Beater-Bar Intake Update

Tags: journal, innovate, think, and designPersonhours: 10

Task: Create a reliable intake system for the Submersible

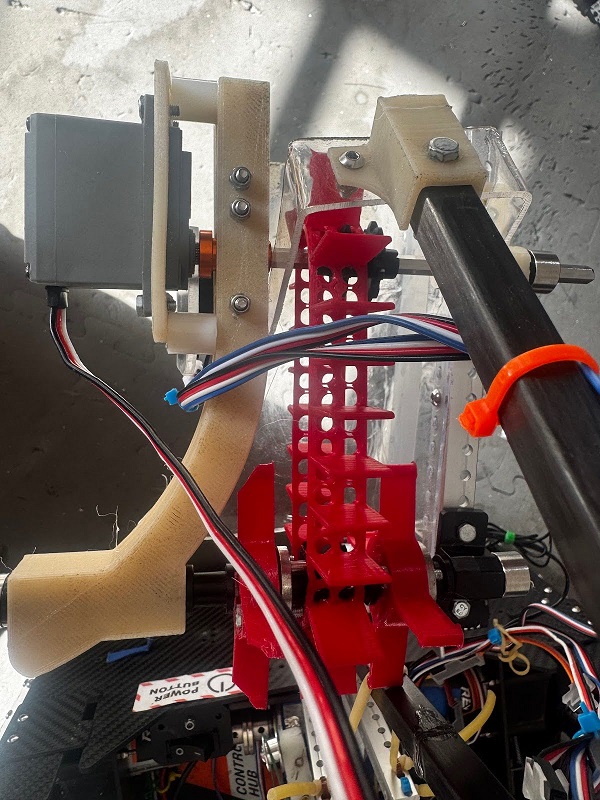

We developed an intake system using a 3D printed beater bar out of ninjaflex. The beater bar is used to pull the sample onto the platform. We used clear 1 mm polycarb to form the walls of intake. The walls curve slightly allowing samples faced in many angles to correctly position itself to enter the intake via the beater bars. The beater bars move via an axel connected to a servo. We also connected a color sensor to be able to detect the color of the sample. This will ensure we have either a team sample or neutral sample. If we collect something else, we are able to easily eject it. Due to the light from the sensor, the driver is able to view the color of the sample through the polycarb during tele-op.

Some changes we had to make were the beater bar and the walls of the intake system. We experimented with different sized beater bars and the amount of them. We finally decided to go with thin beater bars that are 15mm and 10mm and use 1 beater bar belt to continue the intake process, while 2 beater bars are on the first axel. This setup allows the samples to be taken in by a multitude of angles, yet continue through the intake until it needs to be ejected. The build of the intake was changed from a rectangle, to having a triangle-like entrance. This change allowed the edges of the samples to get caught and slowly turn the sample to the correct position, creating more intake positions of the sample.

So far this intake system works well. It can intake samples in almost every position, except completely horizontal. This can be fixed by slightly hitting a sample to turn it in-game. It does however allow some samples to eject unknowingly. Another issue we have found is it intakes slowly, causing cycle time to be relatively slow compared to other teams. Overall these are minor issues, and it is an effective intake that we will continue to develop.