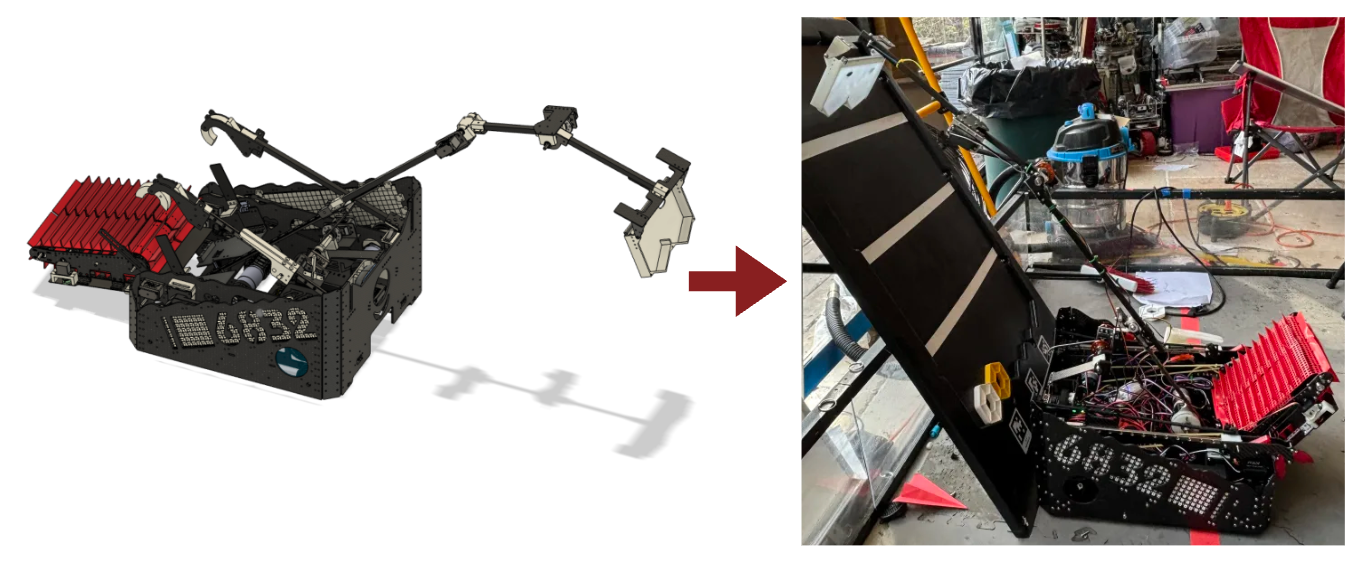

Lessons We’ve Learned Switching from CAD to a Physical Model

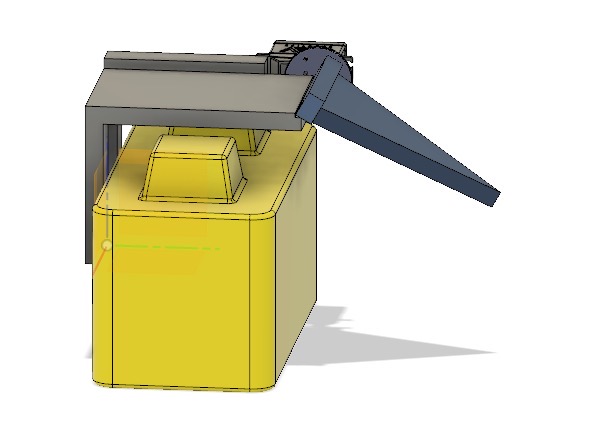

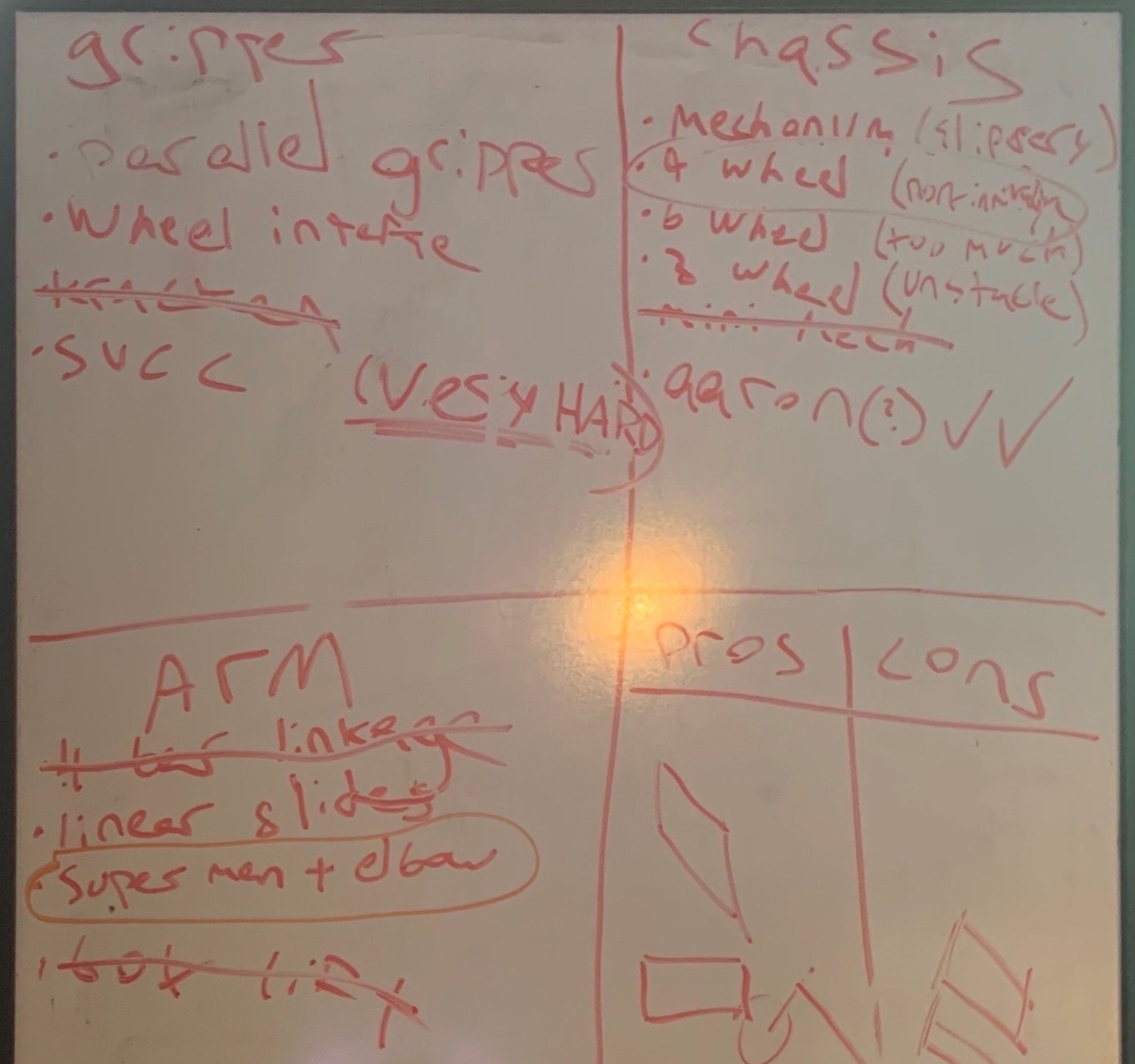

Task: Overview the issues with PPE V3 and the changes that need to be made.

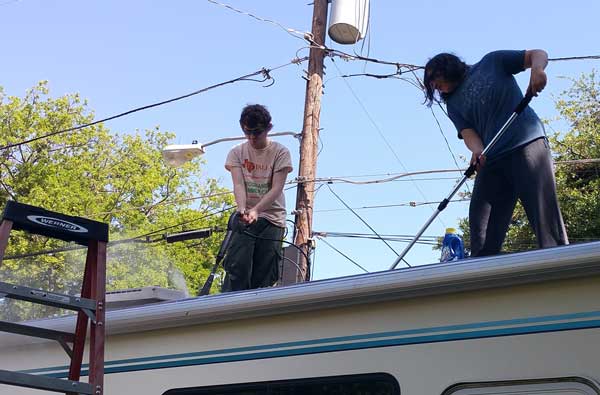

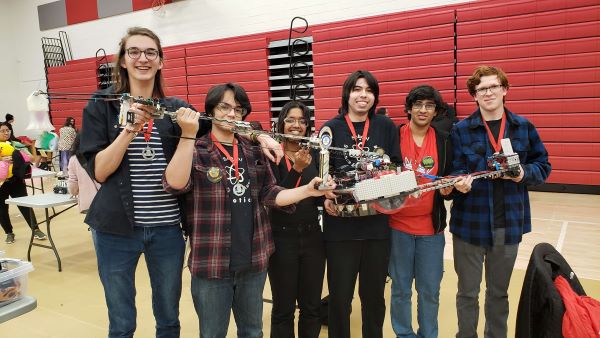

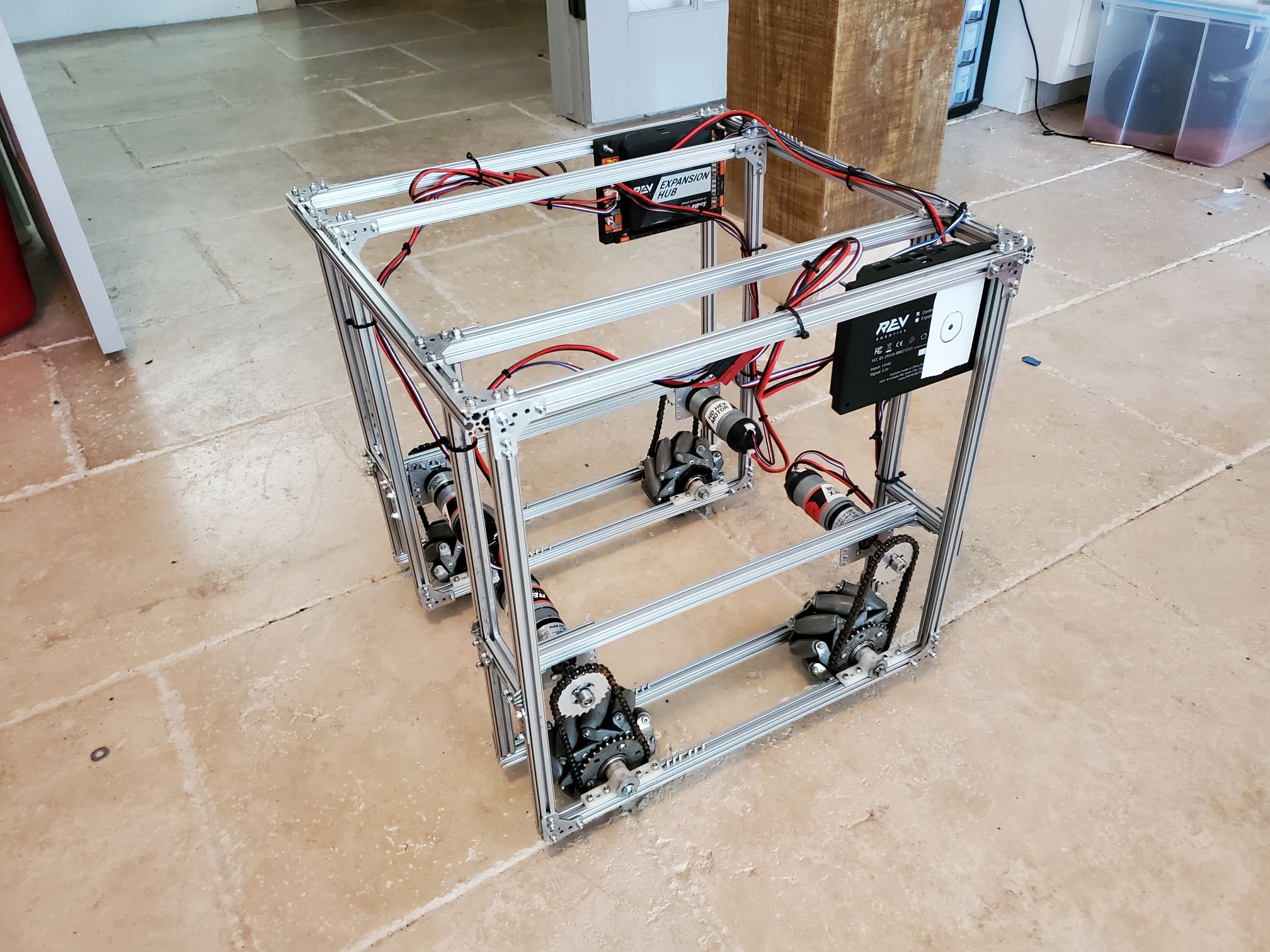

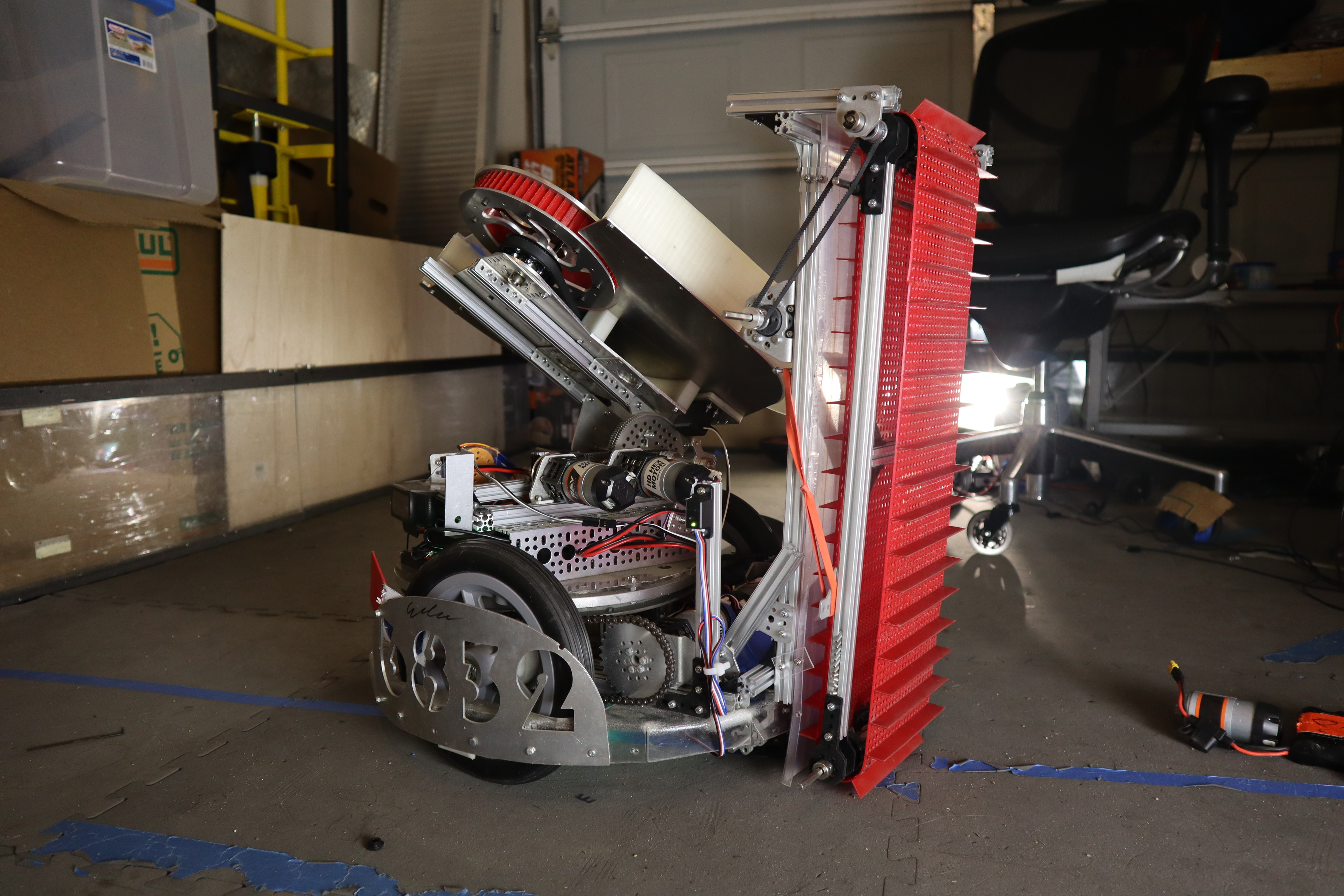

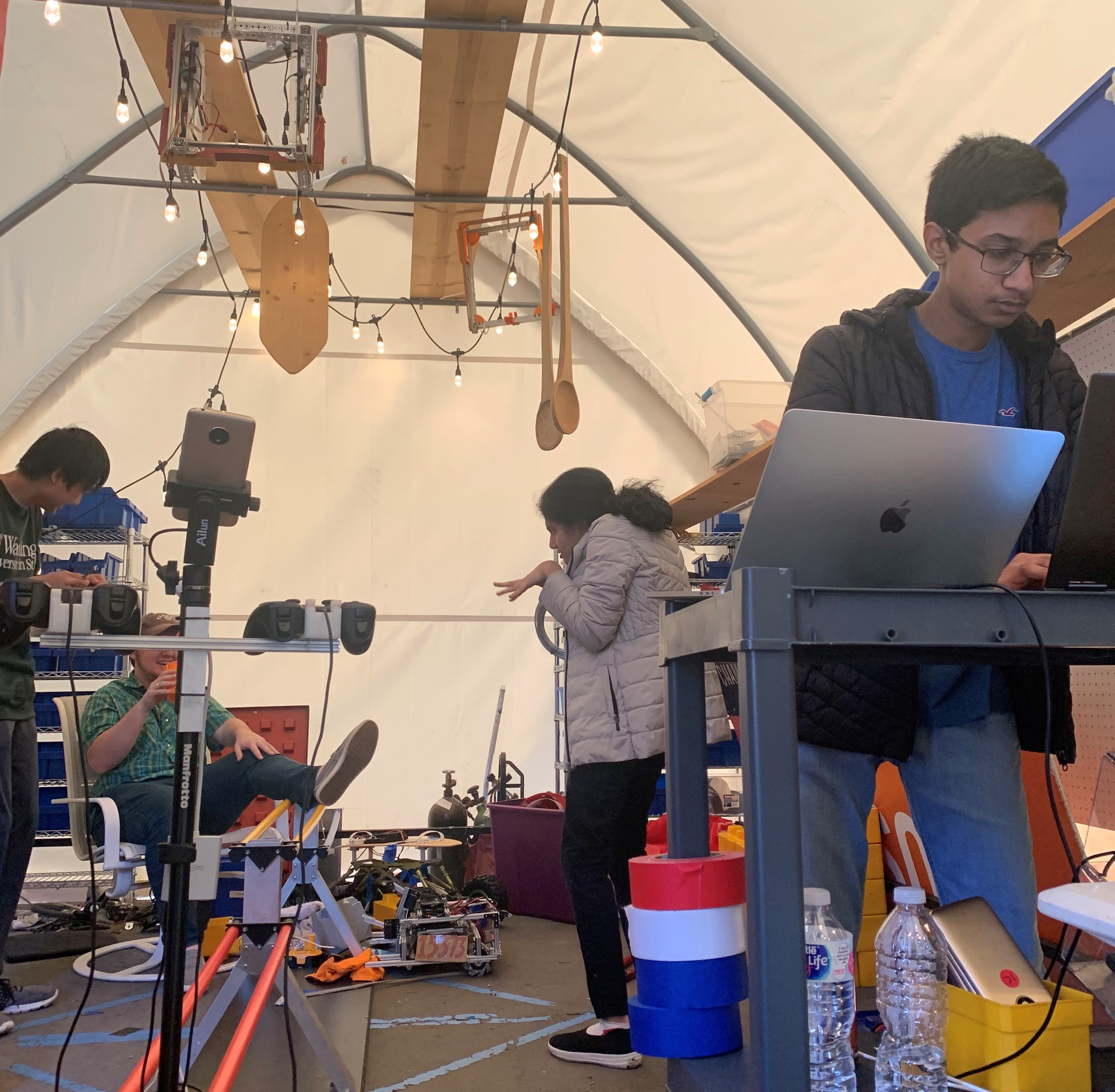

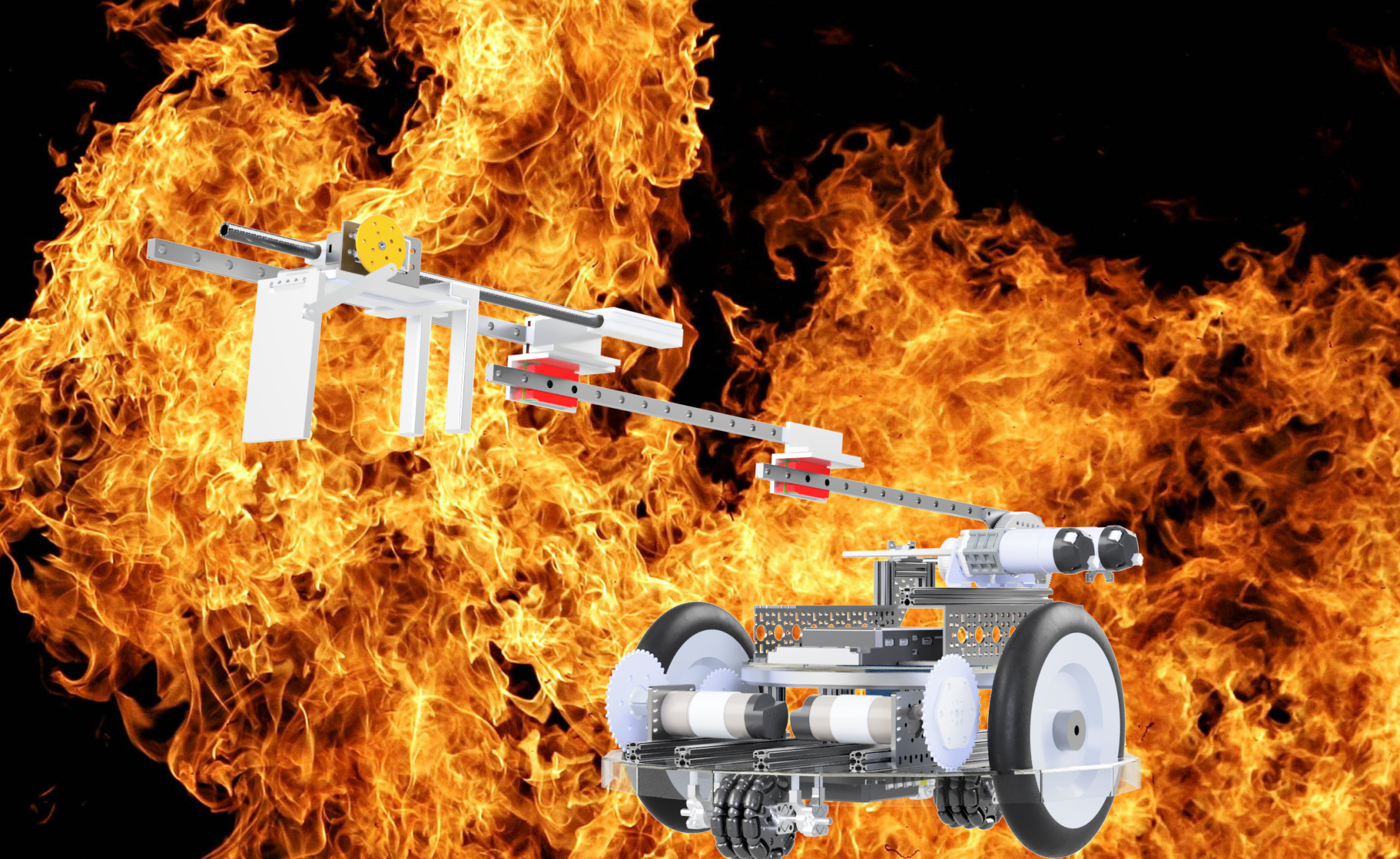

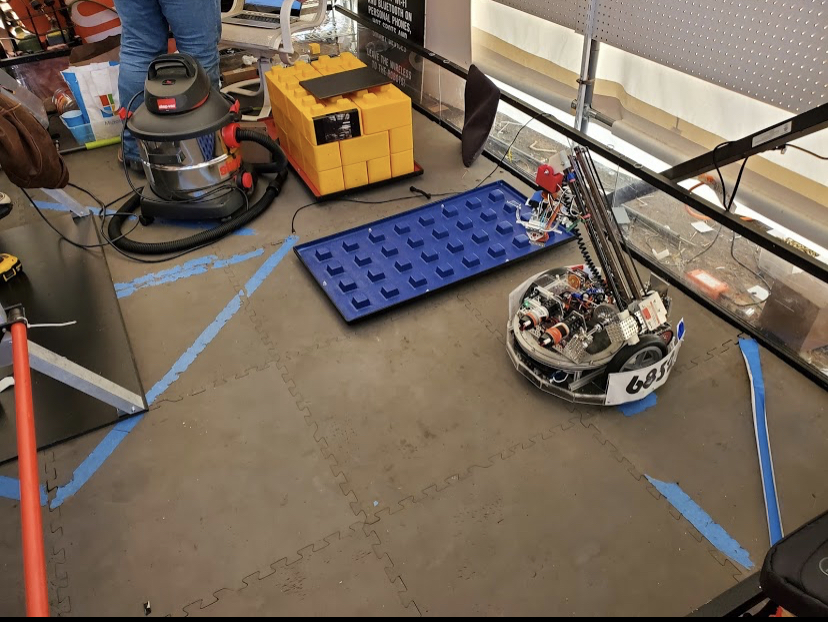

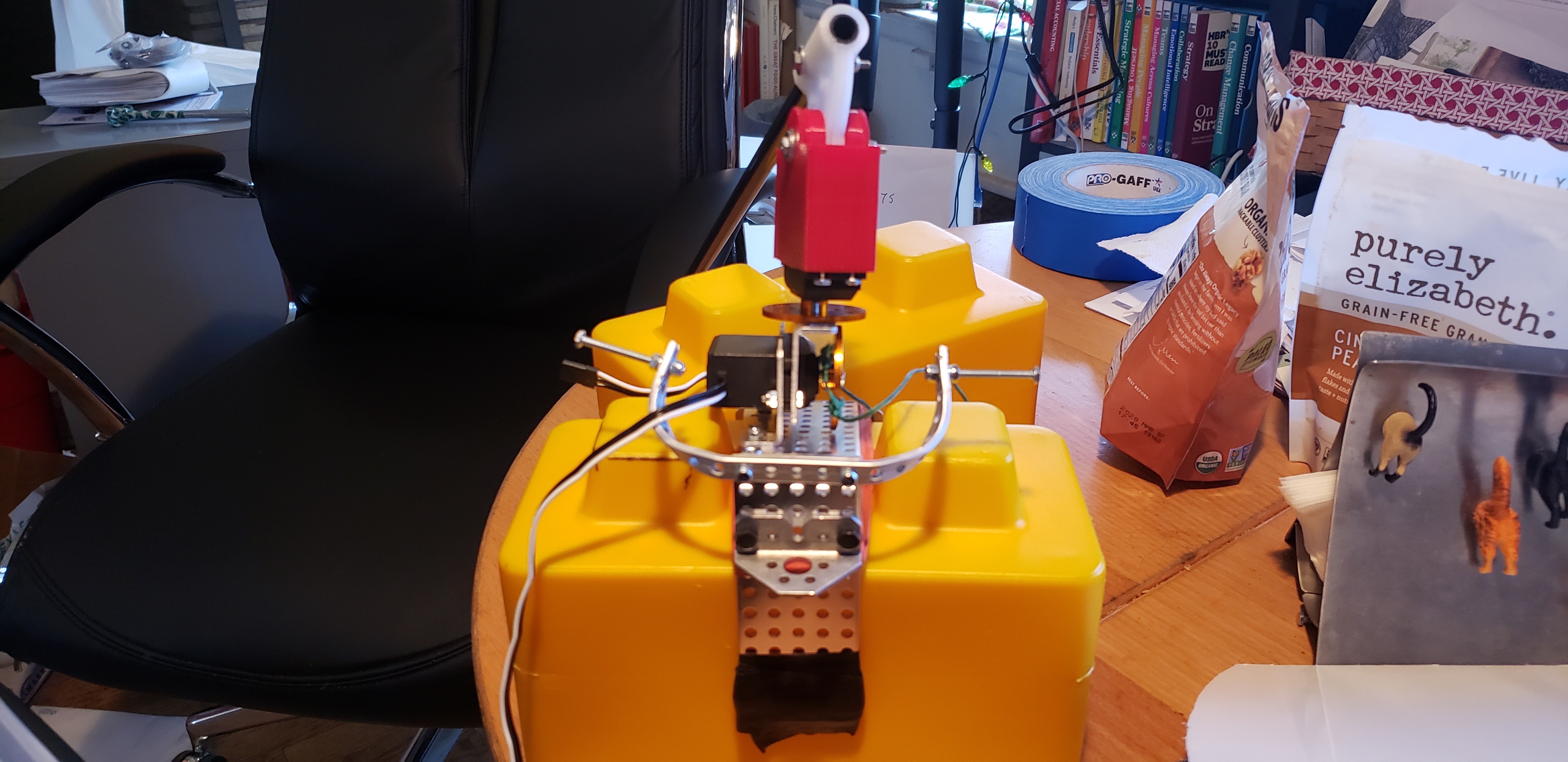

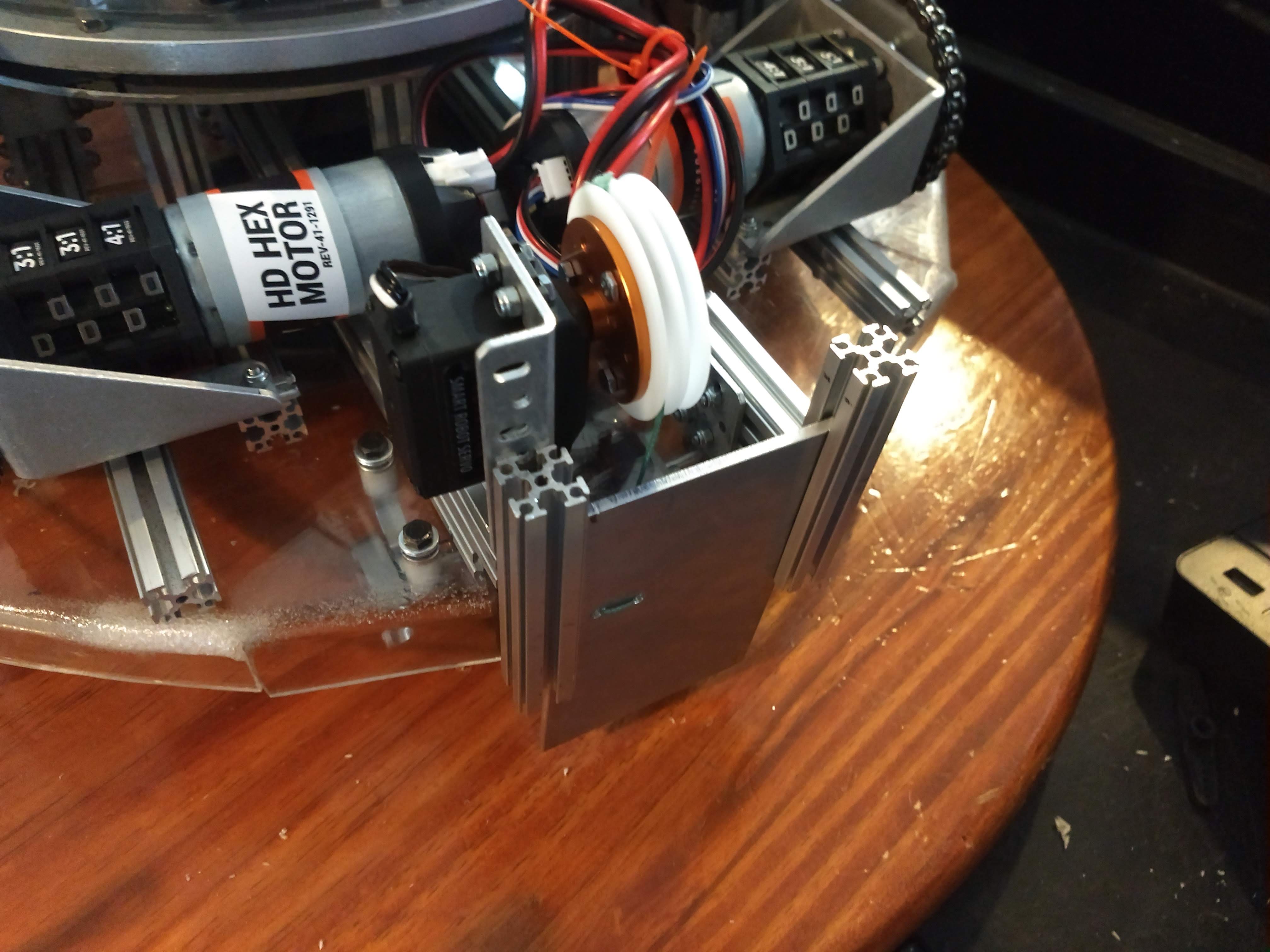

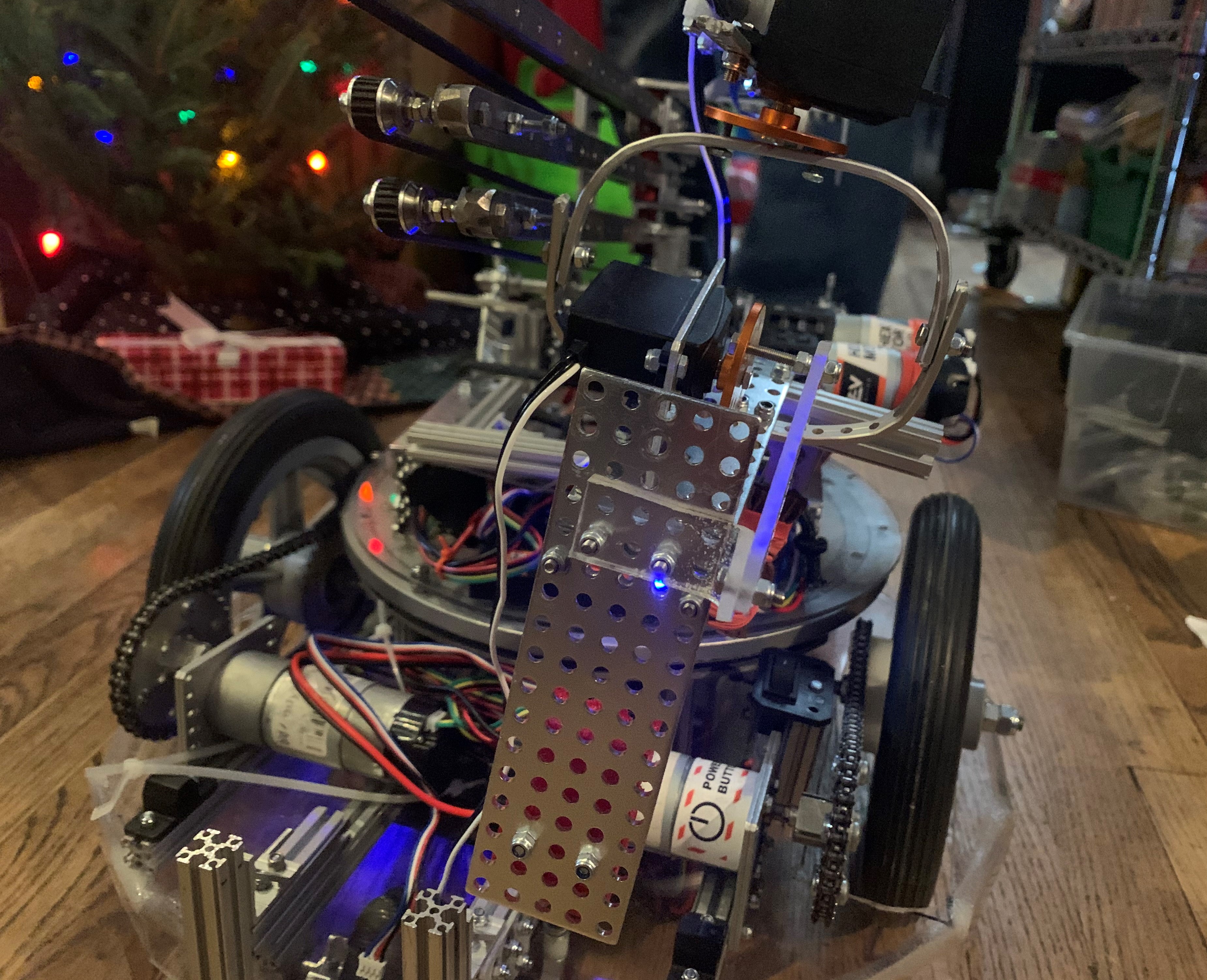

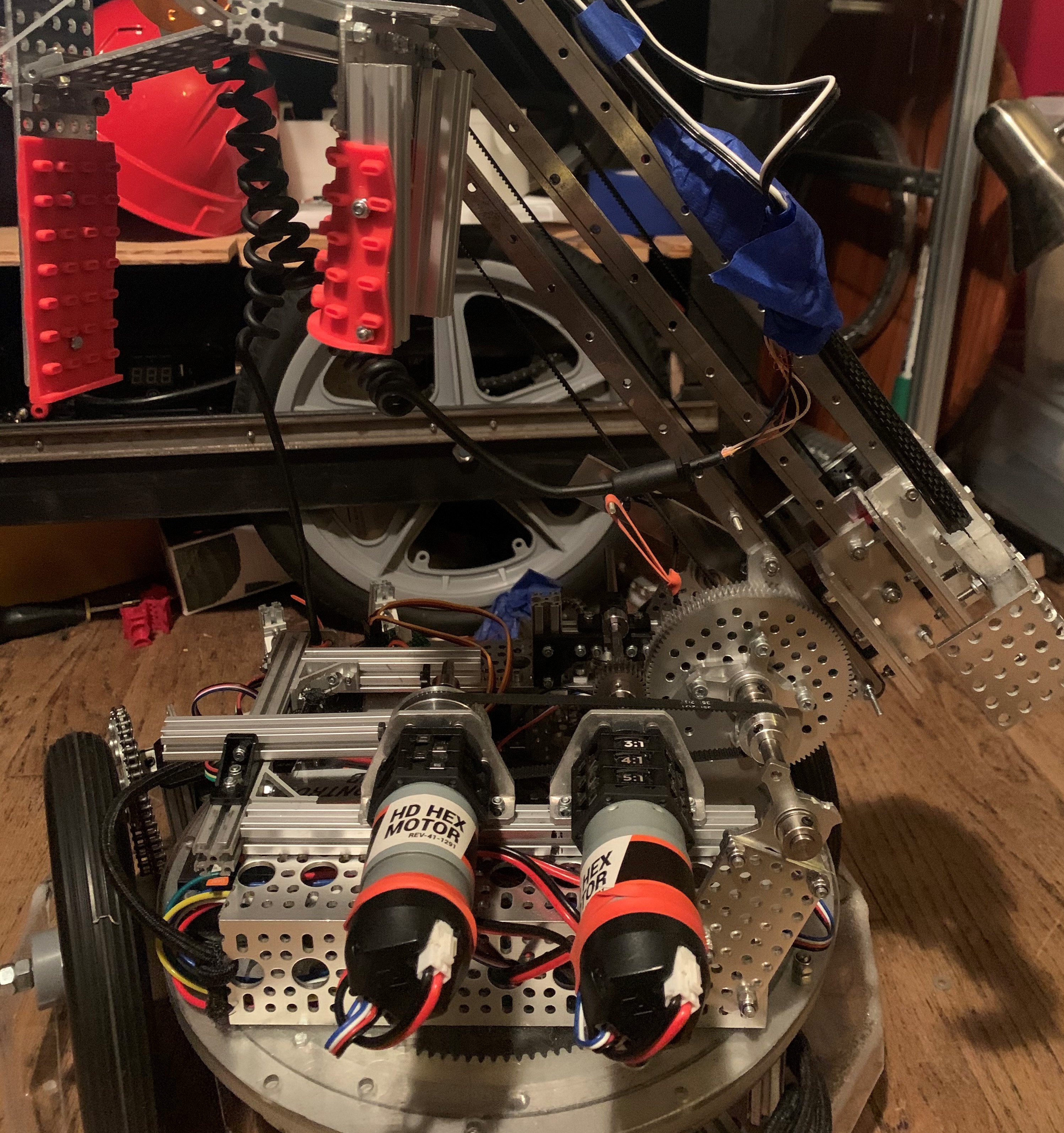

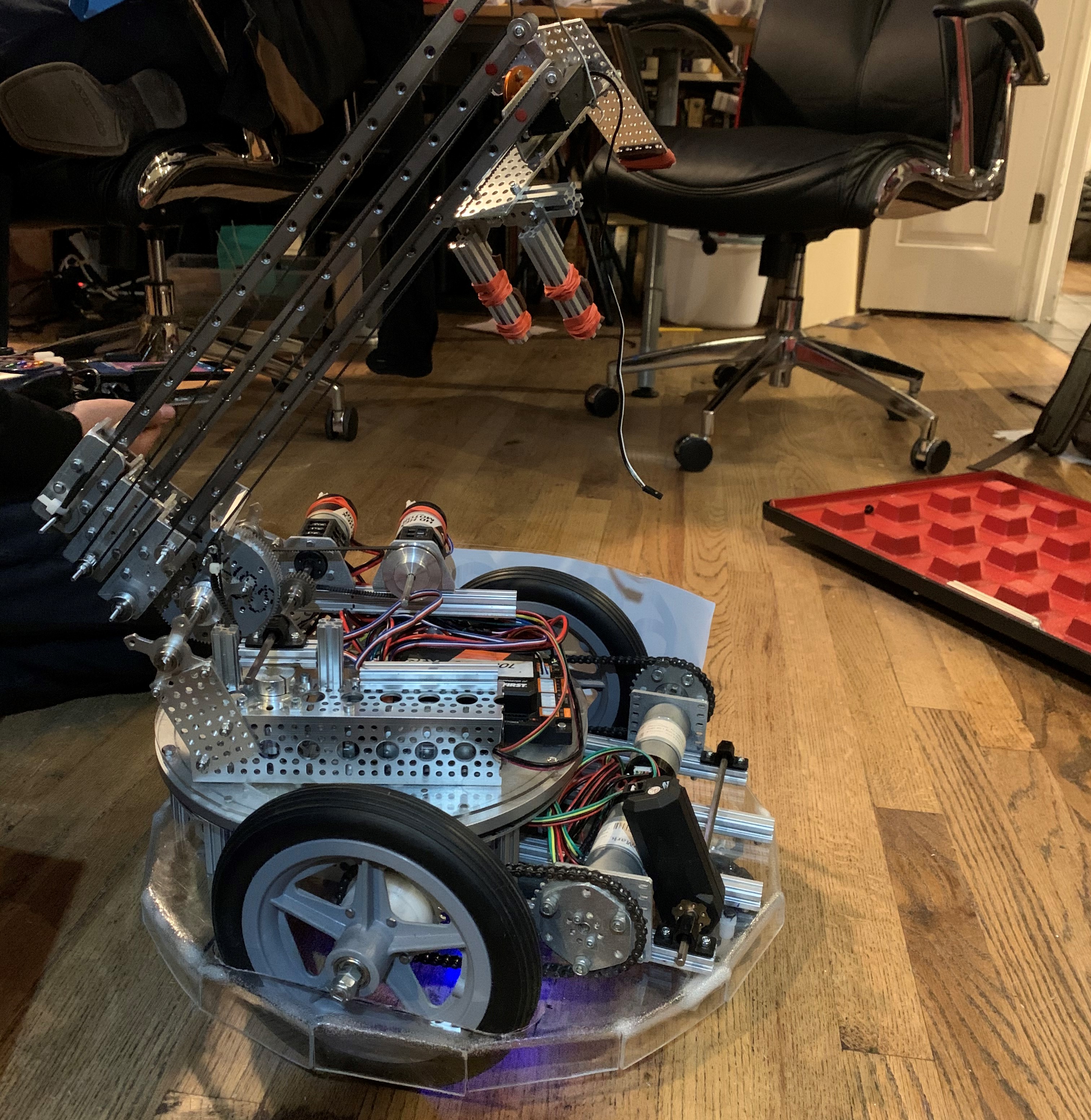

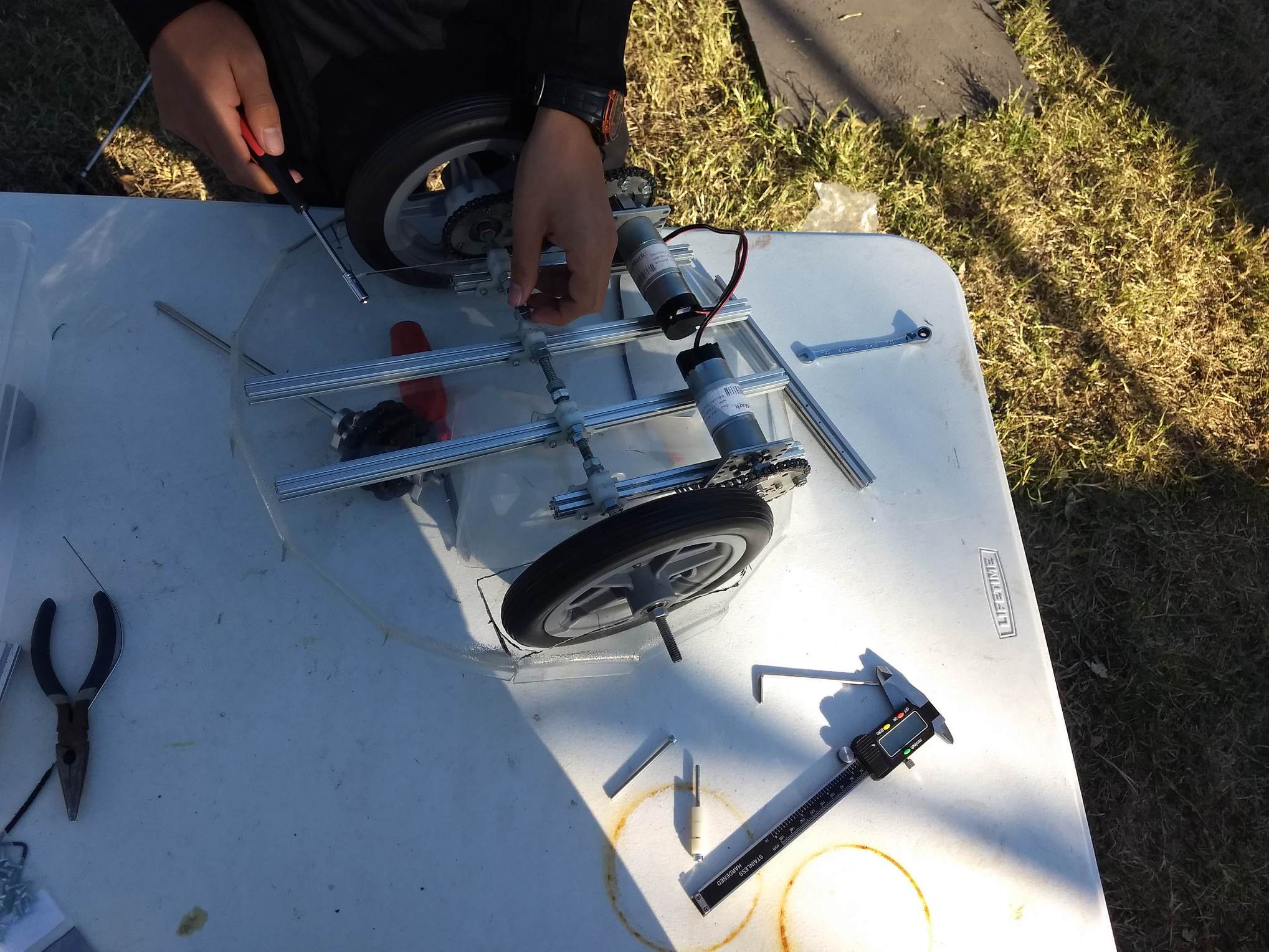

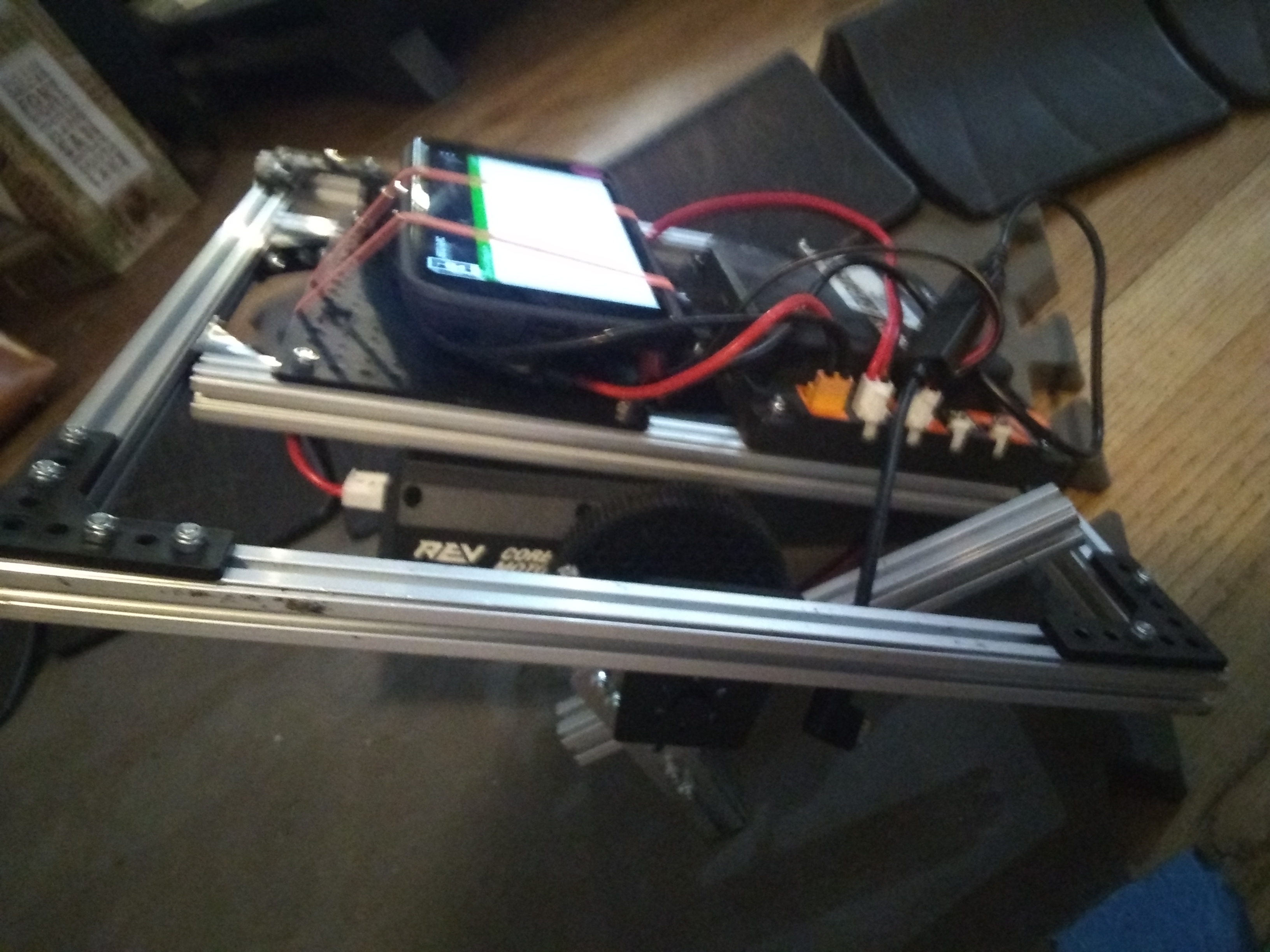

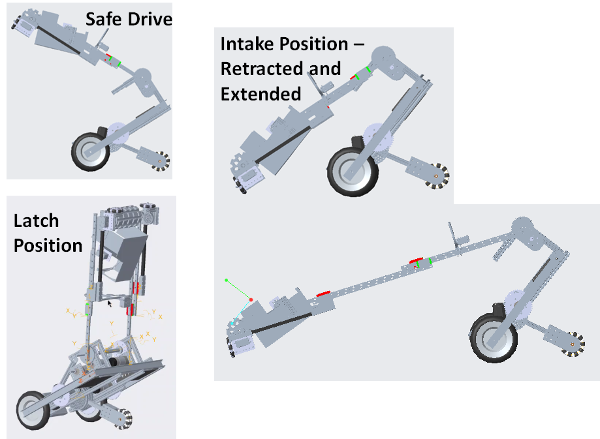

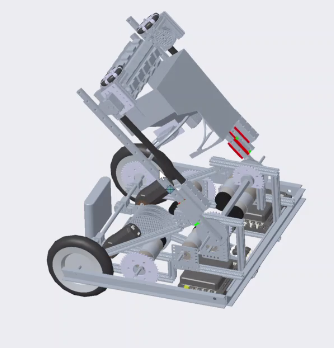

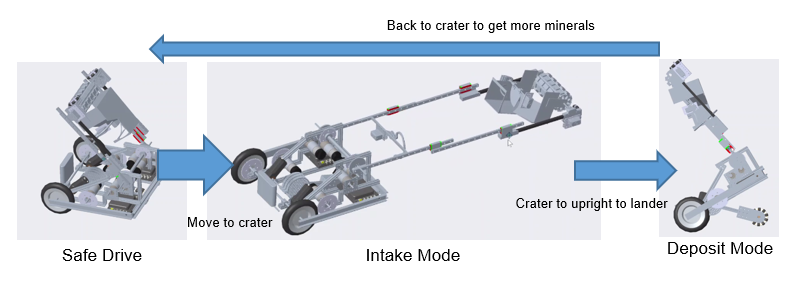

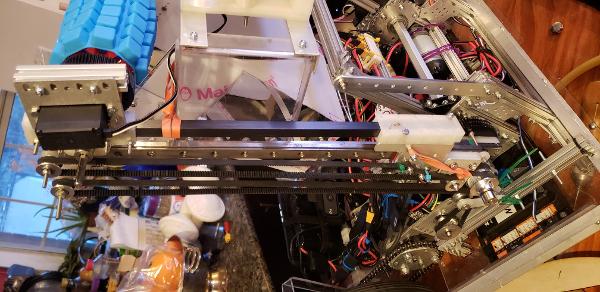

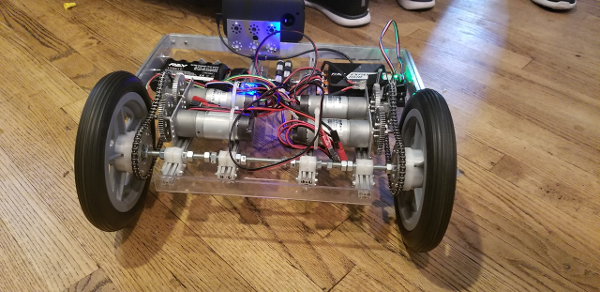

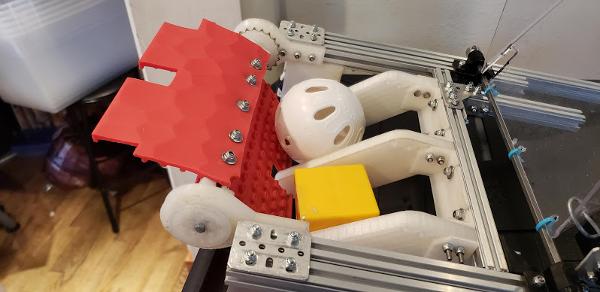

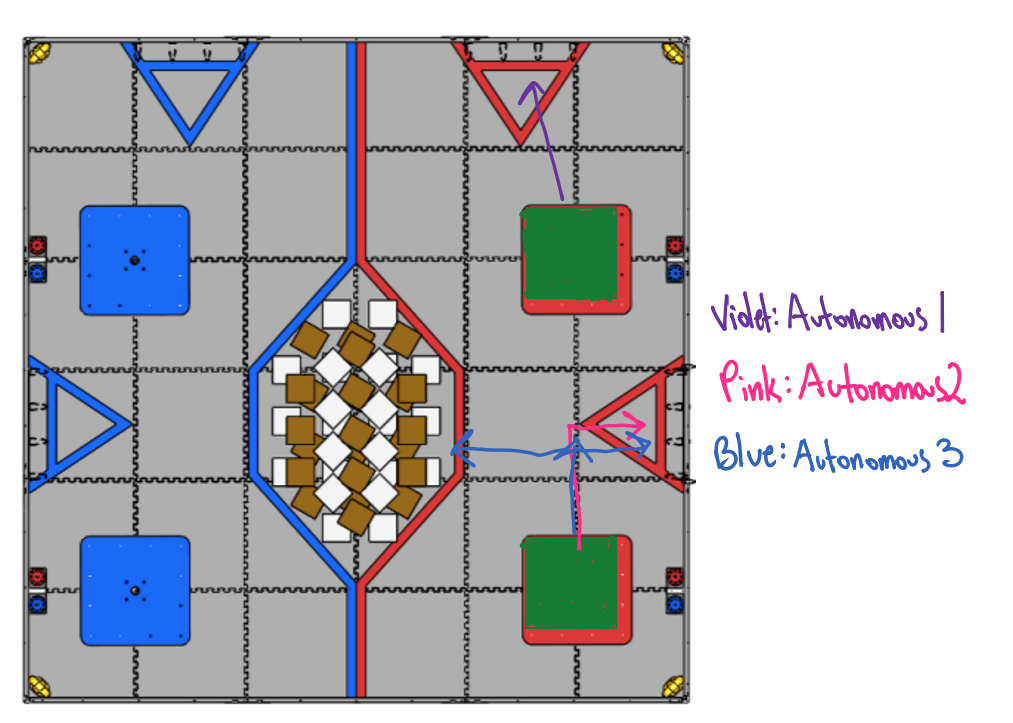

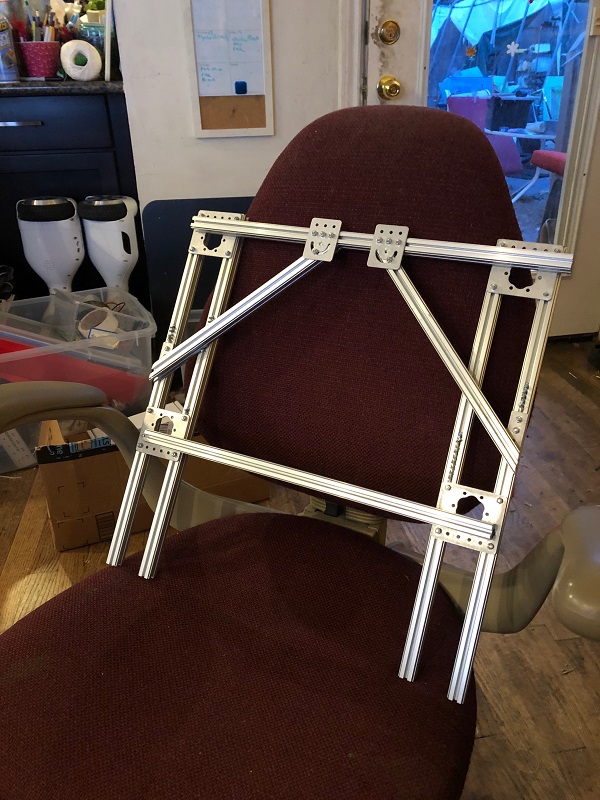

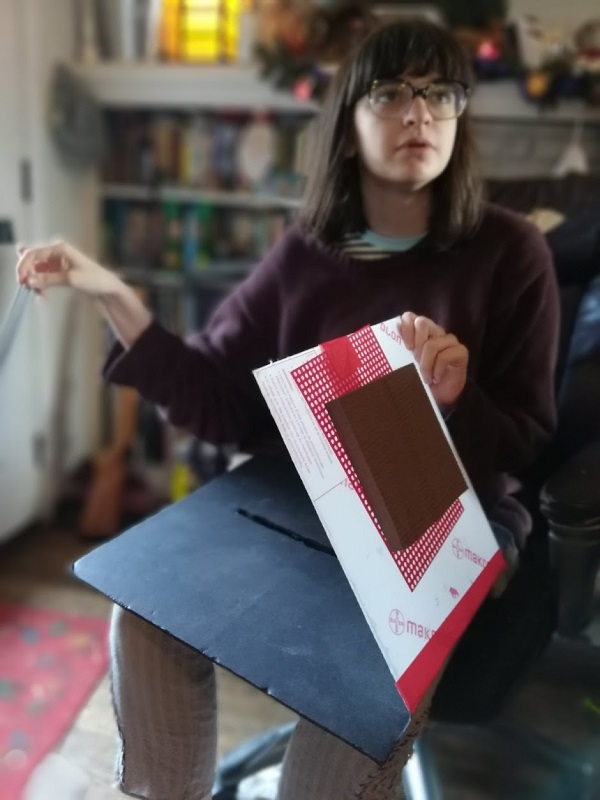

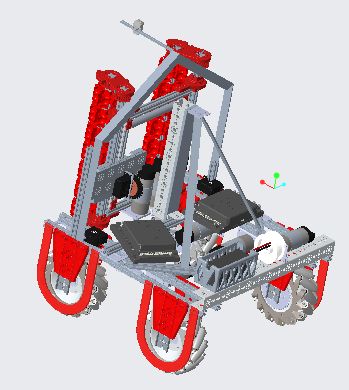

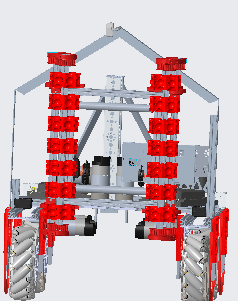

This past weekend, we had our regional competition! We were incredibly fortunate to have gotten Inspire 3 and were the 5th advancements to the FTC Texas State Championship in a couple weeks! However, we went into Regionals with a robot we had barely finished...

...

...

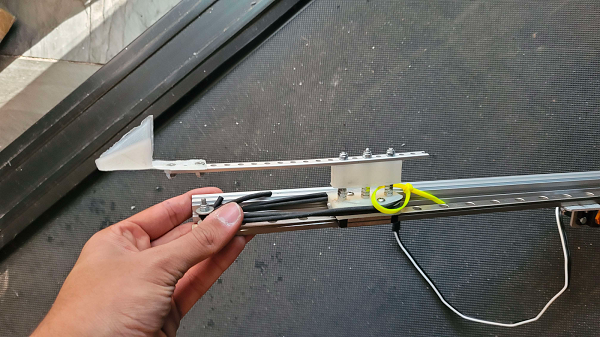

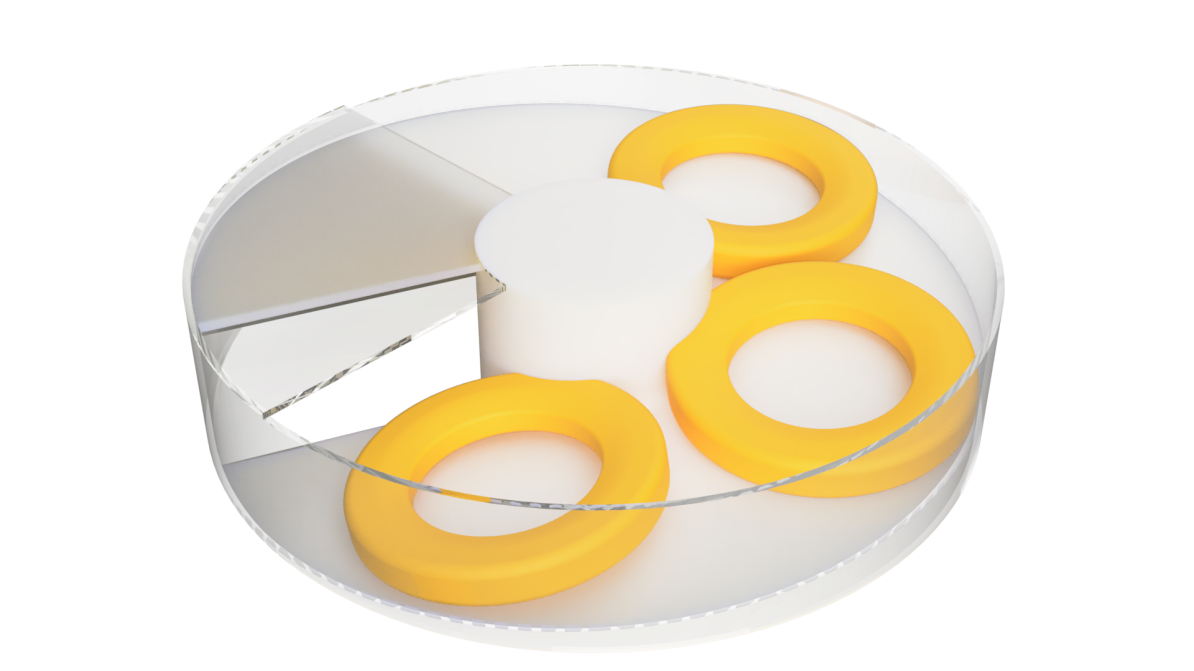

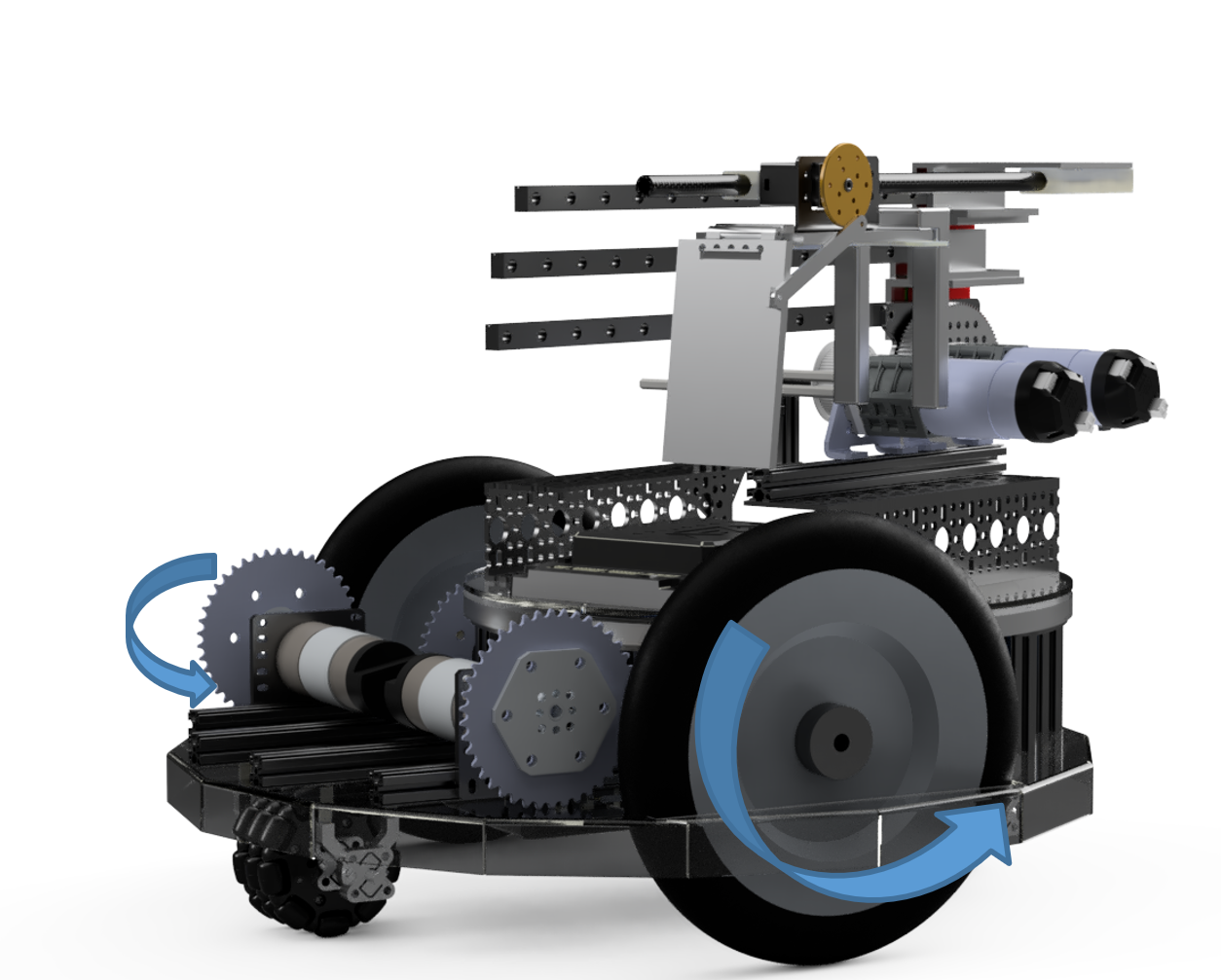

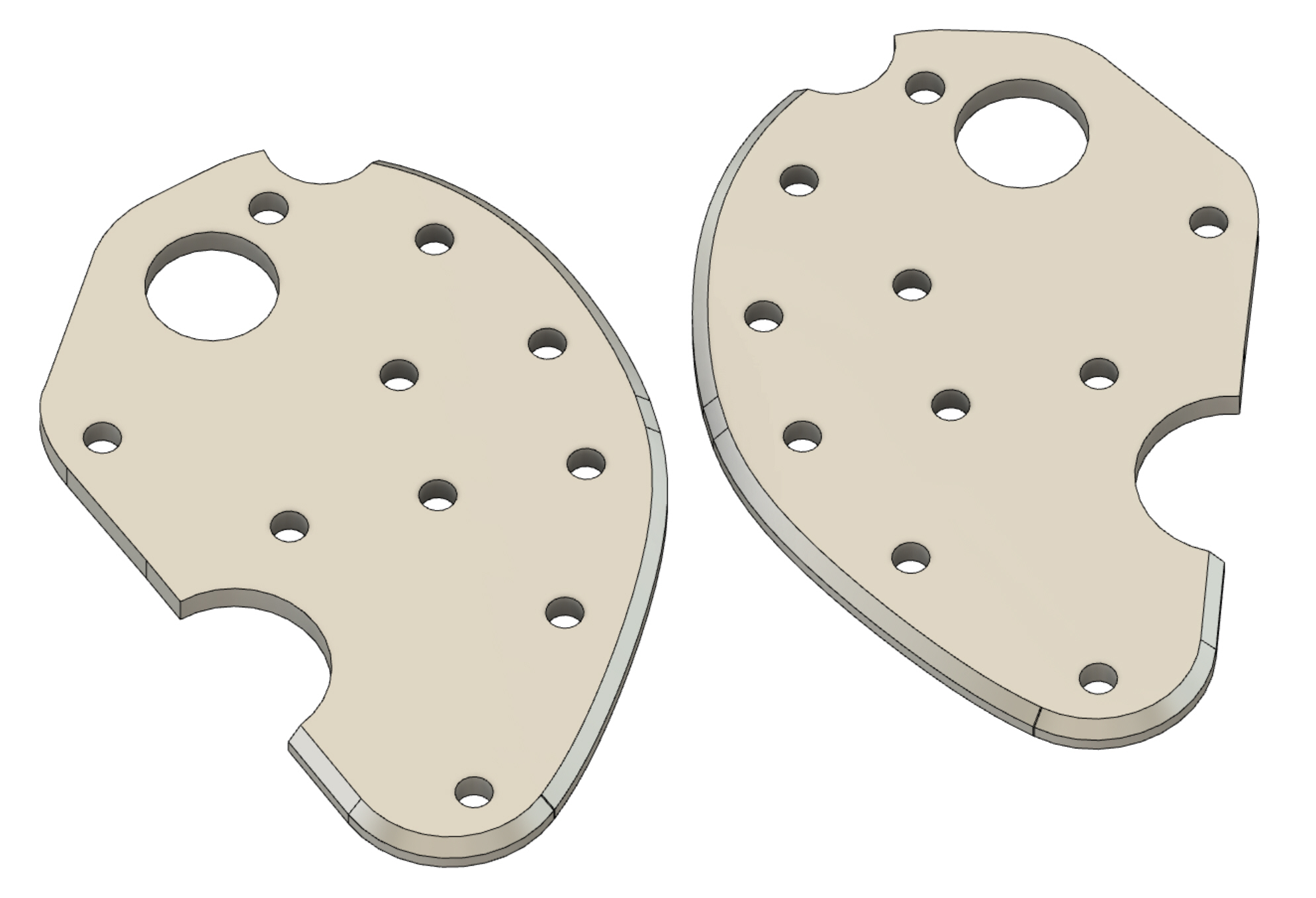

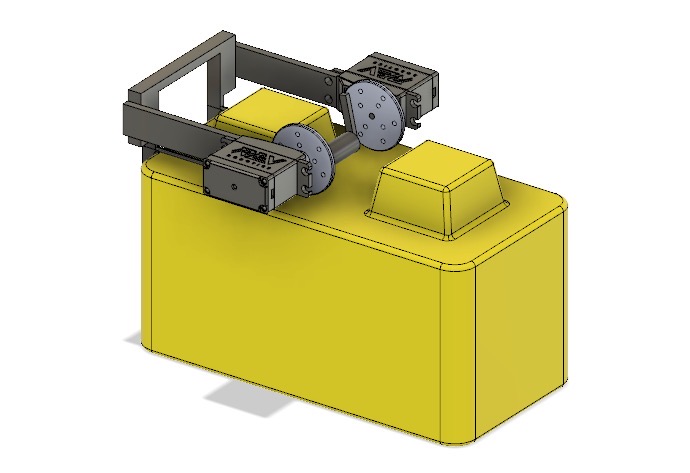

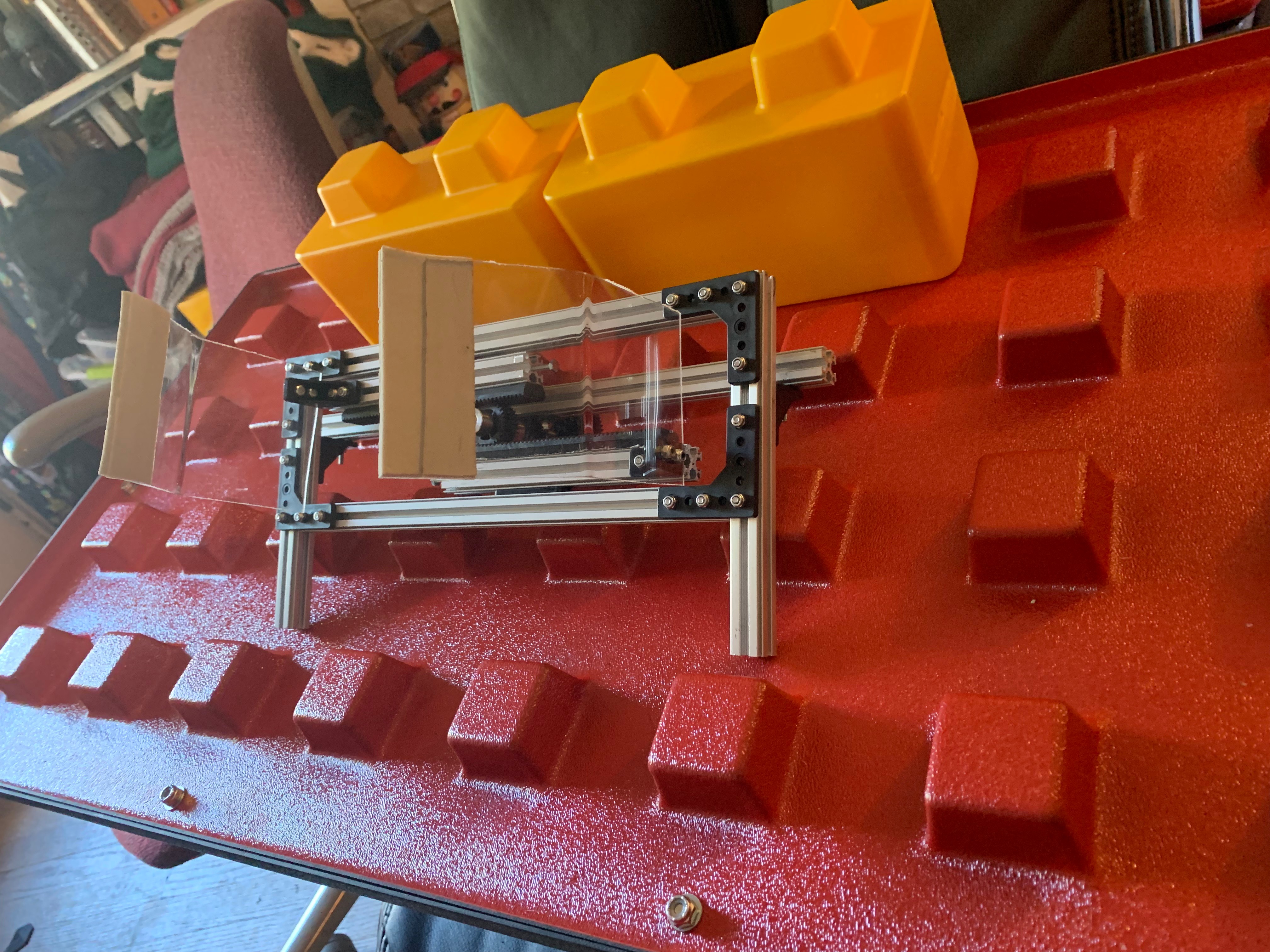

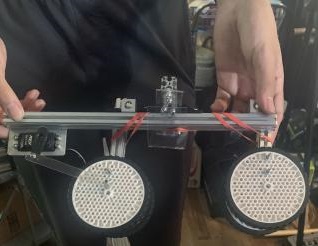

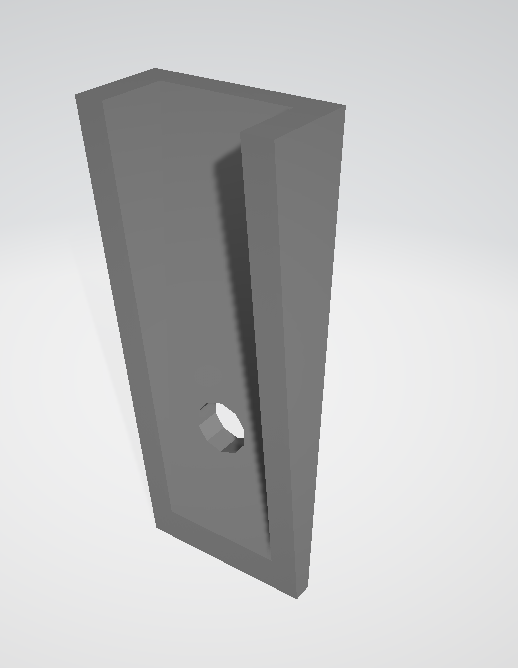

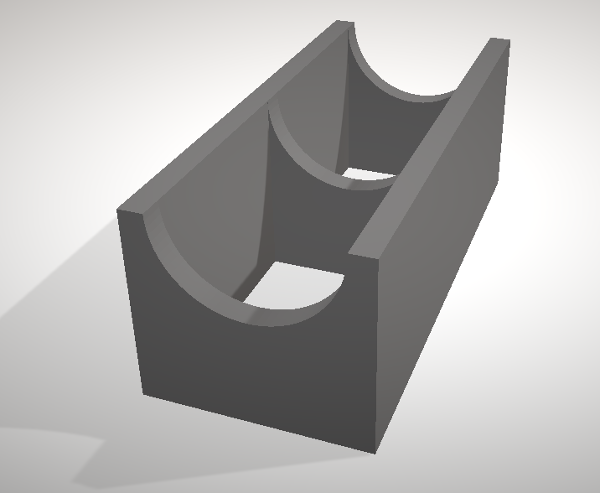

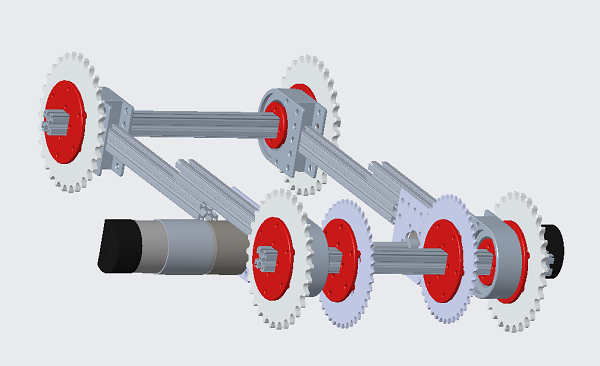

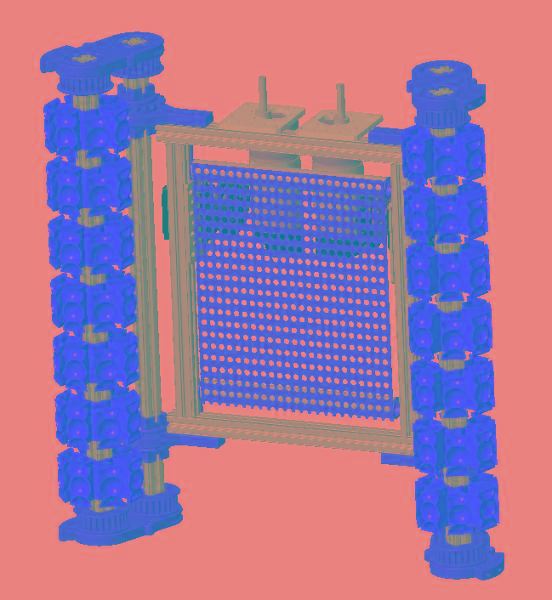

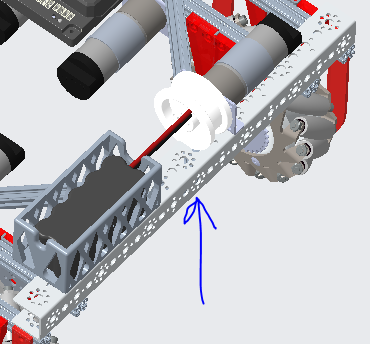

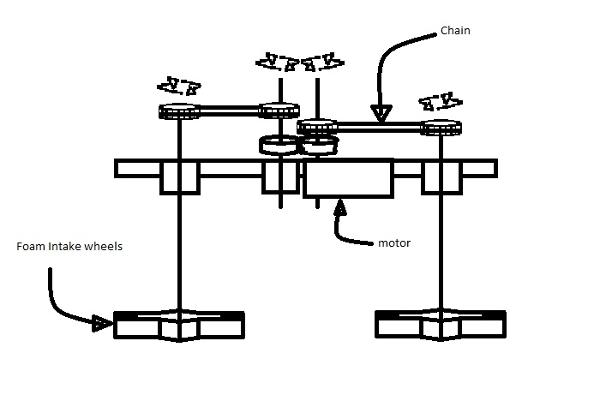

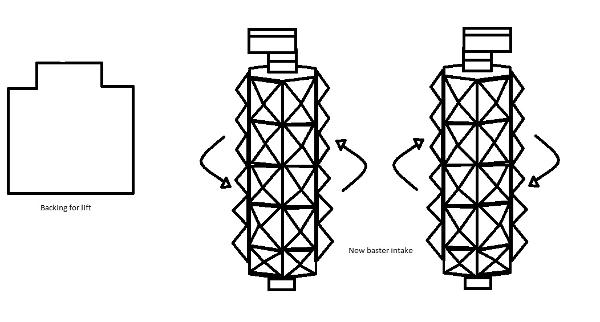

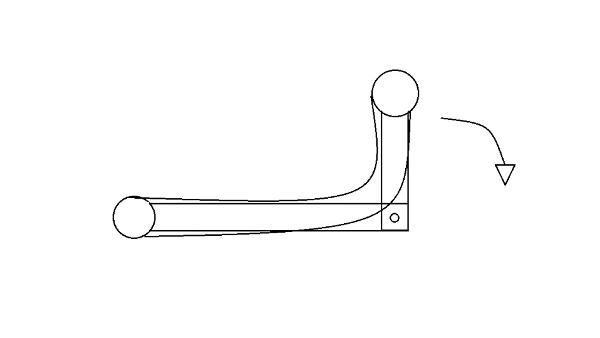

This suggestion uses a...

This suggestion uses a...

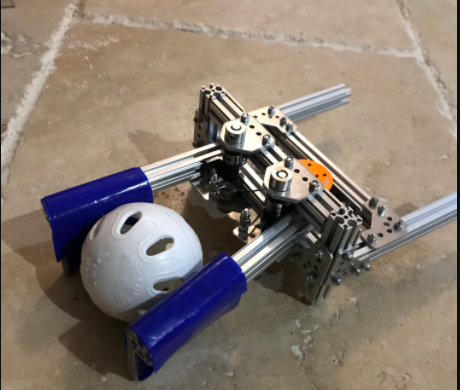

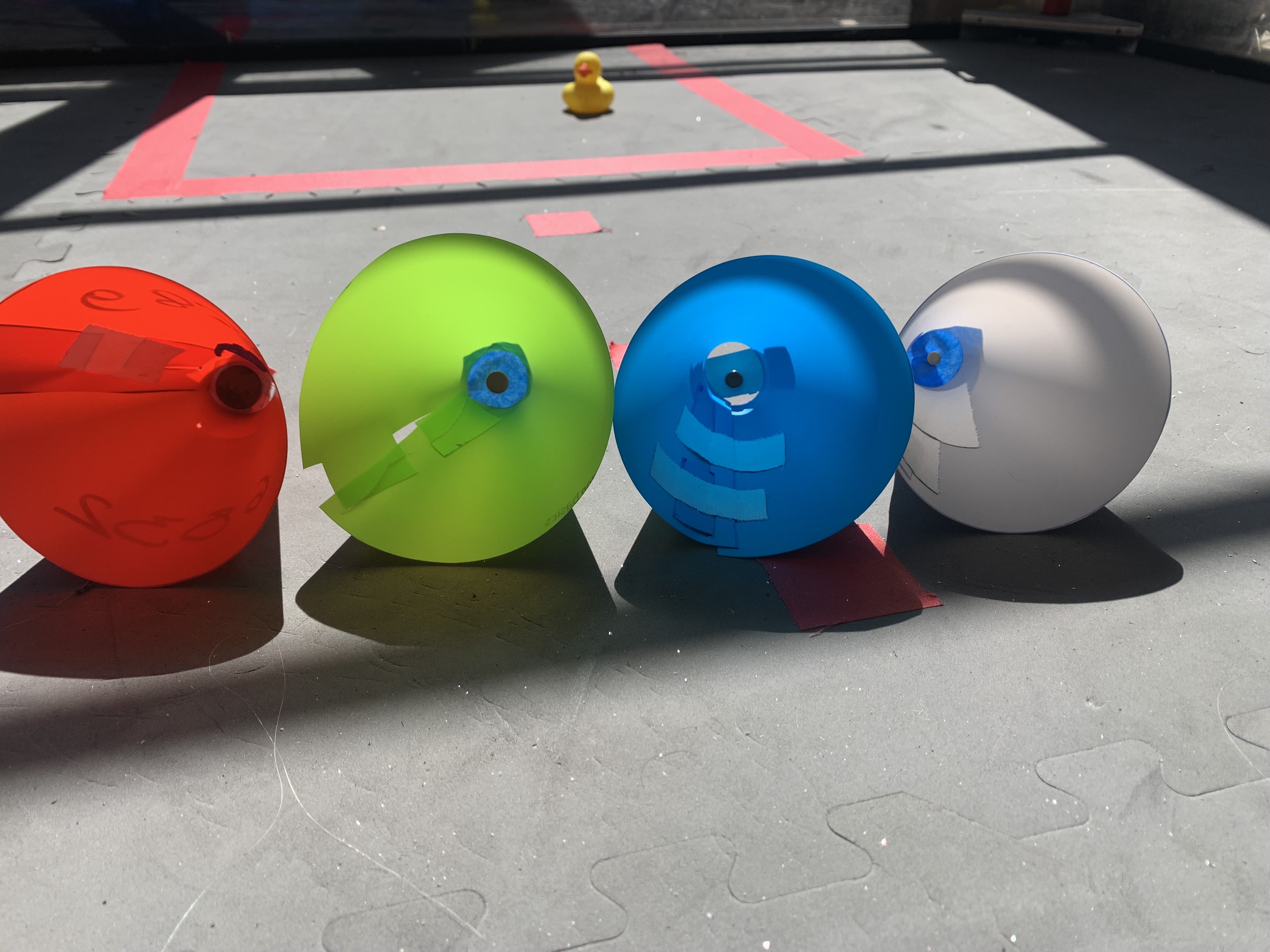

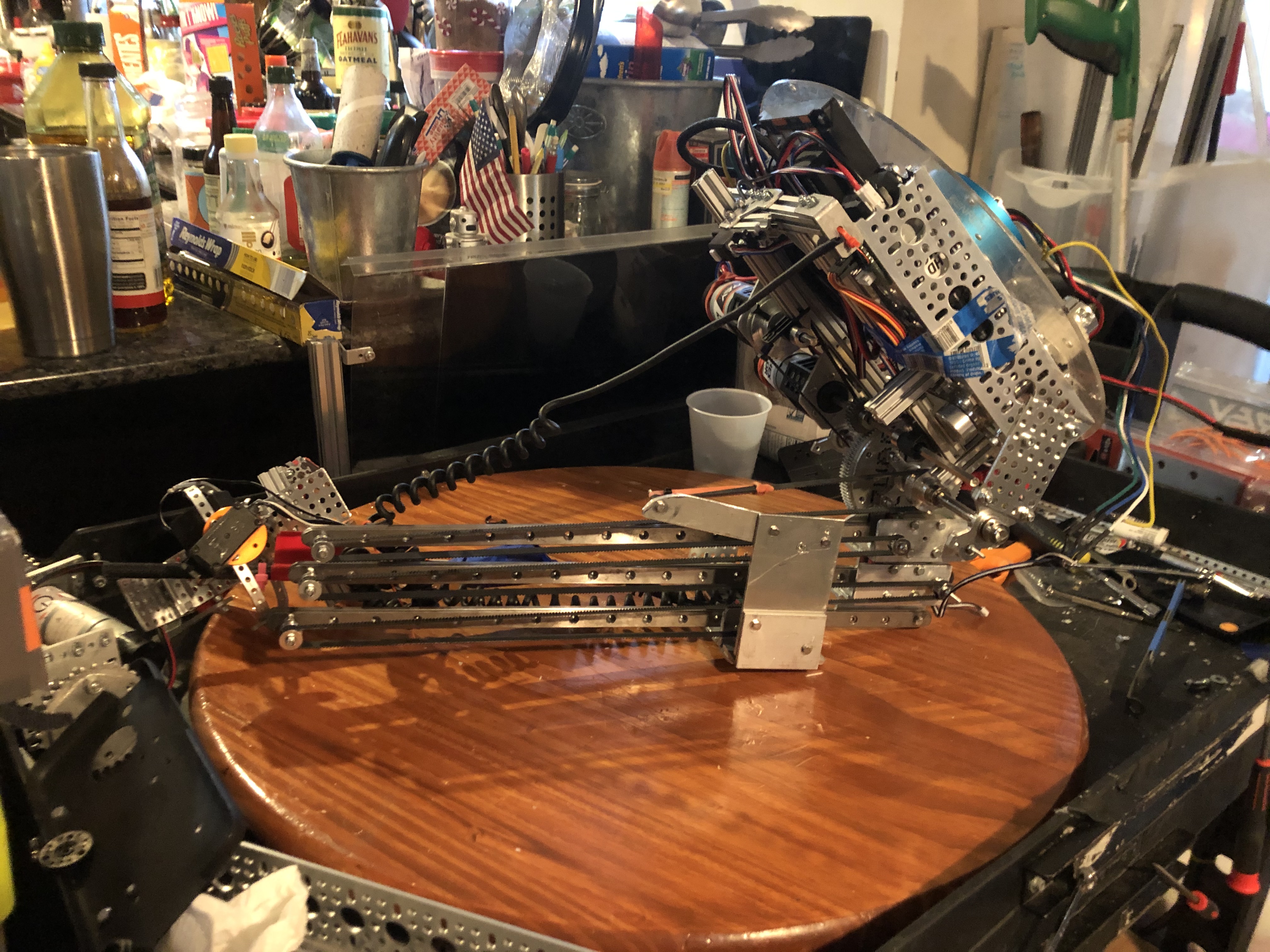

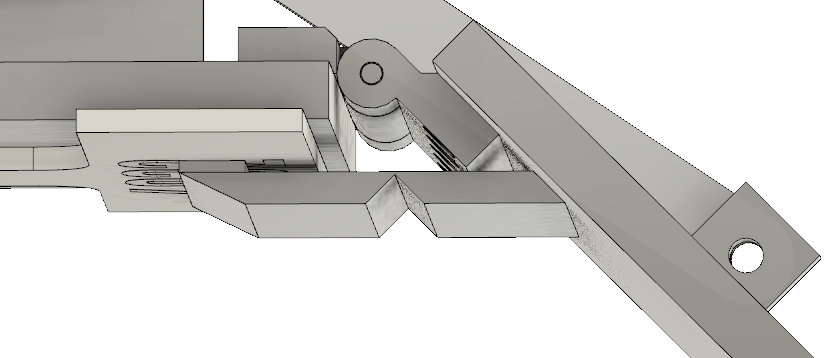

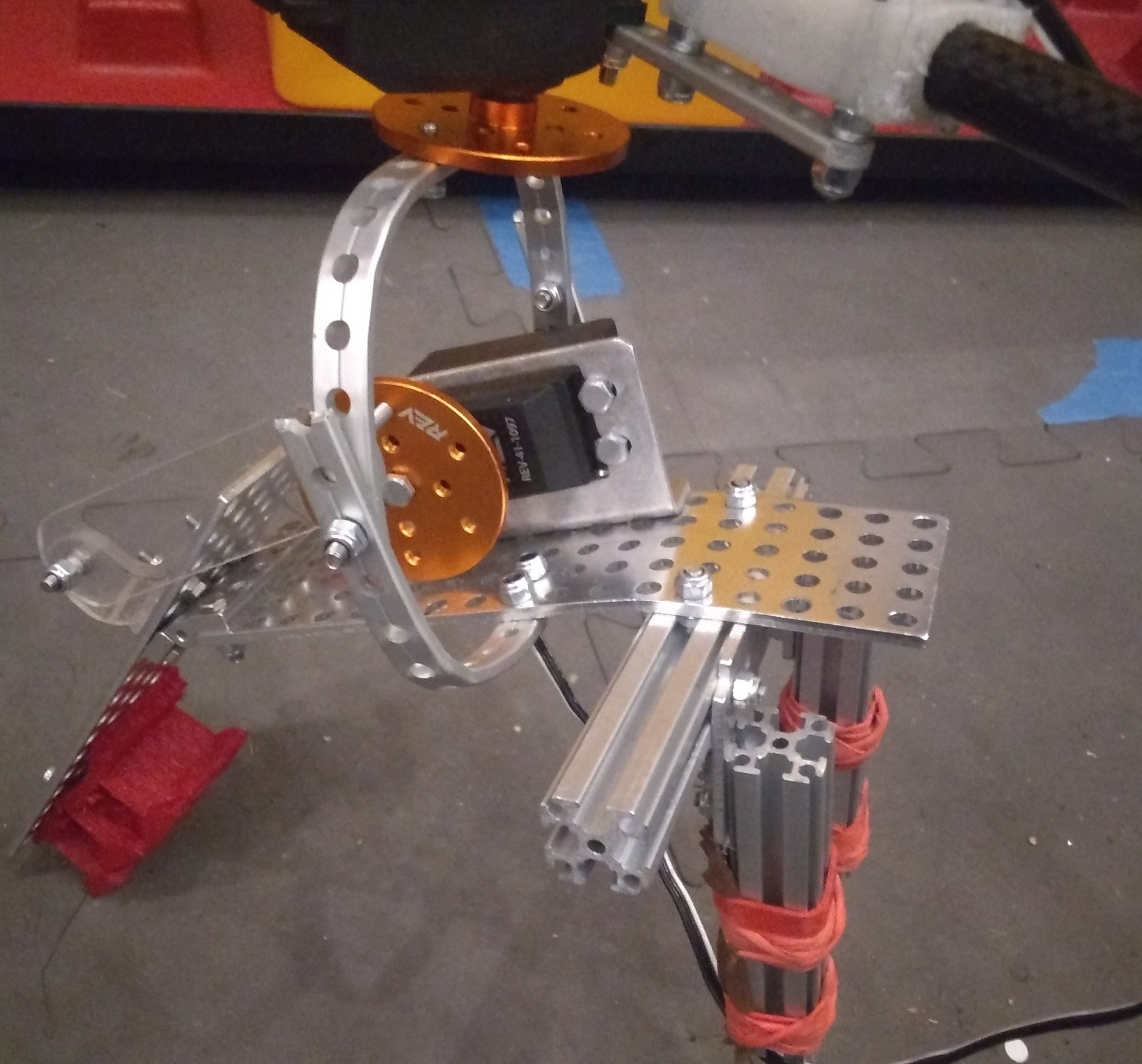

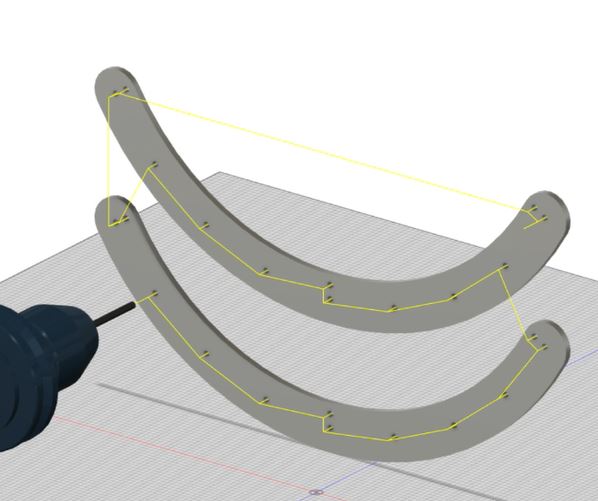

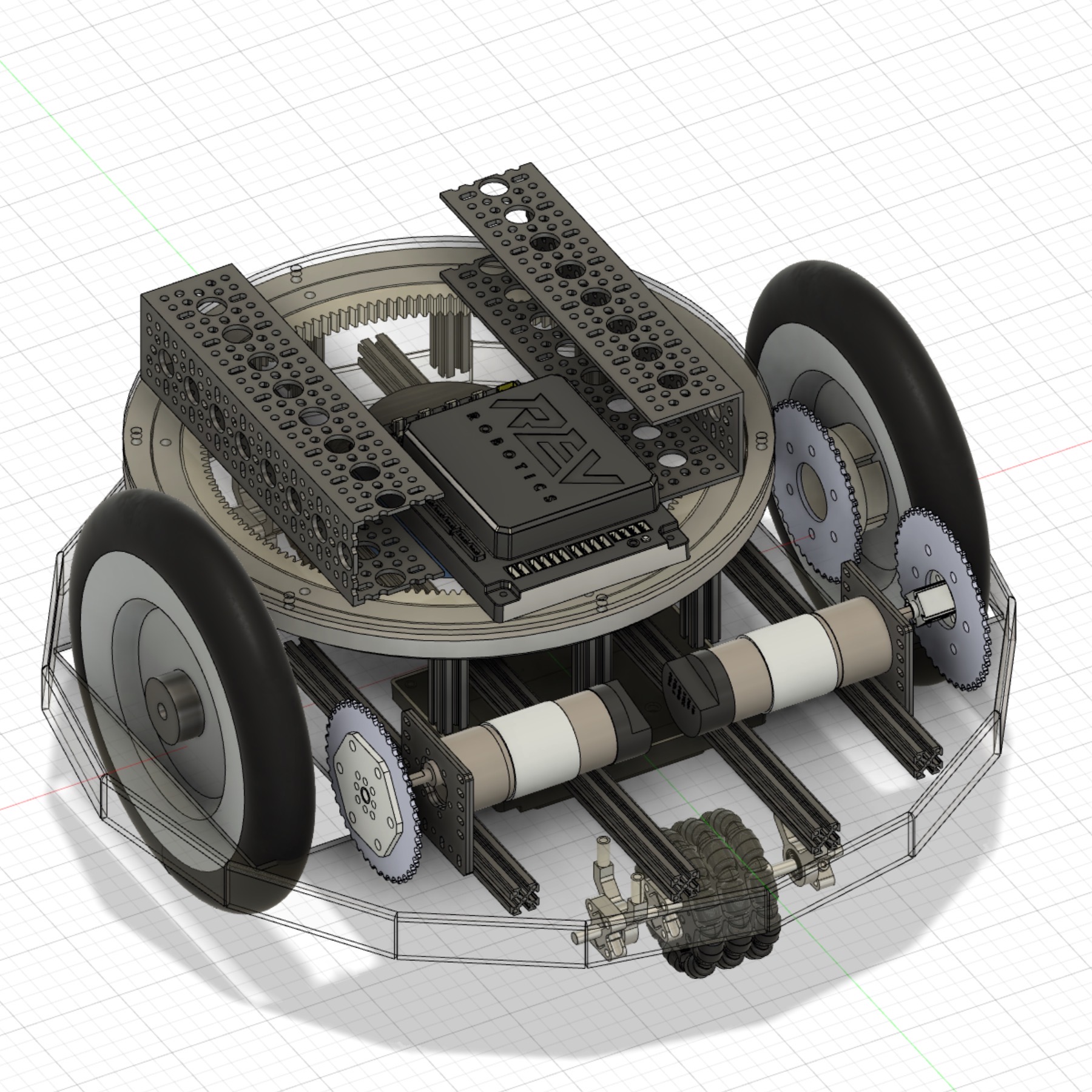

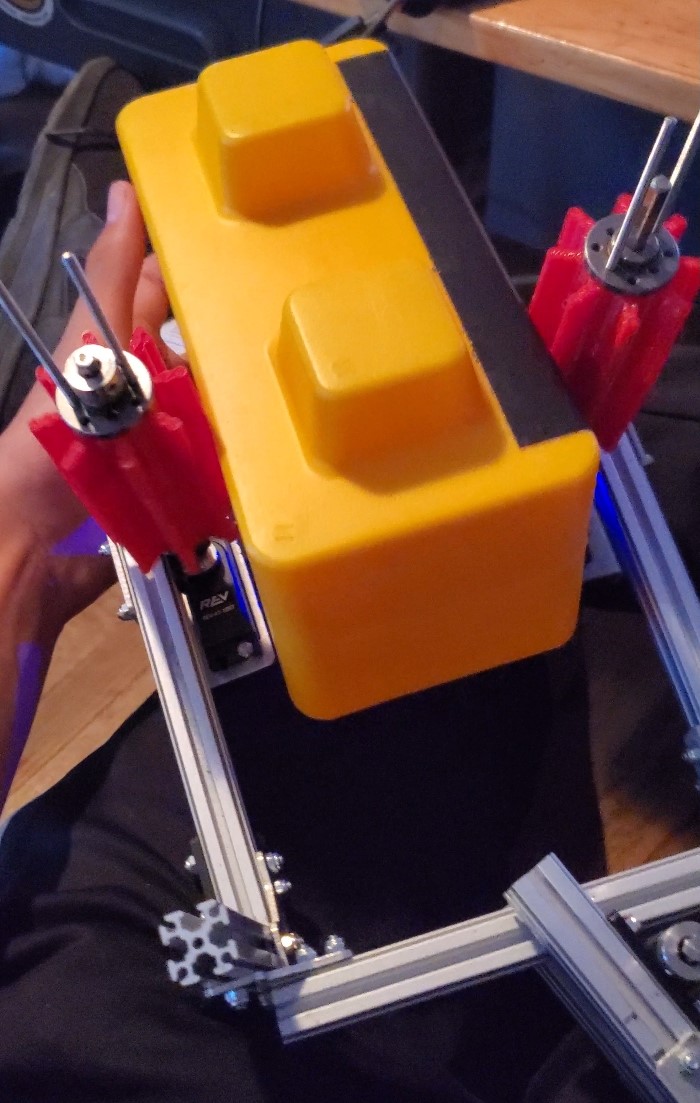

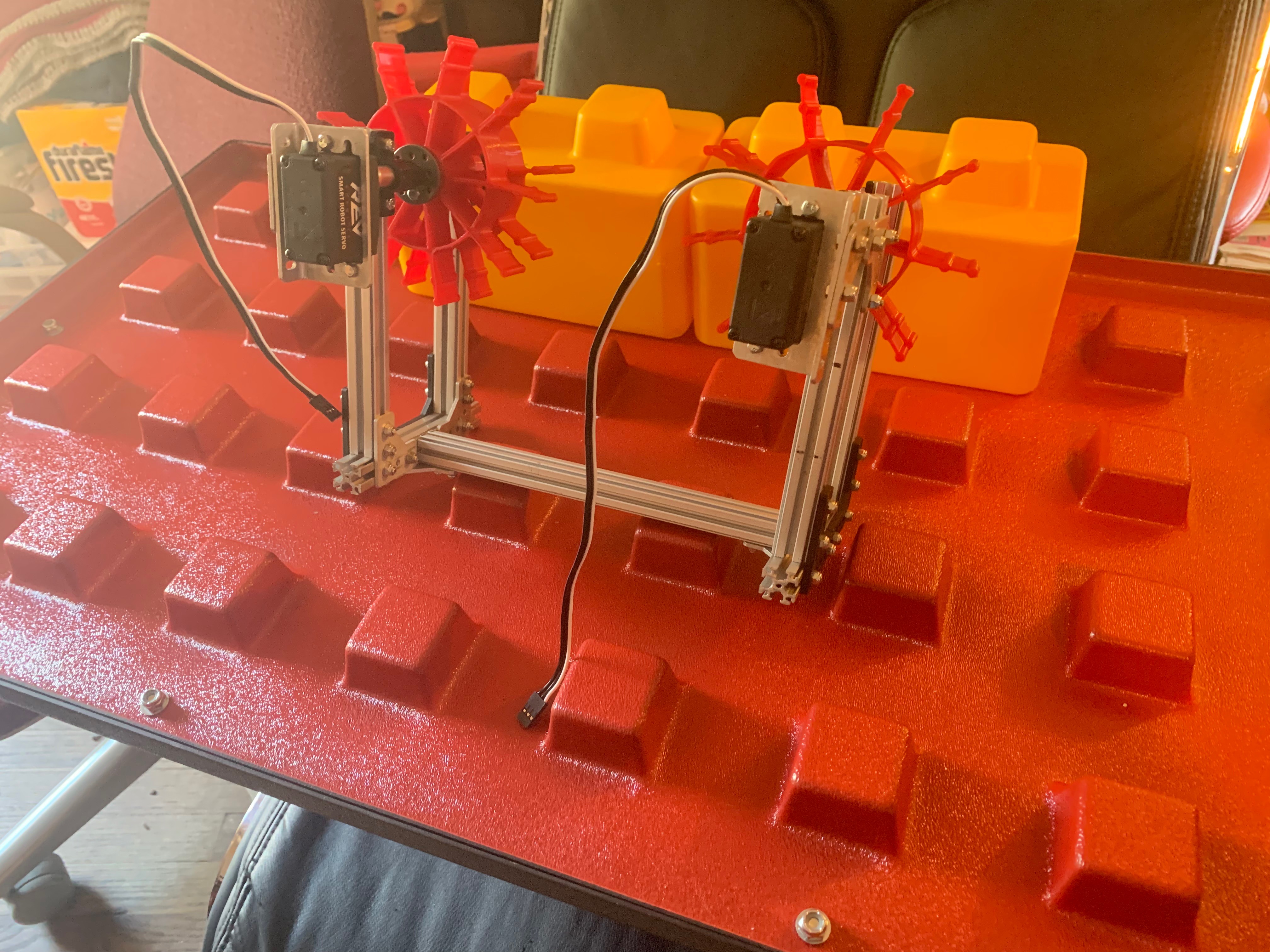

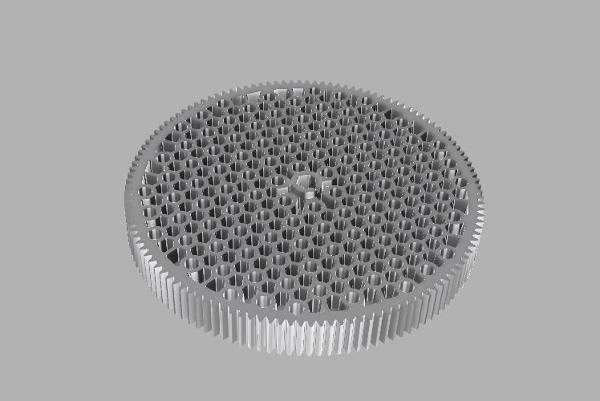

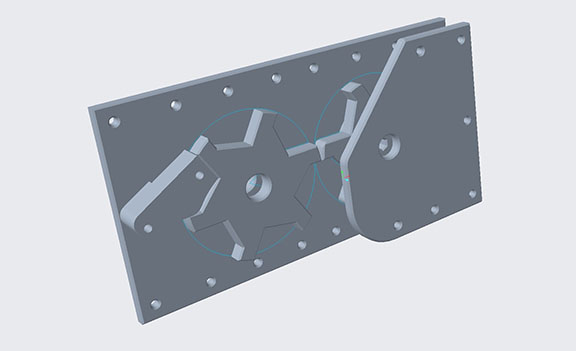

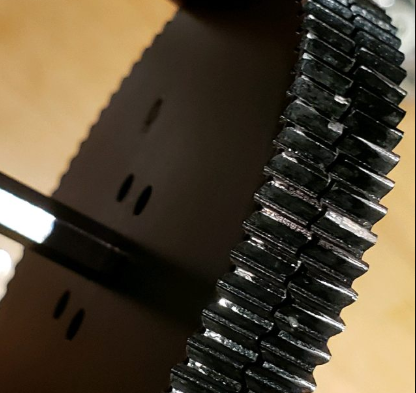

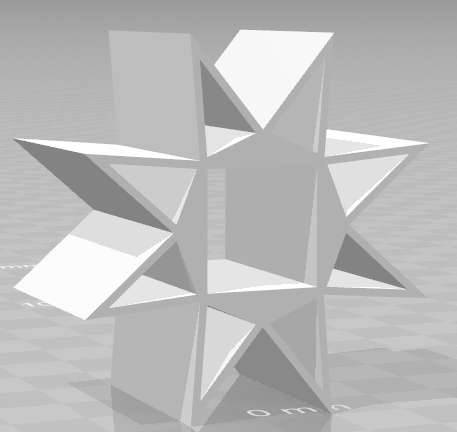

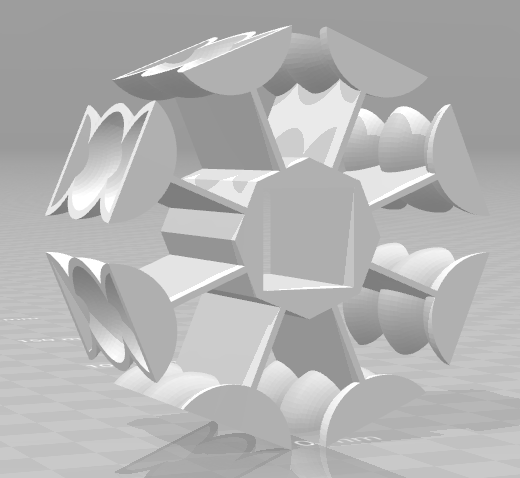

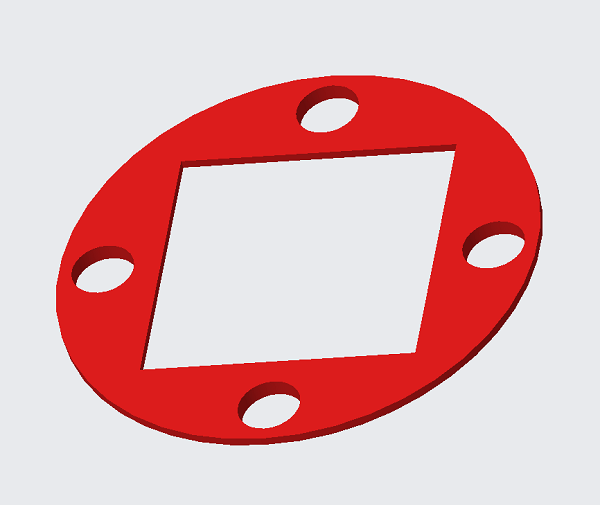

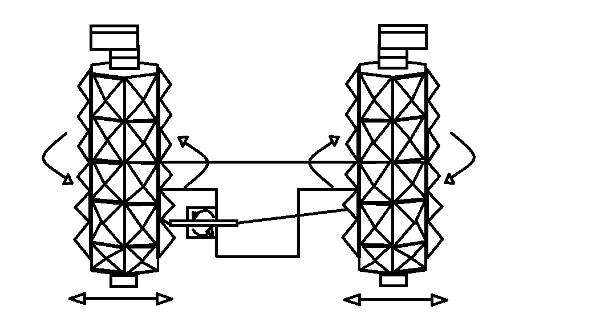

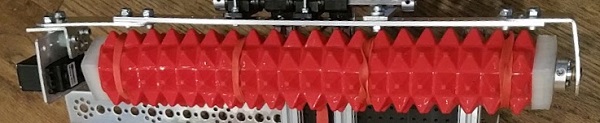

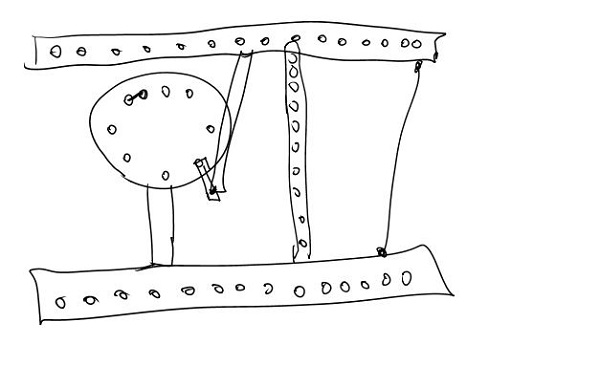

This design was too rigid, we overlooked the fact that triangles tend to be the strongest shape, and therefore this octopucker wasn't as compliant as we wanted, damaging the blocks.

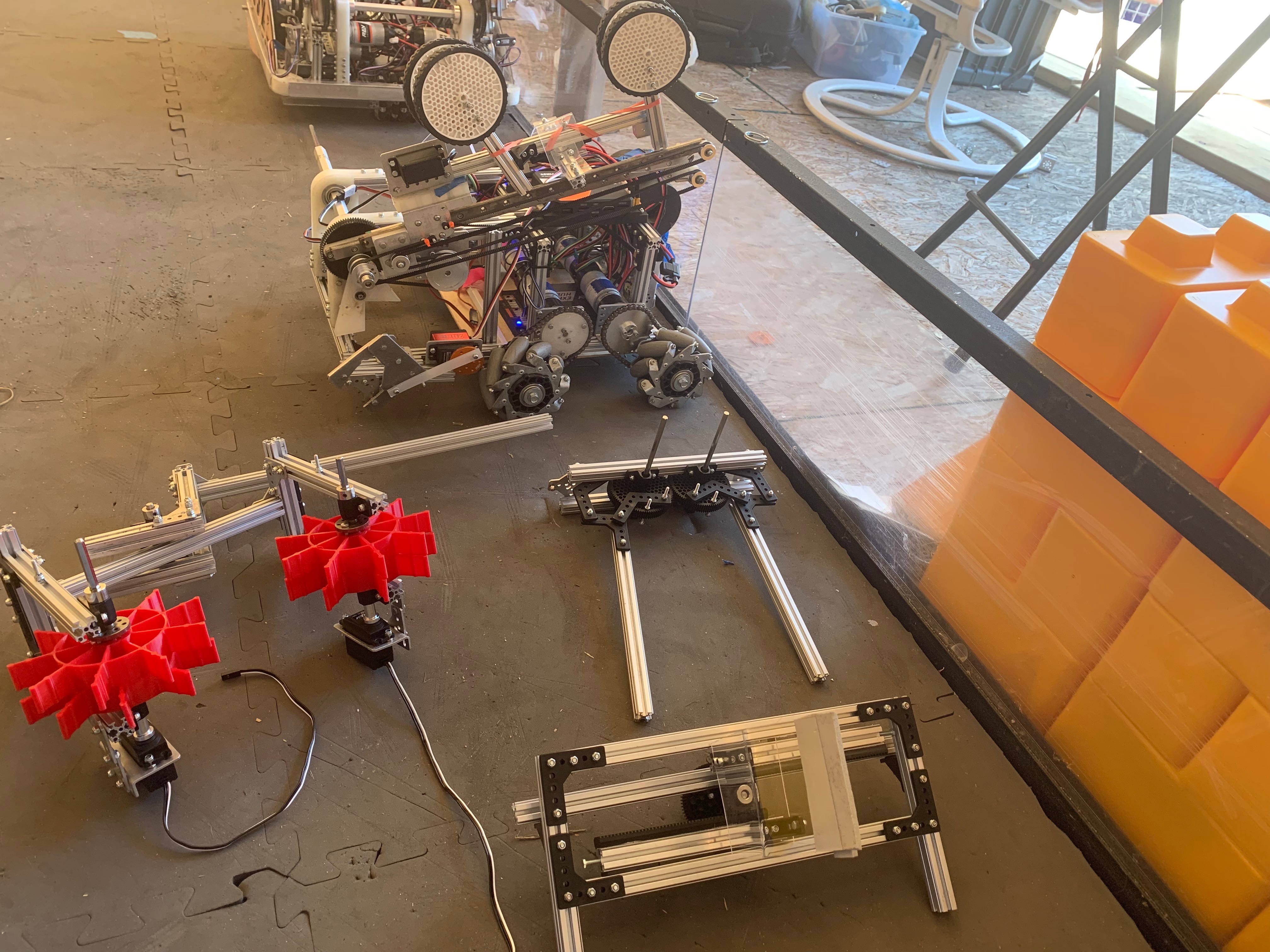

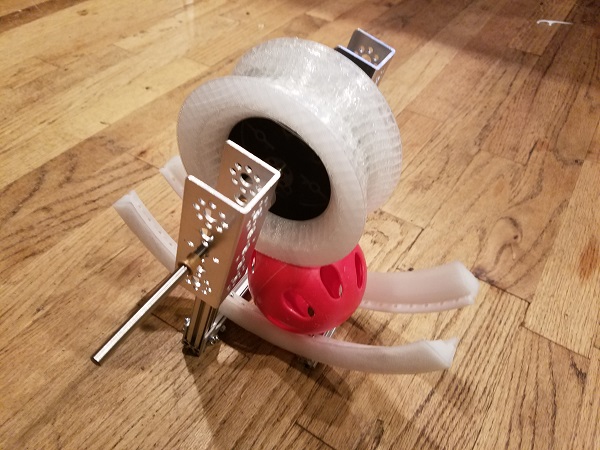

This design was too rigid, we overlooked the fact that triangles tend to be the strongest shape, and therefore this octopucker wasn't as compliant as we wanted, damaging the blocks.  This design was really good, and we used it for 3-4 tournaments. Our initial design of these wouldn't damage the blocks significantly at the levels...

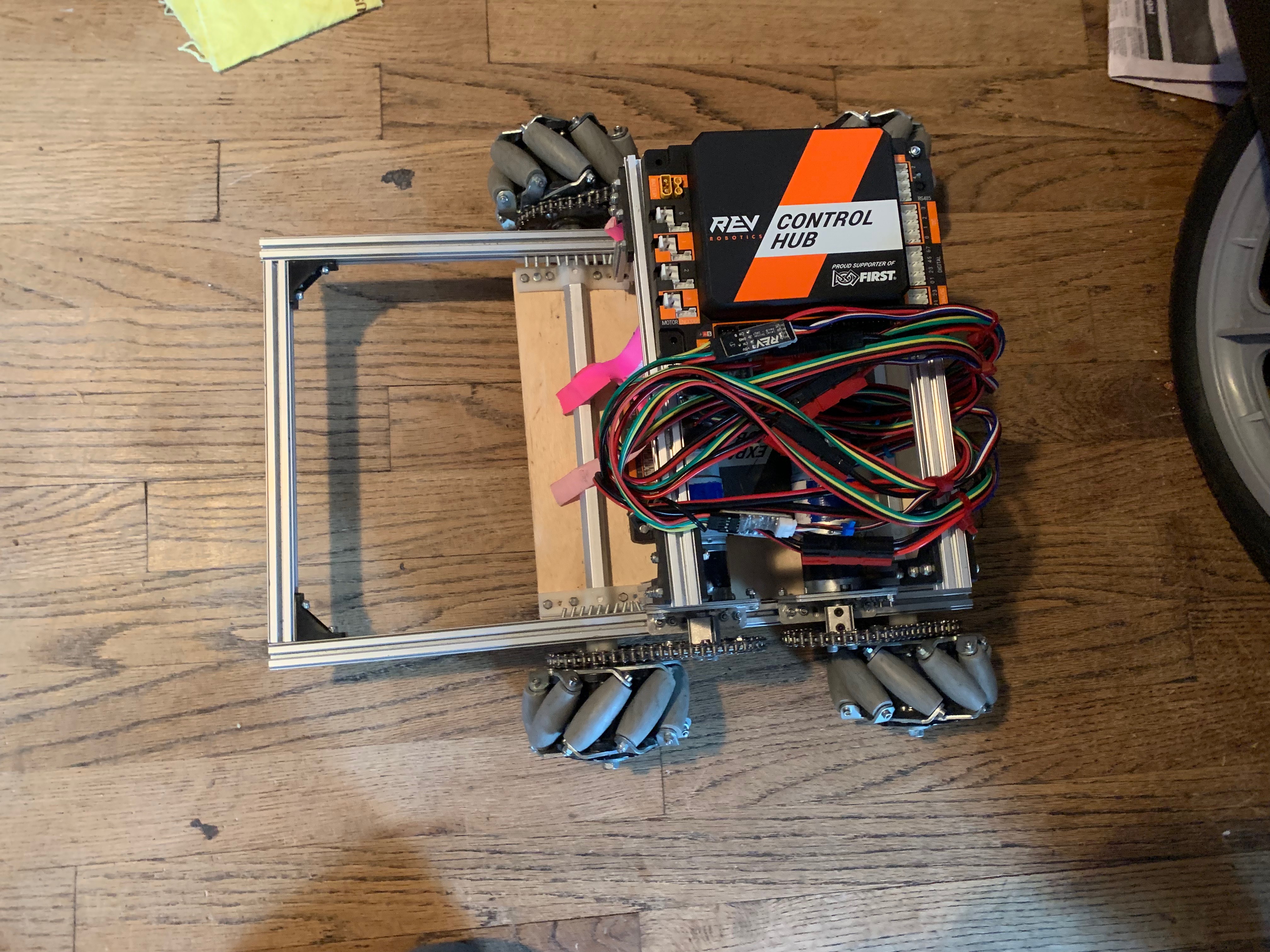

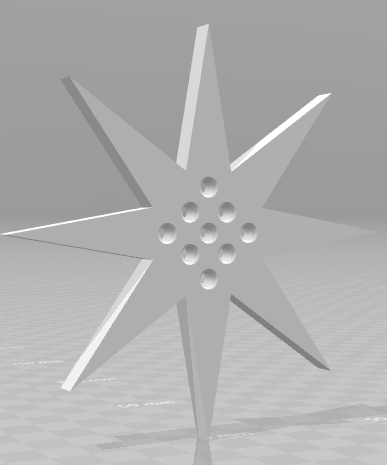

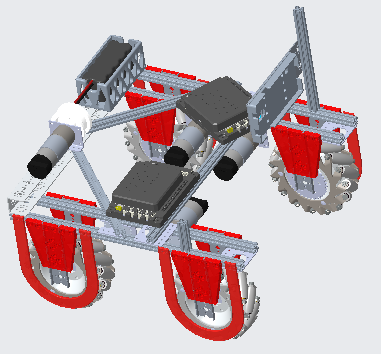

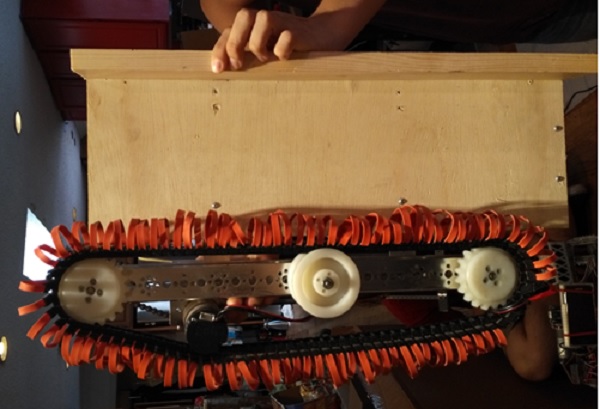

This design was really good, and we used it for 3-4 tournaments. Our initial design of these wouldn't damage the blocks significantly at the levels...

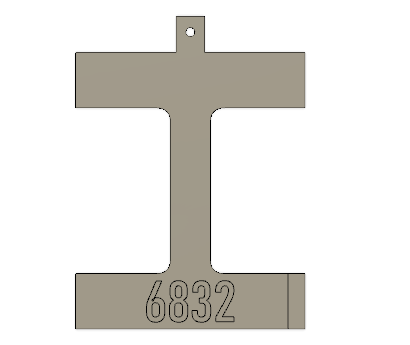

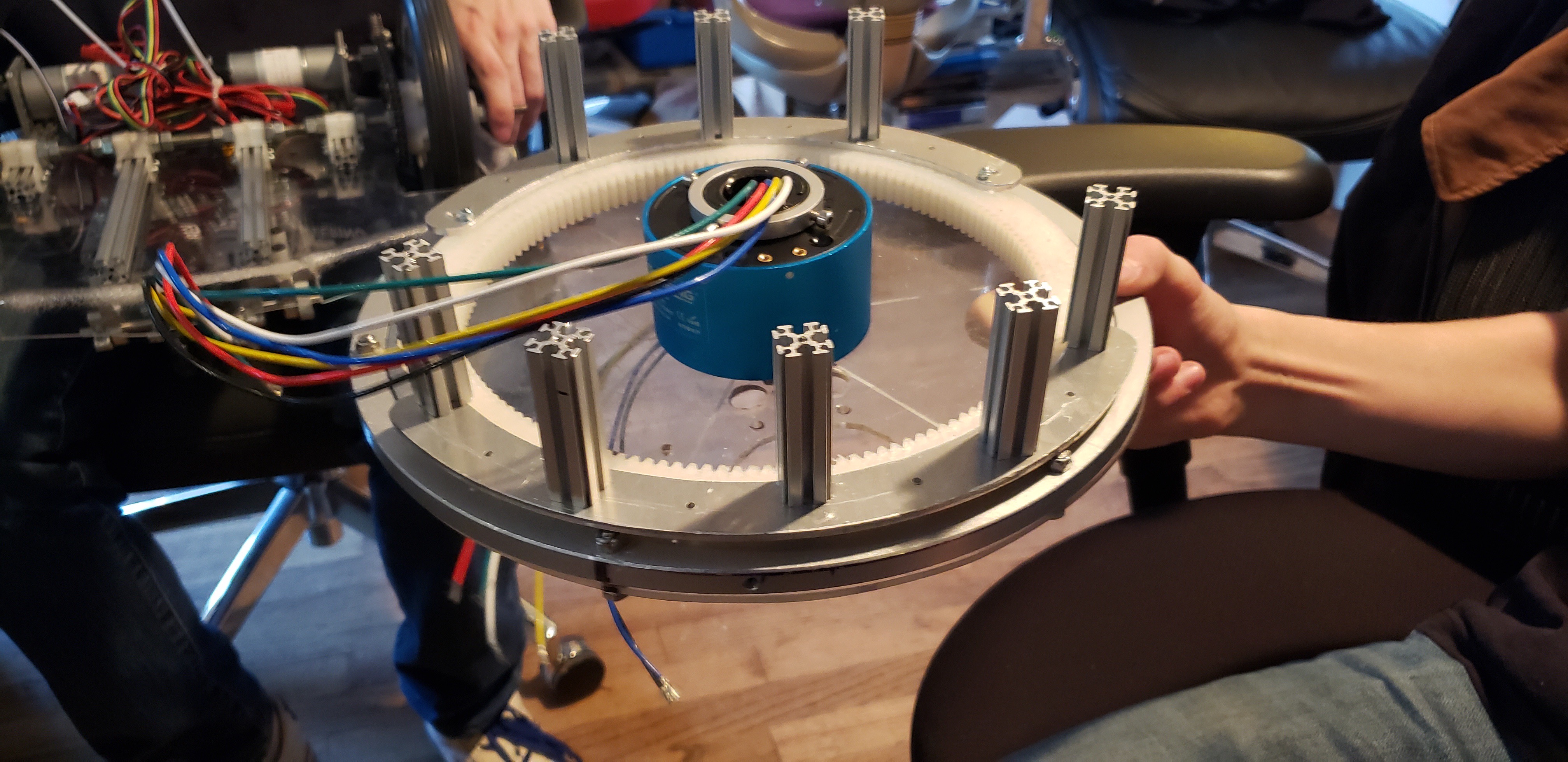

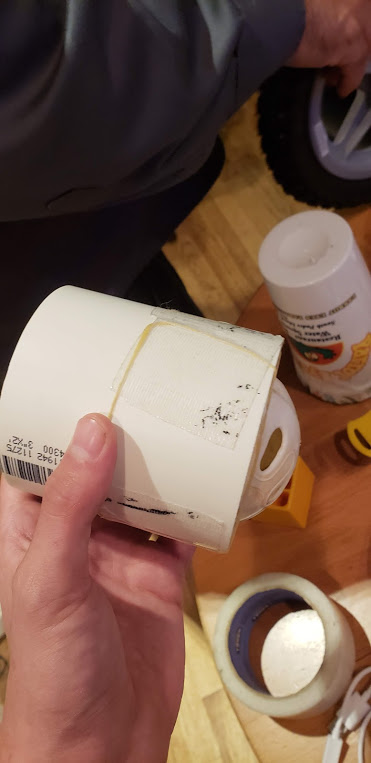

The cool thing...

The cool thing...