Flywheel V1 Design

Tags: outreach and motivatePersonhours: 5

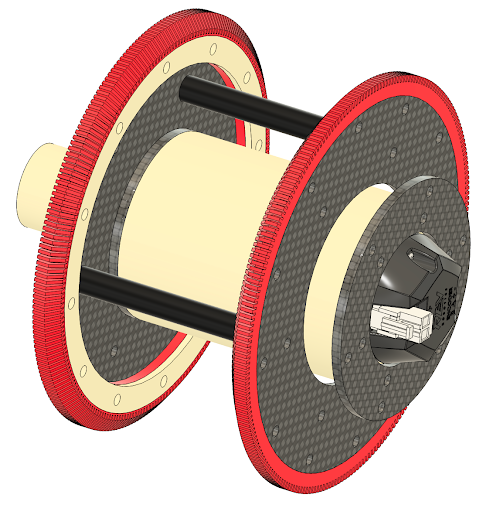

After initial testing during our “Launcher in 2 days” experiment we knew he had a decent way to go before arriving at a properly functional and unique flywheel design. Flywheel v1 is a result of using our original 2 sided concept from “Li2D”, but with a complete design overhaul. Currently this design serves merely as a proof of concept as it still needs some updates in order to assure consistent, accurate, and powerful shots. We will continue to develop this idea as well as other concept designs as the season progresses.

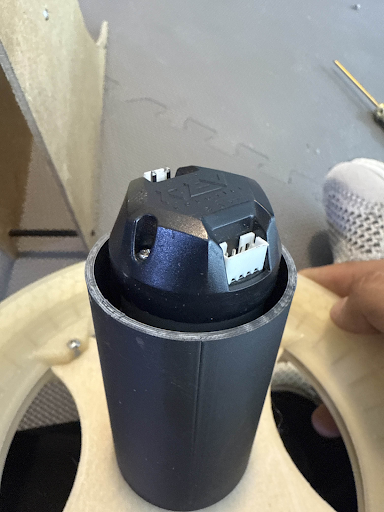

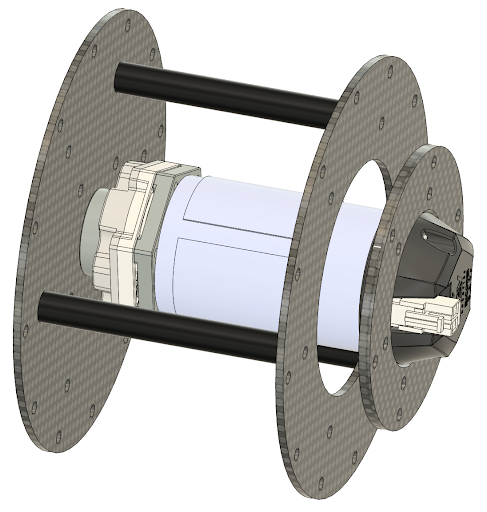

We knew we wanted to keep the hub motor idea, so the first step was to strengthen our motor mount. The original design was made for a different project and it ended up being far too weak for this application. This original version was entirely 3D printed, so it makes sense that it split along the layer lines. For this reason, we decided to break the design up into three separate parts. Two of them are carbon fiber plates that are used for mounting, and the third is a thick 3d printed Nylon shell that surrounds the motor. It's a simple yet highly effective change that should last through rigorous testing and match play.

Next up is the main structure of the flywheel itself. The Li2D version was made up of a central plate to which the two sides were connected via screws and spacers. This 3d printed plate ended up surviving all of our testing, but it instantly broke due to a short fall onto the foam field tiles. The main structure of Flywheel v1 consists of two carbon fiber plates that connect to each other and then mount directly onto the motor output face. We’ve chosen to jump directly to using CF because of its rigidity as well as potential for shorter flywheel rev up times due to how lightweight it is.

While the progress made with this version of the flywheel is substantial, it’s clear that the design still needs some minor updates. It's very unlikely that the new hub motor mount will be suspect to structural failures; however, we’re worried that it could result in the motor overheating as it's almost completely enclosed. The new CF body of the flywheel has been great and has the included benefit of being very lightweight, but it is subject to unwanted oscillations that could lead to unpredictable shifts in the accuracy of the launcher. Finally, the major issue with the current design is that there still isn't enough traction between the flywheel and the artifacts, which results in less launcher power. Stay tuned for future updates and further testing!