Flywheel Review with Dallas Personal Robotics Group

Tags: outreach and motivatePersonhours: 2

We recently presented our flywheel subsystem to the Dallas Personal Robotics Group, and the discussion that followed highlighted the complexity of our problem, but we did end up with several promising directions to explore.

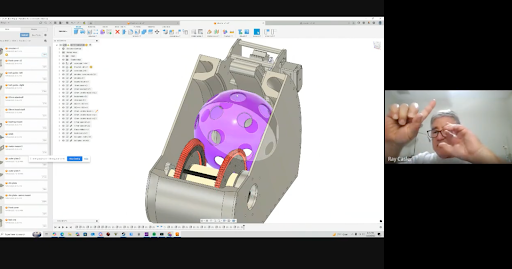

We started off by explaining how our initial prototype worked, and how it was promising. We built it from MDF and REV Rails, featuring a direct-drive flywheel system with TPU flaps. The design included a full ramp that provided approximately half a circle of acceleration, and the results were impressive as we were achieving around a 100 inches in horizontal distance and over 30 inches in height. The TPU flaps were key to this success; they compressed against the ball during launch, and some even entered the whiffle ball's holes to increase traction and help propel it forward.

We explained how that initial version is too bulky to fit into our robot due to the space constraints. We needed to store balls vertically and feed them upward, which meant eliminating the long ramp that had been so effective in our prototype. When we tested the new design, the results were disappointing. We were only achieving 10-20 inches maximum range, compared to the original 90-100 inches. Even worse, we could visibly see that most of the flywheel's energy was going into spinning the ball rather than propelling it forward. The flywheel assembly also had significant wobble issues that we'd been struggling with since the first conception of this design.

Members of DPRG (Dallas Personal Robotics Group) offered several thoughtful suggestions that we're eager to explore. One member suggested adding a TPU strip to the curved guide rails at the back of the mechanism. The idea is that as the flywheel grabs the ball from the front, it would push against this strip in the back, preventing the ball from just spinning in place and ensuring the energy translates into forward motion. This seemed like a promising and relatively straightforward modification to test first.

Another suggestion was to use two counter-rotating flywheels, similar to baseball pitching machines. This would grip the ball from both sides and shoot it out straight without putting torque on just one side of the ball. However, our coach pointed out that our two sister teams are pursuing that approach, and it comes with its own set of challenges. There's only one instantaneous moment when both flywheels compress the ball simultaneously, which requires precise alignment and makes side-to-side accuracy much more difficult to control compared to our hooded flywheel approach.

Interestingly, we received contradicting advice about friction. While one suggestion was to add more friction with the TPU strip, another member wondered if we should actually reduce friction on the guide rails using lower-friction materials or even captivated ball bearings. This really highlighted how nuanced the problem is. We've already been experimenting with different compression depths and materials, starting with nylon and moving to silk PLA for the guide rails, so we've explored the lower friction route to some degree. At this point, we think adding friction might be the better path forward.

The group also discussed adding mass to the flywheel to increase its rotational inertia, which would help it maintain speed when the ball makes contact. Unfortunately, we're already at our power limit. We're using a direct-drive setup at maximum battery voltage with the most powerful motors allowed in competition, so we can't simply add more power to compensate for any slowdown. If we wanted more torque, we'd need to add gearing, but that would reduce our speed, which defeats the purpose.

We also explained one of the other core issues: our new design has a much shorter acceleration path. The ball is only in contact with the flywheel for about one-third to one-fourth the distance of our original design. Using the same flywheel but with significantly less contact distance naturally results in much less energy transfer to the ball. This explained why we saw such a dramatic drop in performance.

We also discussed trying a smaller diameter flywheel, which we haven't explored yet but probably should. Some more creative ideas came up too, like adding a rubber belt drive on the opposite side of the ball or even using a solenoid to give the ball an extra kick at just the right moment.

As the discussion wound down, the group acknowledged that while they'd provided constructive advice, there wasn't one definitive solution handed to us. That's the nature of complex engineering problems. The real answer will come through systematic testing and iteration; however, we left the meeting with several concrete things to try. We're looking forward to getting back to testing and seeing which of these approaches gets us back to that 90-100 inch range we achieved with our prototype. The journey from proof of concept to integrated robot system is never straightforward, but that's what makes this challenge so valuable.