Meeting Log 2/11

Tags: journal and thinkPersonhours: 52

Task: Continue to assemble TauBot2, work on portfolio, and prepare for Regionals

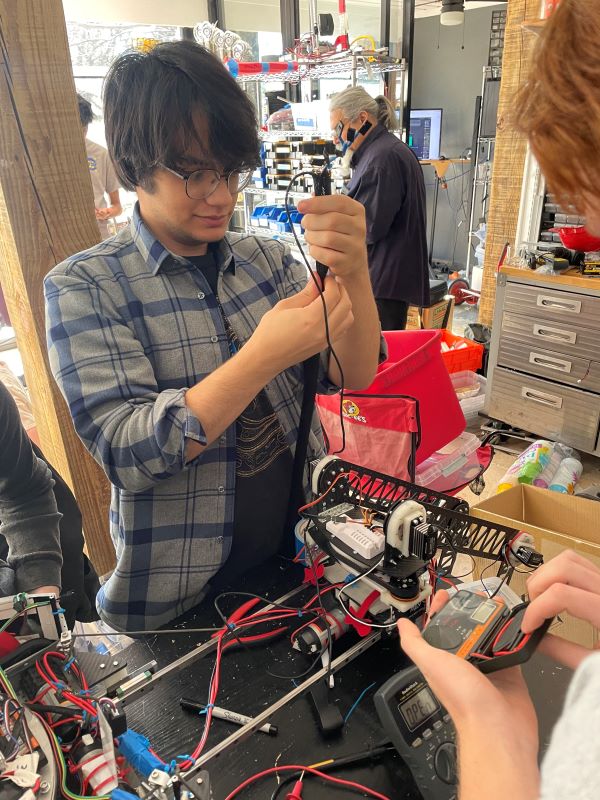

First off, we began assembling and wiring the UnderArm system. In the process of putting the UnderArm together, we ran into a couple of hurdles. The alignment on our parts was incredibly difficult to get right, and in the process of aligning them, we discovered that one of our servos was stripped. After tons of trial and error, we wired the servos that control the joints of the underarm. This was incredibly exciting because this was the first bit of functional mobility that our UnderArm system would be capable of. We strung the wires for connecting the servos, the new power switch, and the camera wire in a wire sleeve. We color-coded a lot of our wire management so that it's much easier to organize and understand for further replacement and continual maintenence.

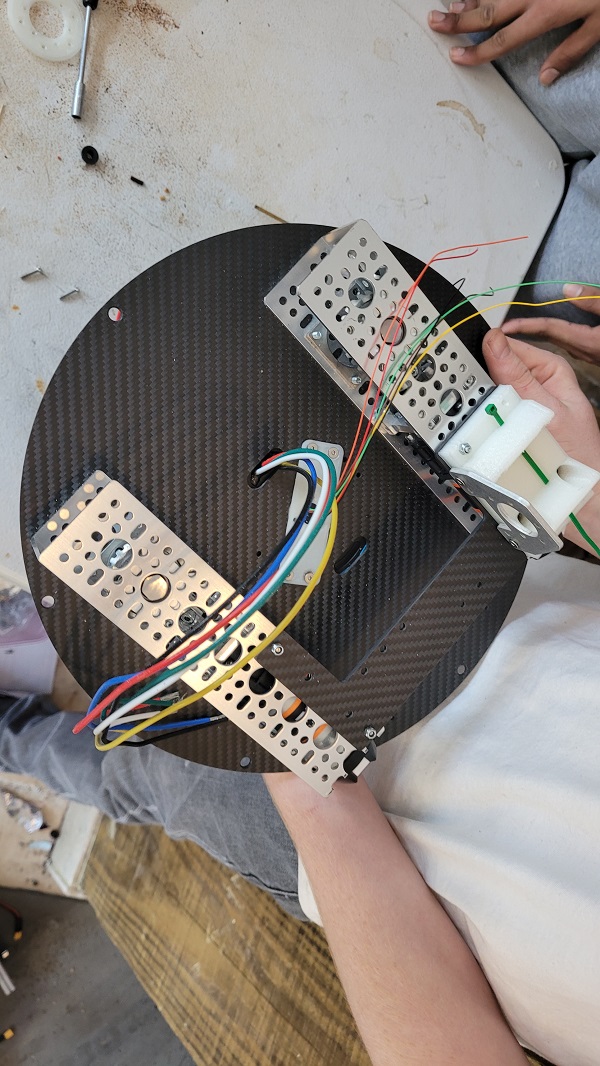

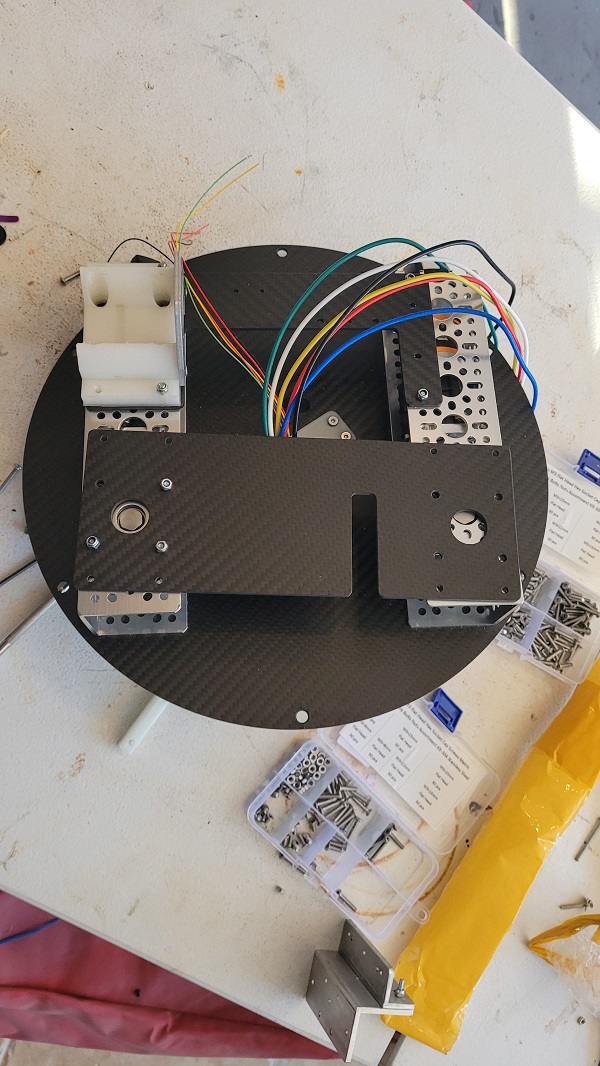

Then, a seperate team worked on assembling the newly designed Shoulder and Turret. Our new Shoulder and Turret are custom-made and improve our robot in many ways. They make our robot lighter through the use of carbon fiber over aluminum. However, this mechanism is very similar to the initial iteration of TauBot. We switched to using an 8mm axle on the shoulder drive because our original shaft was too fragile and would bend under the pressure of the arm. We also worked on sourcing the right-sized bearings for our shoulder. During this meeting, we managed the slip ring wires and attached the slip ring to the carbon fiber base of the turret.

We also attached the nylon 3D-printed motor mounts for the motors that drive both the angle of the shoulder and the extension of the crane and began assembling the new motors with their required gear ratios. Preliminary work on the linear slide system also began as we 3D-printed the requisite spacers and cut the slides down to their proper length. We hope to have both these redesigned subsystems on TauBot2 as quickly as possible.

We continued to cut custom carbon fiber parts using our CNC machine, such as our belt tensioner and one of the motor mounts. In the process, we talked a lot of our new recruits through the CNC process and trained them to be proficient in using the CNC. This will help make our work with custom parts much quicker, as more people are capable of doing it. In doing this, we practiced a lot of problem-solving as we learned the hurdles that came with using a CNC machine. One such problem stemmed from the fact that step motors can't retain their positions. This led to the machine constantly losing where it was and slipping, which called for lots and lots of head-scratching and problem-solving.

Next Steps

Our next steps are to continue to train our new recruits to help make them more valuable assets to the team. With their help, we want to fully assemble and code the UnderArm system, the new Shoulder and Turret system and the new Crane. Once that's done we'd like to test the code and optimize it with the drive team so that we're ready to go for Regionals.