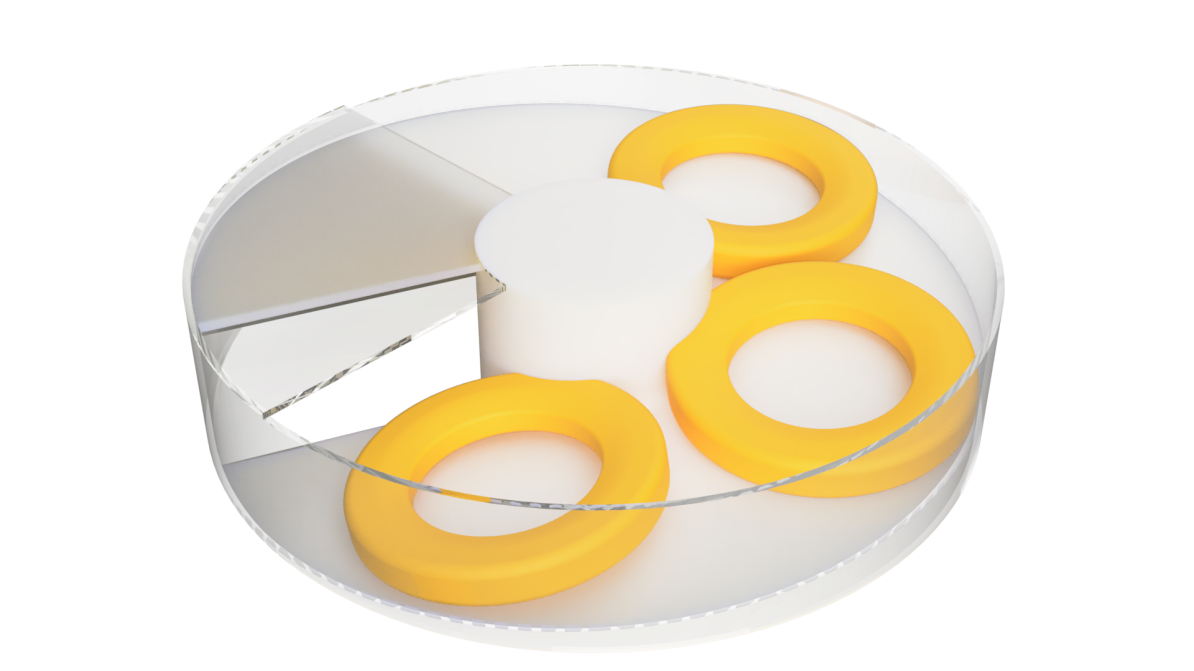

1)Archimedes Intake

This was one of our first designs and it was based on an Archimedes screw. A screw shaped surface would draw the rings from the fields and directly to the launcher. While this would have been a great feeder, our primary issue was that would essentially be a slower system which could likely only draw in ring at a time so it never progressed past its CAD stage.

2) Ladder Intake

This gripper functions with a series of omniwheels mounted in between two rev extrusion bars, which in turn are connected to a ladder-like assembly with a control hub mounted on the first rung of the ladder and to the wheels. As the wheels rolled, they would slide on top of the rings and roll them into the system. The issue with this system was that it had significant delay in "rolling" the rings in since if the omni wheels spun too fast, they would lack the tracton to "grip" onto the wheel.

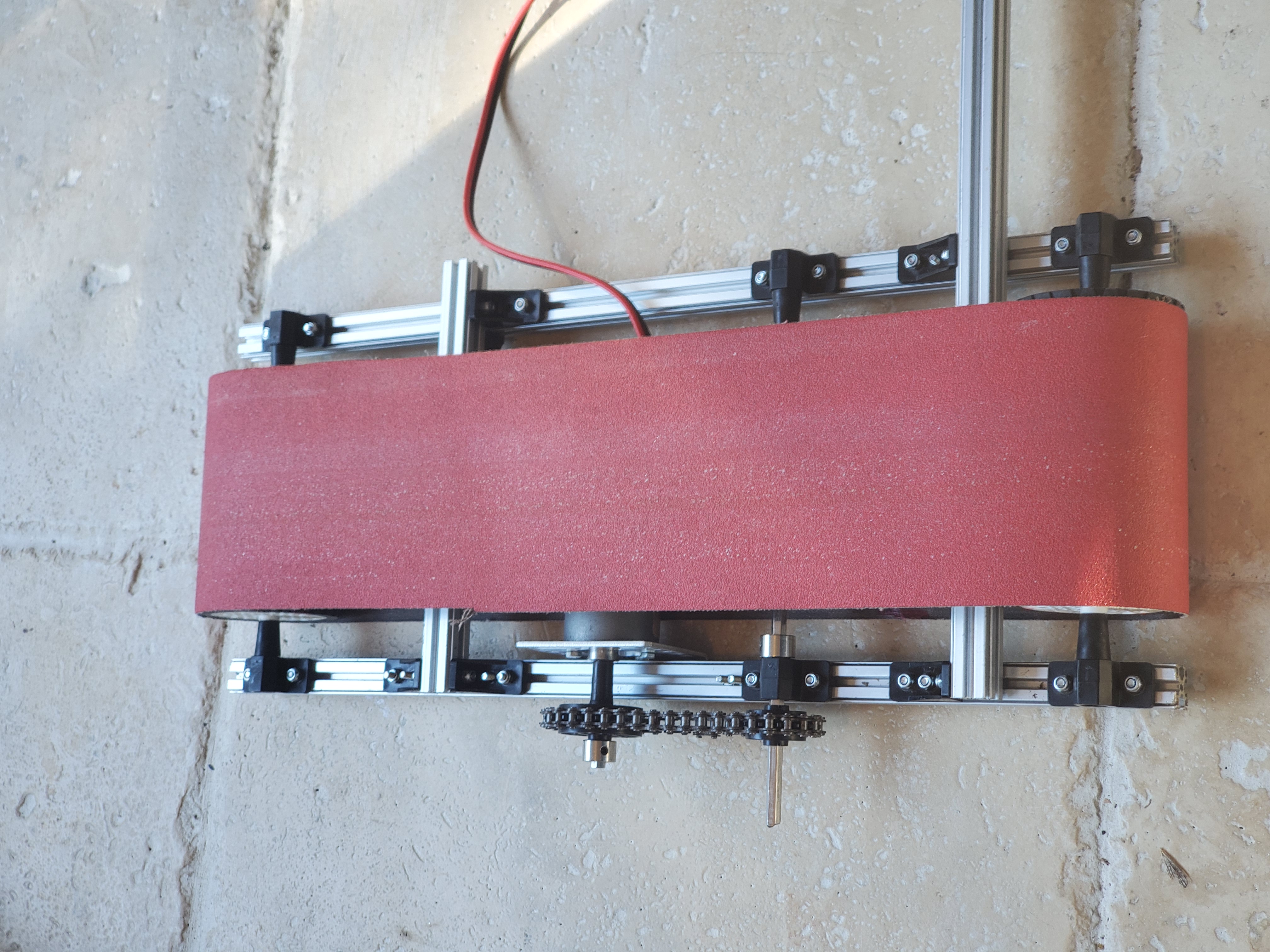

3) Belt Sander Drive

This system was far more simplistic than our earlier ones and had a faster intake speed during testing too. The actual drive would be mounted onto the robot with the "back" of the system sliding over the rings and carrying them across the conveyor belt to the top of the robot. Despite its efficacy, it had one main issue - it didn't have the gription needed to ensure the rings slid across the belt.

4) Caterpillar Intake

Luckily, the gription issue could be resolved pretty easily with the caterpillar intake. This system was dual tracked unlike the first one, and had rubber bands threaded through the tetrix tracks to improve gription with double the power. Ultimately, this was a pretty successful issue but it did not have as much speed as it could have and lacked the signature Iron Reign charm.

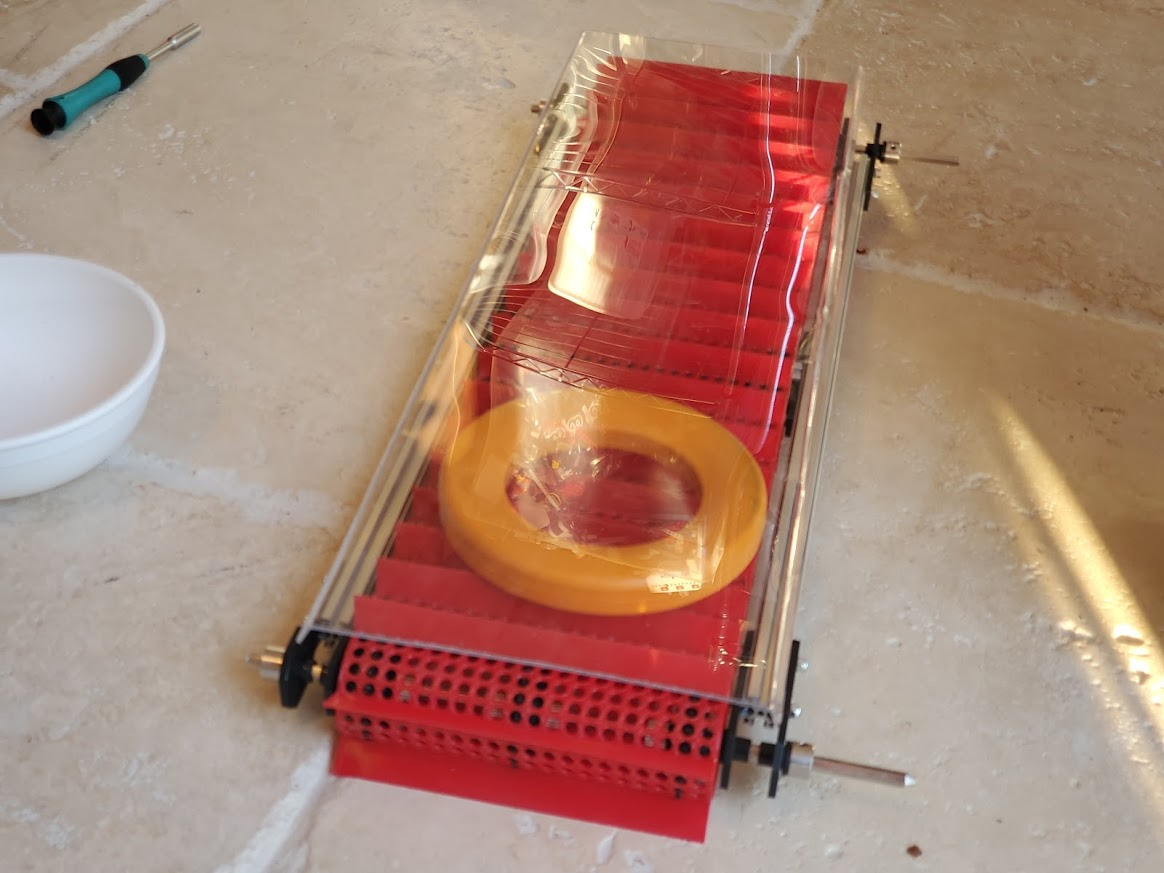

5) Ringevator Ultra Flex Unlimited Intake

This gripper, the Ringevator, for short was a combination of our two previous best systems - the belt sander drive and the caterpillar. It possessed the mono-drive from the belt sander and similarly drew in rings from its back and carried them across a conveyor belt to the top of the robot and like the caterpillar, had a means for increasing friction with the surface of the rings. While the caterpillar intake did this with rubber bands, the Ringevator accomplished it with ninjaflex "fins" layering the "belt" to sweep in the rings. Both sides of the intake are covered with polycarb to encase the conveyor built internally and to ensure the rings don't fall off when picked.

Next Steps

Now that we have analyzed all of our intake designs so far, it will be easier for us to streamline the best design to mount on the robot. While the ringevator seems to be our best choice, we still need to conduct further testing to see which one is the most efficient.