V3 Sampler: Problems and (maybe) Solutions

Tags: journal, mechanical, and designPersonhours: 18

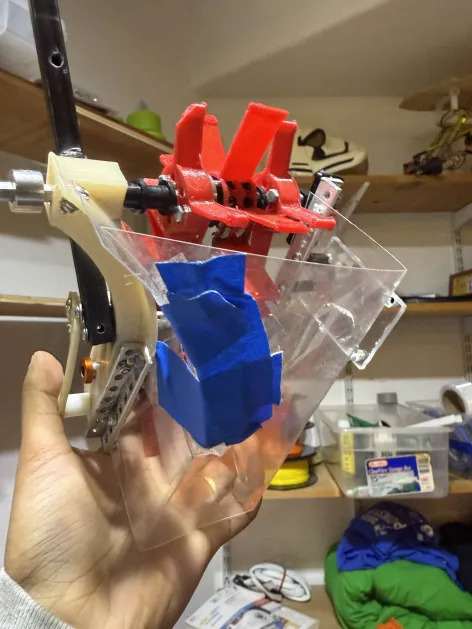

After working with V2 of our Sampler for a while, we decided it was time to get to a more streamlined building process, involving a template for the polycarb base of the Sampler. However, because we needed to get this new version of the Sampler on the robot ASAP, we essentially moved over everything that wasn’t the polycarb base from the old version onto the new version.

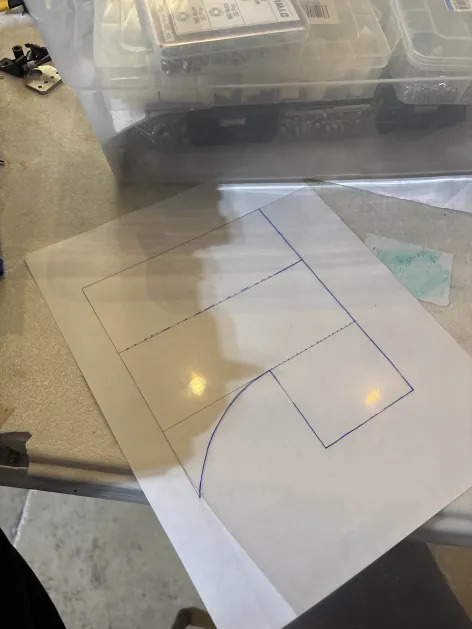

First step was figuring out how to make a template. I had very little experience with .dxf files so I had to come up with my own way to convert .dxf files to a printable file. Using this template, I made the base for the rest of the design. I accidentally didn’t add crenellations so we could fold the bottom curved part up to meet the deflector, which is where the first of the problems started.

This resulted in us adding crenellations to the curved deflector, which was attached to the underside of the Sampler and the point that attached the two pieces of polycarb was also what was coming into contact with the mats the most often, making it incredibly vulnerable (by the end of the day, it was held together exclusively by Gaff tape and prayers). This also harmed the Sampler’s ability to function so we started rushing to get V4 Sampler started.

While welding the belt which would go on this intake, I didn’t realize that I shouldn’t be using a soldering iron that’s set to 800 degrees F to melt Ninjaflex so I ended up burning the joints quite badly, so how long the belt would function wasn’t looking very good.

Updates: After a few weeks of use, this is what V3 of the Sampler looks like.