Lessons Learned From CNC Failures

By Fernando, Ren, and Sol

On December 20th, Iron Reign began cutting carbon fiber to assemble our redesigned Arm and Shoulder for V3 of our Into the Deep robot.

We underestimated the time it would take to CNC as we did not allocate enough time for errors. Our inexperience with the CNC led to numerous time-consuming mistakes we did not account for in our planning. Our coach had to step in and run the remaining operations to ensure that our sister team had enough time with the CNC.

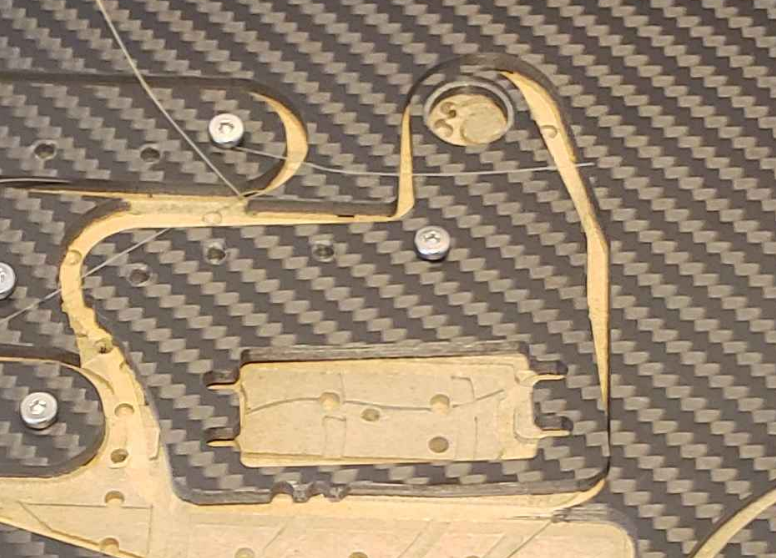

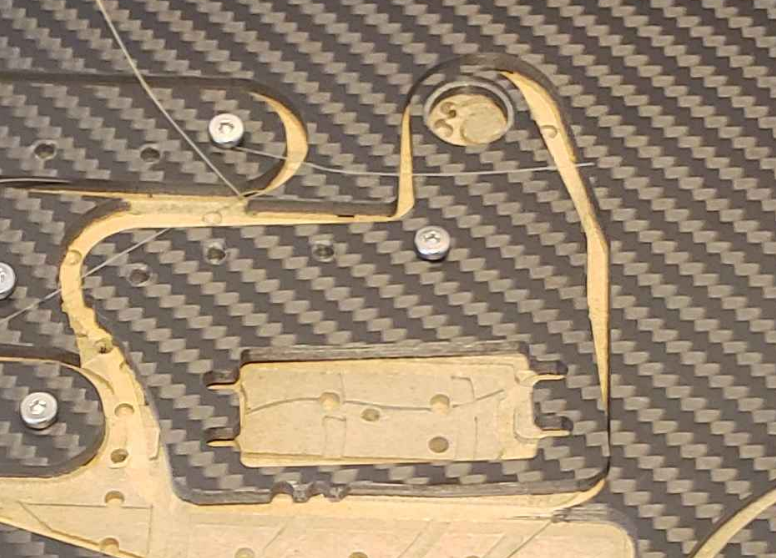

Since we re-cut the large arm mount plates, we had large waste sections. Since we rushed the process, these pieces did not have work-fix bolts. This meant those pieces lifted from the board and were too big for the vacuum. Later in the contour operation, the pieces got trapped in the baffle and jammed on other parts. This jammed the machine and ruined the cut, losing the work origin.

When we eventually added work-fix bolts, we added too few. This resulted in some contour damage as the pieces rotated during cutting. Because of these issues, we will need to acquire new motor plates later. Ultimately, our creation of a high-stakes environment made learning and executing the complex skills behind CNC quite difficult. This issue that emerged during this cut reflects a larger issue that we as a team struggle with. We also identified this shortcoming after our last league meet and are working on fixing it!