14 Dec 2025

Post 32

Awards: journal and think

League Meet 2 SWOT Analysis

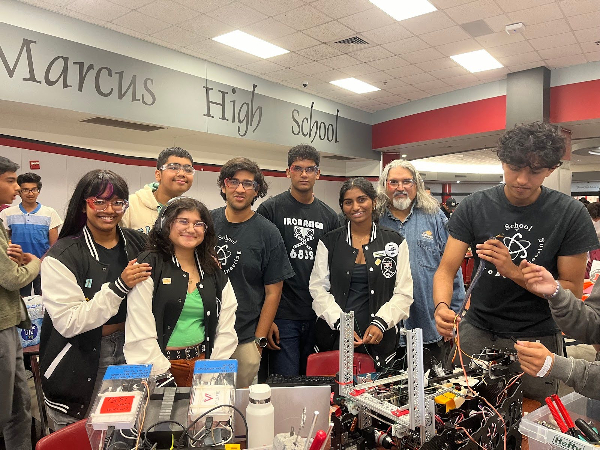

By Elm, Anda, David, Fernando, Alyssa, Pavit, Nirjha, and Nalin

Following League Meet Two, we conducted a comprehensive SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis to guide our strategic planning. This analysis combines performance data and technical observations to help create a roadmap for improvement.

Strengths:

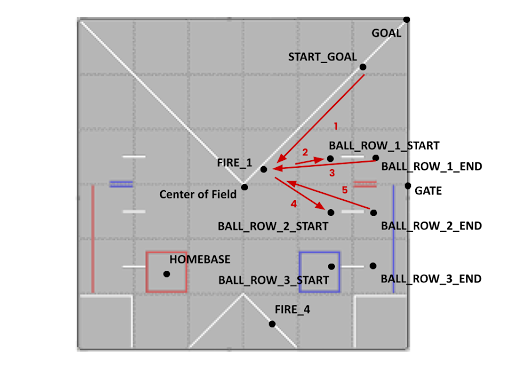

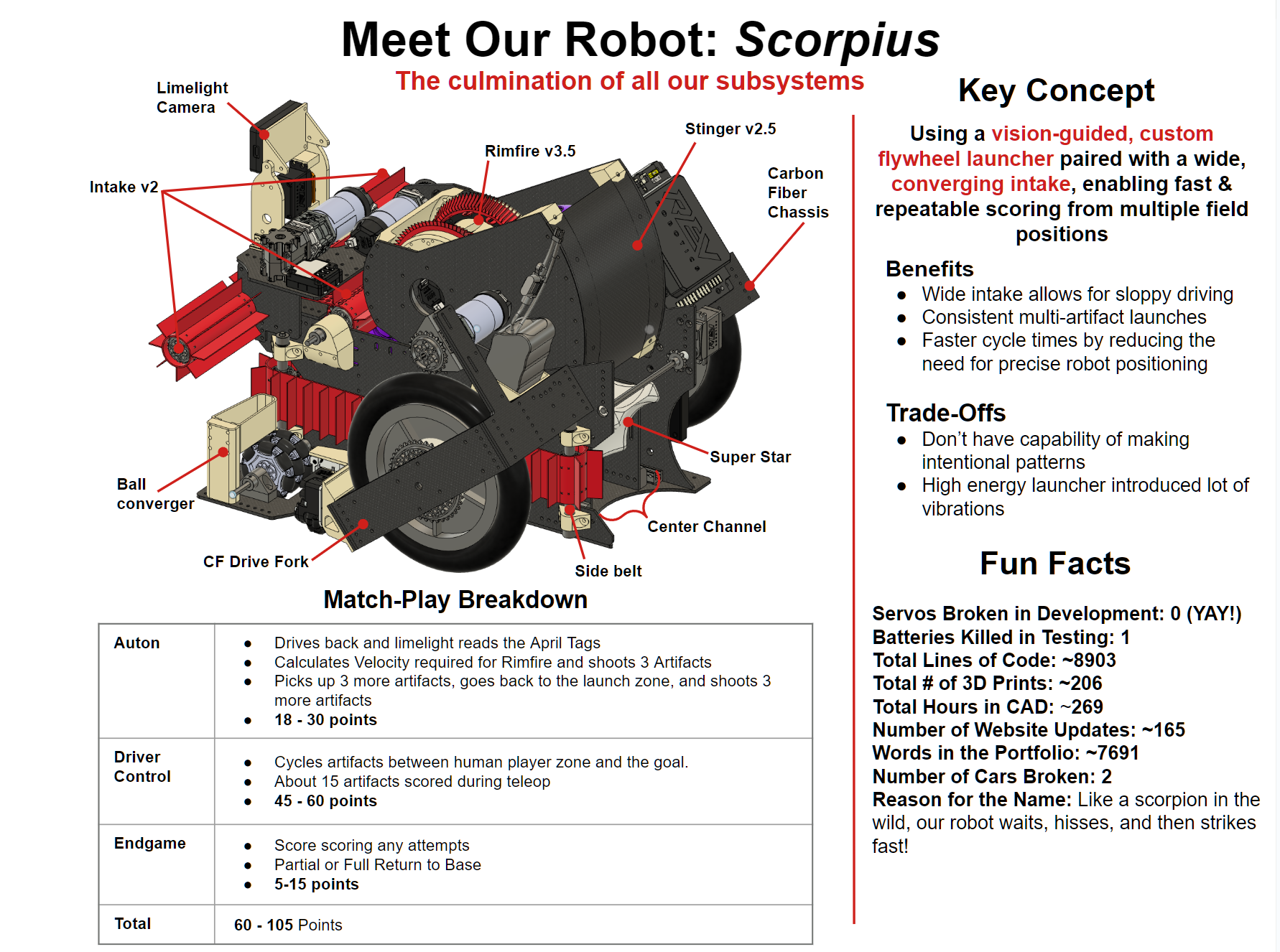

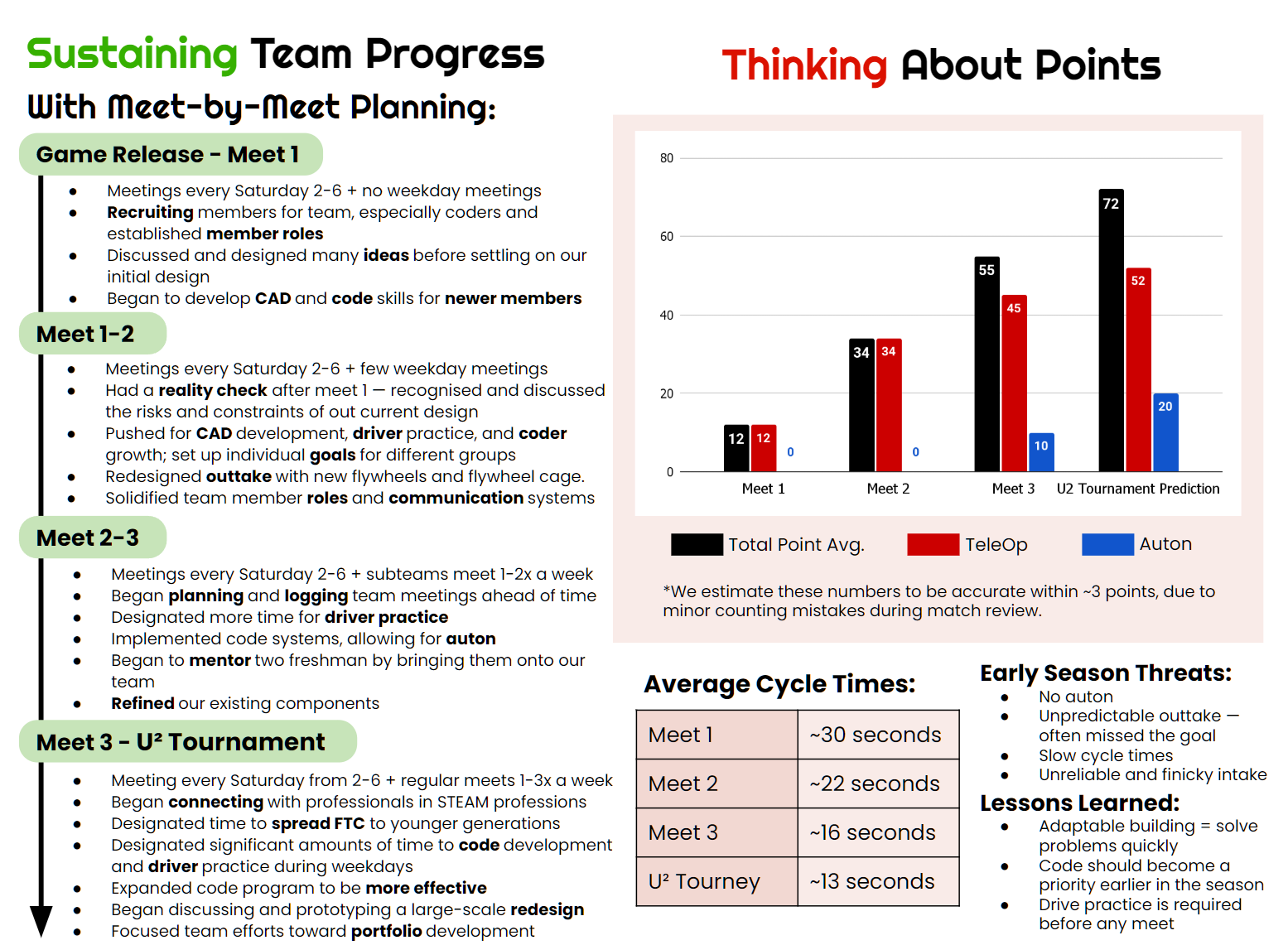

Autonomous Performance: Our autonomous routine has become a significant advantage. Consistently scoring 2-3 artifacts before leaving the shooting zone gives us a strong foundation in every match.

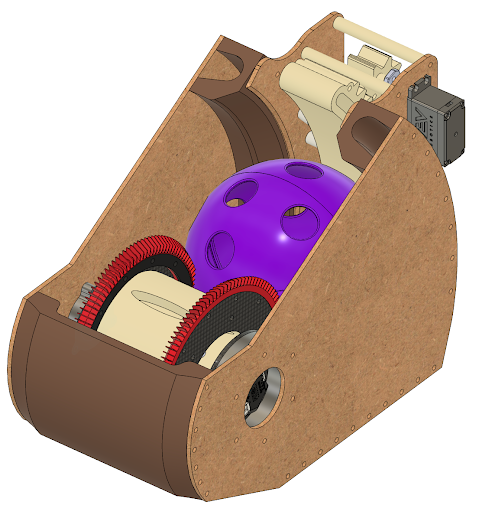

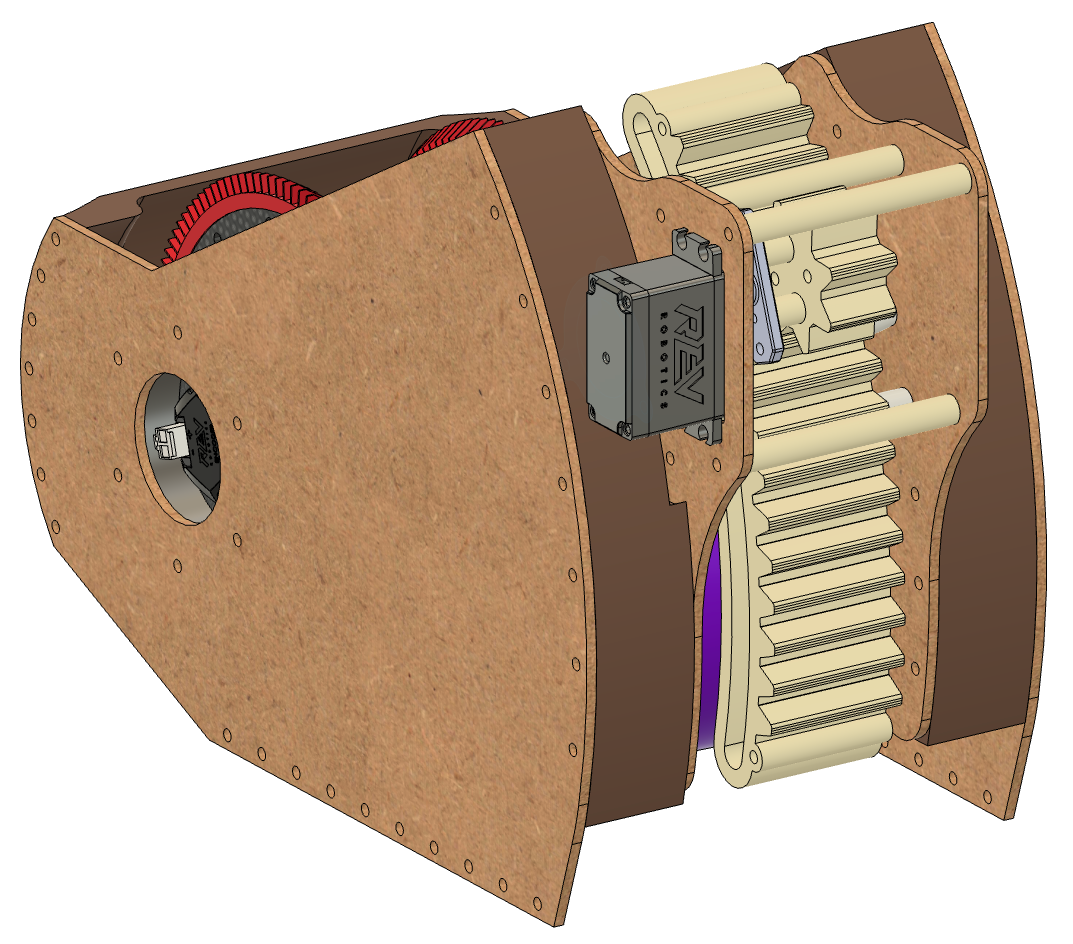

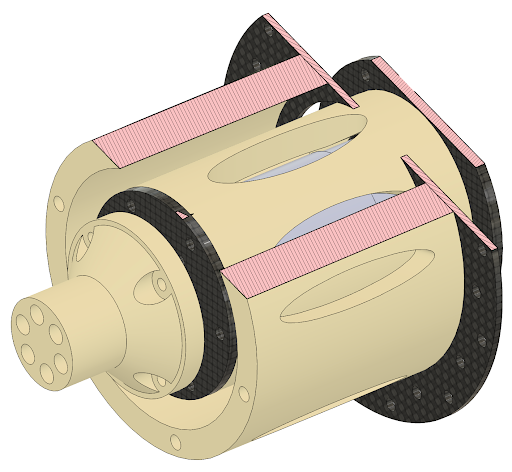

Three-Artifact Shooting Capacity: We can shoot three artifacts in sequence without needing to reload between shots, allowing us to score more points per cycle. While our overall cycle time remains slow, this capacity provides a tactical advantage in maintaining scoring momentum.

Versatile Chassis Design: The unconventional chassis shape enables both full and partial parking configurations during endgame, giving us strategic flexibility. This design choice has proven valuable in close matches where parking points make the difference.

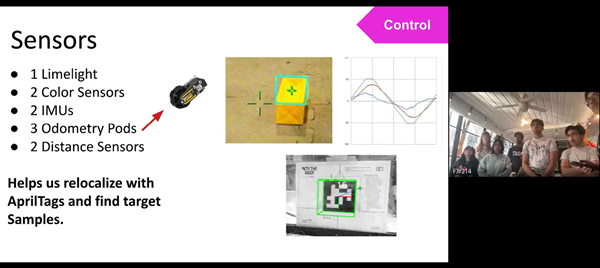

Limelight Auto-Alignment: Our vision system provides consistent auto-alignment for shooting, reducing driver burden and improving accuracy. The system even demonstrated resilience when an opponent collision knocked us off position since the Limelight automatically repositioned us. However, this feature can be further optimized through code refinement.

Solo Scoring Potential: In one round, we achieved approximately 80 points operating independently, granted we did receive 30 points due to the other alliance committing 2 major fouls.

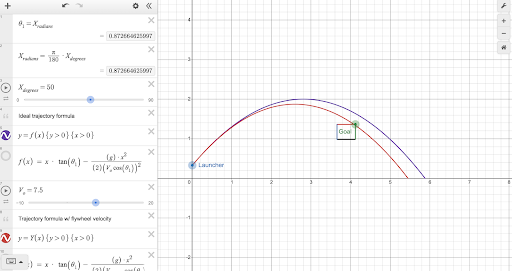

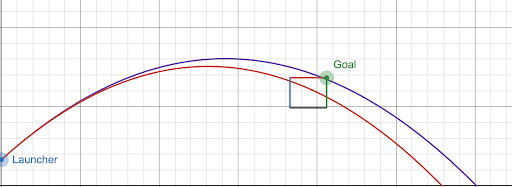

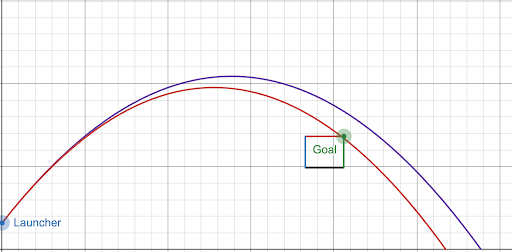

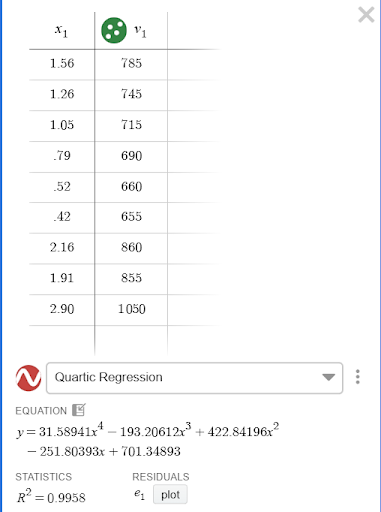

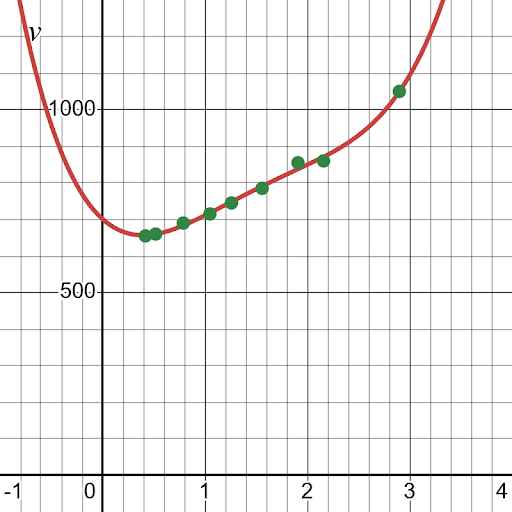

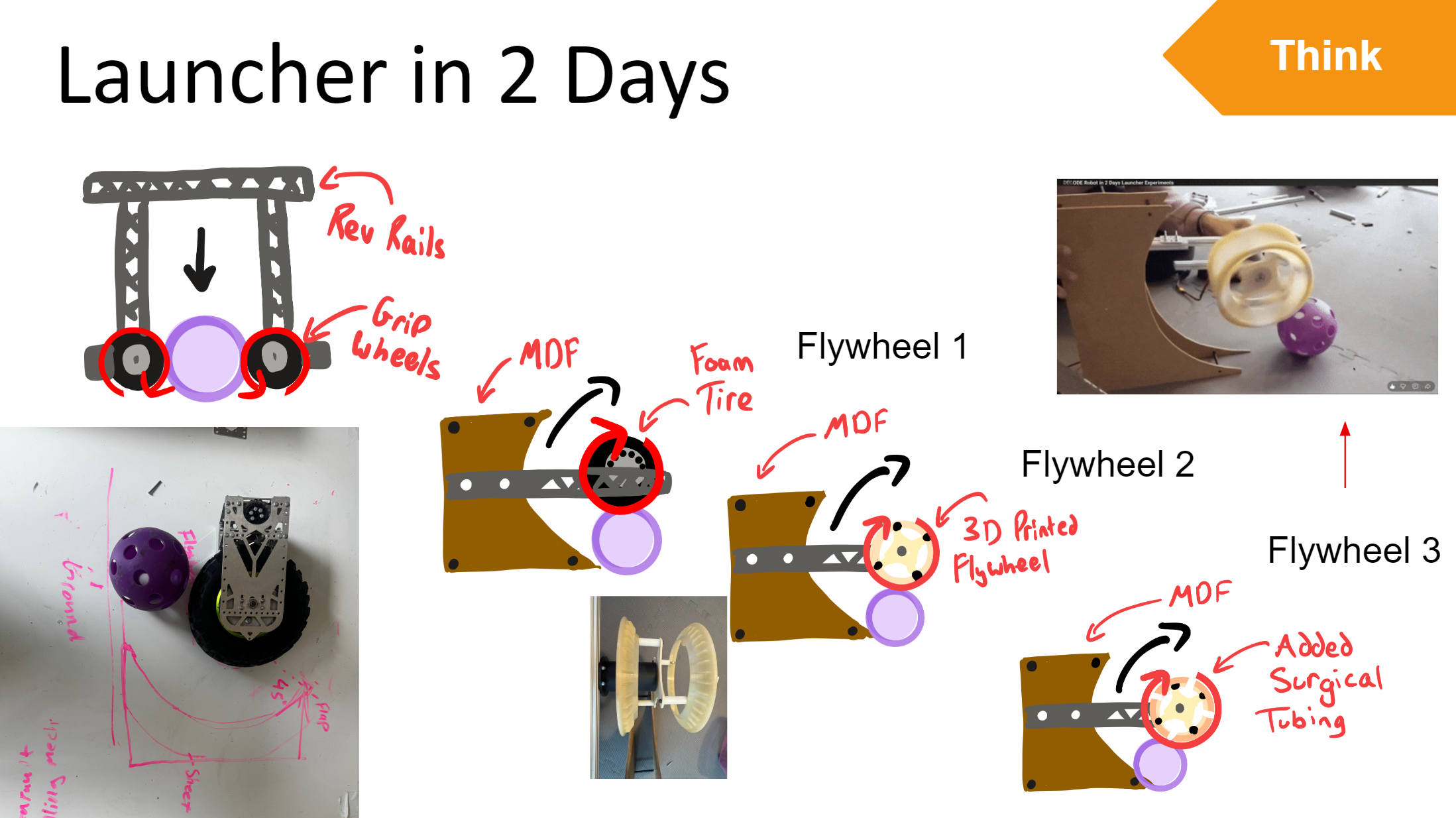

Anda's Equation: Our custom flywheel velocity equation provides somewhat functional shooting across a narrow set of field positions. While this equation was developed from just a single test rather than extensive field mapping, it worked to a practical extent.

Weaknesses:

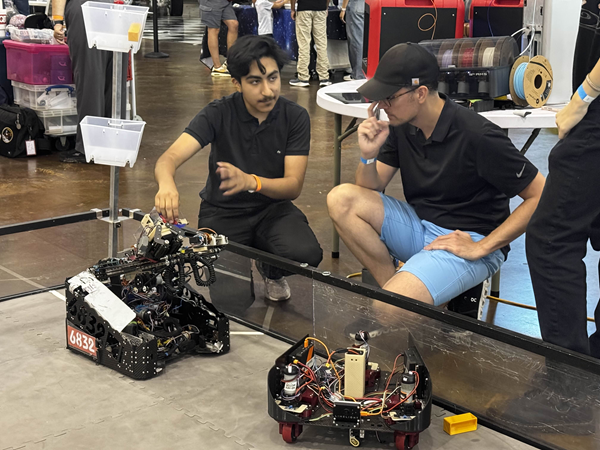

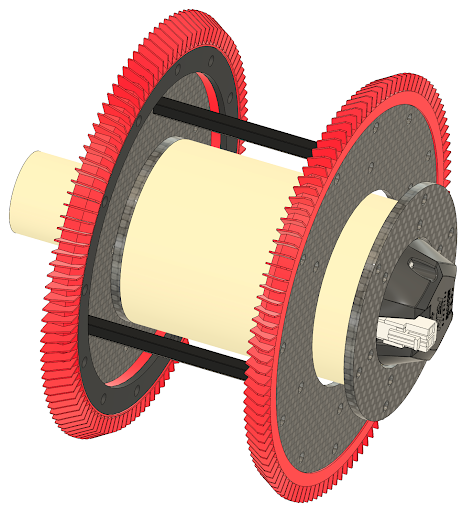

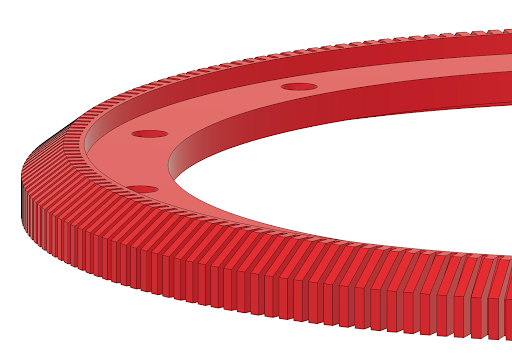

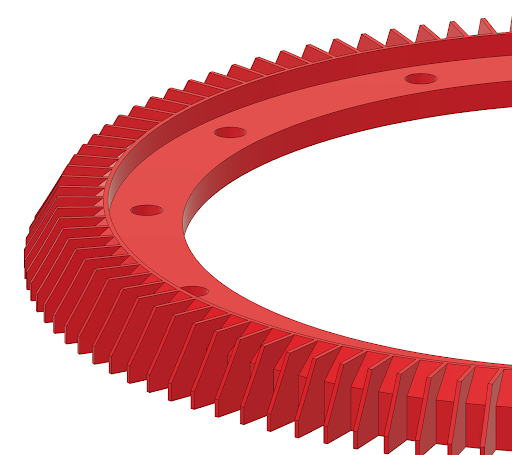

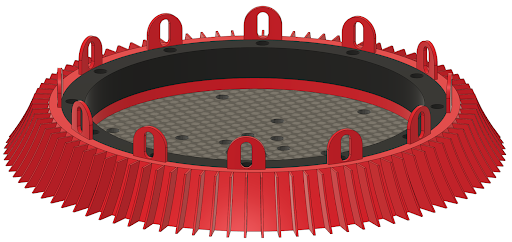

Cycle Time Inefficiency: Data analysis revealed our critical bottleneck: shooting cycles are significantly slower than competitive teams. Within each cycle of three artifacts, the first shot takes approximately 7 seconds while shots 2-3 take 3-4 seconds each. This pattern repeats because our flywheel spins up to full speed, maintains momentum for quick follow-up shots, then decelerates. The flywheel's control strategy, accelerating to maximum speed then reducing to reach desired velocity, wastes time and energy with every cycle. More problematically, the gaps between cycles that are spent intaking artifacts average 30-40 seconds, which is too inefficient.

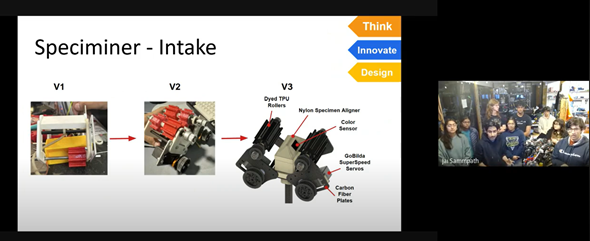

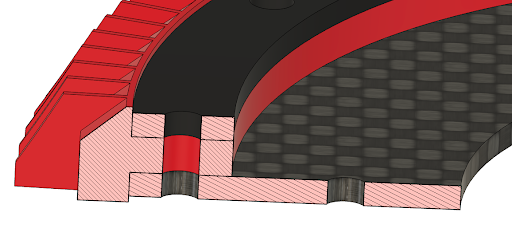

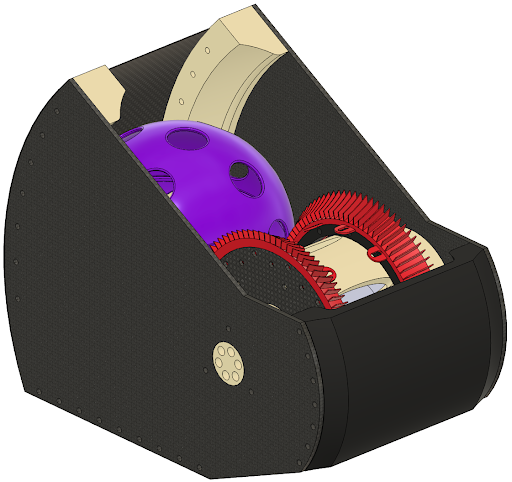

Intake Design Limitations: The intake mechanism is too narrow, causing artifacts to either bounce away or deviate from the intended path. This directly contributes to our long intake times and missed scoring opportunities.

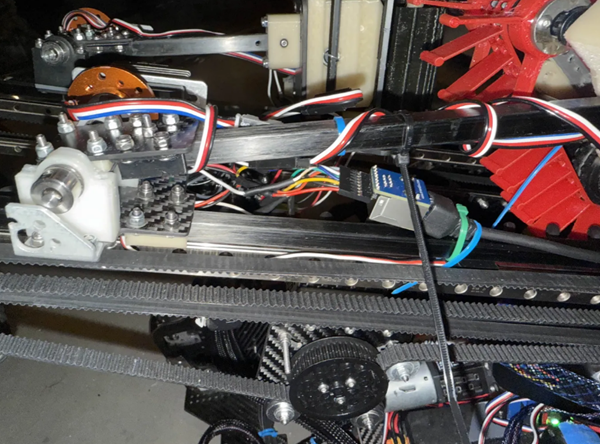

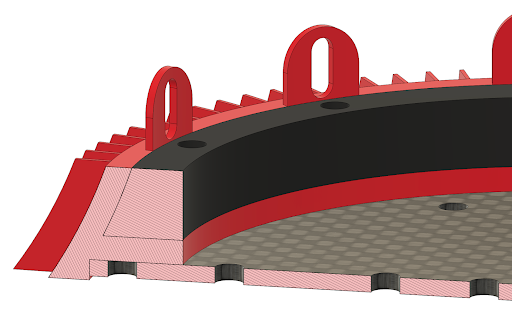

Mechanical Issues: The paddle mechanism occasionally gets stuck between artifacts, causing jams. Wire management remains problematic. The robot is excessively back-heavy, affecting handling and stability.

Ranking Point Generation: Even in matches we win, we're not accumulating enough ranking points. This weakness could hurt our tournament seeding.

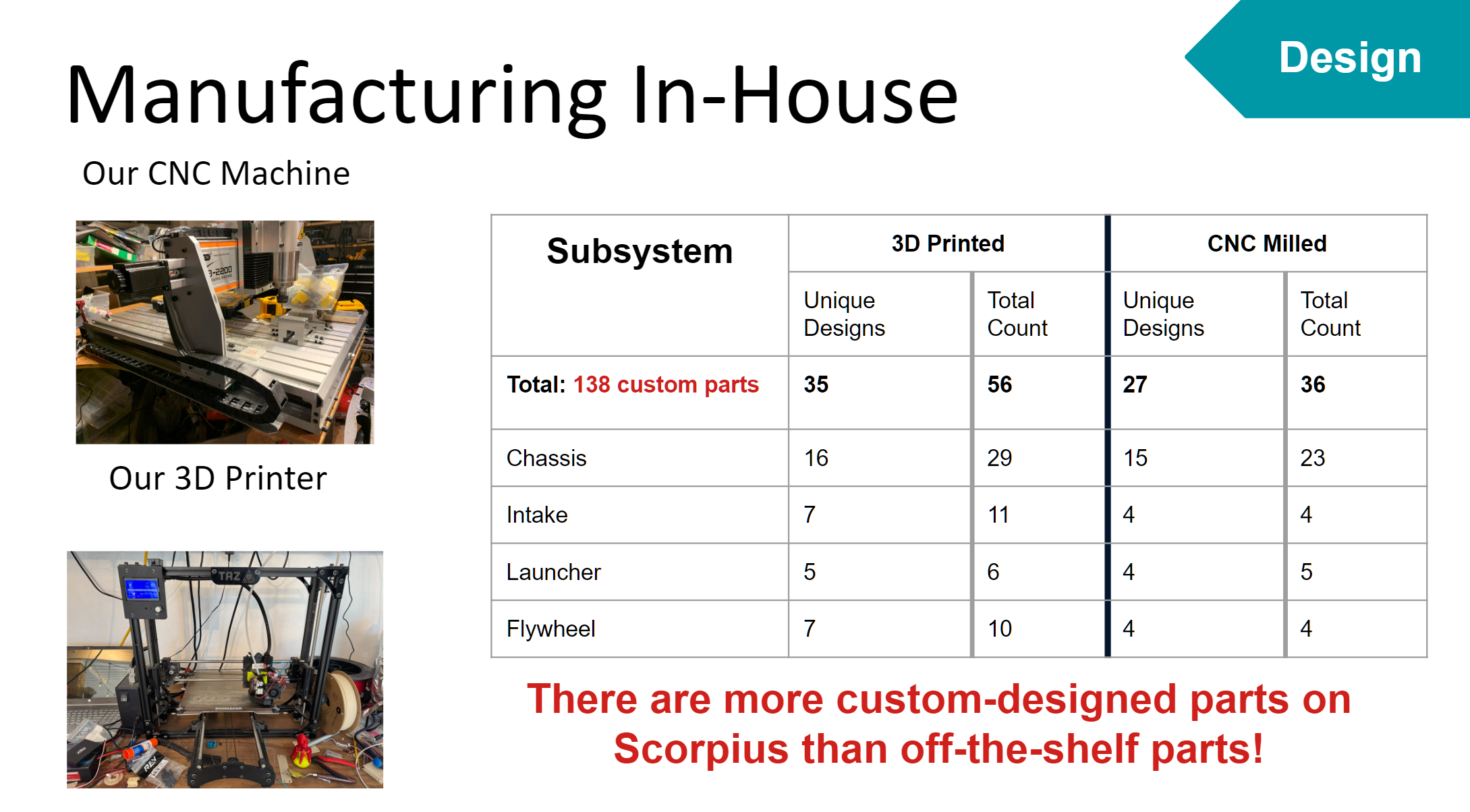

Lack of Funding: Limited financial resources constrain our ability to purchase materials and iterate on designs.

Opportunities:

Refine Anda's Equation: Further refinement of our flywheel velocity calculations could optimize shooting accuracy and consistency across all distances.

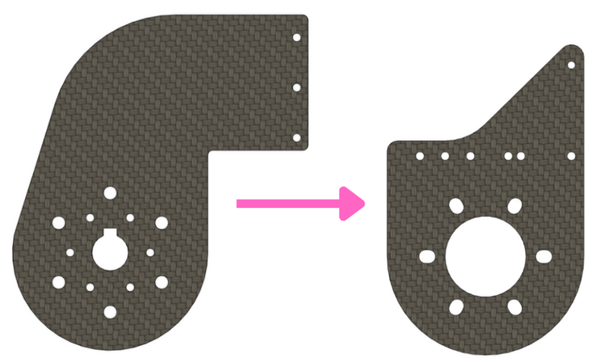

Mechanical Redesign: Curved Ramp: Replace the paddle lift mechanism with a moveable curved ramp that allows artifacts to roll naturally into the flywheel. This could eliminate jamming issues and improve feeding reliability.

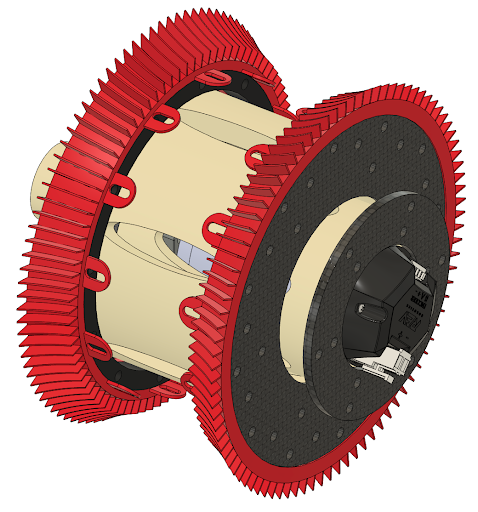

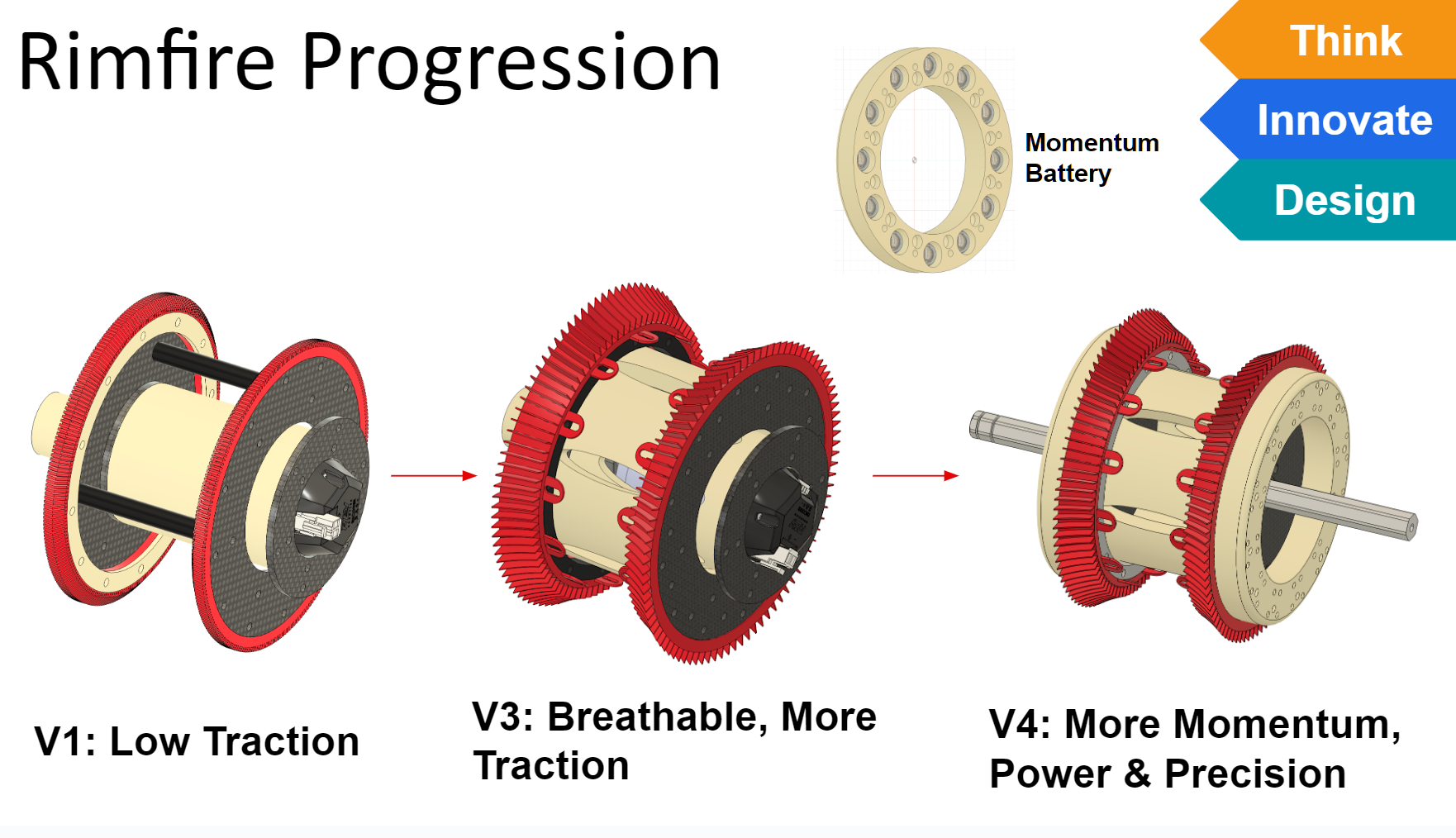

Two-Motor Flywheel: Adding a second motor to the flywheel should significantly reduce spin-up time, addressing our cycle time weakness. This could cut a significant amount of time per shot in each cycle.

Enhanced Autonomous: Expand autonomous to score additional artifacts beyond our current 2-3 artifact routine. With our autonomous reliability, adding scoring could generate crucial ranking points.

Odometry Pods Integration: Implementing odometry pods with RoadRunner path planning would enable more sophisticated autonomous routes and precise field positioning throughout the match.

Limelight Distance Refinement: Further tuning of distance calculations from the Limelight could improve positioning accuracy and reduce alignment time.

Flywheel Compression Testing: Experiment with artifact compression in the flywheel, potentially removing the clear adhesive material to optimize grip and launch consistency.

Visual Communication Systems: Install LED lighting on the robot's rear to improve communication between the driver and human player, reducing coordination delays.

Hardware Upgrades: Brass plates instead of CF could add weight to the flywheel for better momentum. New diagonal-flap belts might force artifacts sideways and inwards for more reliable intake.

Increased Driver Practice: Additional practice sessions focused on efficient cycles and endgame parking would directly improve match performance.

> Threats:

Defensive Vulnerability: Our robot is prone to defensive pressure from opposing teams. Since our robot is super lightweight and short, we are more vulnerable to being hit by bigger robots and/or being pushed while we try to score.

Advanced Autonomous Routines: Competing teams have demonstrated sophisticated autonomous routines that significantly outpace our current capabilities.

Cycle Time Gap: Some robots can shoot three artifacts in the time we shoot one. This 3:1 performance gap represents a threat that must be addressed.