Continued: Errors without Trials

Tags: control, innovate, mechanical, and softwarePersonhours: 8

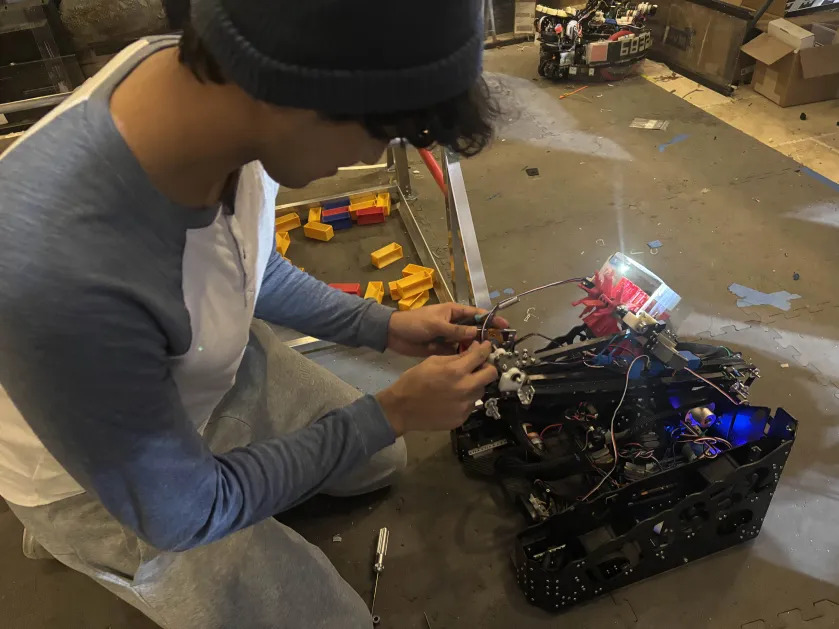

Today, the debacle continued with V4 Sampler. While we were trying to finish up solving the problems that arose last time, we discovered that some of the solutions we'd come up with created a whole new set of problems.

New Problems:

- New bridge for Sampler doesn't fit into sizing

- Re-tensioning the intake belt shed light on old issues

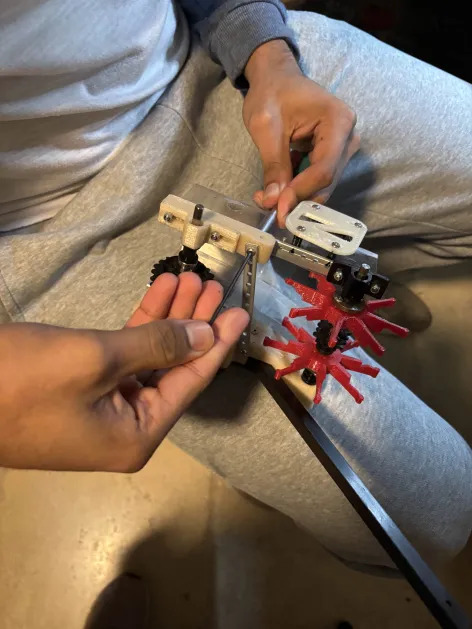

The origin of the problem started at trying to find the angle the Sampler needs to be at to efficiently pick up samples from the floor and the submersible. We reimplemented our bridge mechanism to have the Sampler on a changing angle, but created another problem: it no longer fits within sizing because of the extra space the bridge takes up. We were making the bridge because the angle adjuster which would keep it at a rigid angle was also not fitting within sizing properly and we thought a rigid attachment point just wouldn't be as effective as having it flexible, but that option also failed. We ended up reverting back to the original fixed angle and opted for software adjustments in this iteration; however, we have plans to make an option for flexibility in the joint angle of the CF tube and Sampler in the next redesign of the subsystem.

The beater belt was re-tensioned so it would stop slipping off the sprockets and it was discovered that a cause for the derailment of the intake belt was the spacing of the holes that were changed due to the original welding of the belt. The welding takes up more space than the usual pattern so the belt sometimes has a weird skipping problem when it runs over the sprockets. However, the additional weld that was done to increase tension doesn't seem to have the same problem and the original weld can be fixed in the next edition.

As we continue to work on getting V4 Sampler ready for use on our robot, new problems will definitely pop up but we're ready to deal with them as they come.