Intro

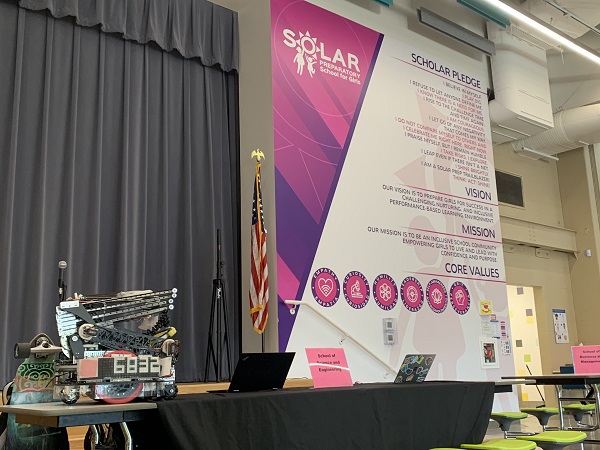

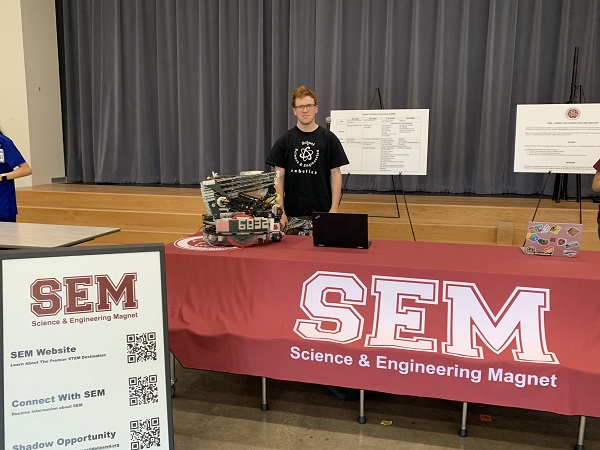

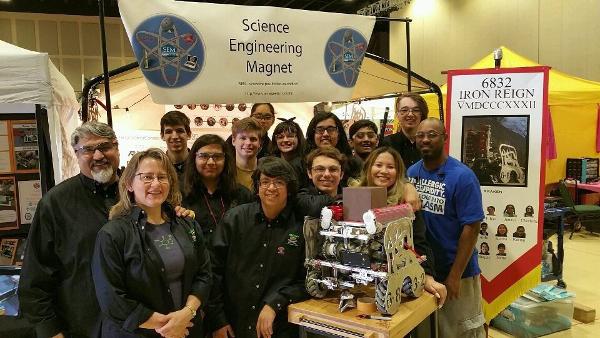

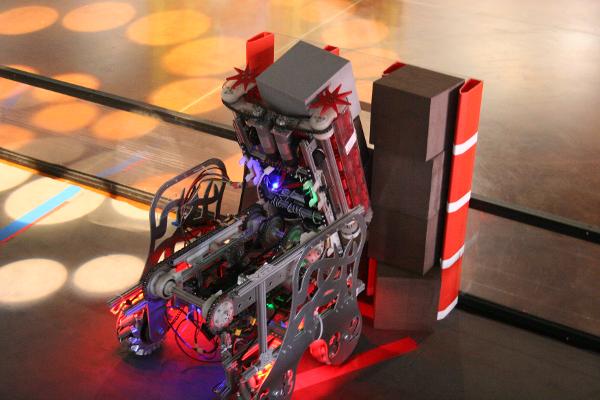

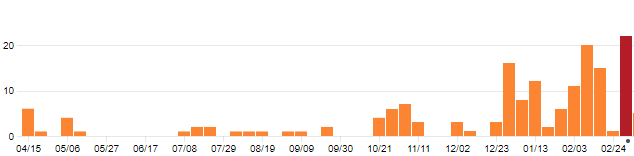

Iron Reign has existed, in one form or another, for the past

eight years. We have competed in FLL, Google Lunar X Prize Challenge, and now,

FTC.

While our team originated at WB Travis Vanguard and Academy,

we are now hosted by the School of Science and Engineering at Townview, in

DISD. Despite our school being 66% economically disadvantaged and being Title

1, our school consistently ranks in the top 10 nationwide. As well, our school

has numerous other award winning extracurricular, including CX Debate,

Math/Science UIL, and more.

A History of Iron Reign

Iron Reign has been a team for eight years. We initially

started as an FLL team, plateauing in regionals every year we competed. We also

did Google’s Lunar X Prize program every Summer,

achieving finalist status in 2011 and 2012. Upon moving to high school, we

started doing FTC, as FRC was too cost-prohibitive to be parent-run.

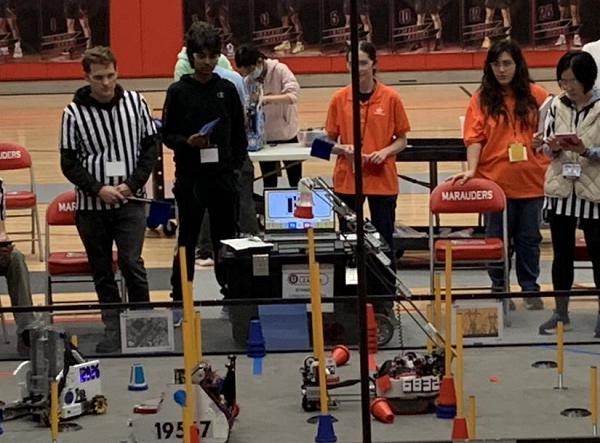

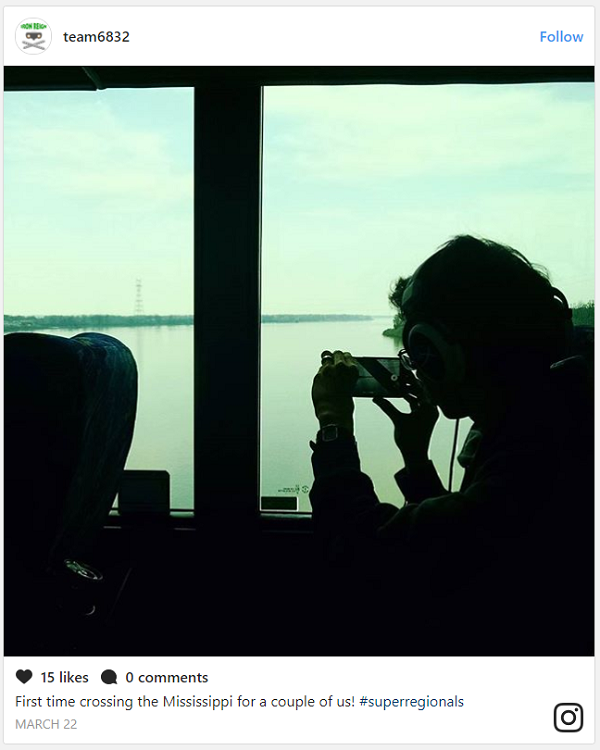

We have been an FTC team for 6 years, advancing further and

further each year. Last year, we got to the South Super Regionals, qualifying

by winning the North Texas Inspire Award. In Georgia, we were the first alternative for Worlds if another team dropped out due

to cost.

Also in FTC, we compete in the Texas UIL State

Championships. For those unfamiliar with UIL, it is the main organizational

committee for all public school academic and athletic events. Through UIL, we

helped compete in the first test program for the UIL Robotics program and since

then have competed in every subsequent tournament.

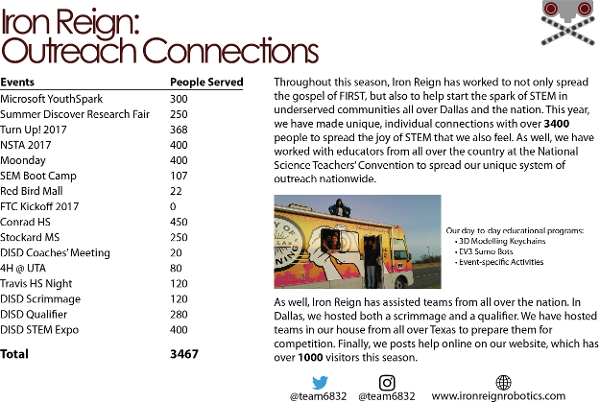

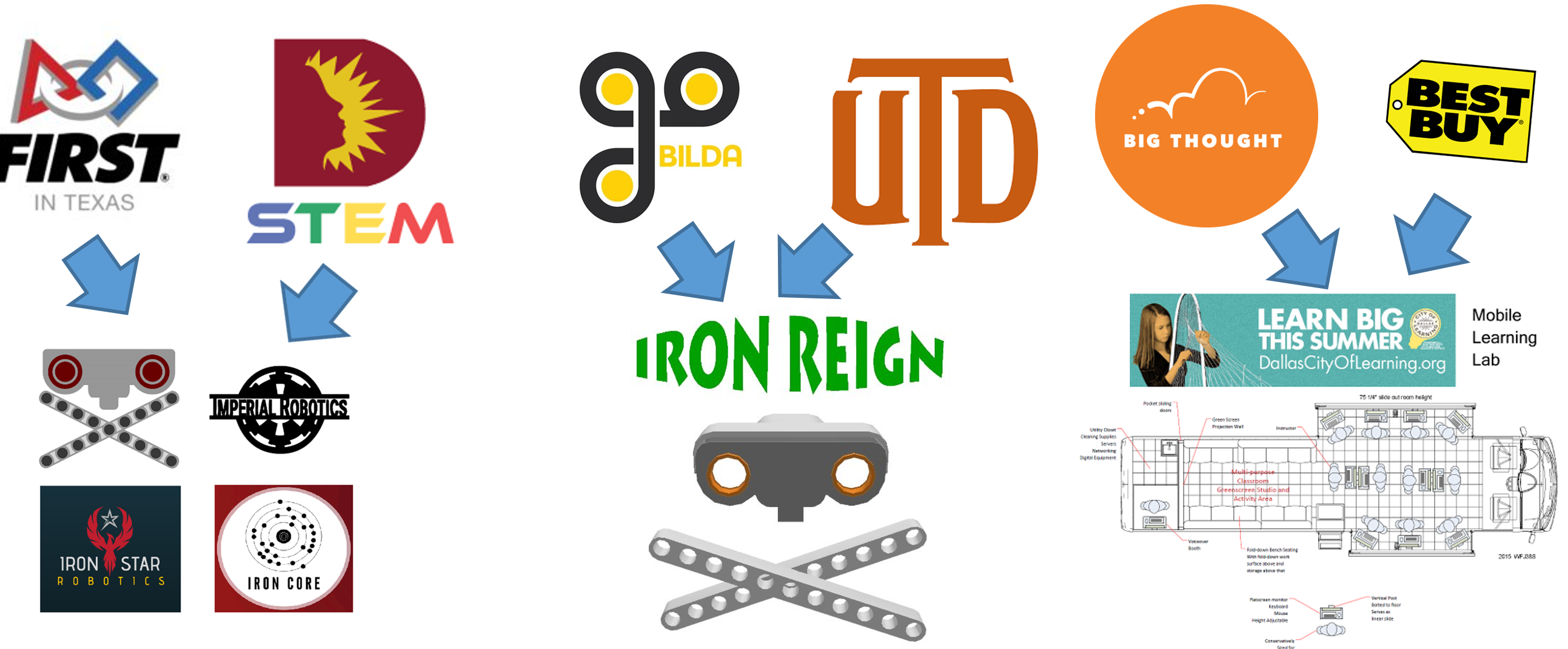

Outreach

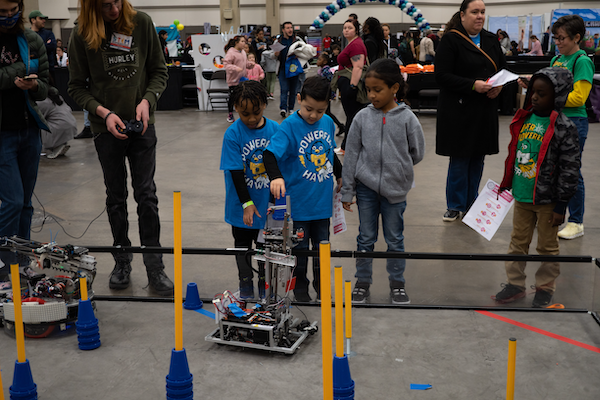

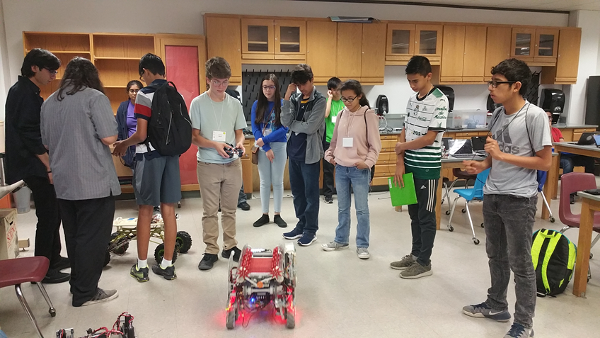

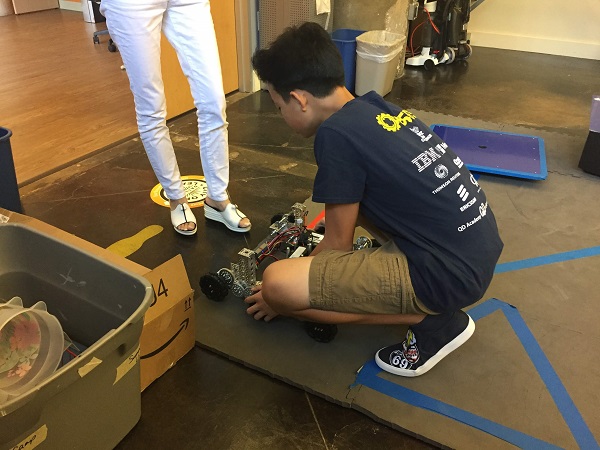

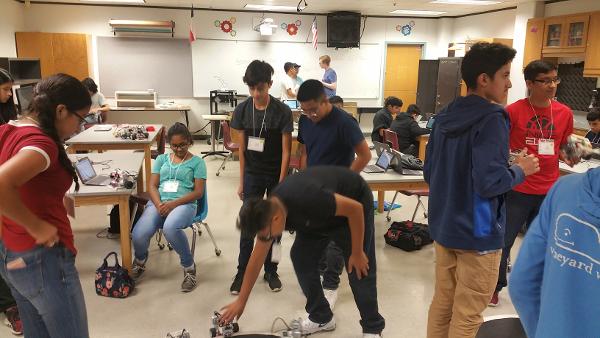

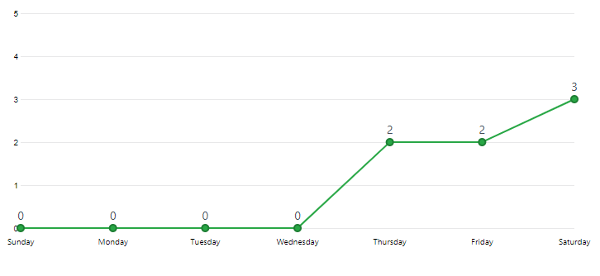

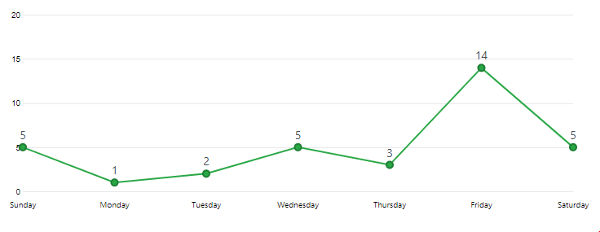

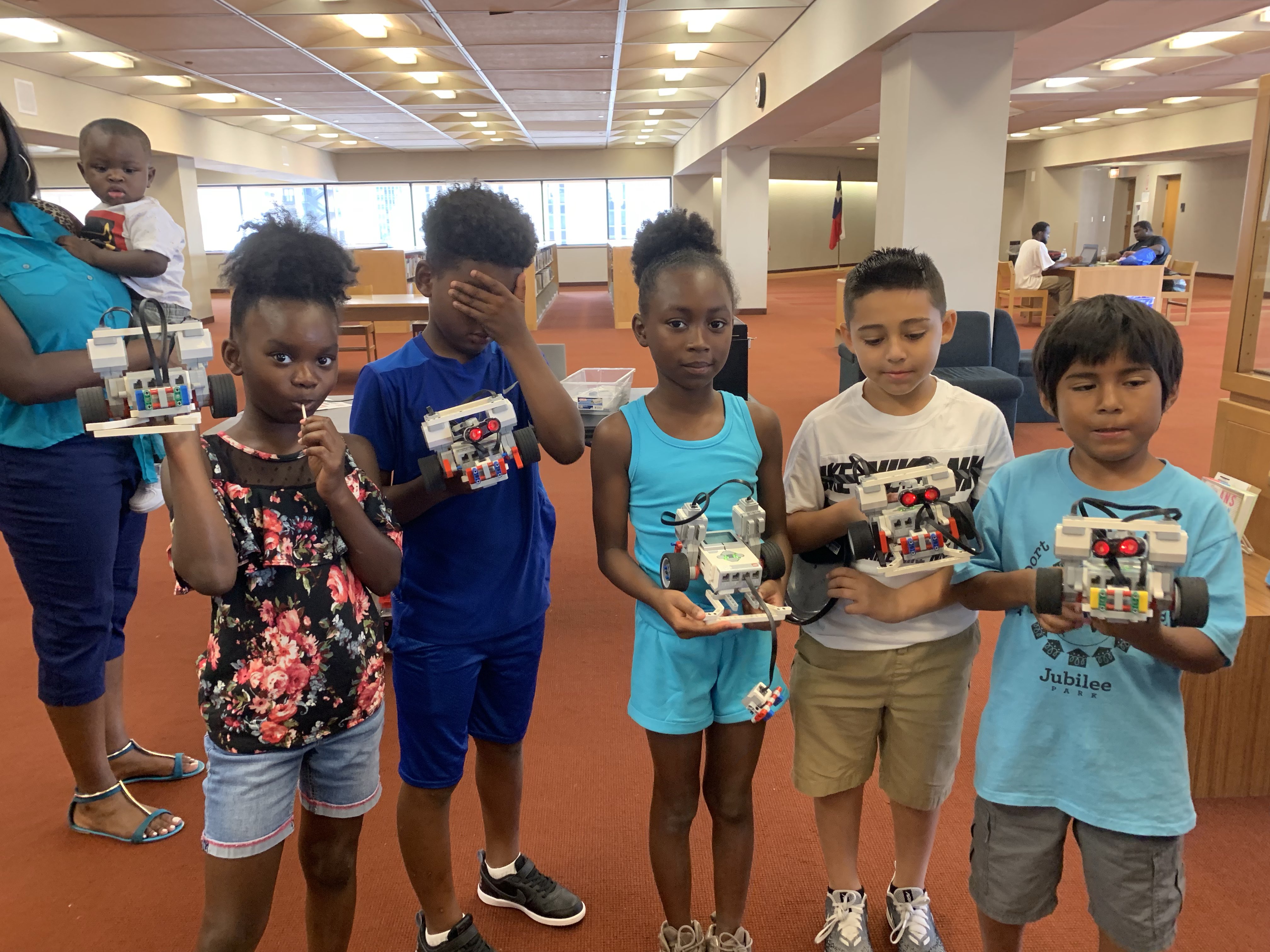

Iron Reign spends a large amount of time on outreach. This

year alone, we have put in 500 man-hours and created 2800 individual

connections to people in our community. Our goal of this outreach is to reach

disadvantaged children who would not normally have the opportunity to participate

in STEM programs in order to spark their interest in STEM for future learning.

Some of our major outreach events include presenting at the National Science

Teachers’ Association Convention in Florida, hoping to inspire people in other

regions to adopt our methods of outreach. We volunteered at a Microsoft youth

convention to spread STEM awareness, as well as volunteering throughout our

school district.

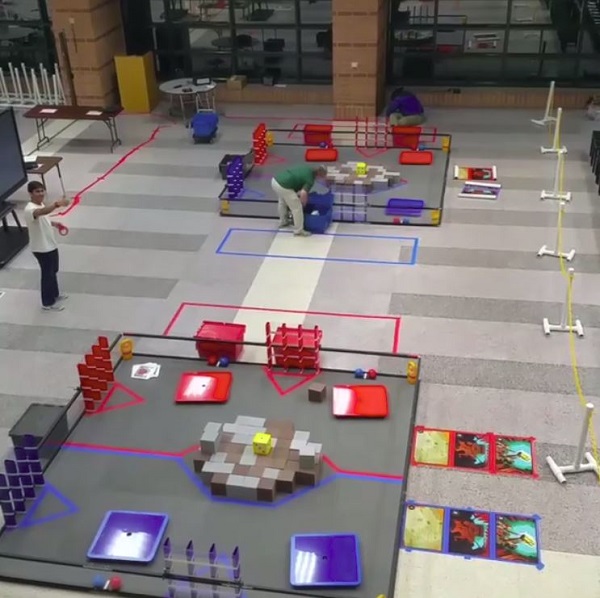

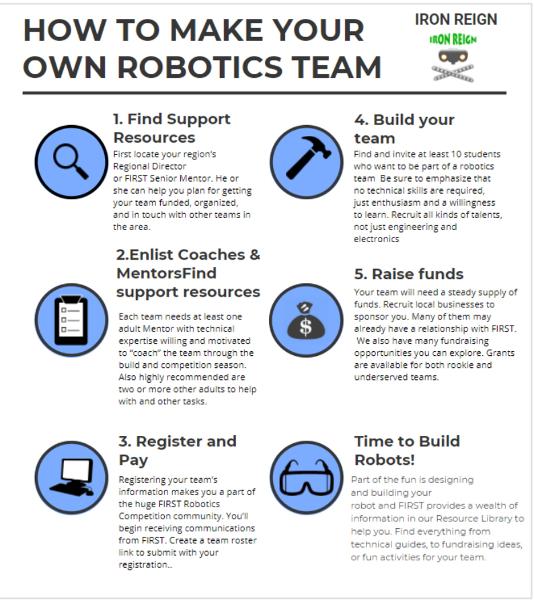

We also volunteer for FIRST. We have hosted a scrimmage for

our entire school district, DISD (one of the largest school districts in the

country), and are hosting a qualifier for the North Texas region in December.

We also instruct parents and educators on how to start a FIRST team when

volunteering, as Iron Reign itself was started by parents at WB Travis.

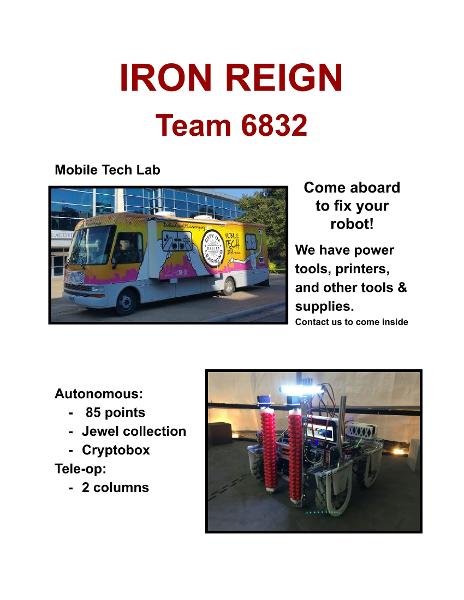

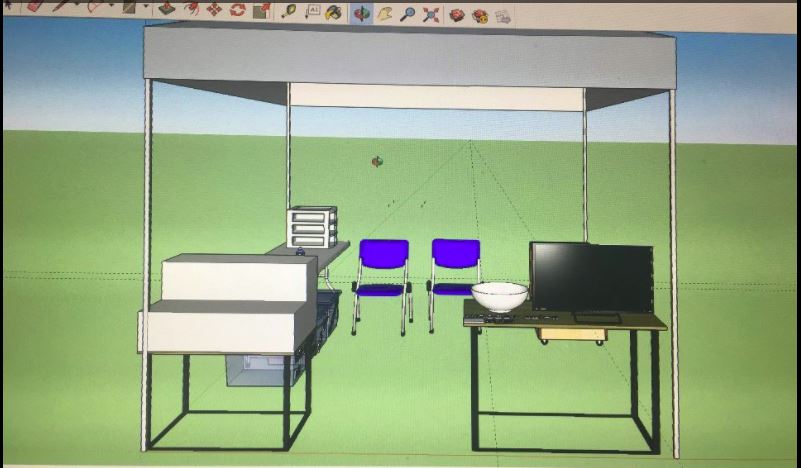

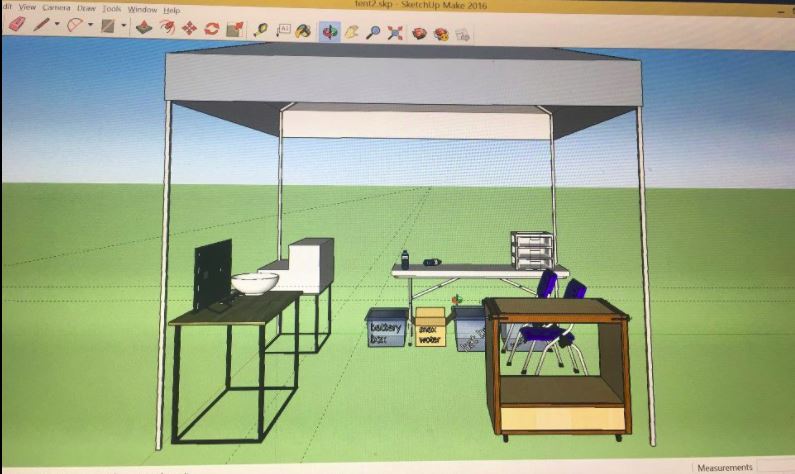

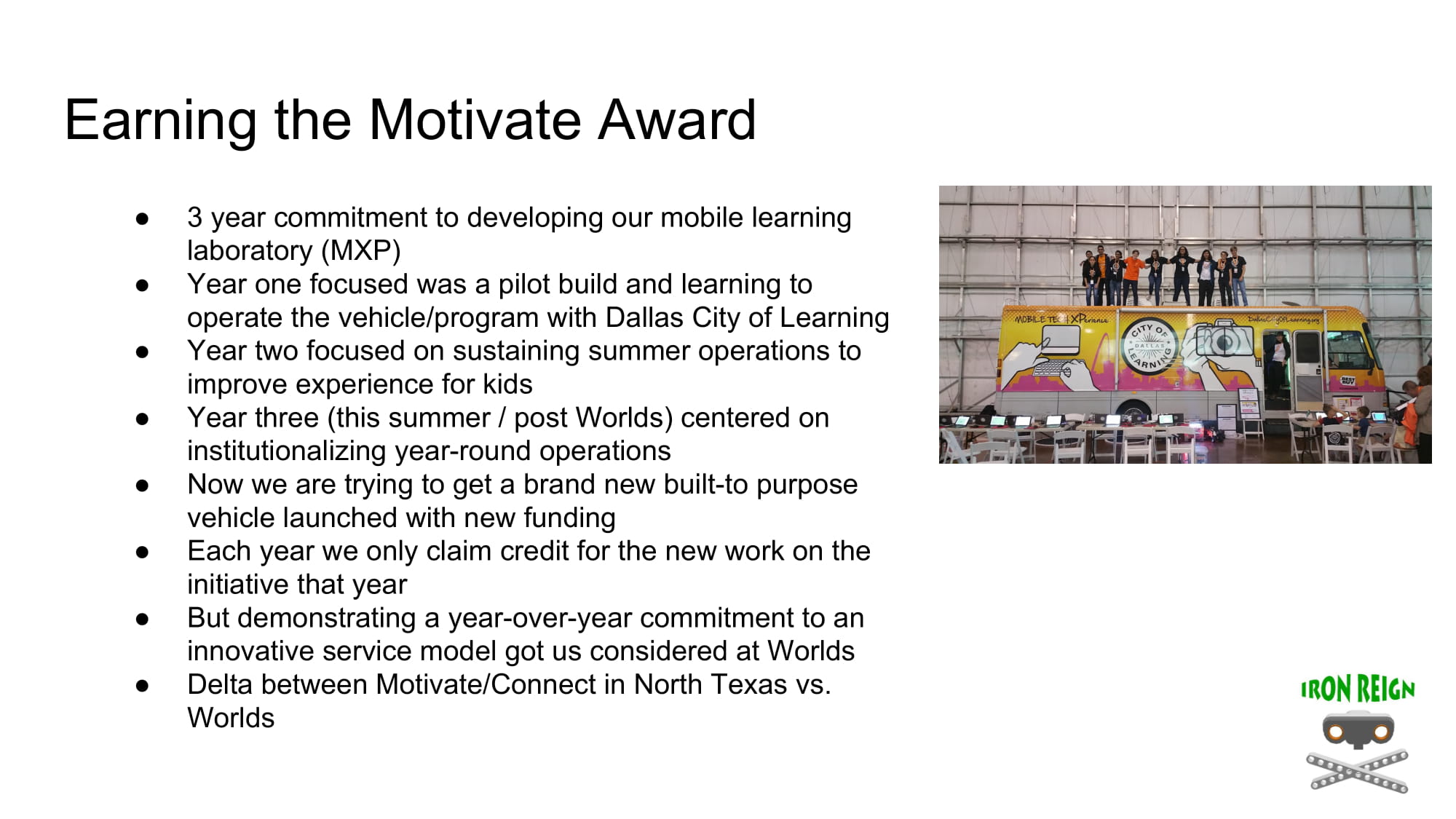

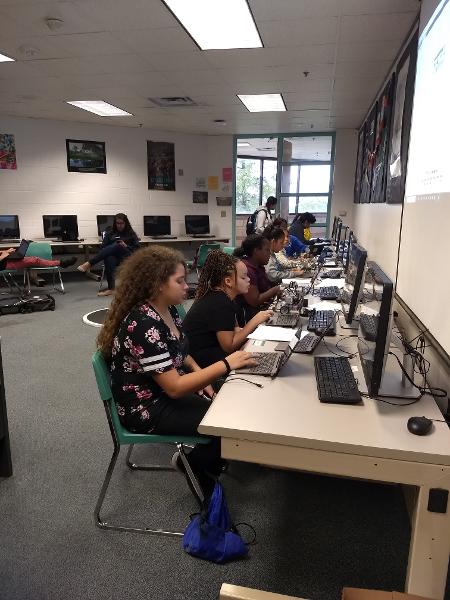

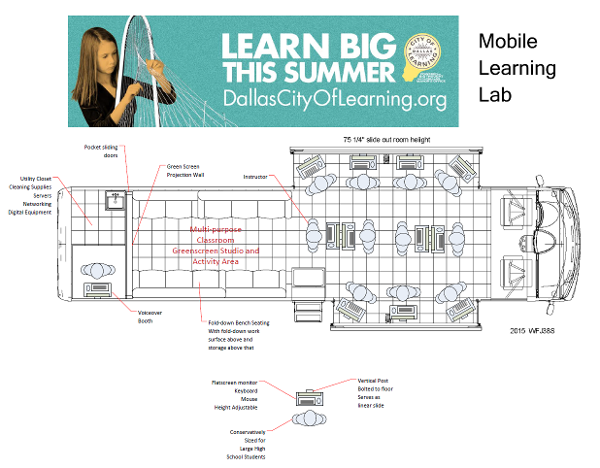

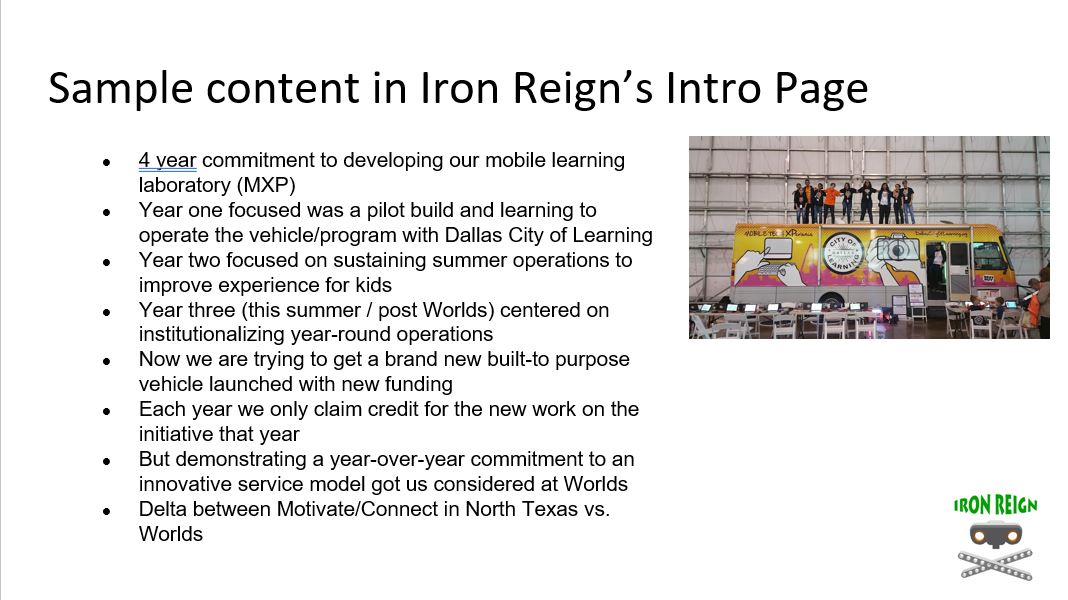

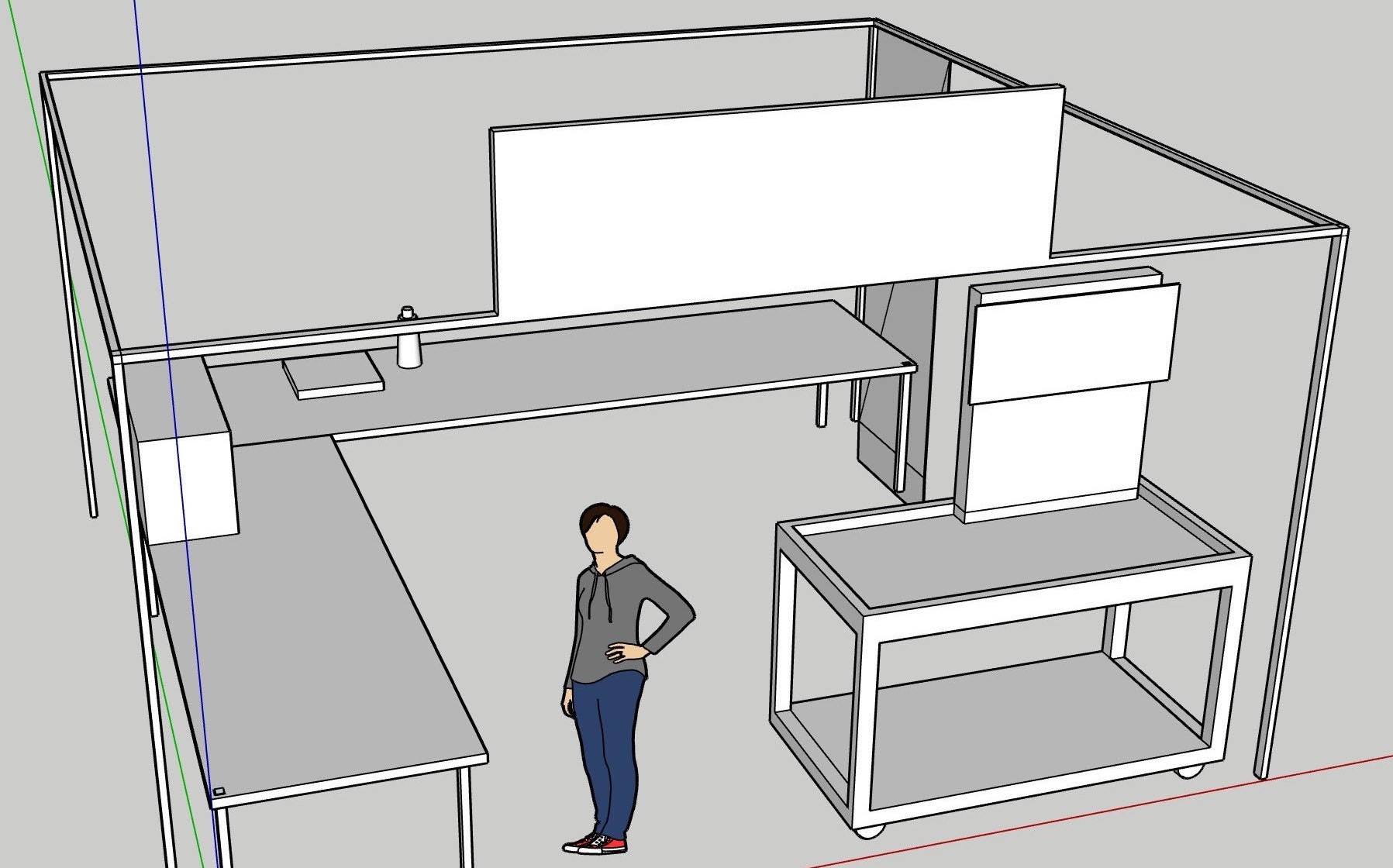

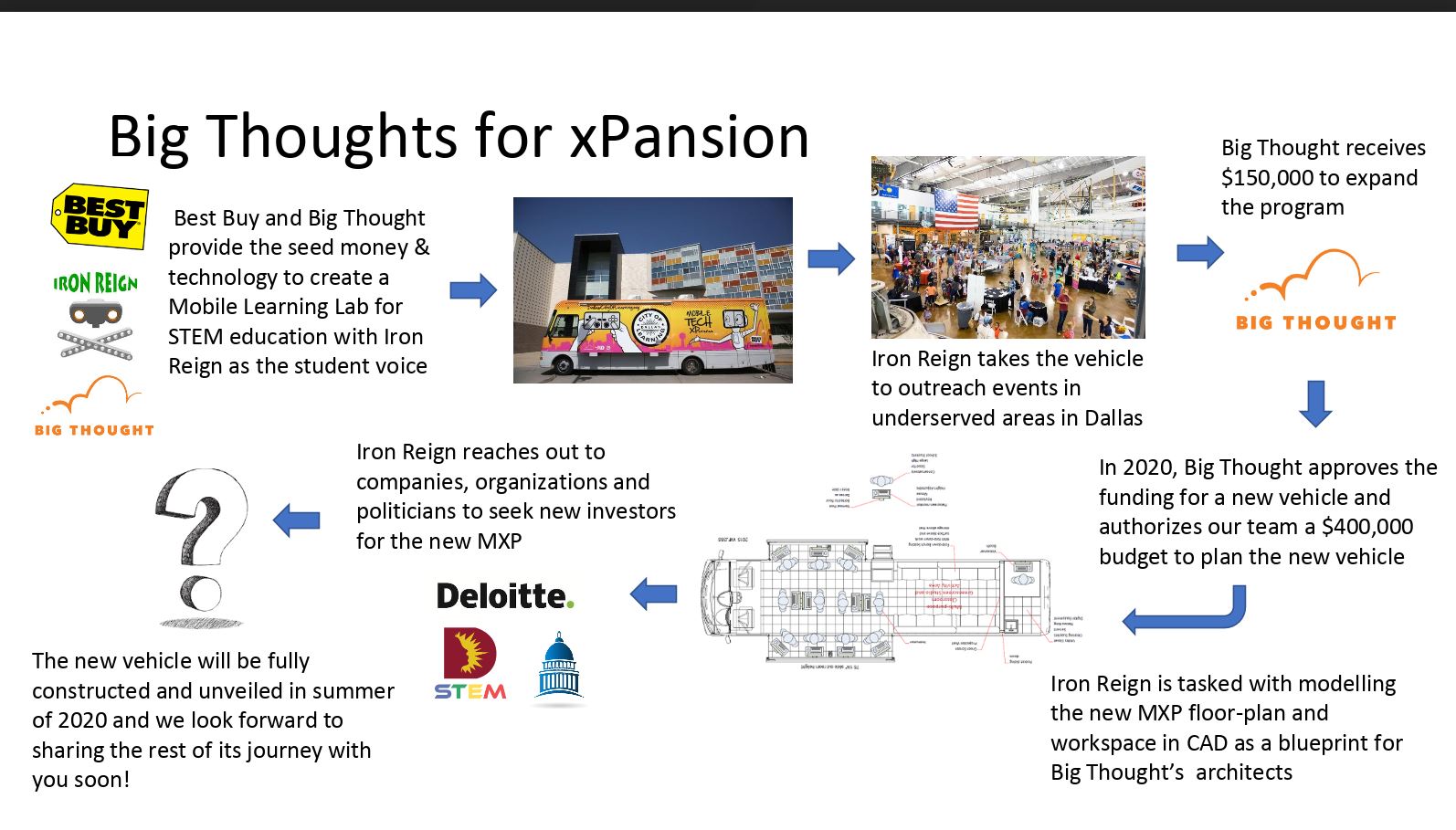

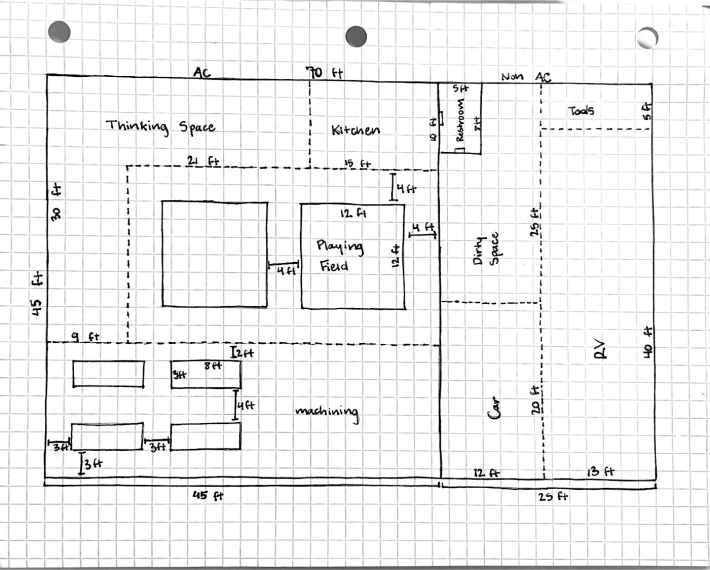

Our outreach stands out from other teams through our mode of

presentation. Last year, we renovated a 90’s Seaview Skyline RV, took out the

“home” components, and turned it into a mobile tech lab to read underprivileged

demographics within our community. Our RV currently holds 4 3D Printers, 30+

computers, 3 widescreen TVs, and 1 microwave. Our current curriculum consists

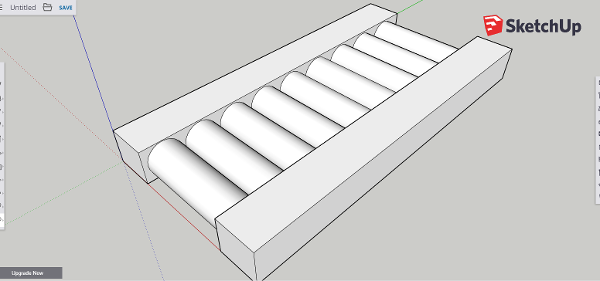

of teaching kids 3D modelling in the back of the RV, using Google Sketchup, as

it is free and available to any family with a computer. We usually help them

design keychains, as they are memorable, but don’t take excessive time to print

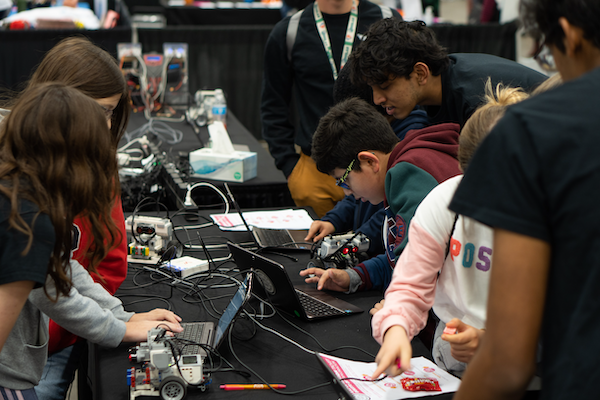

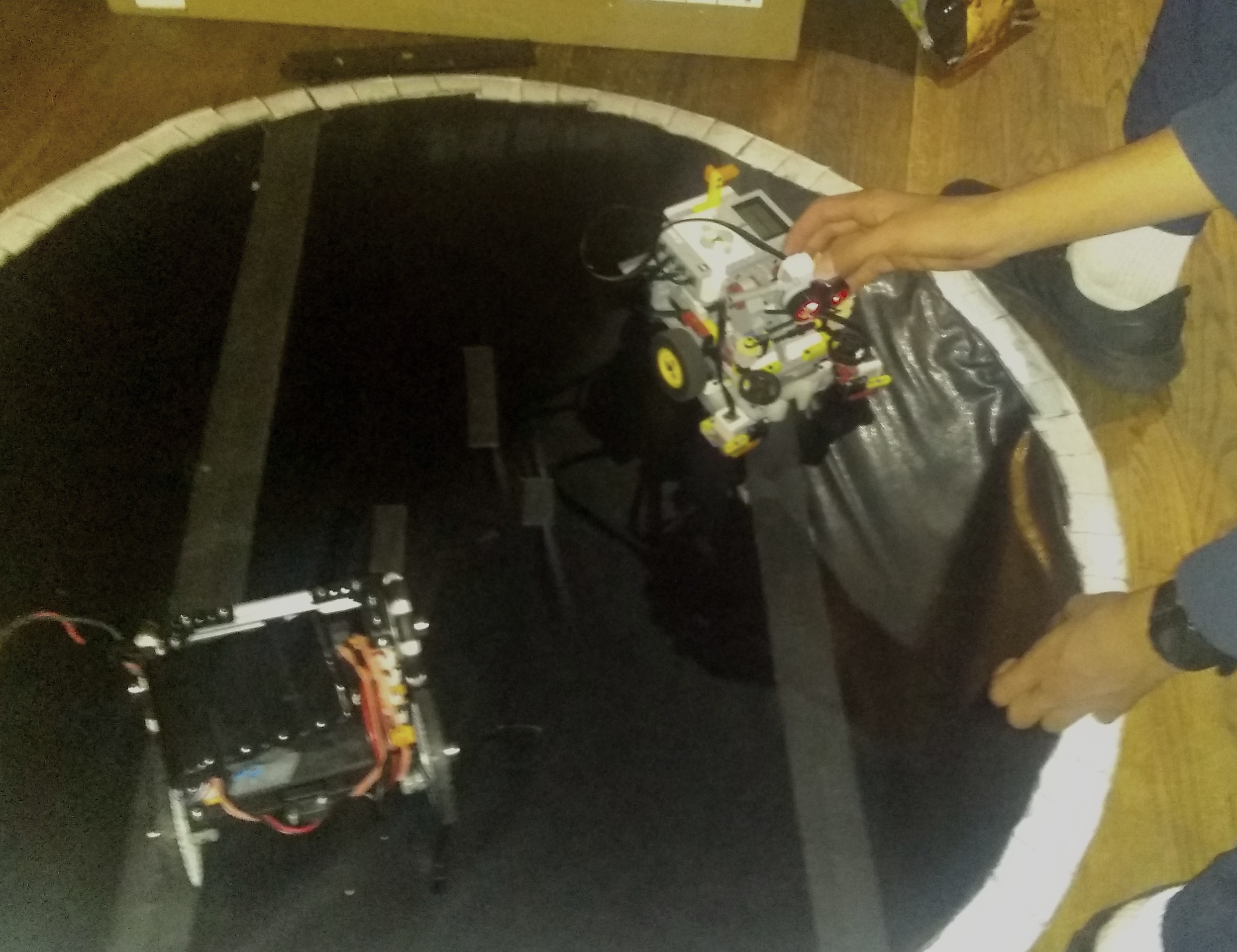

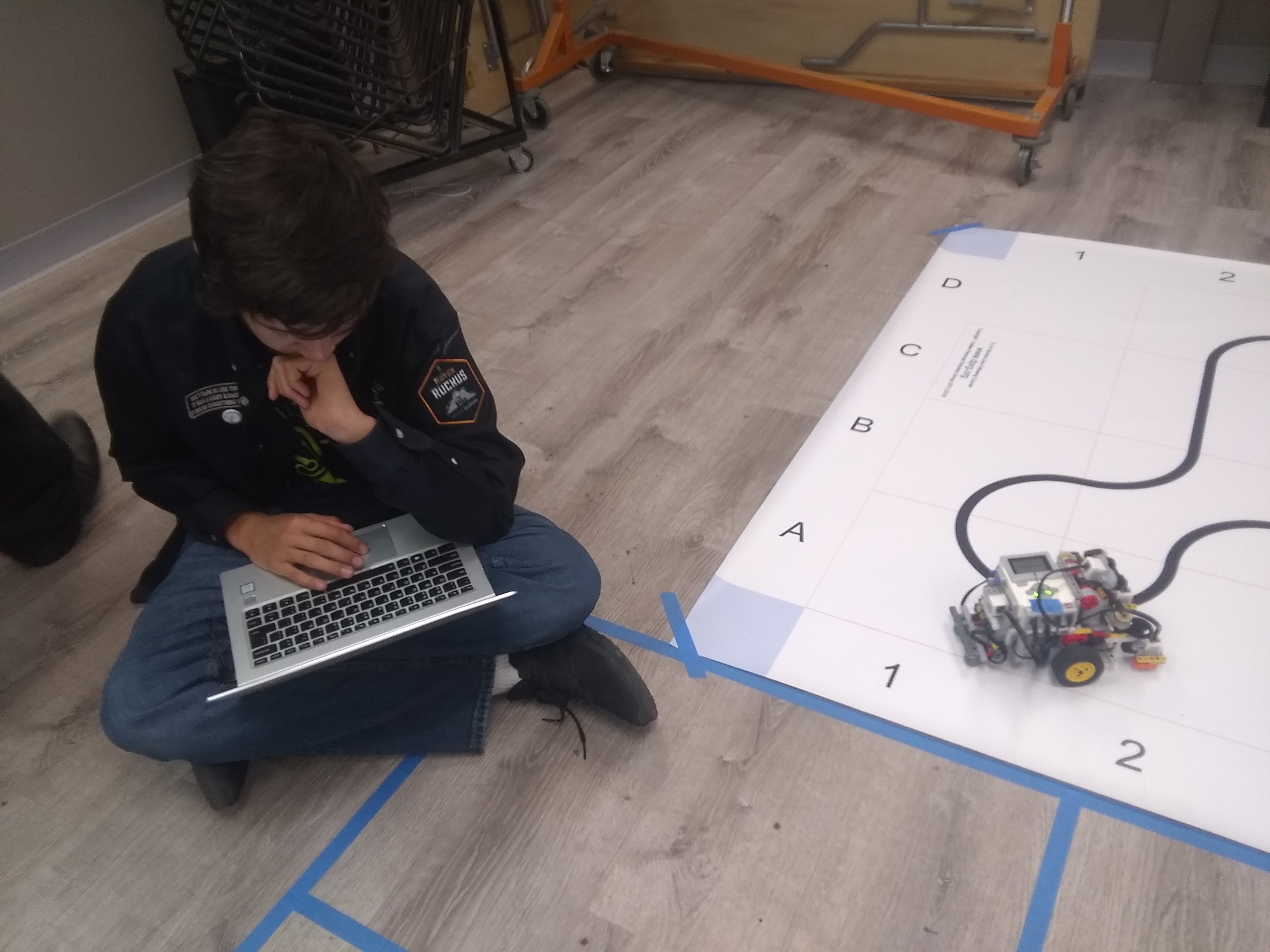

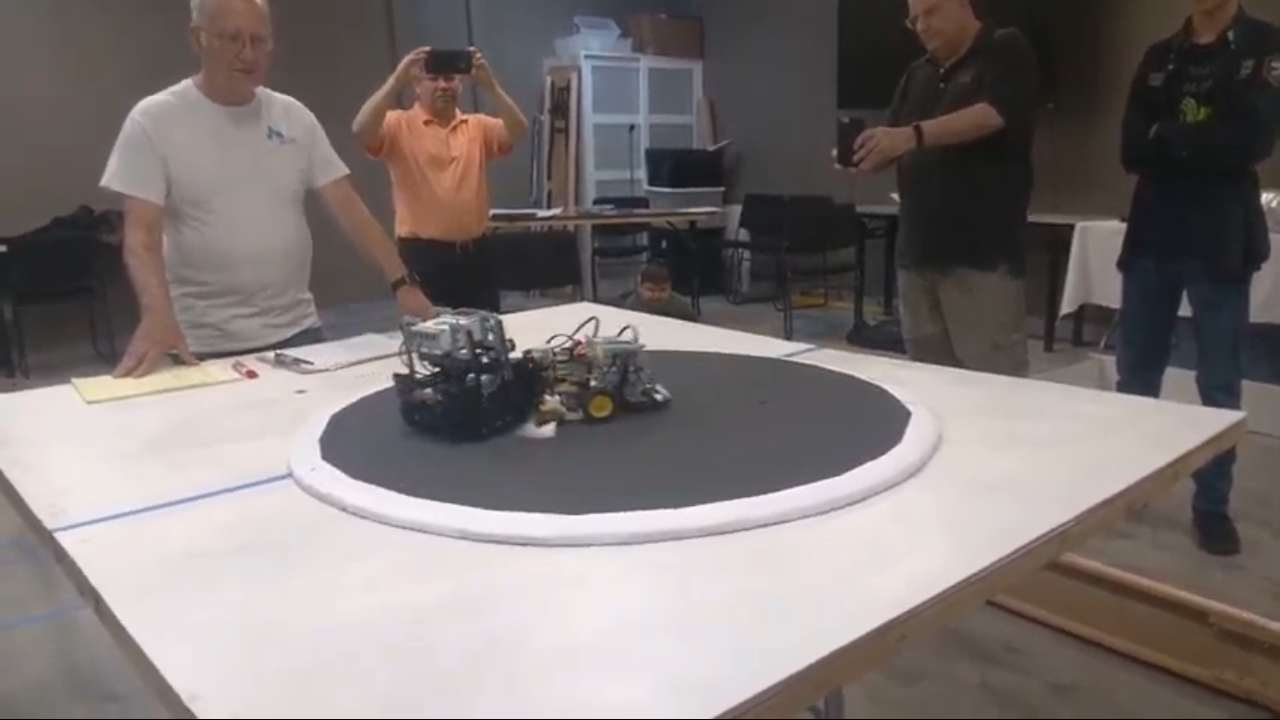

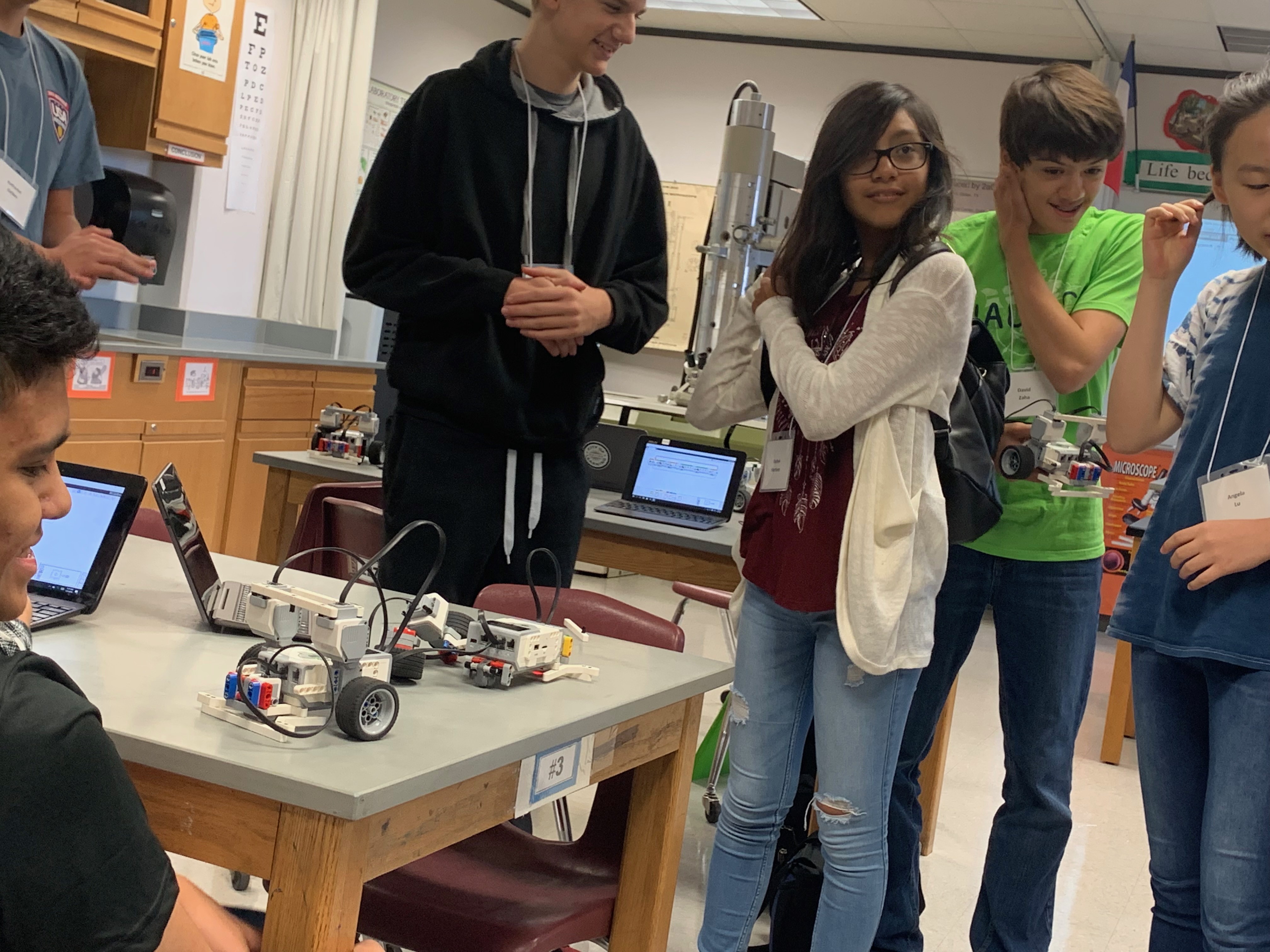

on our printers. In the front, we teach kids how to use EV3 robots and teach

them how to use the EV3 programming language to compete in a sumo-bot competition.

We also give advice to parents and educators on how to start FIRST teams. To

fill and staff the RV, we have received grants from Best Buy to purchase the 3D

printers and laptops, grants from non-profits such as BigThought and Dallas

City of Learning to fund the building and upkeep of the RV, and staffing from

BigThought and AmeriCorps, as well as our own team. The AmeriCorps staffing is

especially notable, as it is a US Federal Government program to support civil

service within communities.

When not in outreach service, we can transform our RV into

tournament mode. We have taken numerous long-distance road trips aboard our RV,

with locations such as Austin, Arkansas, and Florida. We substitute the laptops

for bandsaws and drill presses, use the flat screens

to program, and bring our higher-quality personal 3D printer. At tournaments,

we encourage other teams to board our RV, not only to encourage them to start

their own similar programs, but also to help them with mechanical and building

issues.

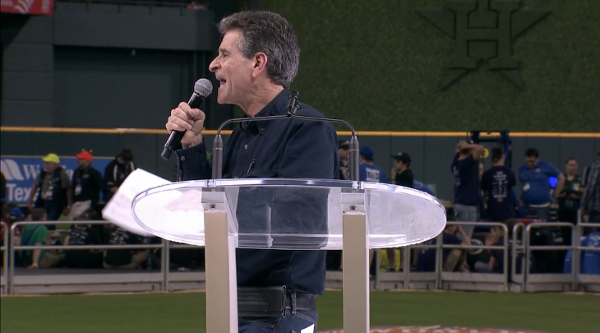

Business and Funding

Normally, Iron Reign does not get major funding. However,

this year, we have seen our funding, sponsorships, and grants increase

exponentially. Currently, those include:

·

BigThought - RV materials, staffing, and upkeep

·

Dallas City of Learning (DCOL) – RV materials

and upkeep

·

Best Buy – 4x3D Printers, Laptops for RV

·

AmeriCorps – RV staffing

·

DISD STEM - $3000 of REV parts and 2 full

practice fields

·

Dallas Makerspace – Access to machining tools

·

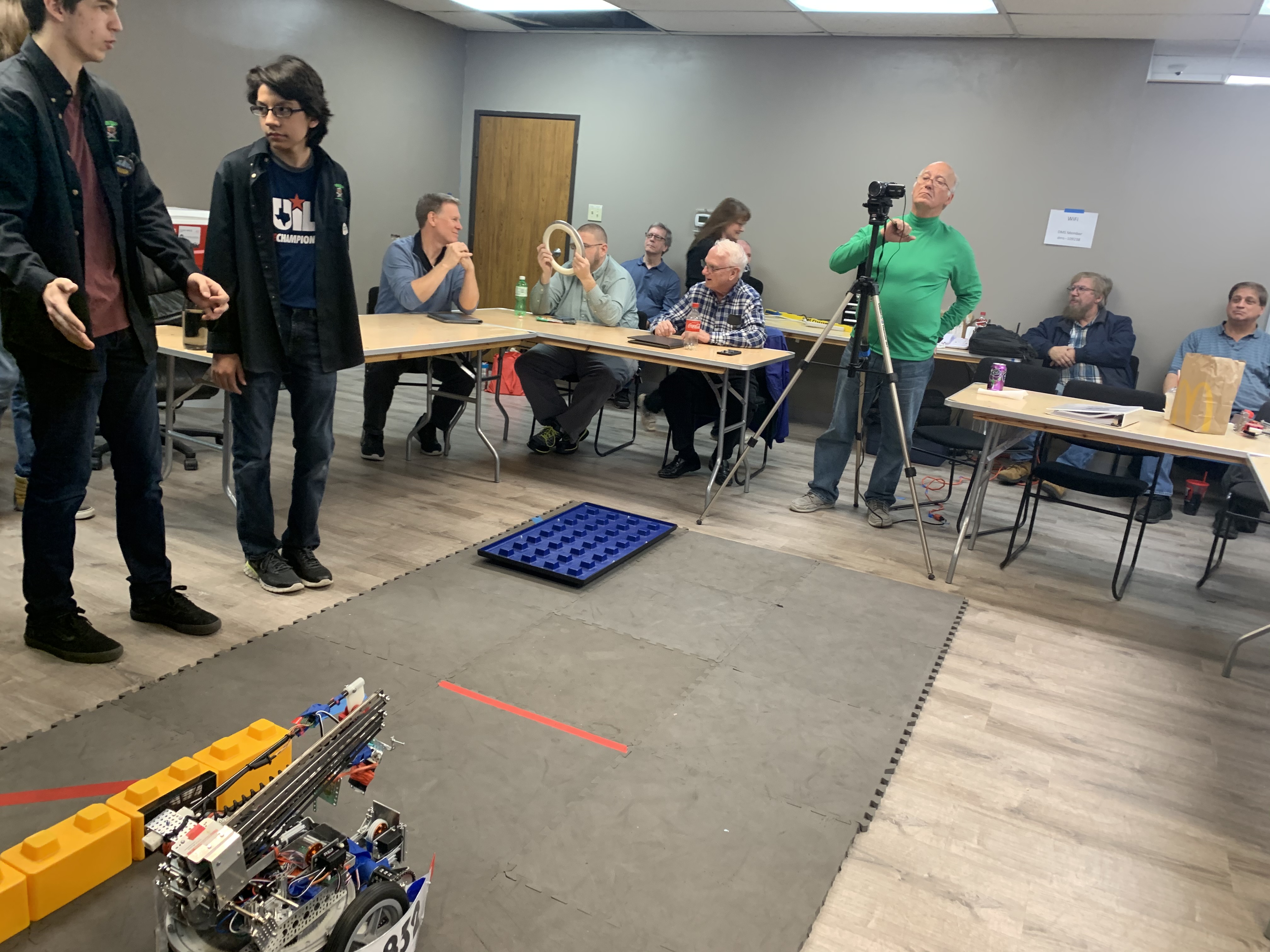

DPRG – Robot assistance

·

FIRST – Tournament fees

·

Texas Workforce Commission – Grant

We are always seeking out new sources of funding. In the past, we have applied for prior grants

by sending letters to STEM-curious companies in the Dallas area. For example,

we have previously applied for a $4000 Orix grant, a STEM foundation dedicated

to spreading STEM to the underserved. Also, recently, we received an additional

grant from Best Buy for our distinguished service to the underprivileged within

the Dallas area.

In previous years, we have lacked the ability to get

significant transportation fondant to tournaments. However, through our

partnership with DISD, we have solved that problem. And when DISD is unable to

provide transportation due to short notice, we can provide our own

transportation due to our building of the RV.

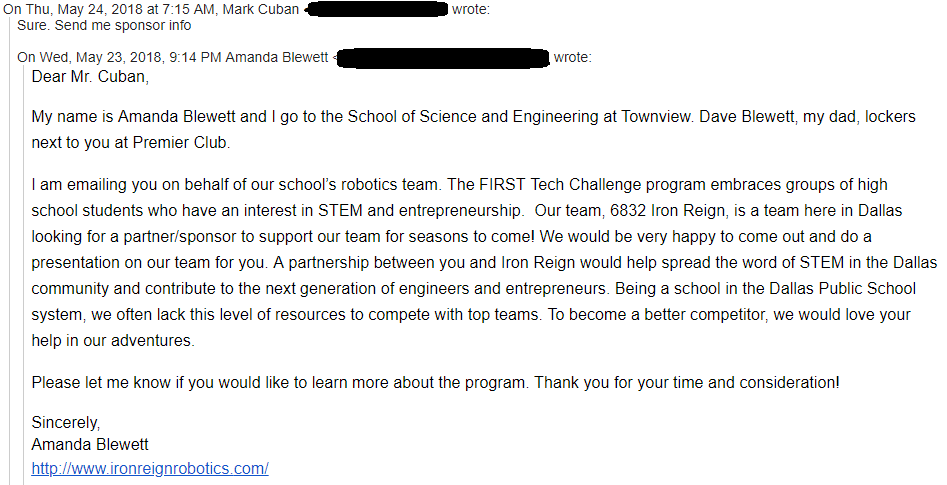

Reference Business Letter from Last Season

“Dear Orix,

Iron Reign Robotics, a

robotics team of 7 years, is competing in the 2016/17 First Tech Challenge

Velocity Vortex game. We are based out of the School of Science and Engineering

(SEM) in Dallas which is a title one school.

The population of the

public school is racially diverse and 68 percent of the students are on

free-or-reduced lunch. In spite of our economic challenges, SEM is regularly

considered the school that offers students the most growth in the entire

district (highest effectiveness index) and is regularly in the top 10 in many

national rankings. But as the second robotics team to be formed at this Dallas

ISD Magnet, we are underfunded by the district and need to reach out to

organizations that are investing in the long-term future of our community.

Each year we deepen

our advanced robotics skills, improve our ability to organize around common

team goals, and learn how to better communicate with technical professionals so

that we will prepared make an impact as we continue through college and

eventually join the workforce. Last year our team made it to the Regional

Championship during the FTC season and then proceeded on to the UIL State

Robotics Championship in Austin during the summer. This year, with your

support, we are striving to make it to the 12-state super regional in Georgia

and go from there to the World-wide competition in Houston.

Yet we spend a

significant amount of our efforts investing in younger students outside the

team. We work very hard to let young students in North Texas know about the

opportunities in STEM education. We mentor students in elementary and middle

schools. We regularly participate in a series of STEM outreach events to help

younger students think of themselves as future scientists, engineers and

technical professionals. This includes presenting at events like the Dallas

Mayor’s Back to School Fair, Earth Day Texas, and Moon day at the Frontiers of

Flight Museum just to name a few. Last year (2015/16) our outreach involvement

amounted to 400 team person-hours in service to 2,200 people. We are unaware of

any other FTC team in our region that does as much outreach as we do.

This year we’ve

stepped those numbers up to over 500 person-hours serving over 2,000 people so

far just this summer. This was because we took on a project to renovate an RV

to create a mobile learning laboratory for the Dallas City of Learning. Not

only did we turn the interior into a mobile technical classroom with 3D printers,

but many team members volunteered to teach robotics and 3D modelling and

printing on board while volunteering for AmeriCorps with Big Thought this

summer. The team was featured as a “Class Act” on TV channel CW33 because of

this effort.

Unfortunately, time is

money and the time it takes us to contribute to each of these events costs us

dollars we don’t have. We all love teaching young children who are interested

in robotics and technology and we hope what they receive is beyond value. But

we also need to raise our competitive game and new parts cost money. When jerry

rigging and reusing parts unsuited for the job, we waste time that could be

used to make more progress and continue the advancement of our robot. As we

continuously refine our design, new parts are needed and some need to be

replaced as we strive for an efficient and reliable entry. The other piece of

the financial puzzle is transportation costs. This year we plan to take part in

multiple competitions including out-of-state competitions in order to deepen

our competitive potential and improve our chances of advancing to the next

level. Competition expenses beyond the standard local track are some of the

hardest expenses to fund.

We are asking for

$4,000 to help us continue our journey into robotics and we hope that Orix can

become a major supporter of our team while we continue to invest in the futures

of many more students in North Texas. We would love a chance to visit with you,

show you our robot in its current form, and discover together how much our

mission and your focus areas have in common. Please let us know how to schedule

that time. Until then, you can access much more information about Iron Reign on

our team blog: http://www.ironreignrobotics.com/

Warmest

Regards,

Iron

Reign “

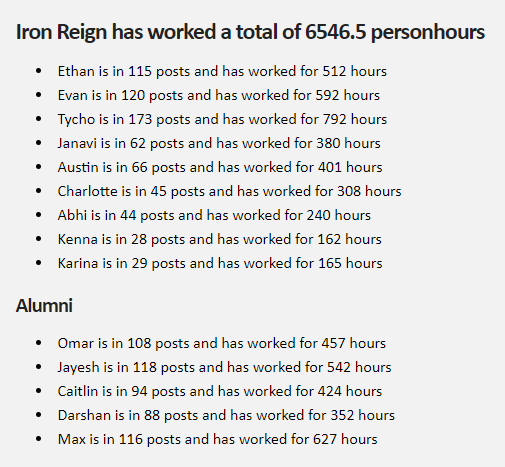

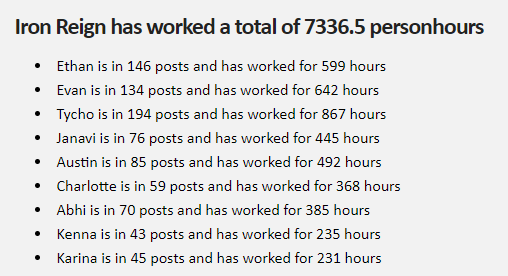

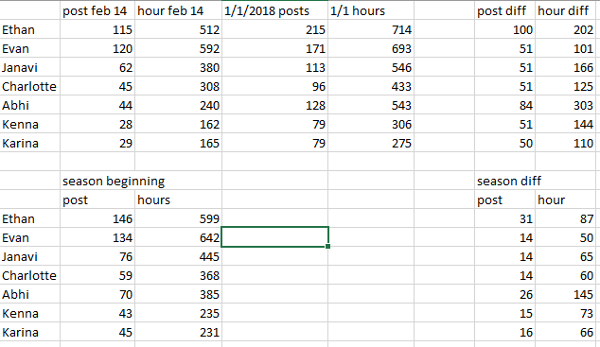

Looking Back, Moving Forward

In the past, sustainability has not been a major concern of

Iron Reign’s. We’ve essentially had the same team for seven years. This year,

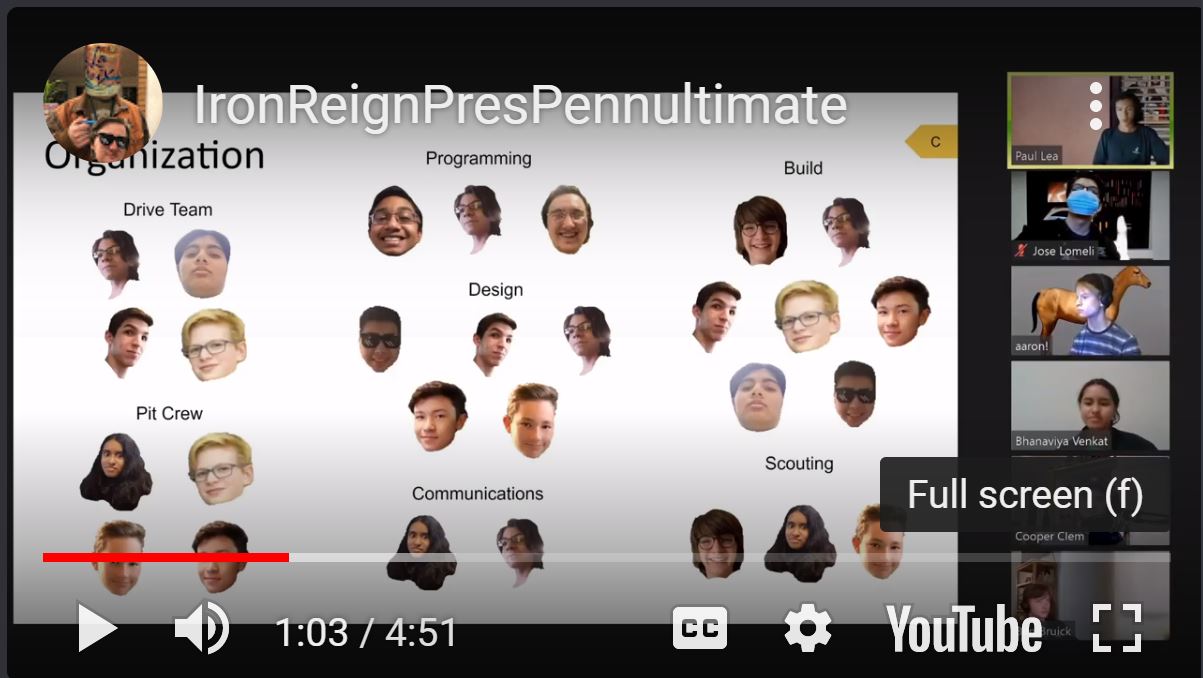

our eighth, we’ve finally lost members through graduation. As a result, we’ve

had to substantially reconsider our approach to recruitment and how to manage

our changing team.

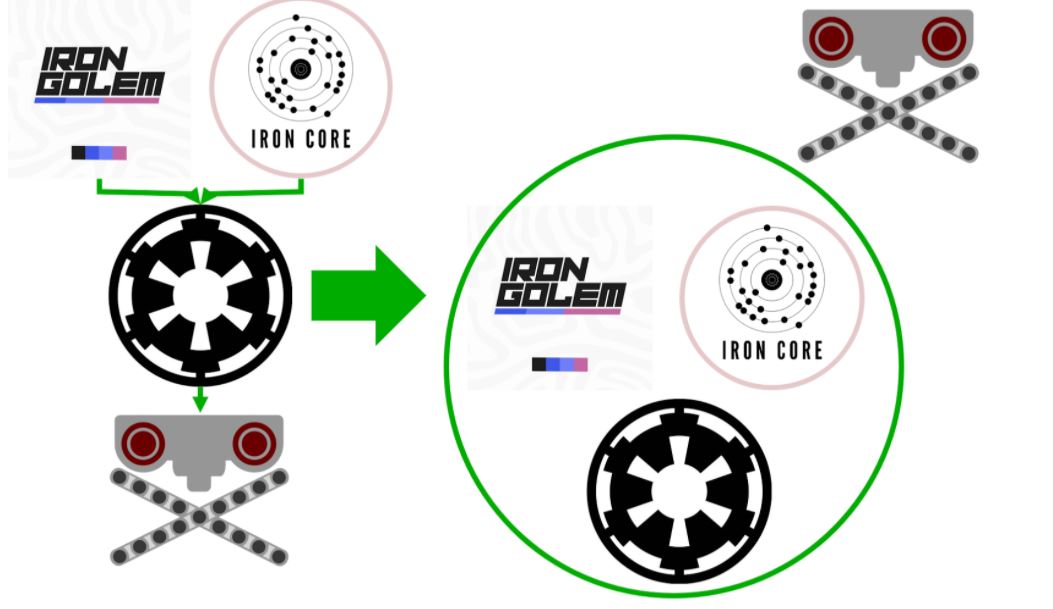

We already have another team in our school, team 3734

Imperial Robotics. 3734 is an entirely

different team, with different sponsors, members, robots, journal, outreach,

and codebase. That being said, we recruit the more accomplished members of

that team. The teams’ relationship is most similar to the difference between a

Junior Varsity team and a Varsity team.

We tend to recruit based on robotics experience, but having

robotics experience alone is not a guarantee of joining our team. Iron Reign

has a specific culture, and we tend to recruit people whose personalities fit

our culture. We also do not accept people who only want to join robotics as a

resume booster. While robotics is indeed a resume booster, and we allow every

member to claim co-captain on their college applications, members of Iron Reign

ought to join out of their genuine passion for robotics, not because of it

getting them ahead in the rat race of college applications.

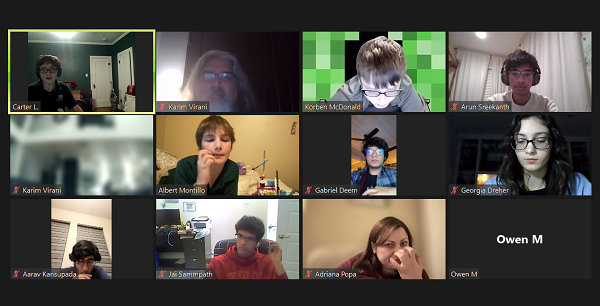

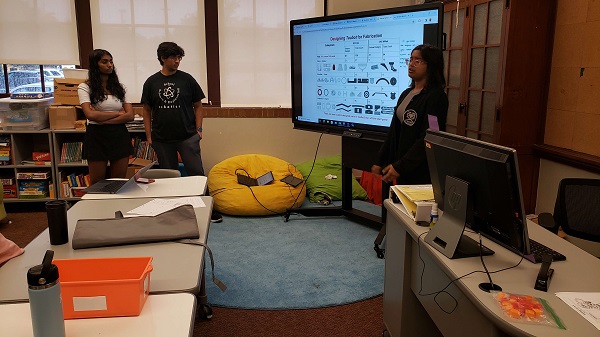

Since this year was the first year in which we lost a

substantial number of our teammates, we had to learn how to effectively

transfer knowledge. First, we were losing our master of 3D modelling, Max, so

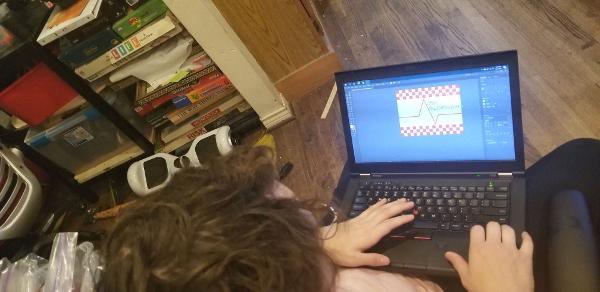

we had two members, Abhi and Charlotte, learn under his wing throughout last

season. Because of that effort, they have now designed a variety of parts on

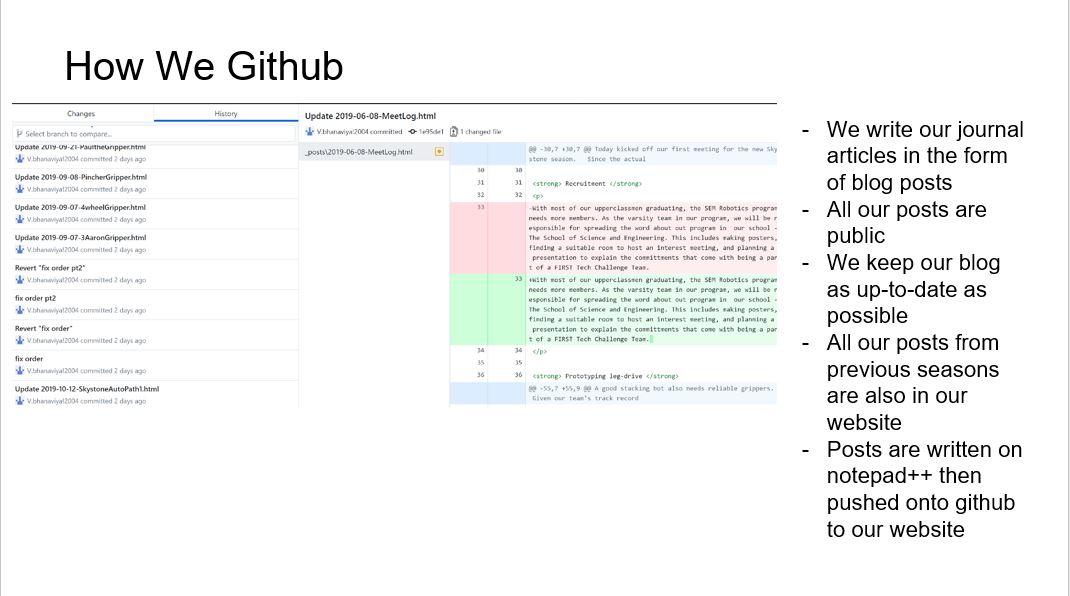

our robot. For the blog and engineering journal, Ethan learned under Lin’s

tutelage how to use Jekyll, Shopify, and manage the blog. This year, we face

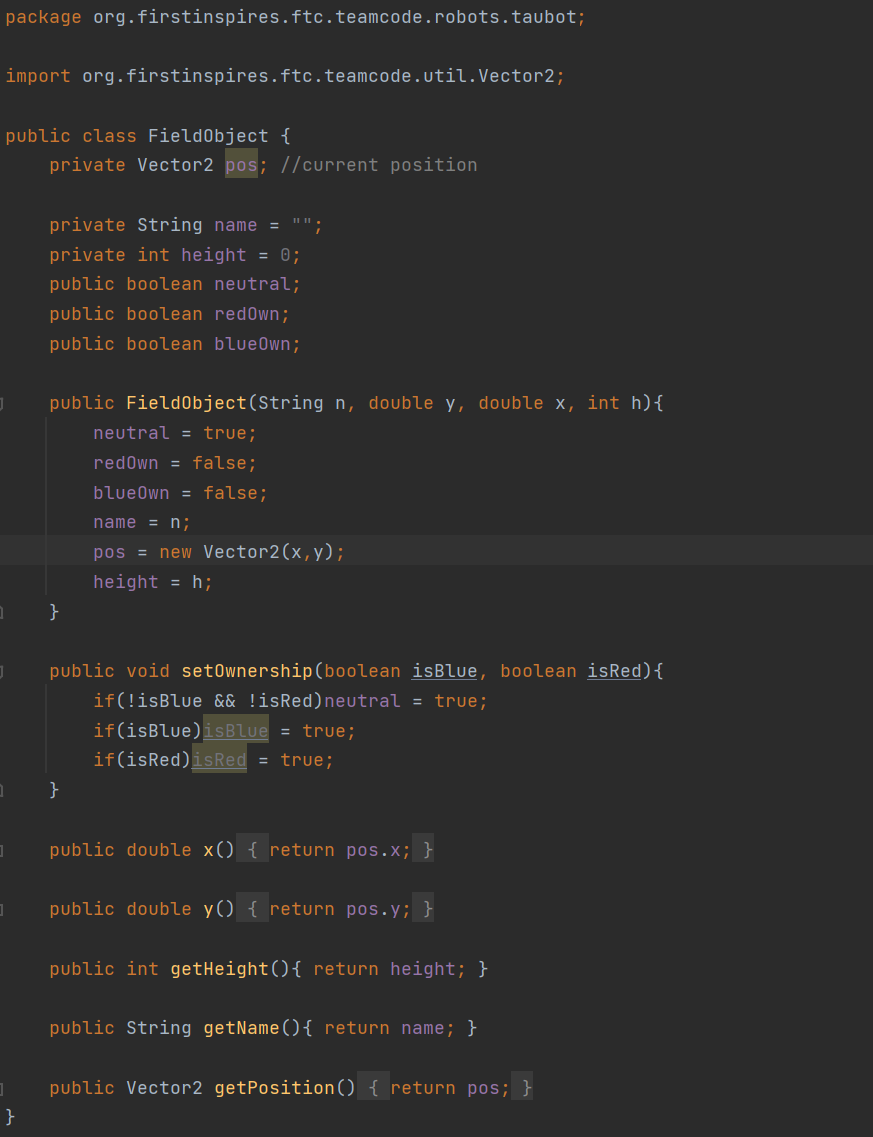

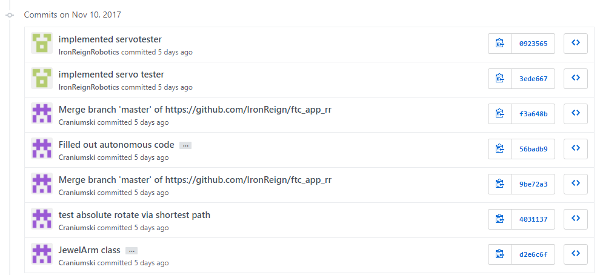

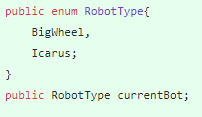

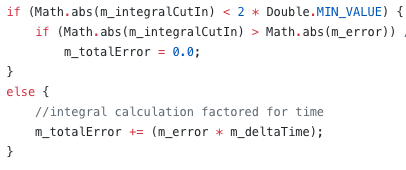

difficulties, as we will lose our lead programmer, Tycho, for next season. To

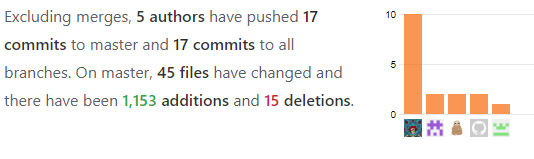

combat that, our members Abhi and Janavi, are learning the intricacies of our codebase that we’ve kept since we first started using

Java.

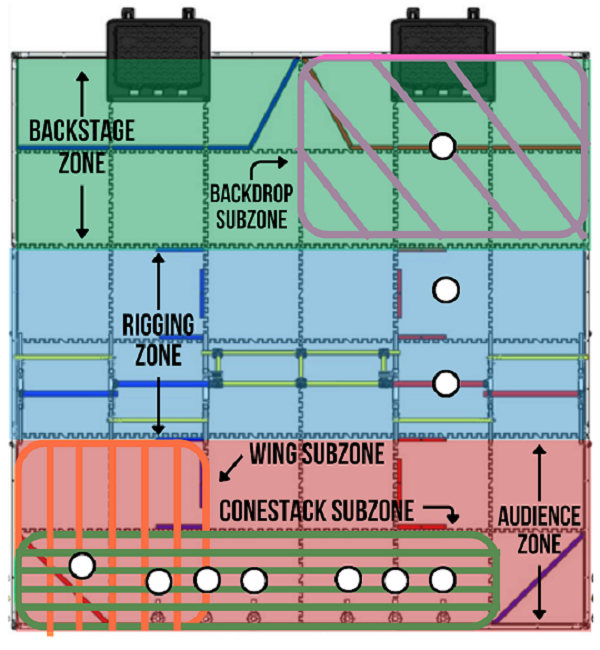

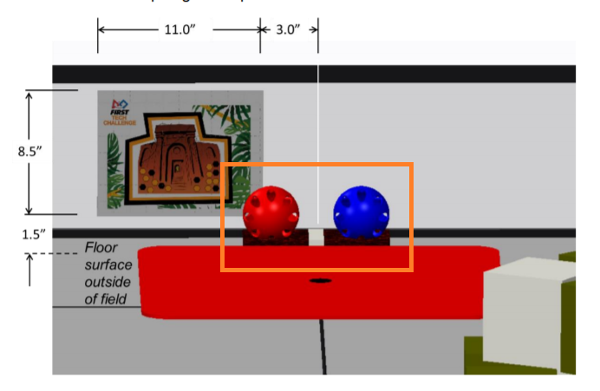

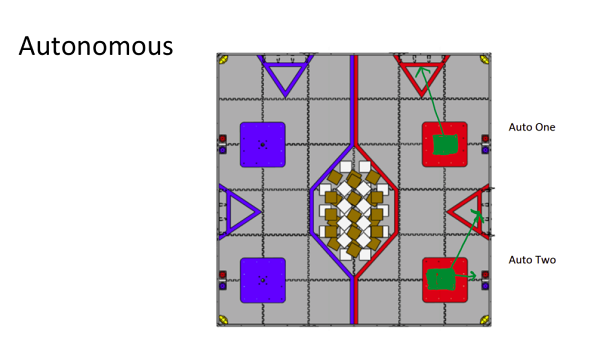

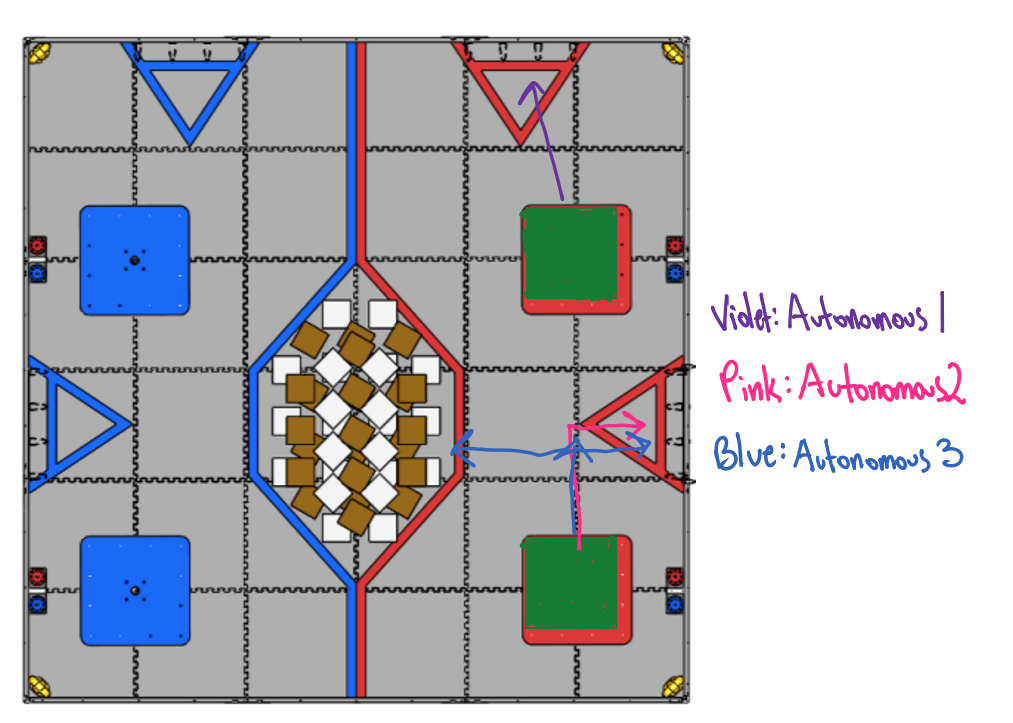

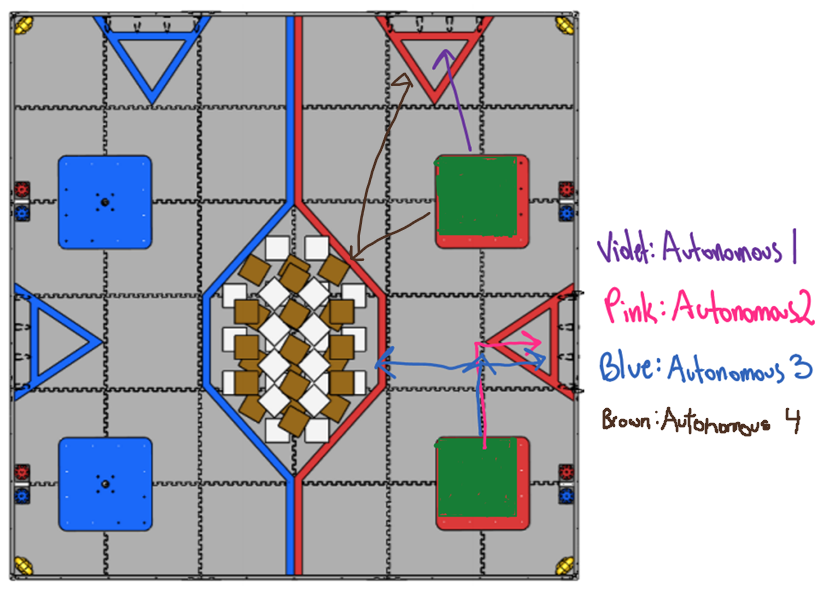

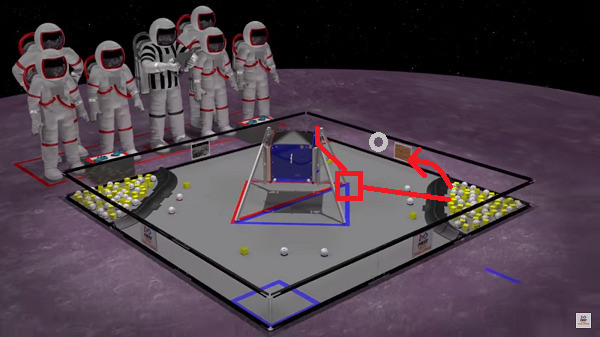

Game Strategy

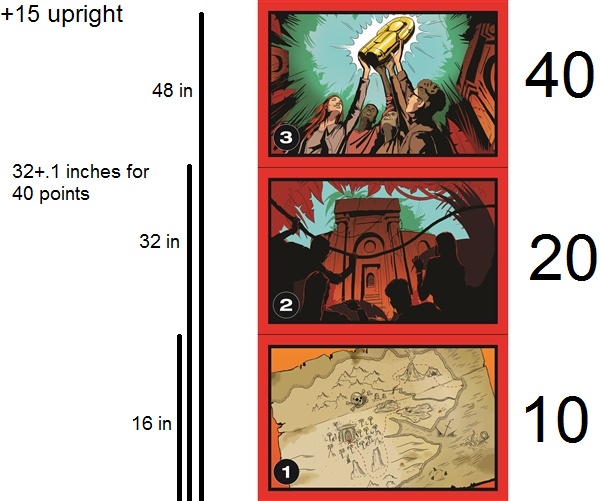

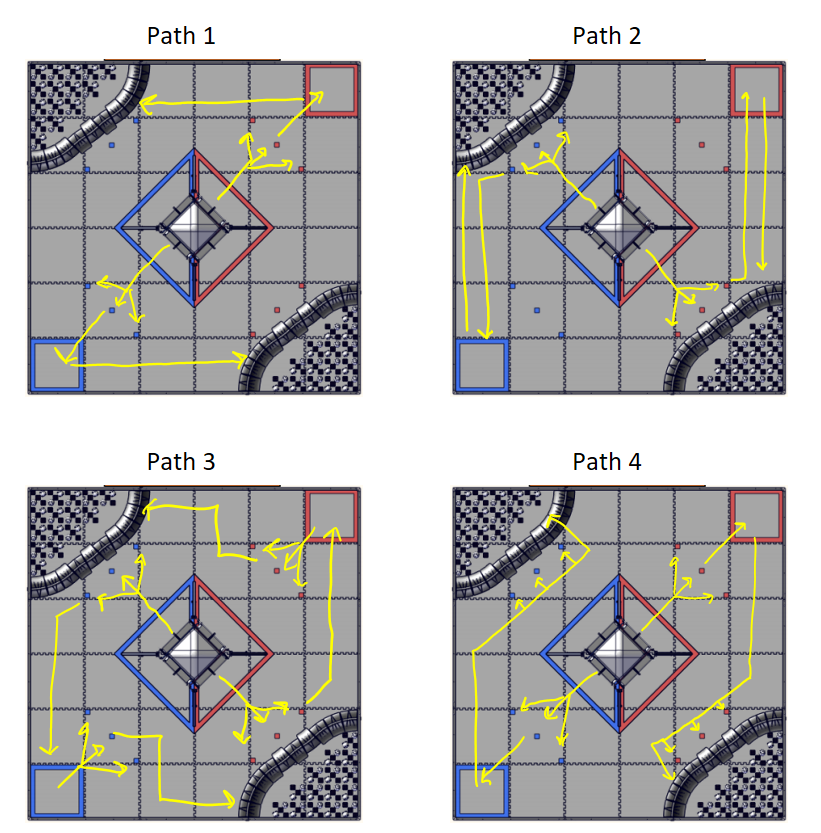

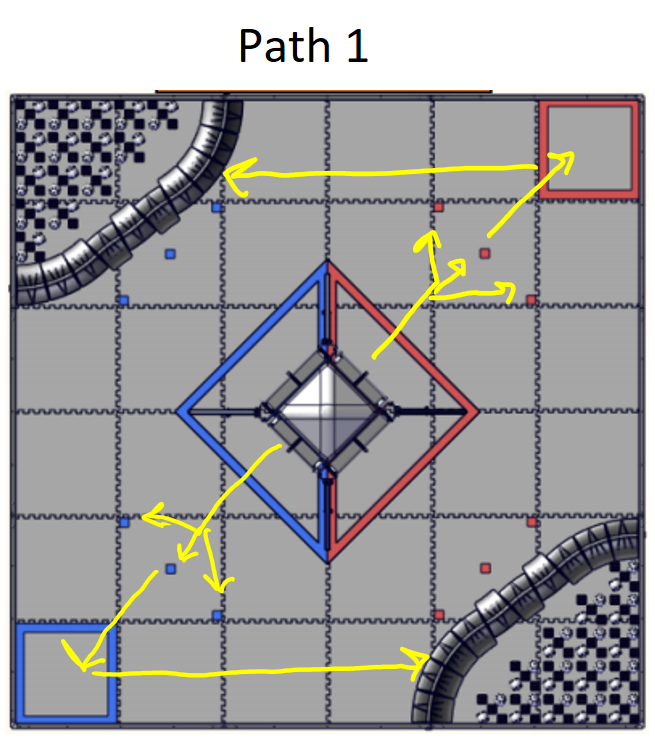

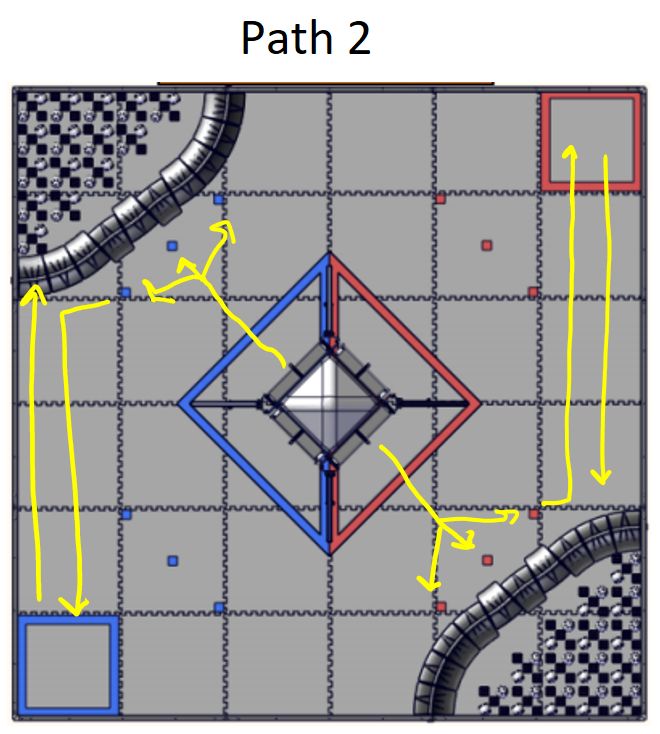

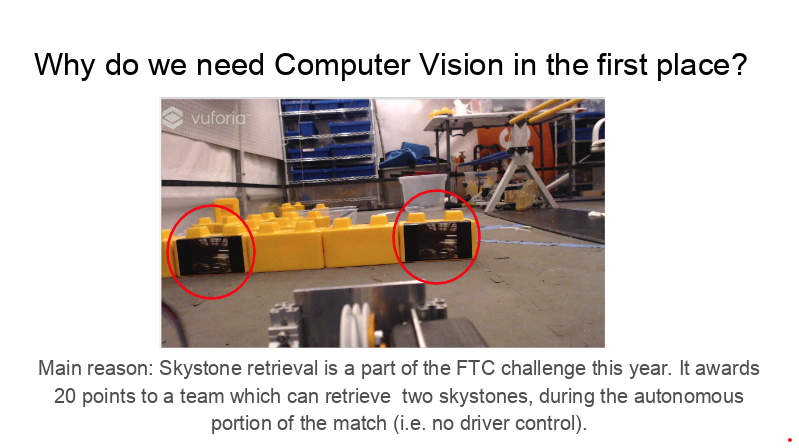

This year, we were faced with a conundrum. The central

question was this – “Should we focus on scoring the cryptoboxes, relic, or

jewel?”. We settled on the order of Cryptobox >

Relic > Jewel.

Our game strategy was based off of the fact that we could

build a robot which could score one block initially, and easily score a column,

giving us 40+ points right off the bat. As well, the cryptobox process is

simplistic enough that we could get to the balance stone to gain even more

points in the endgame, without doing any point-risky challenges such as the

Relic.

When we finish the cryptobox designs and autonomous, our

next goal is the Jewel. The Jewel challenge is simplistic enough that it could

be done in 1-2 meetings without interfering with any other design processes.

Our current planned design process is first to create an arm with a color

sensor attached like most teams, but eventually we plan to remove that color

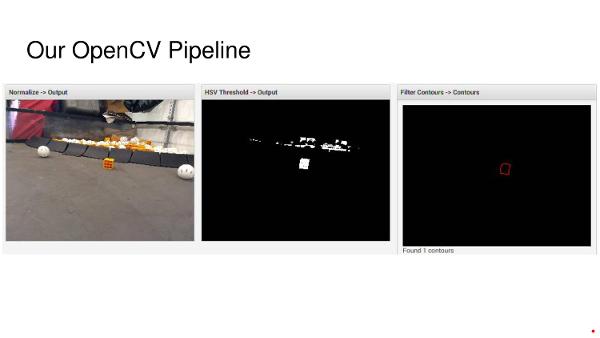

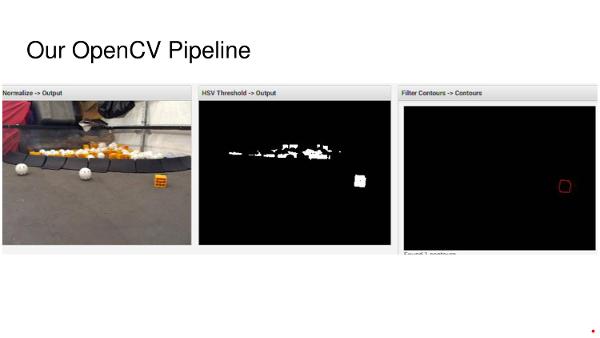

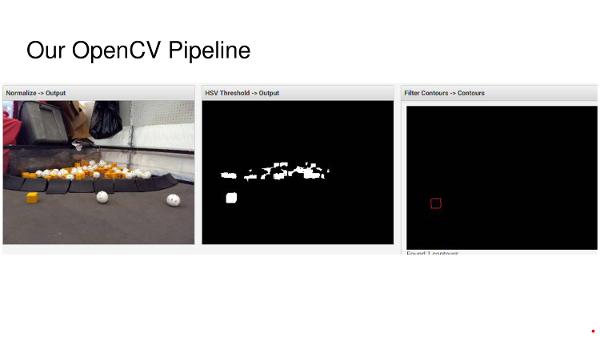

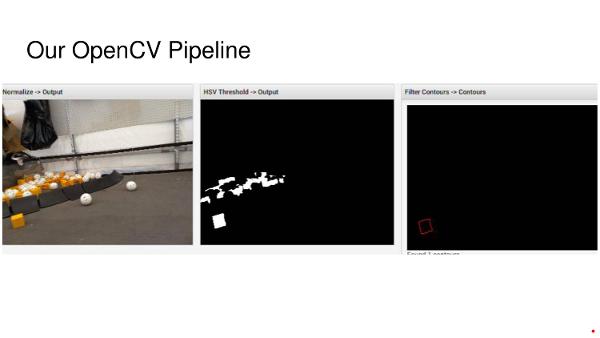

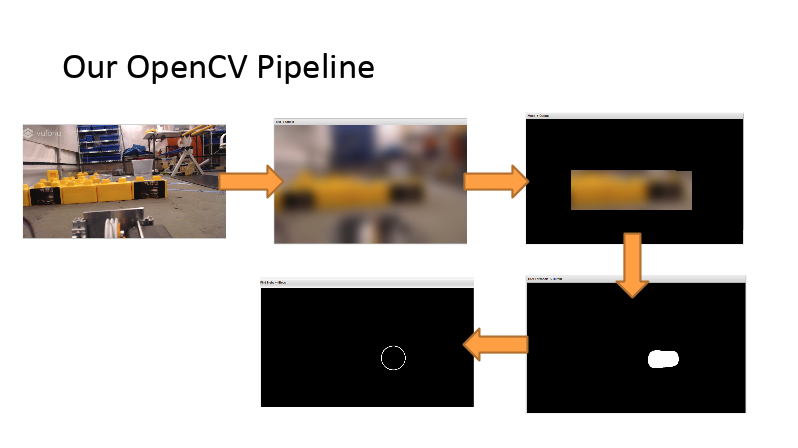

sensor and identify the Jewel only by OpenCV.

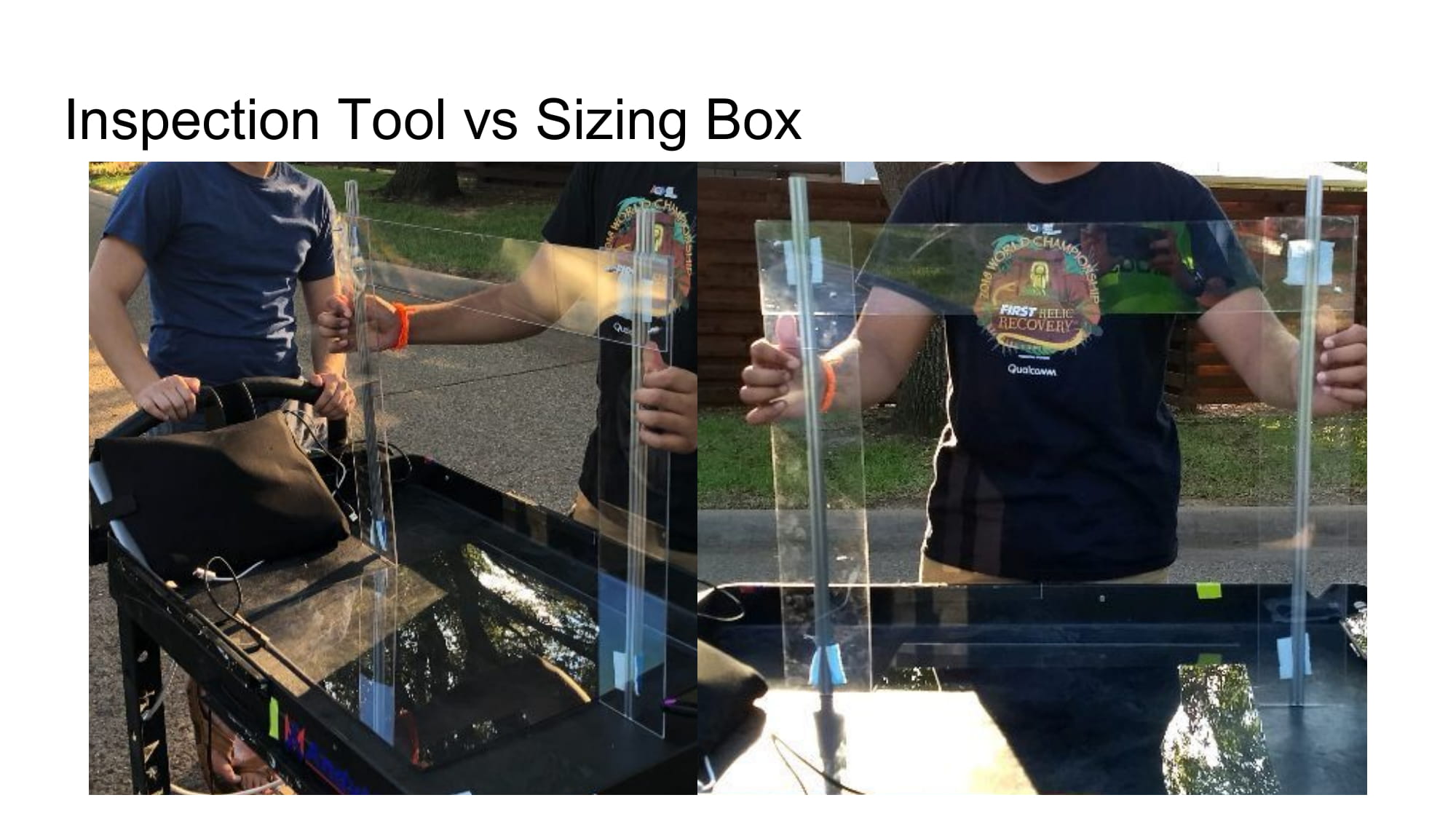

Finally, our last area of focus is scoring the Relic. Scoring

the Relic involves a high degree of difficulty, and the risk grows when you

consider that you have to score the Relic upright in order to gain the most

points. As well, building an arm that can score the Relic while still staying

within the 18x18x18 size limits increases the design difficulty of the robot.

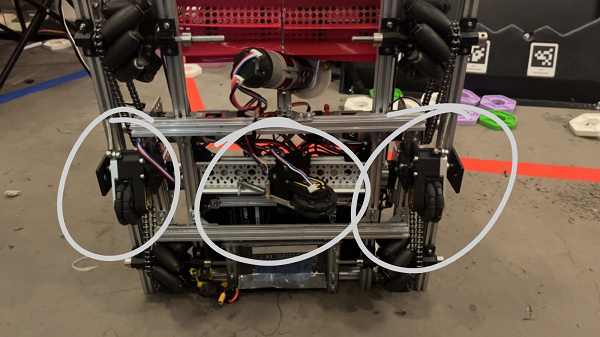

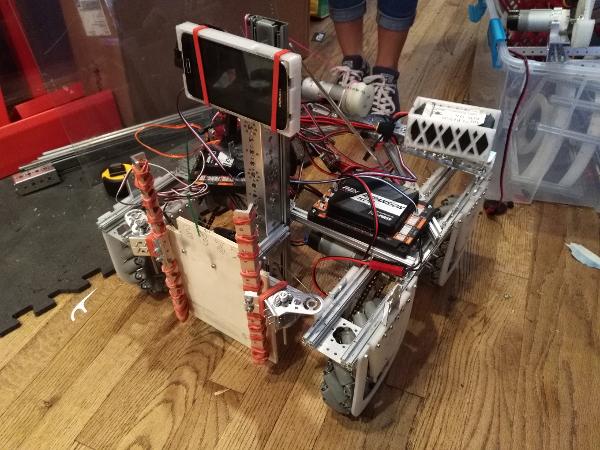

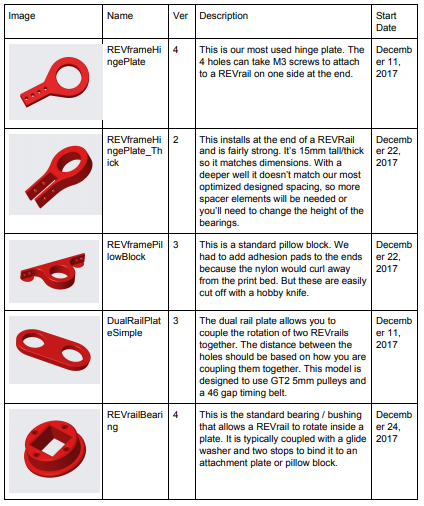

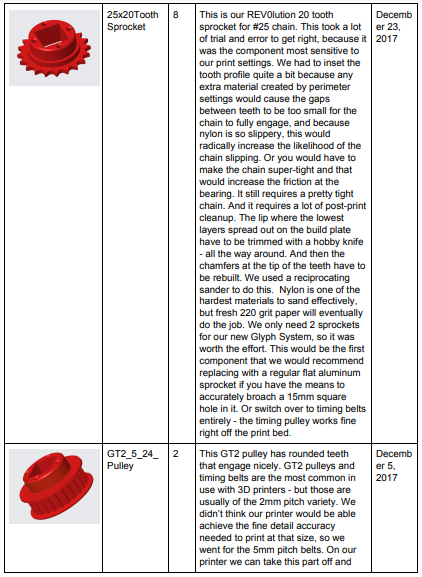

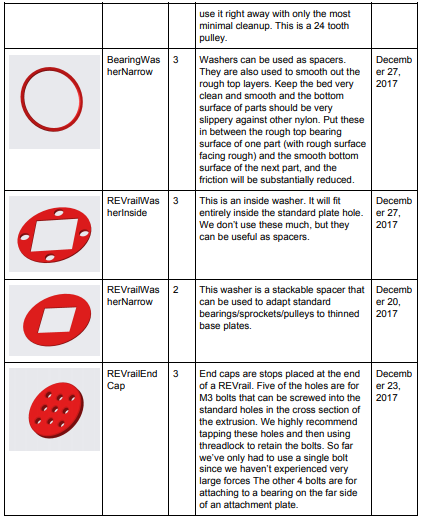

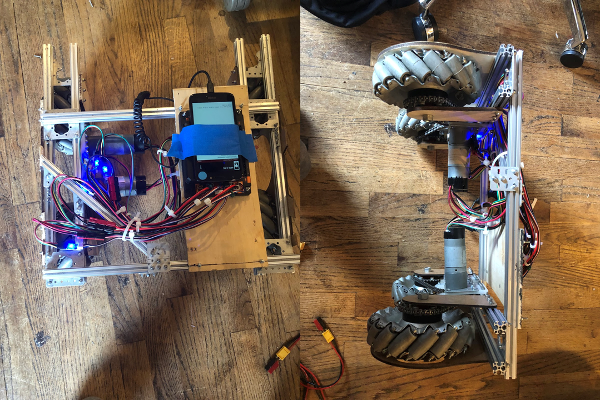

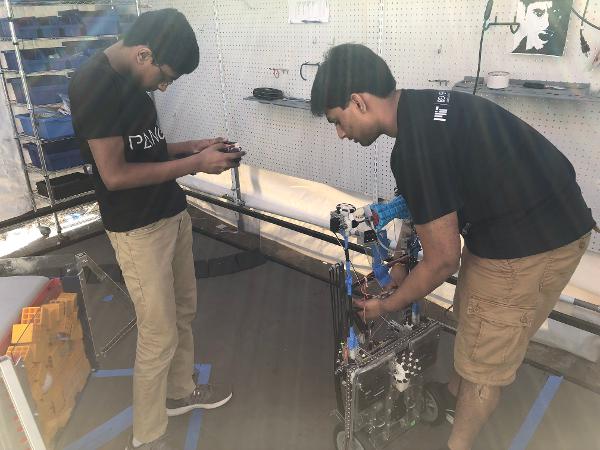

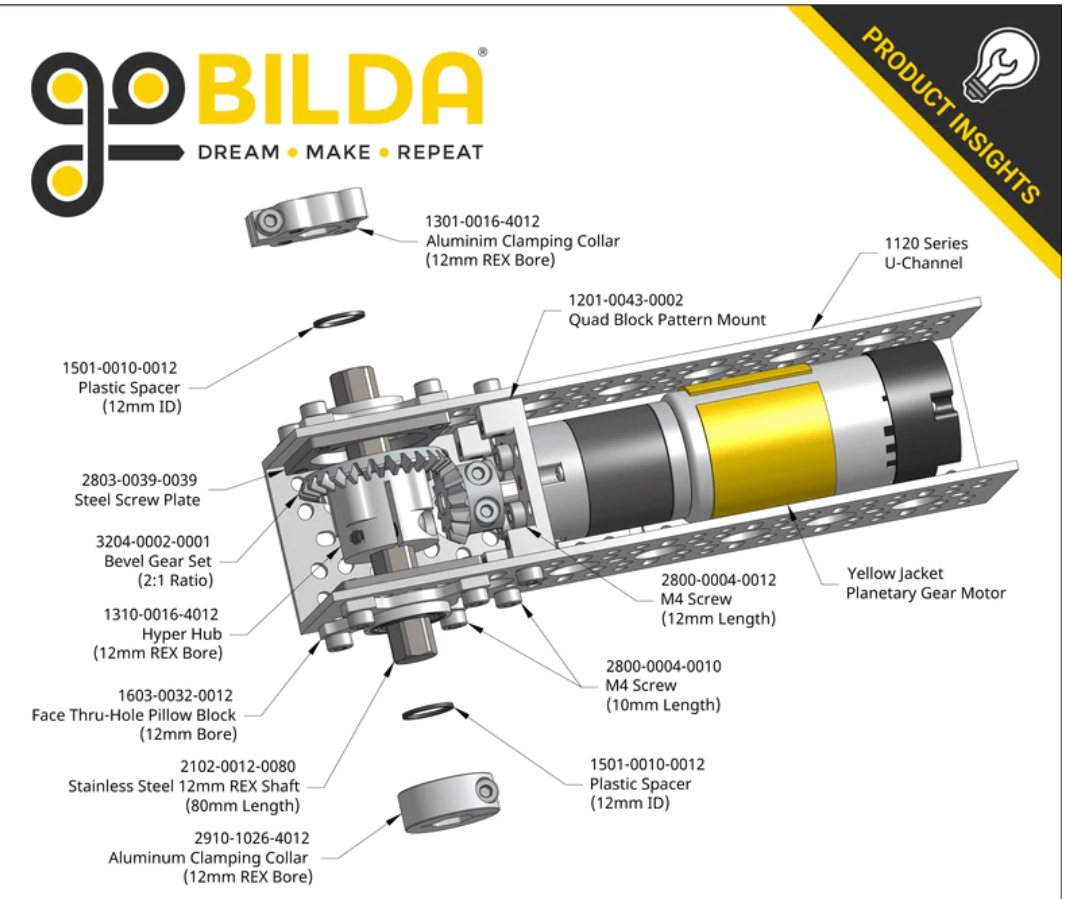

Building

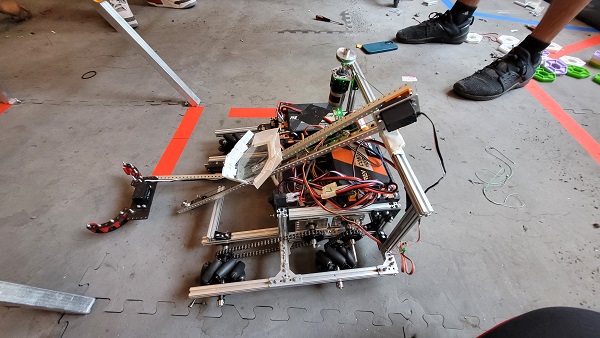

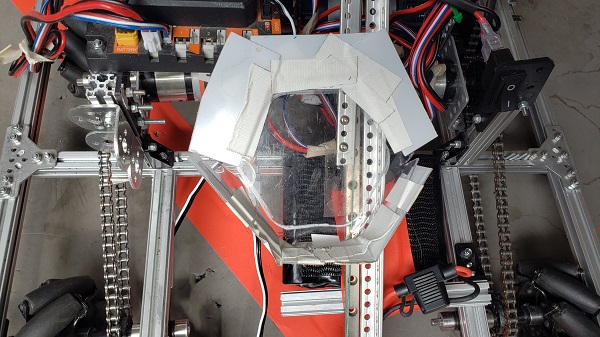

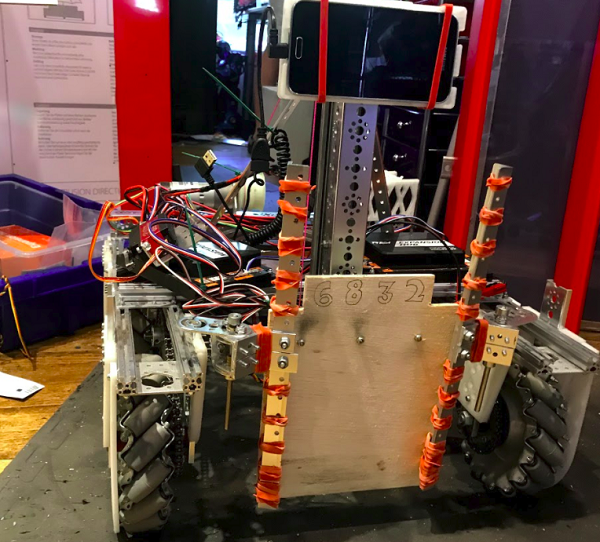

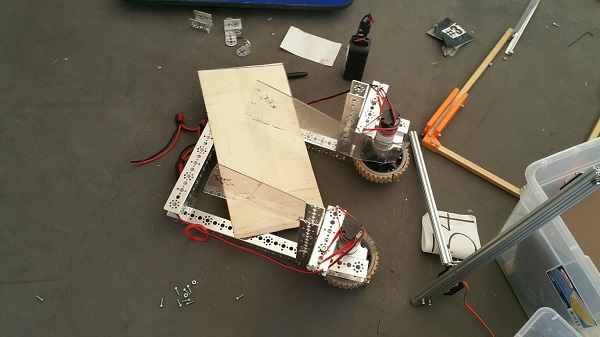

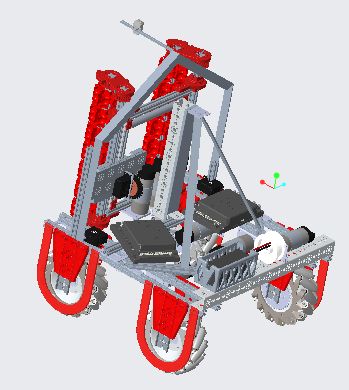

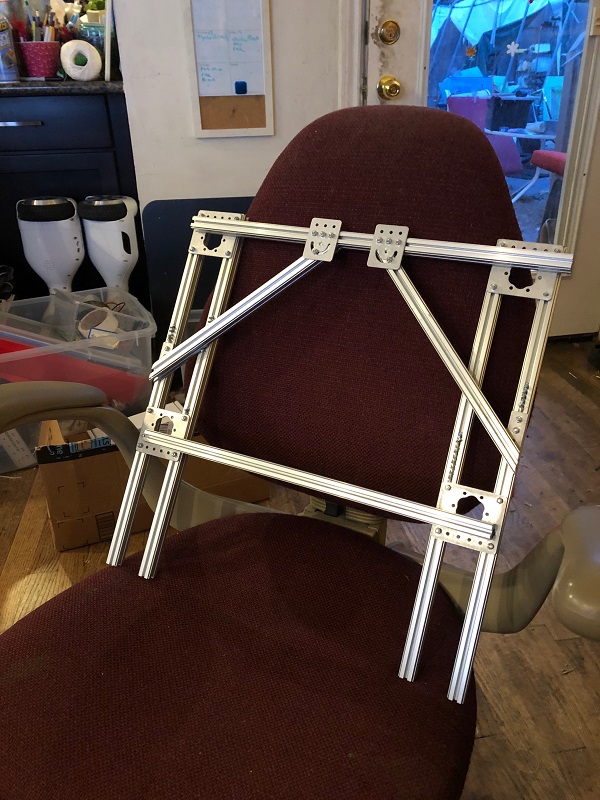

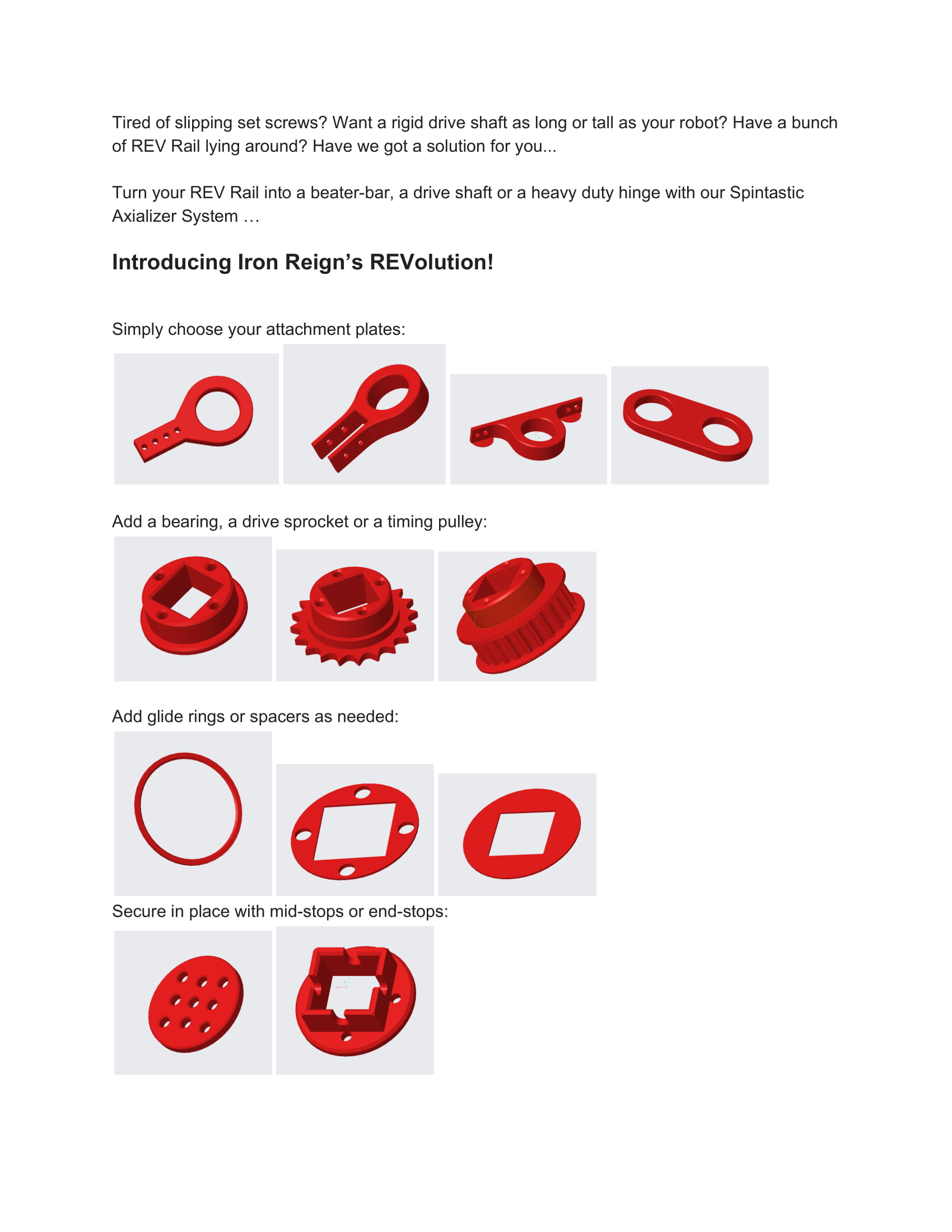

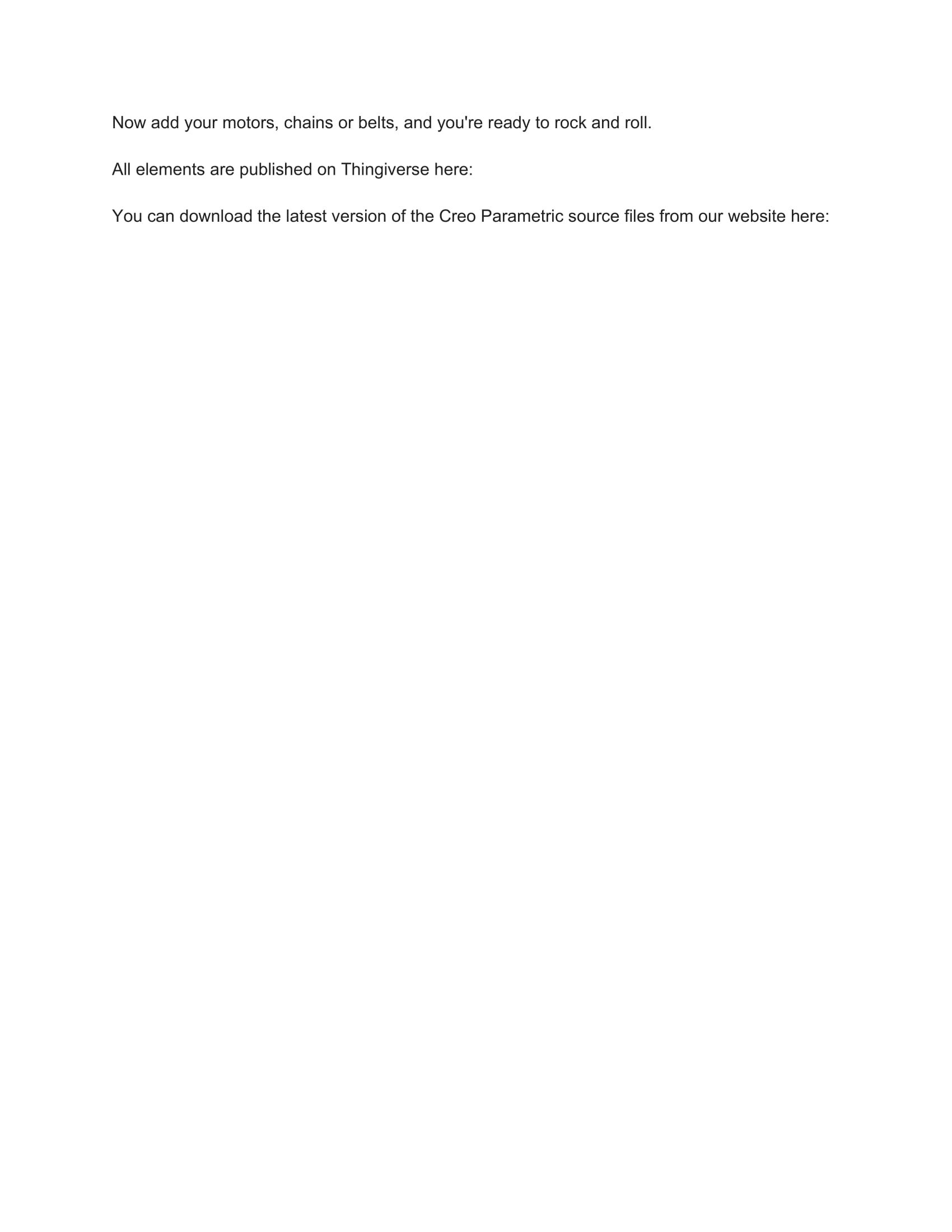

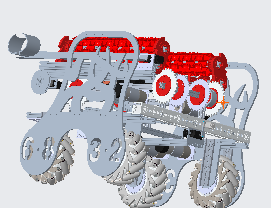

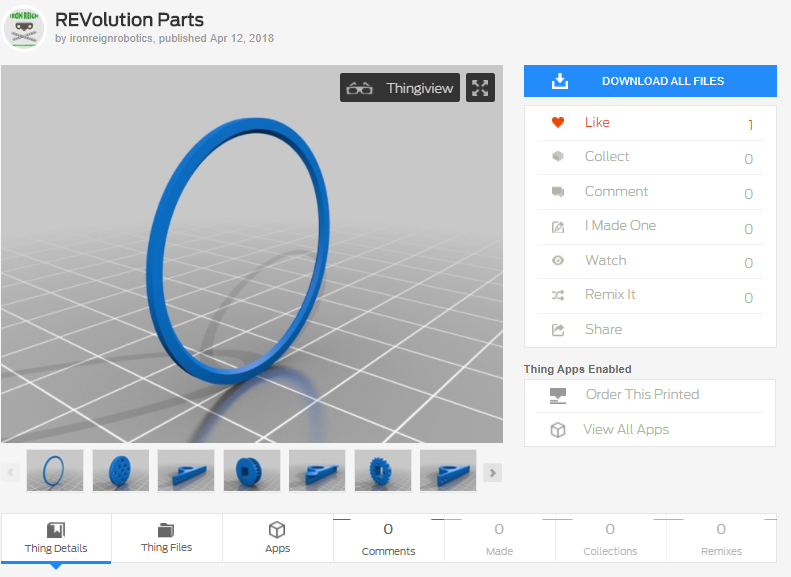

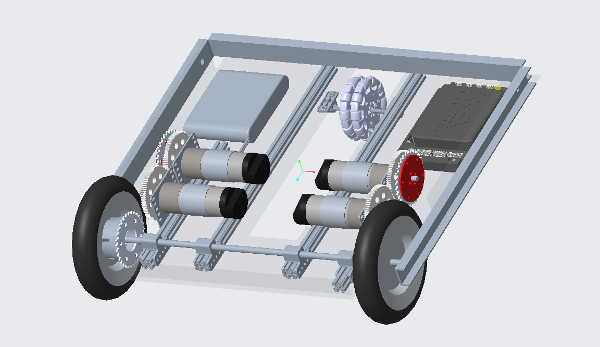

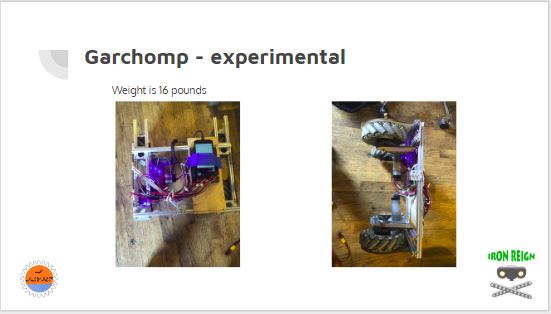

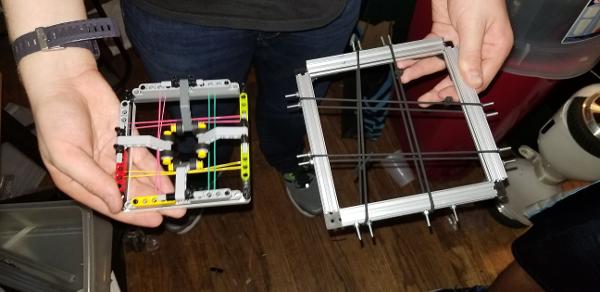

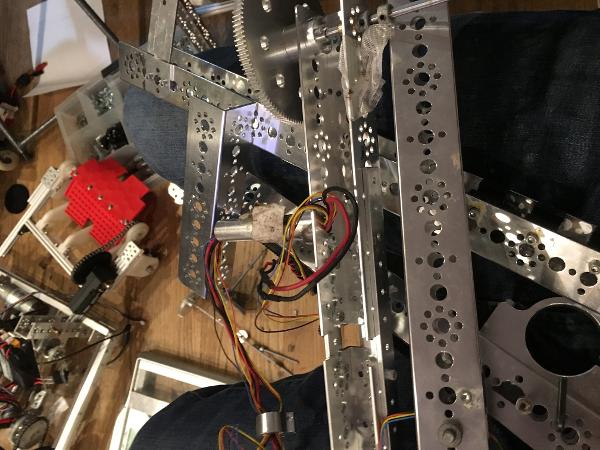

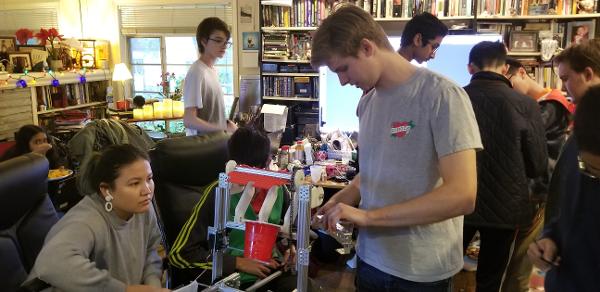

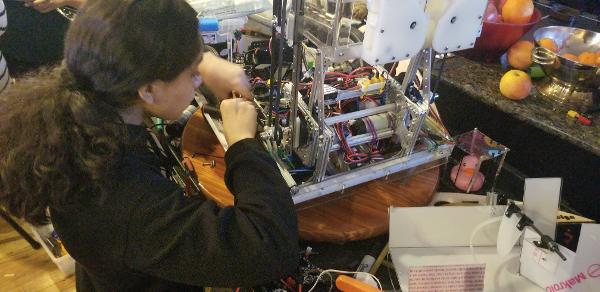

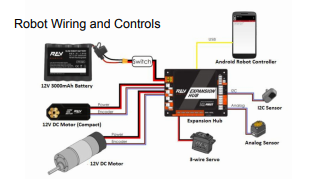

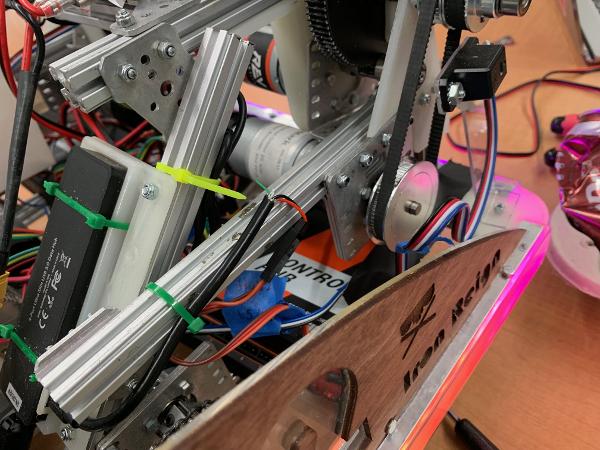

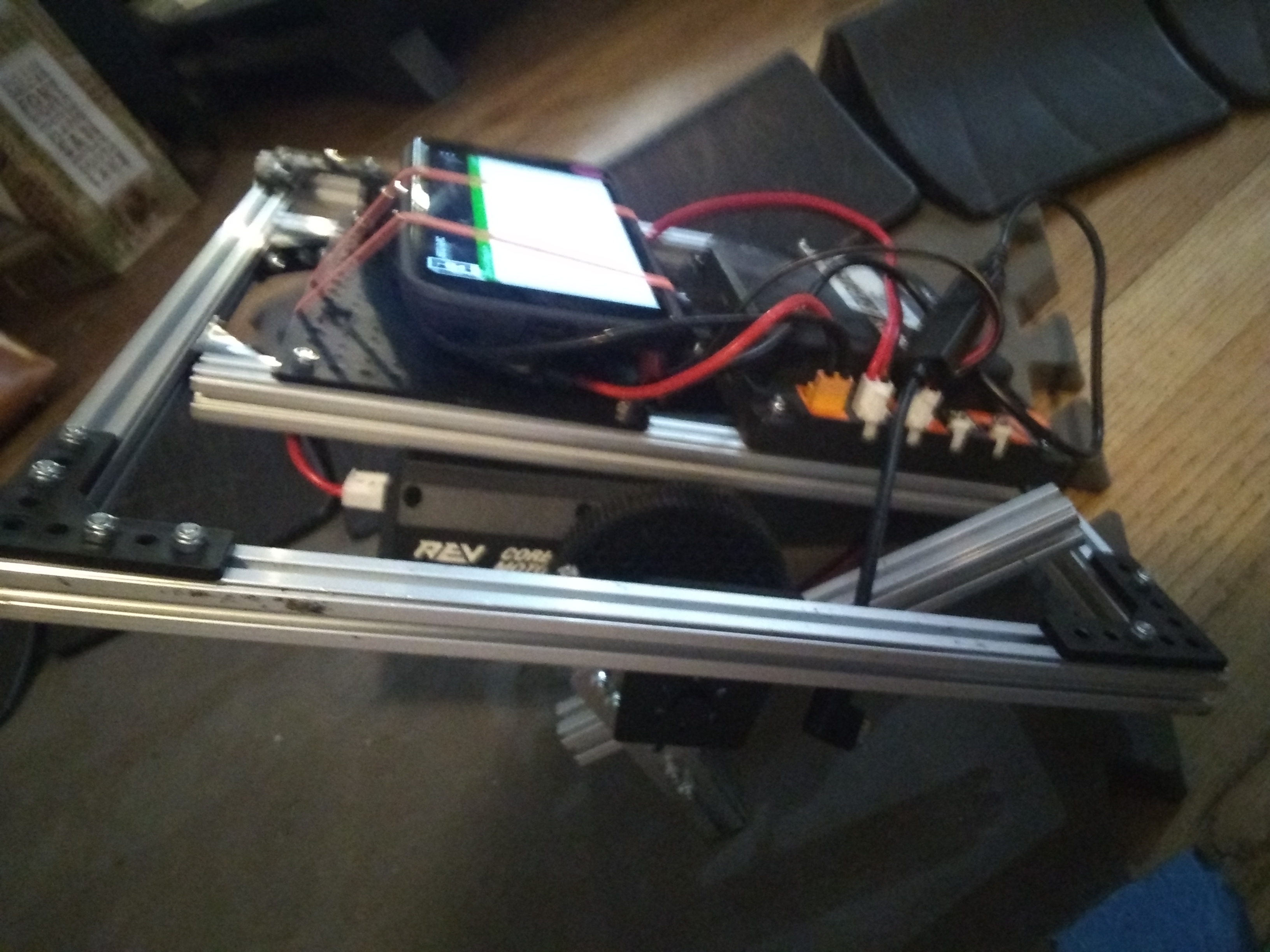

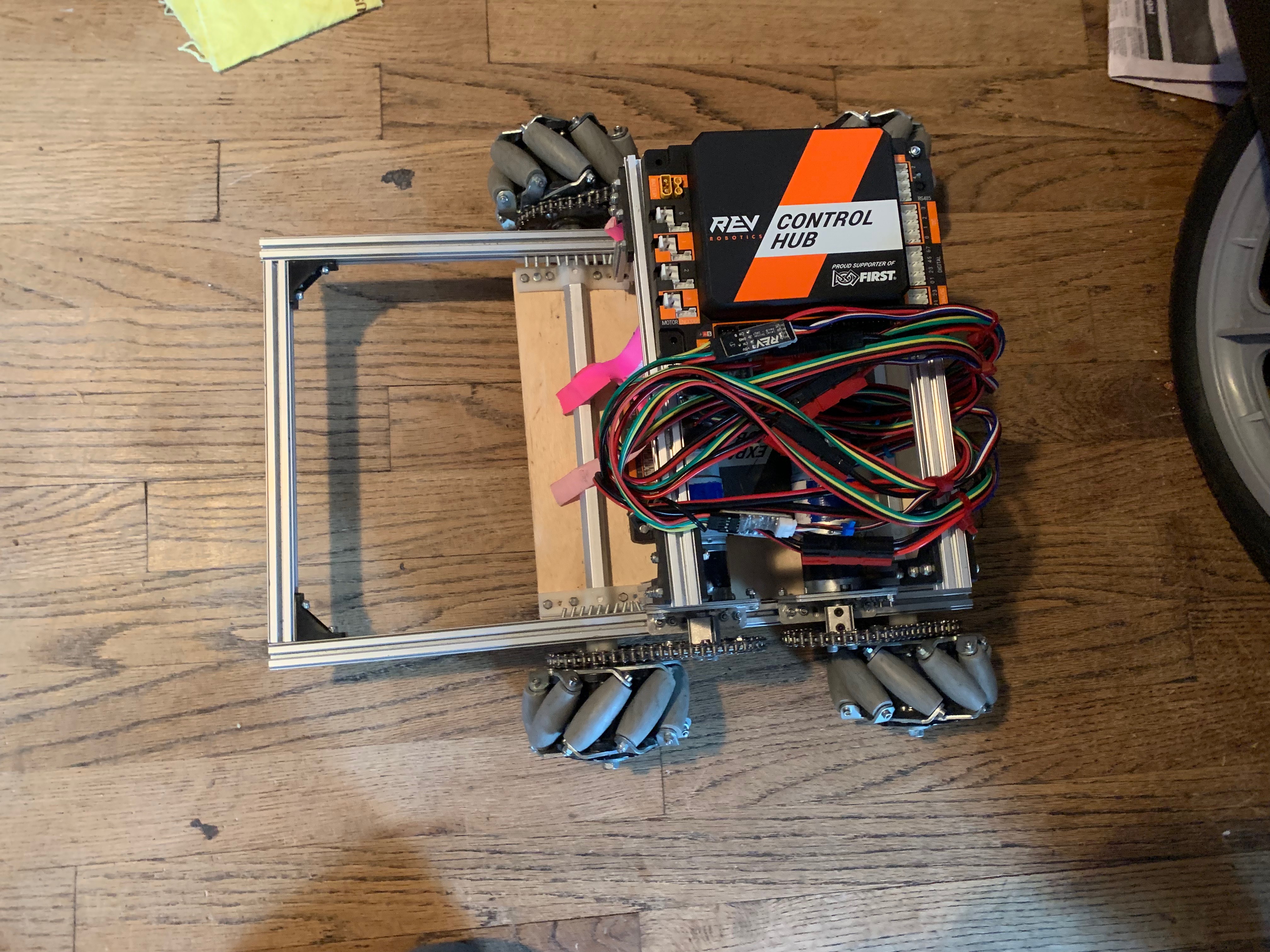

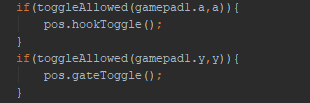

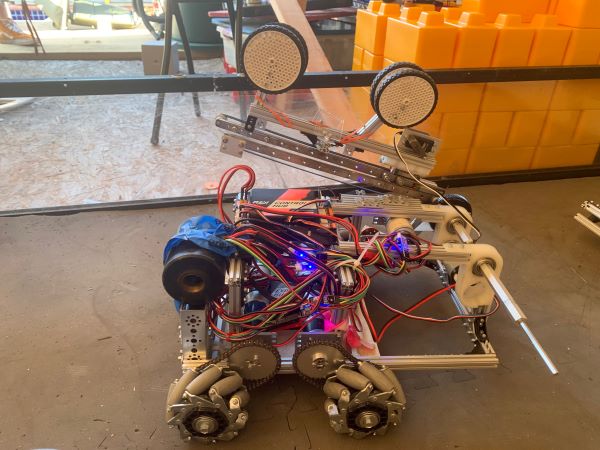

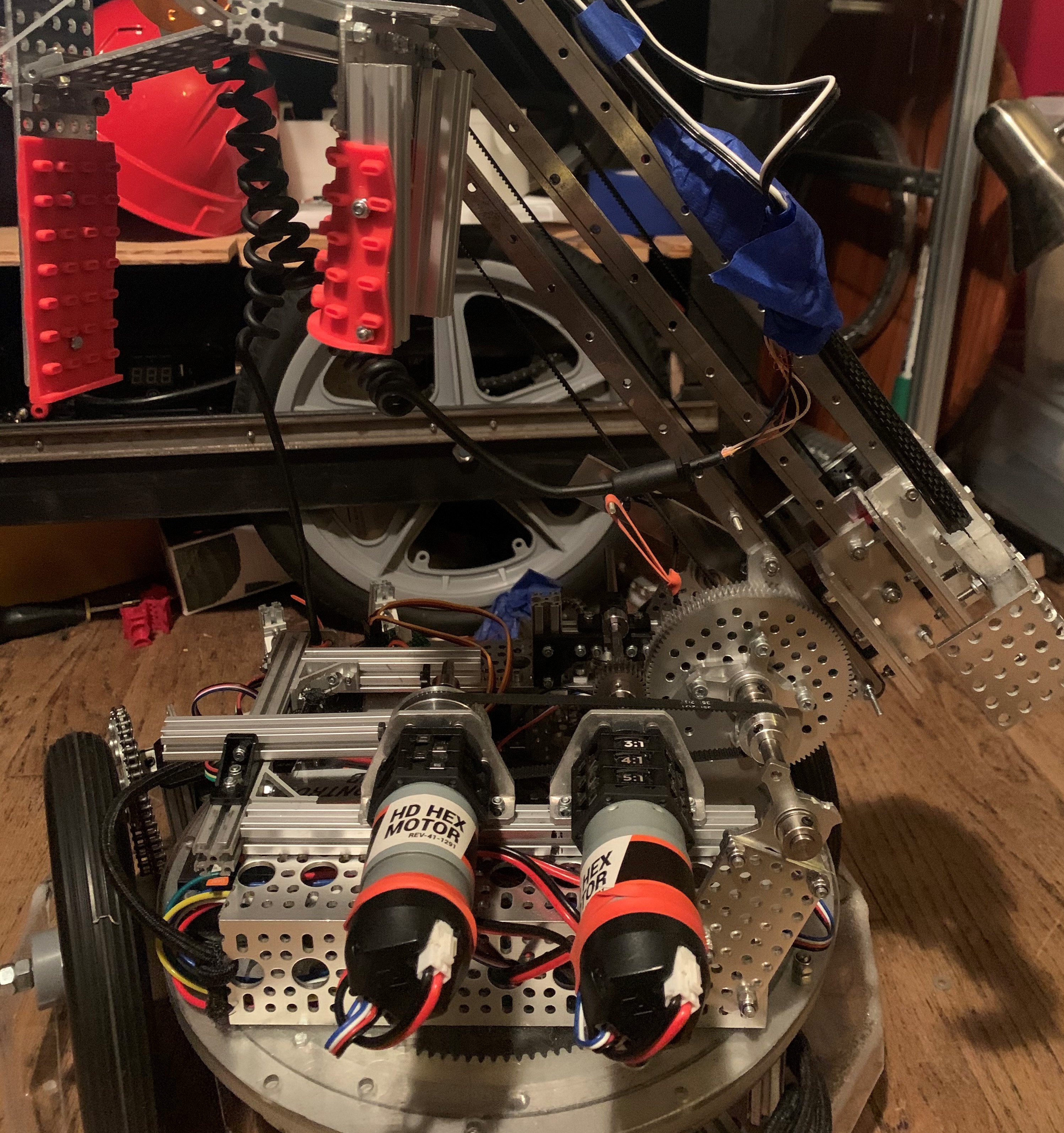

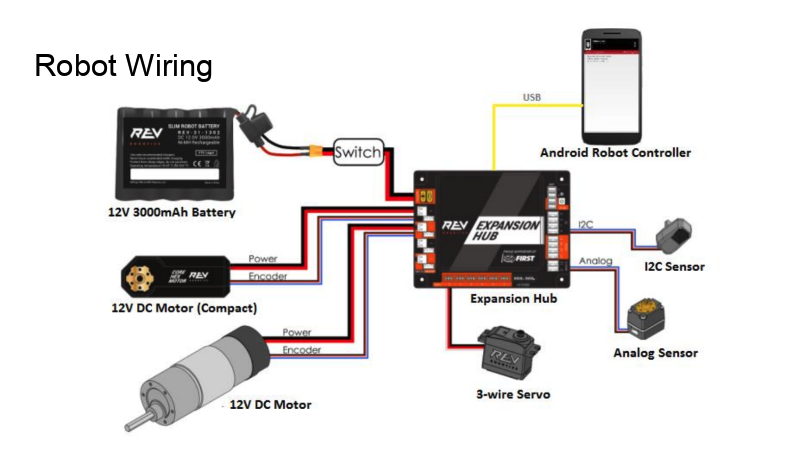

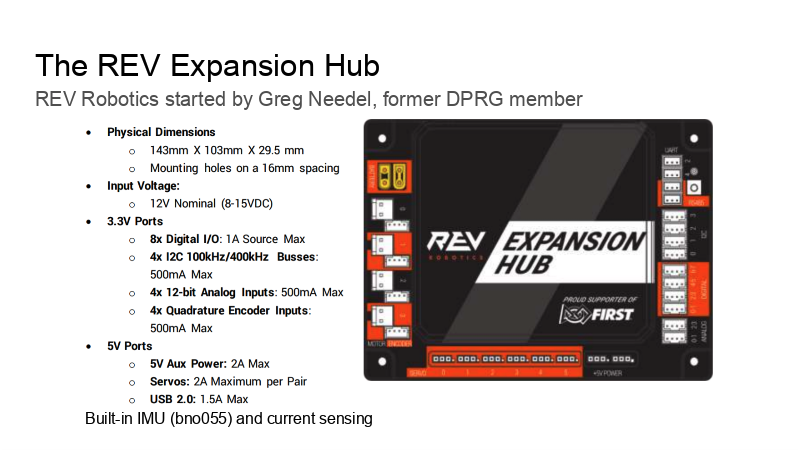

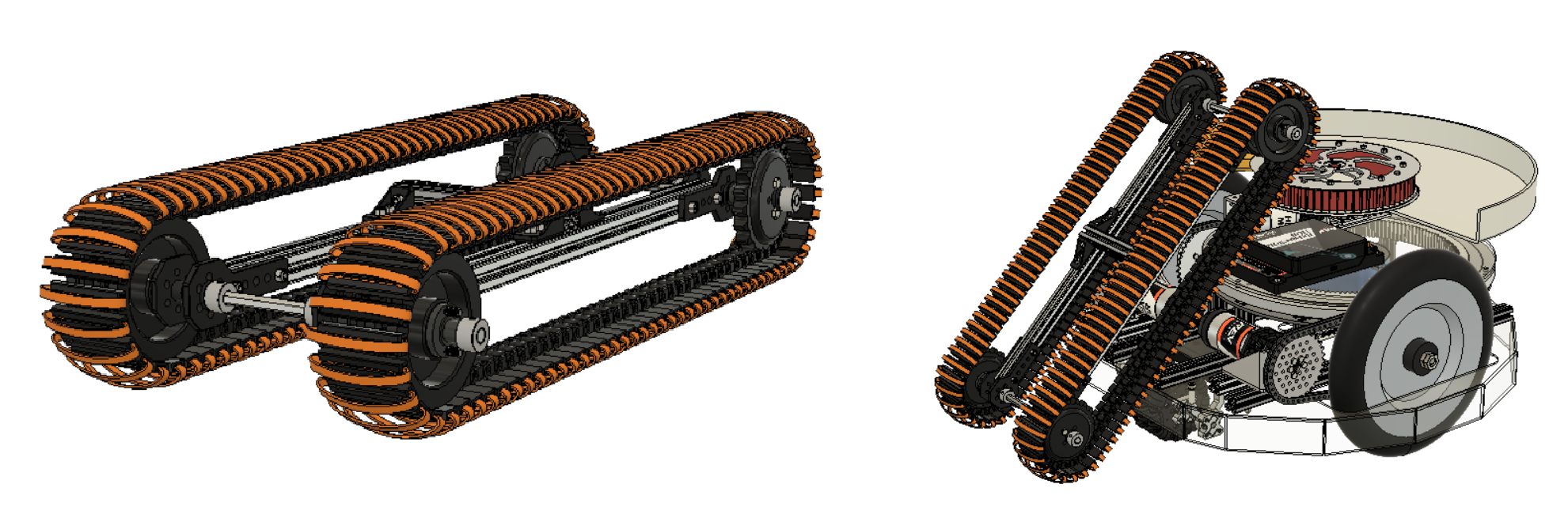

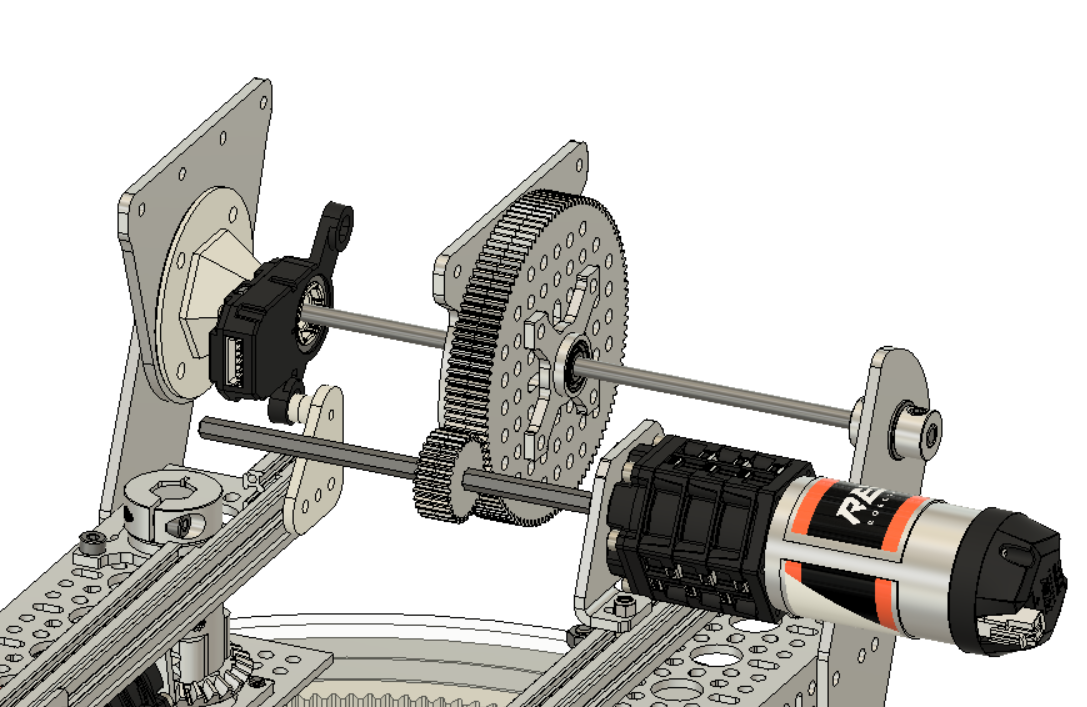

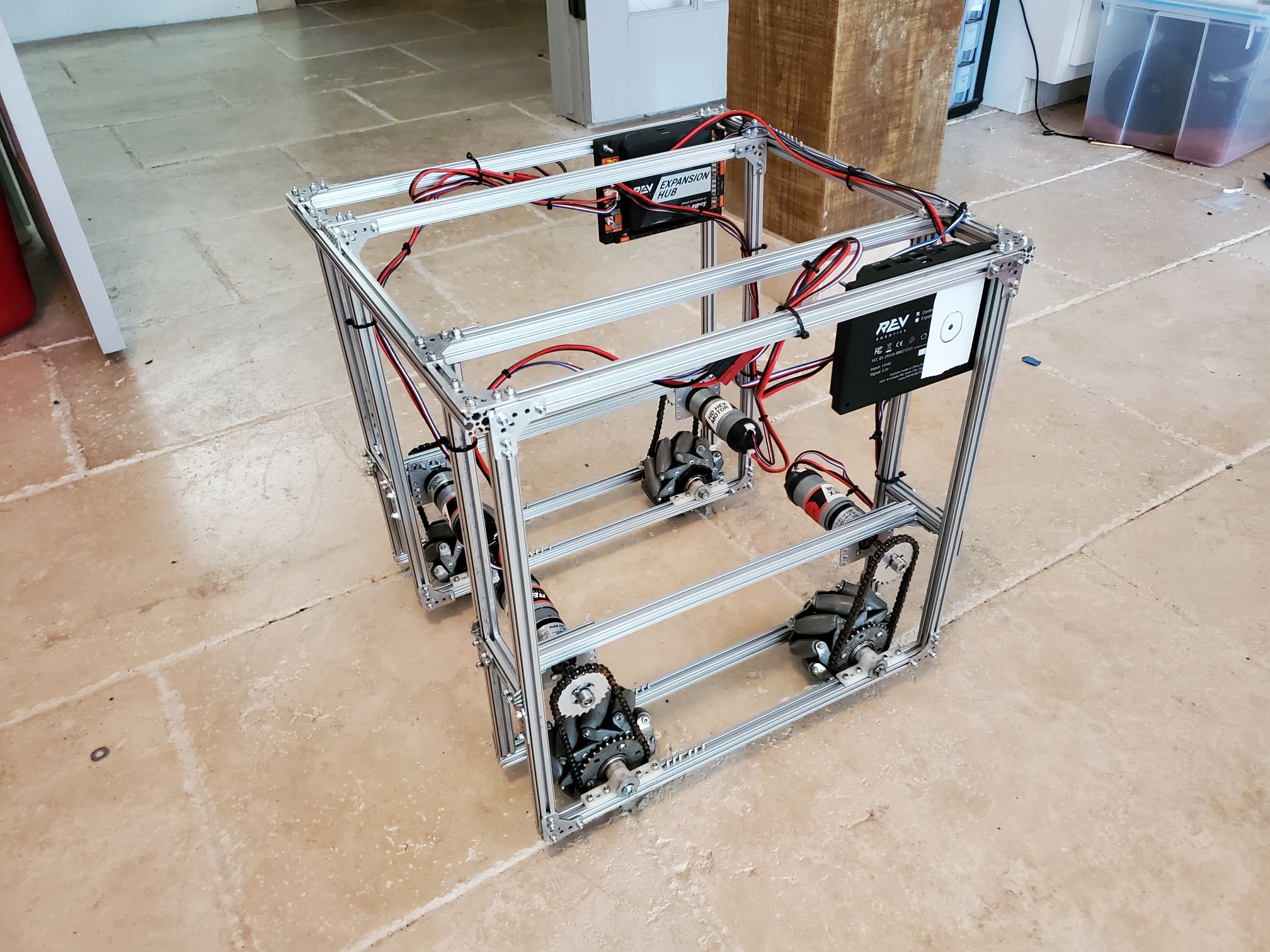

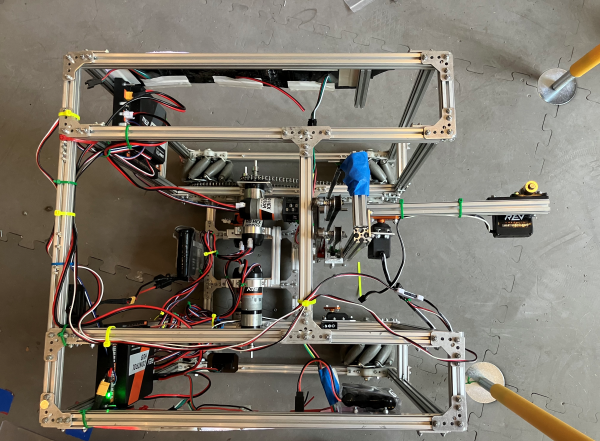

This year, Iron Reign has drastically changed how it builds

its parts. In previous years, we have relied on primary Tetrix parts, utilizing

AndyMark parts for the drivetrain and other moving areas. However, we happened

to gain access to a motherlode of REV parts, which drastically changes our

designs from previous years.

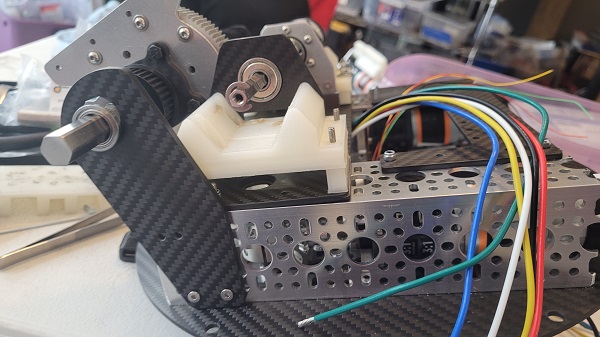

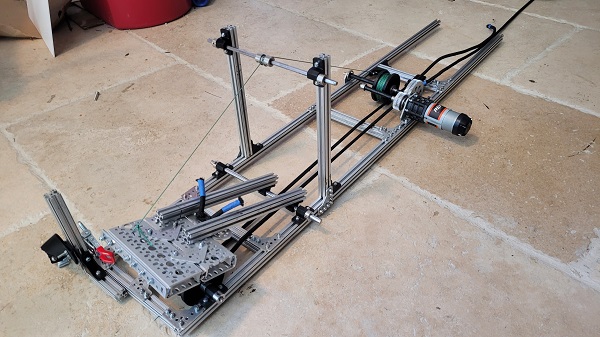

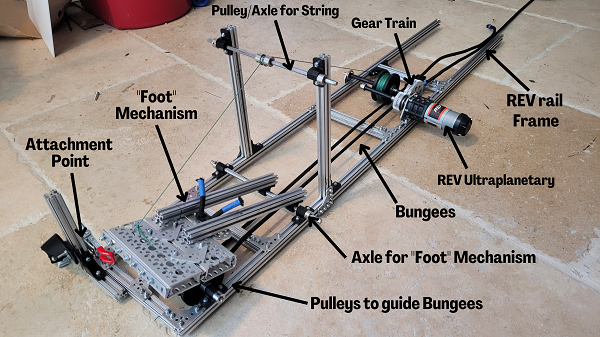

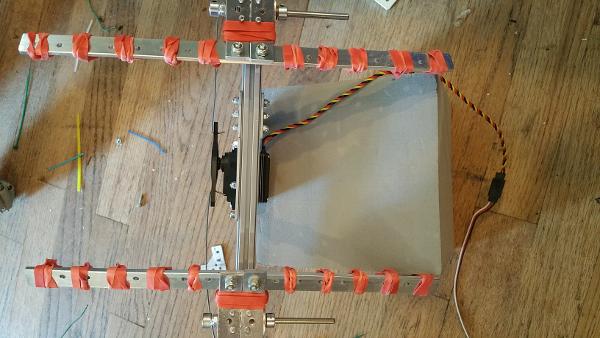

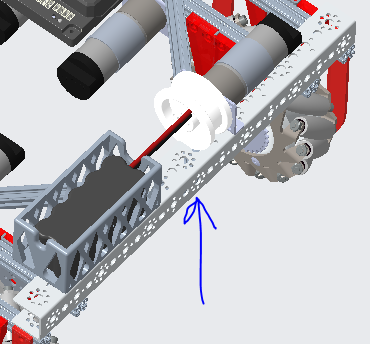

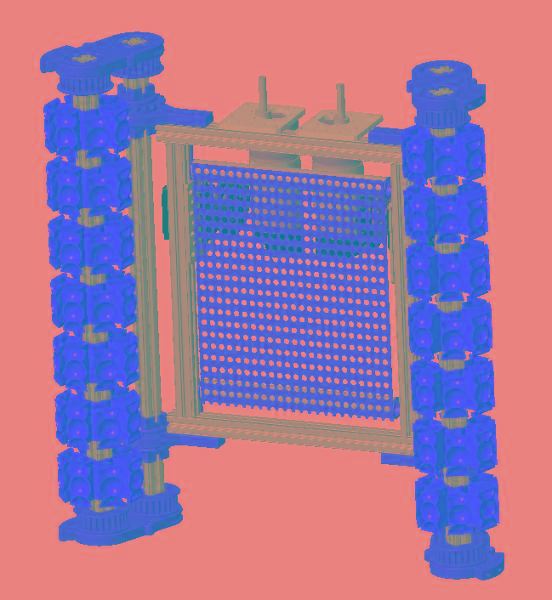

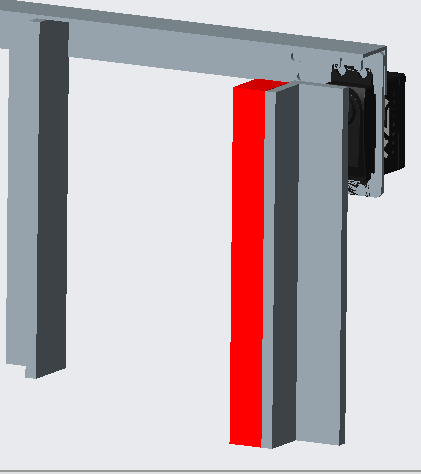

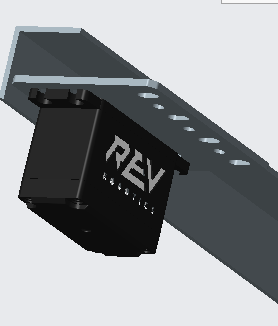

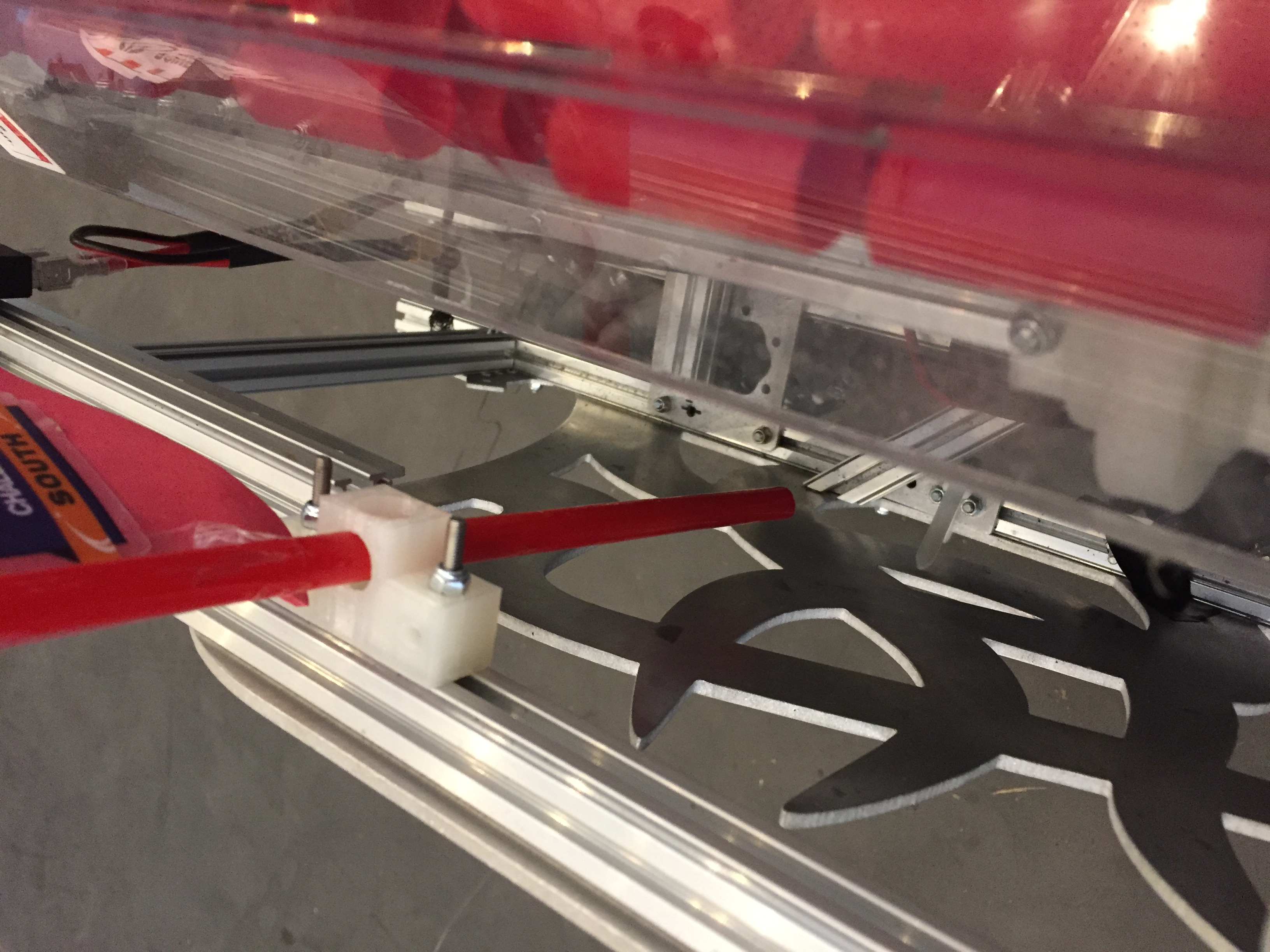

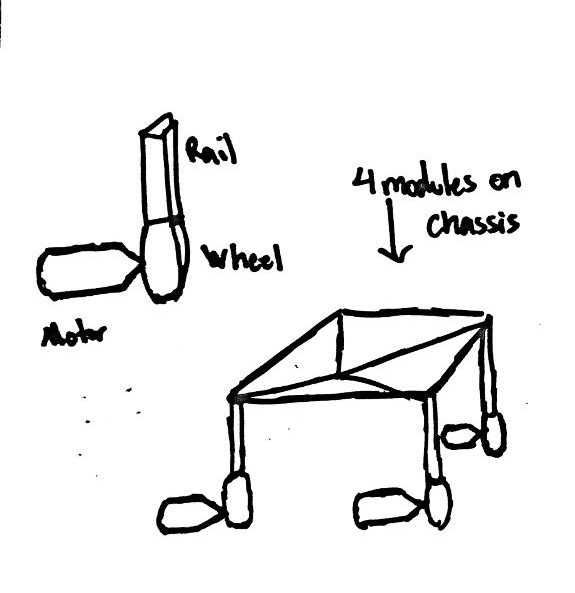

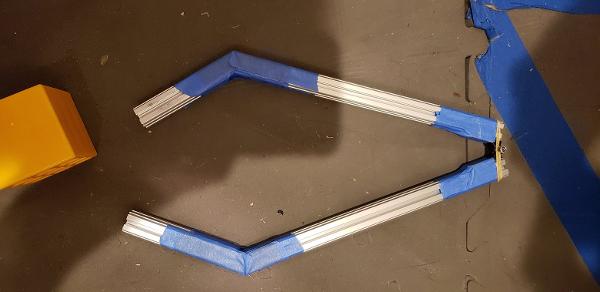

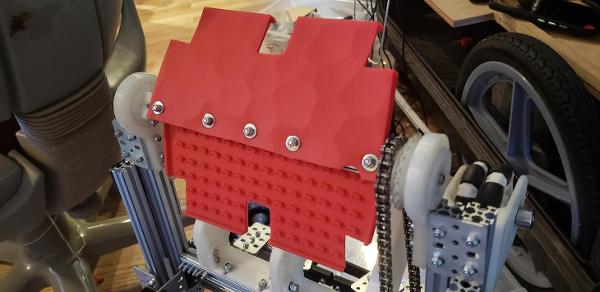

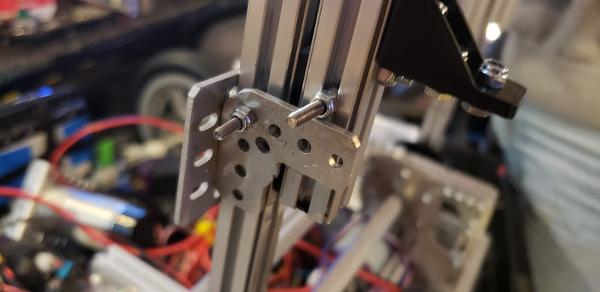

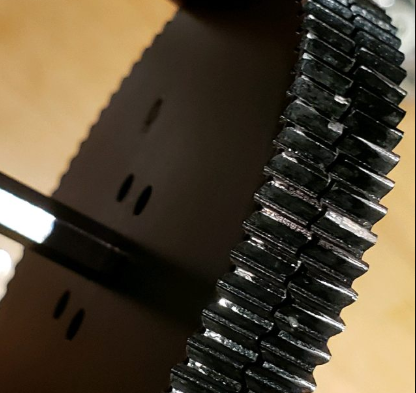

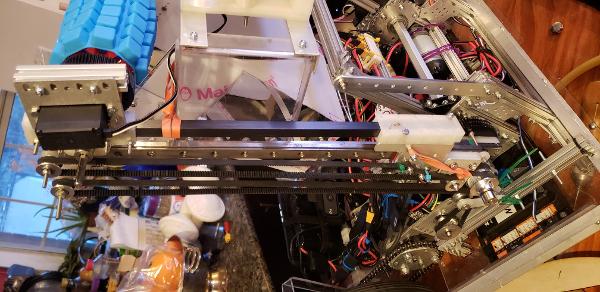

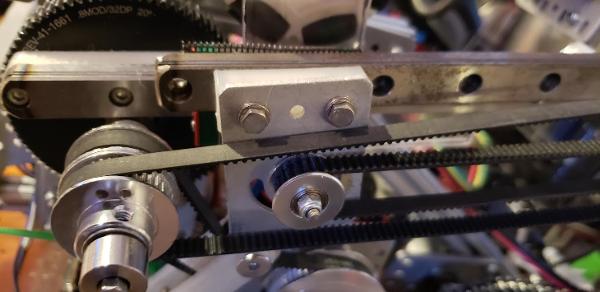

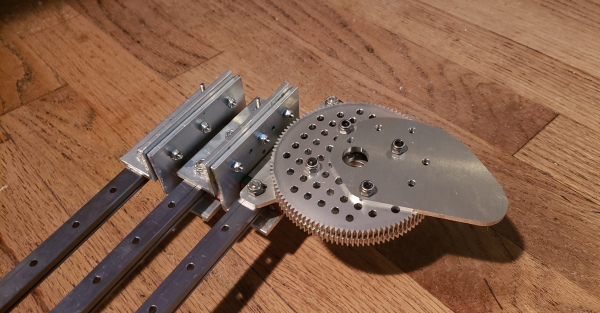

The biggest change enabling innovation is our newfound use

of REV rails within our robot. REV rails allow for basically unlimited mount

points for parts so that we are afforded maximum flexibility in our designs,

comparable to the flexibility of 3D printing.

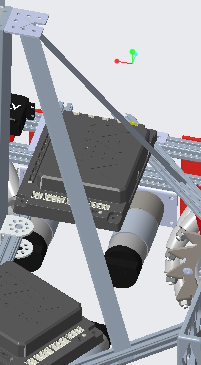

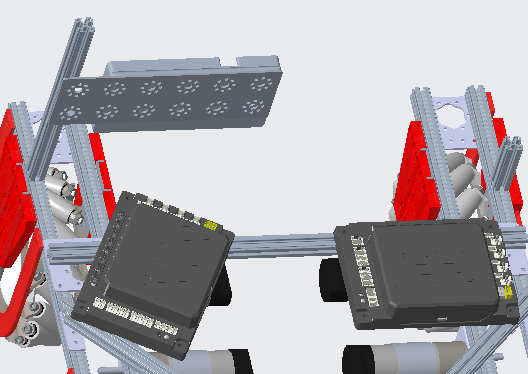

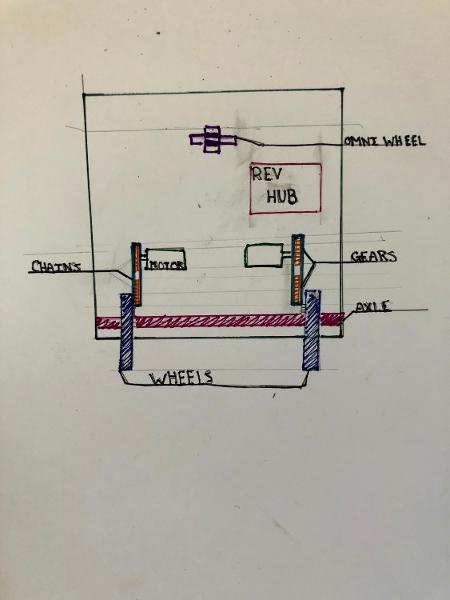

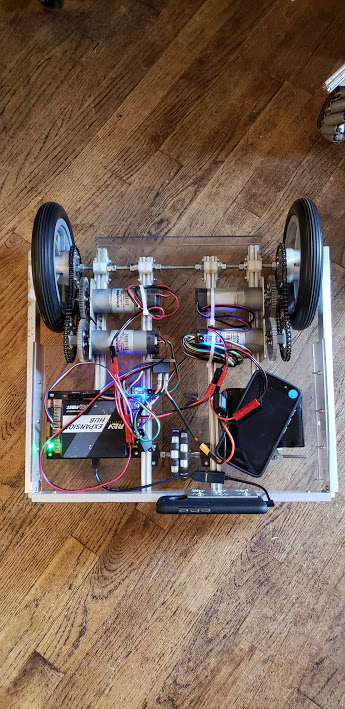

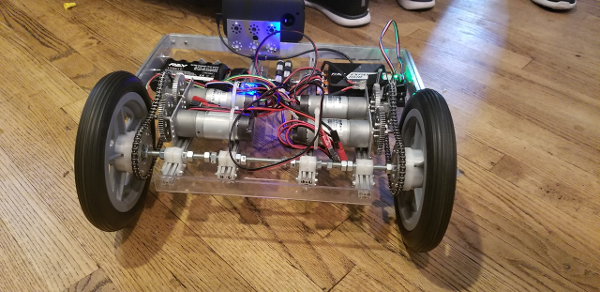

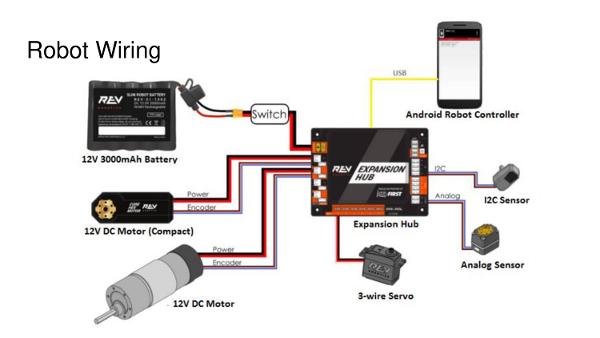

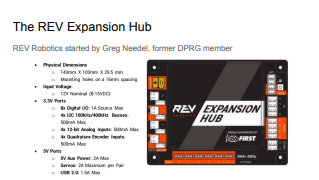

As well, for this year’s robot chassis, we have decided to

take the use of REV parts even further, and use the REV Power Distribution

Module and both Expansion Hubs. The reason for this change is twofold. First,

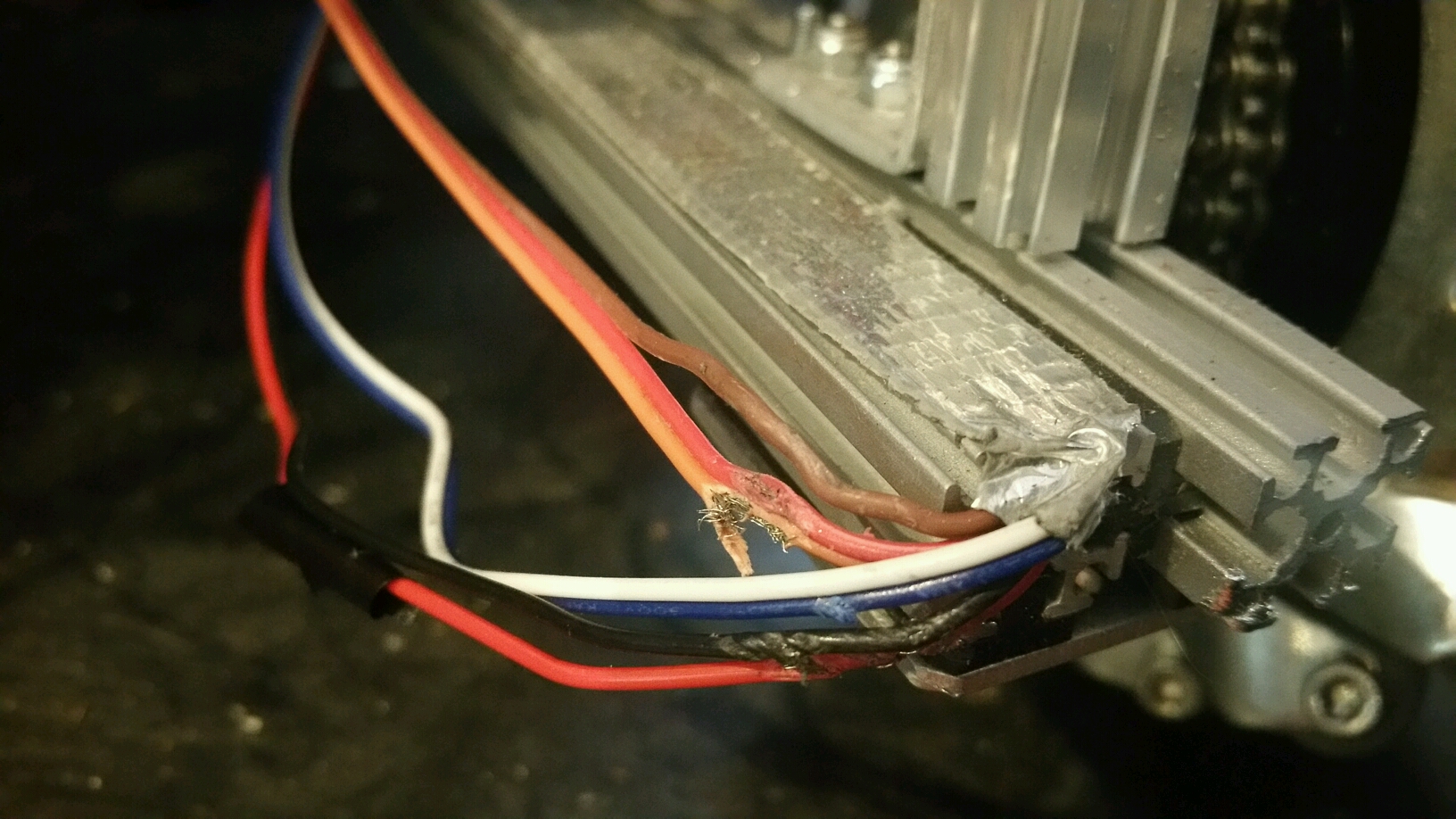

we experienced significant connection and static issues last year with our

robot, partially due to excess static buildup from our mecanum wheels. So far,

we have not experienced any of those issues using REV modules, even though we

are using the same base chassis. Second, the REV hubs allow us to add more

features on to our robot, such as LED strips and extra servos,

that allow us to signal our team as well as create more innovative

components of our robot.

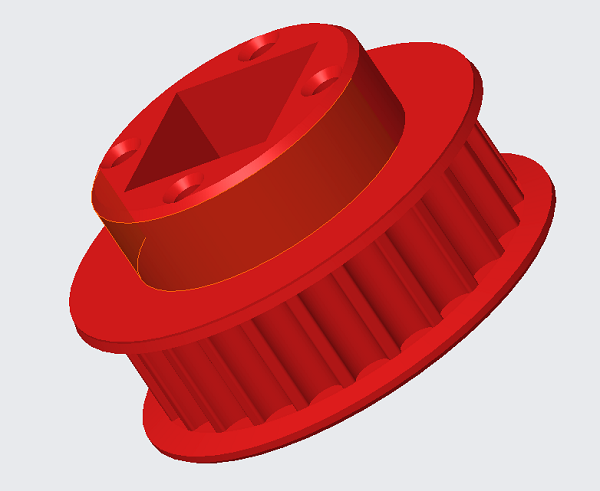

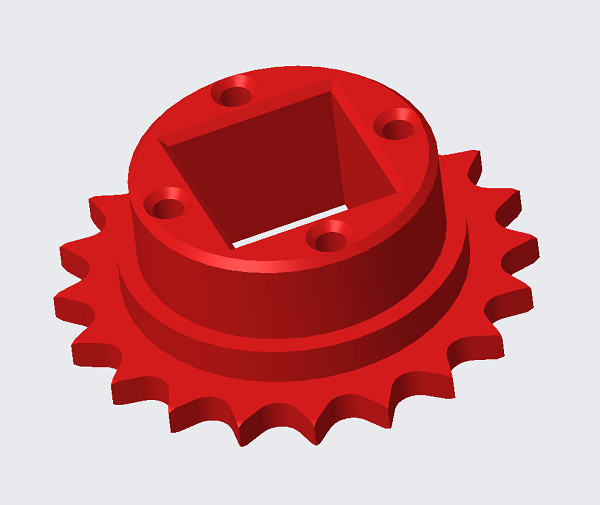

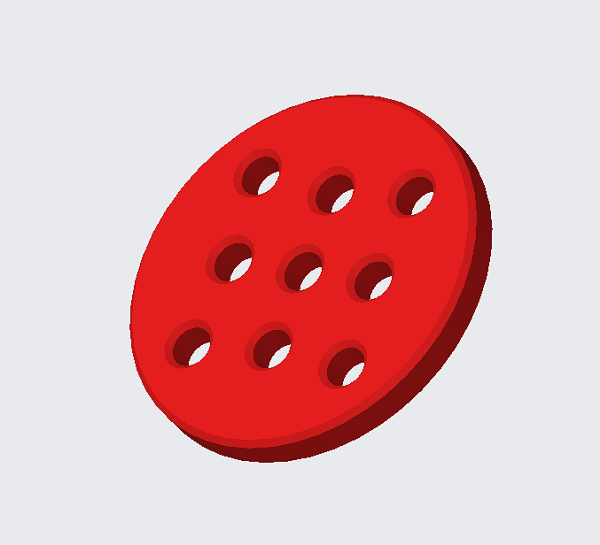

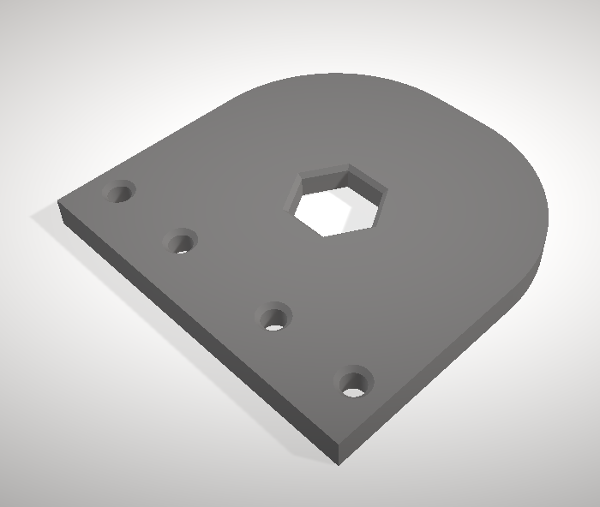

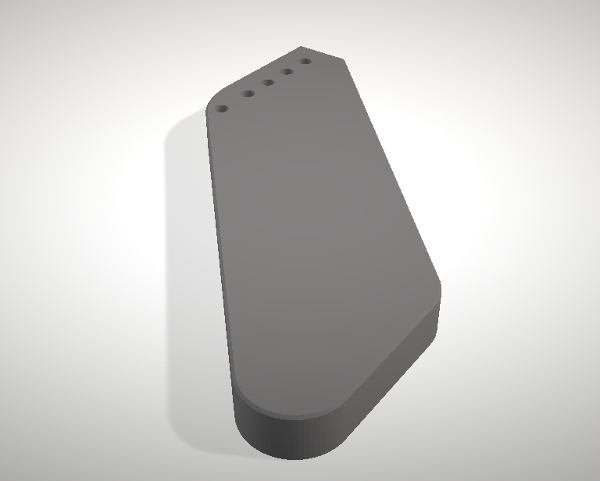

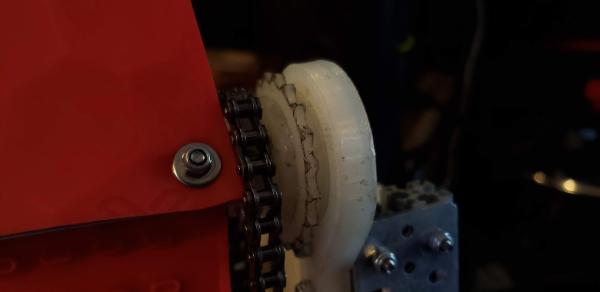

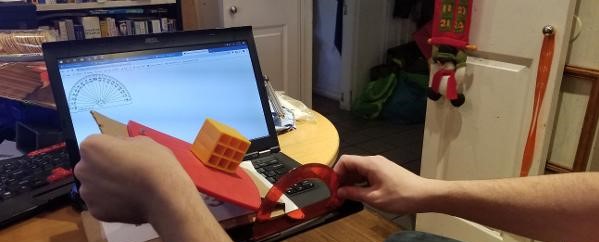

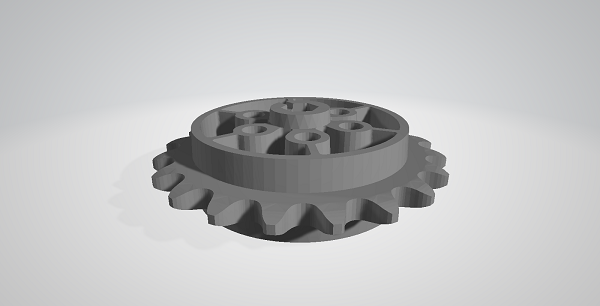

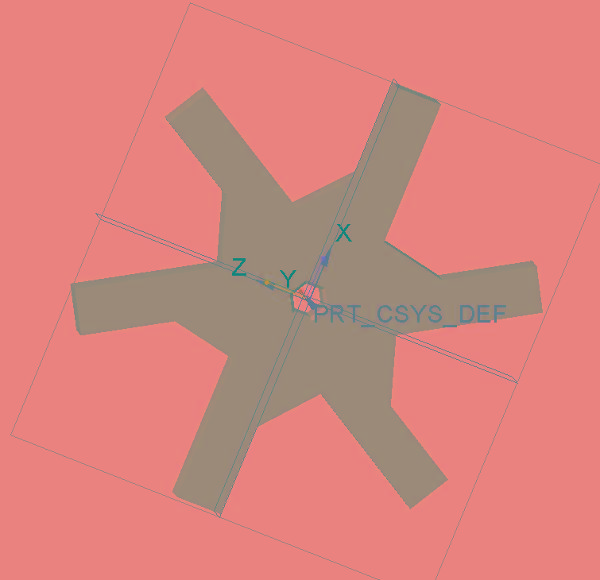

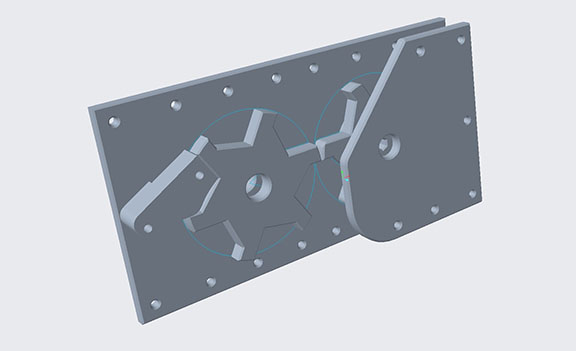

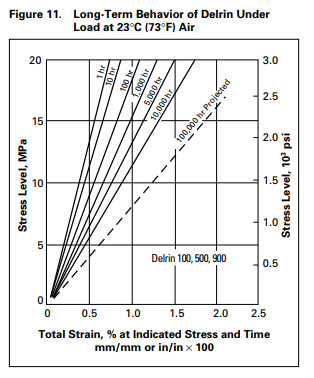

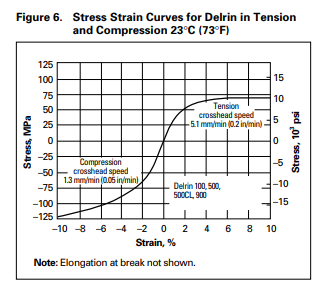

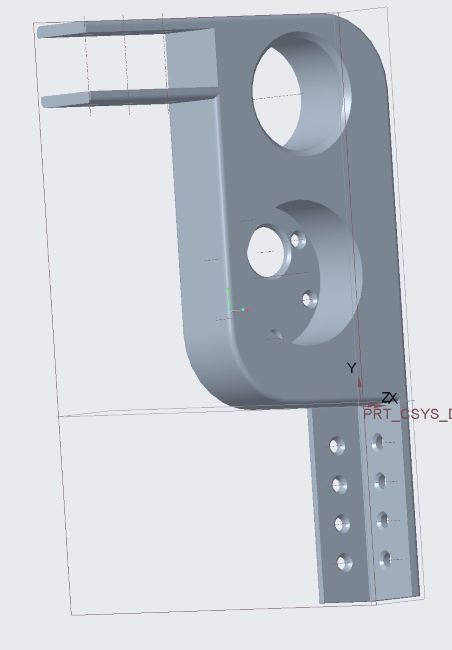

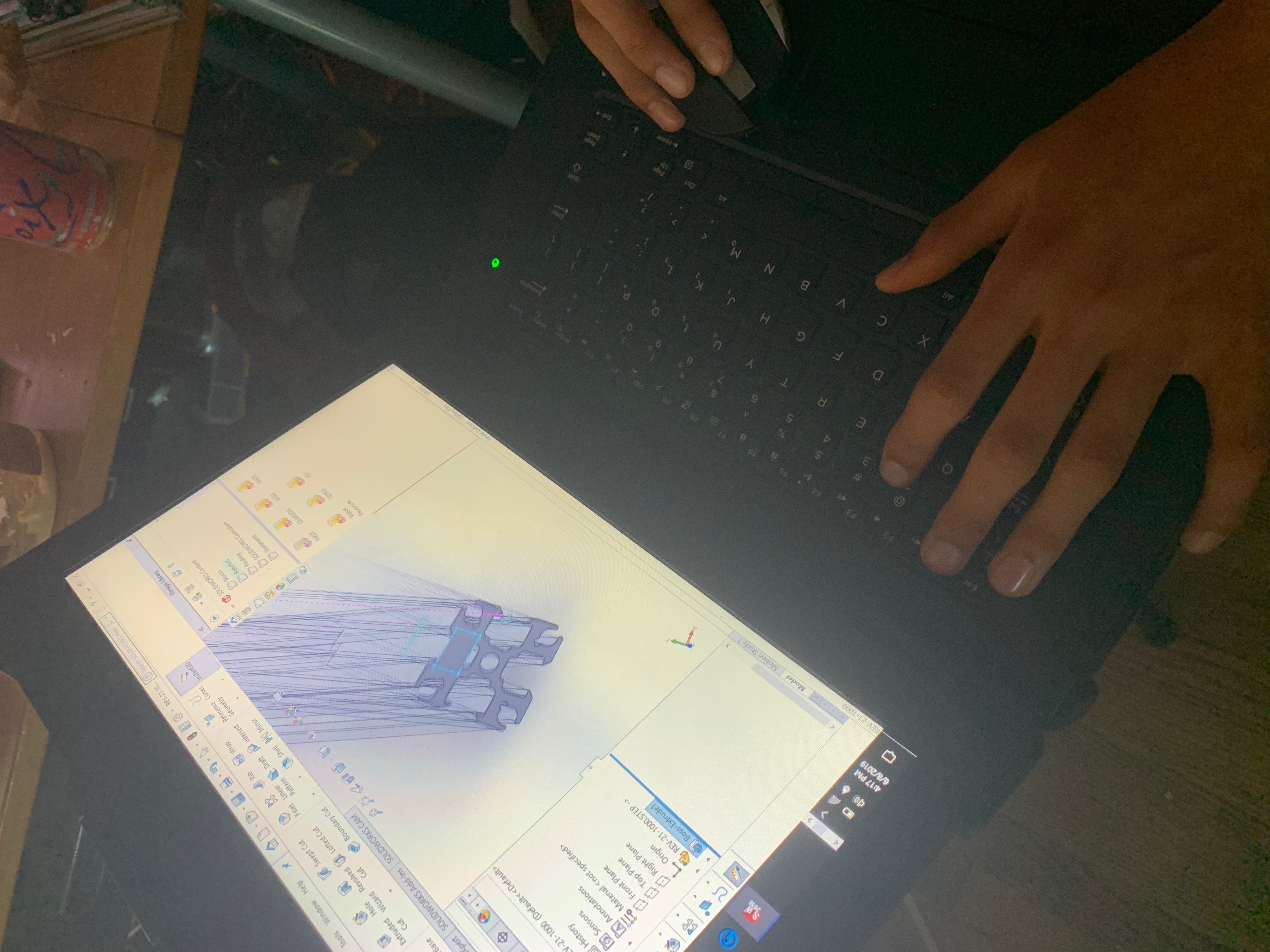

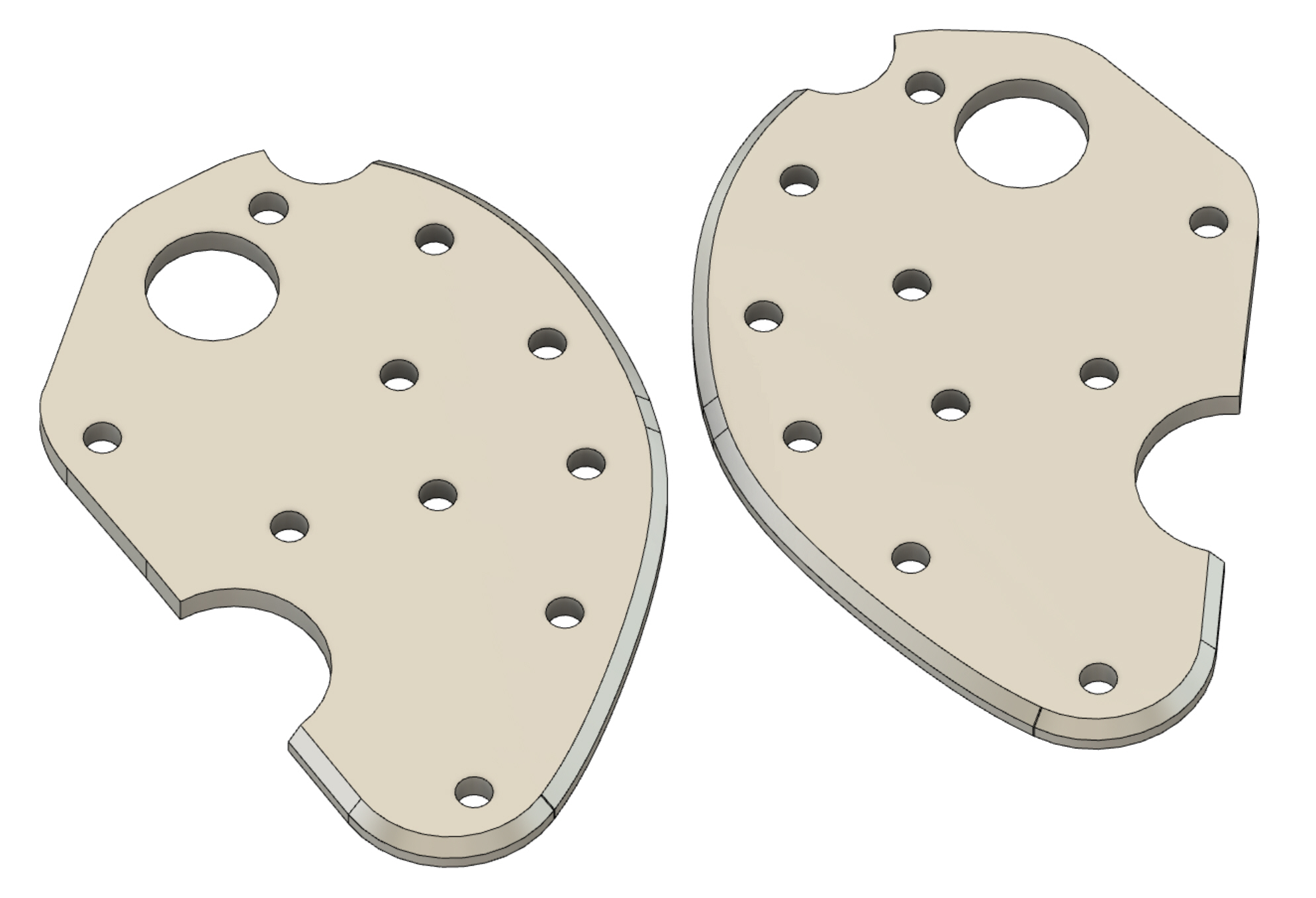

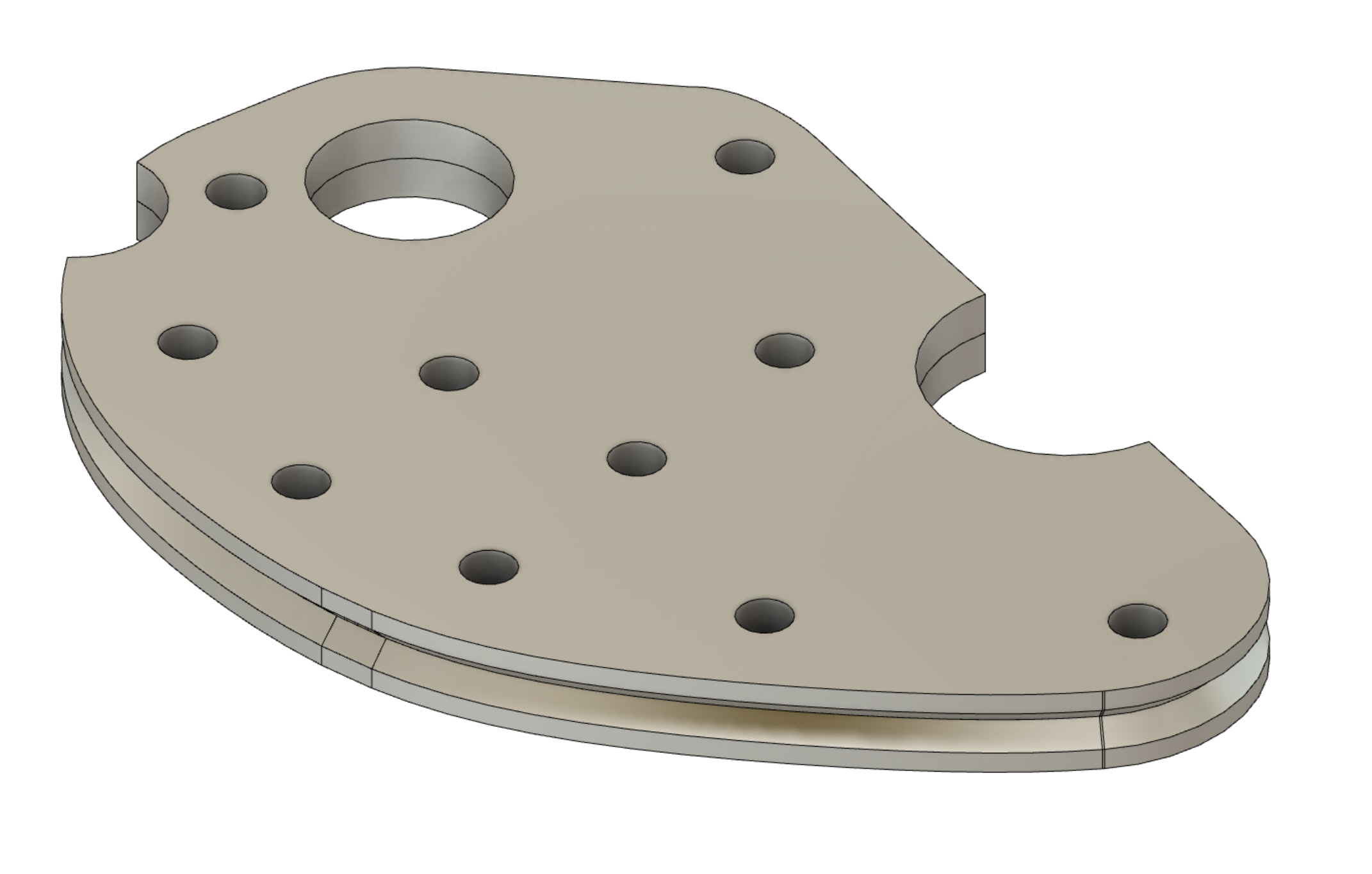

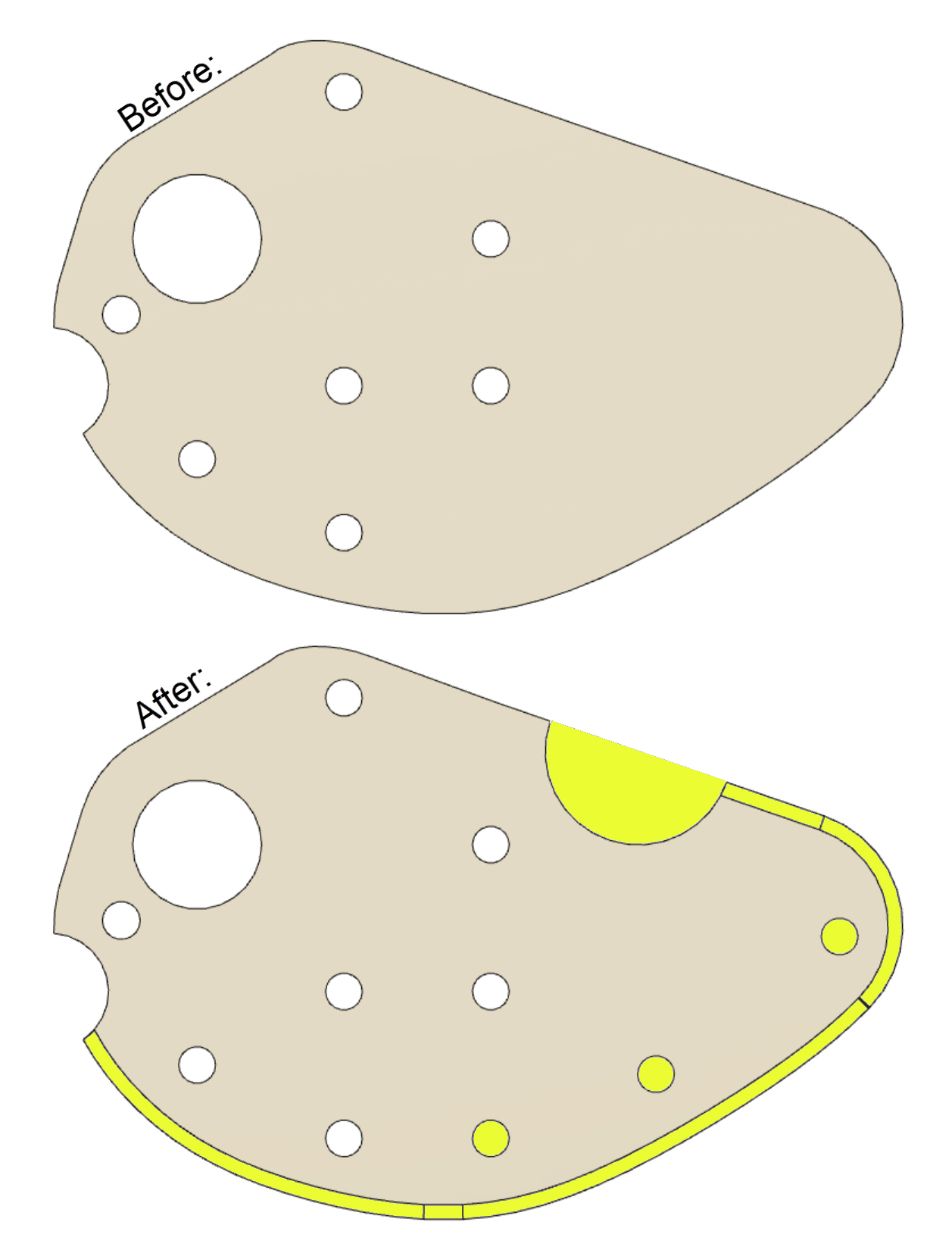

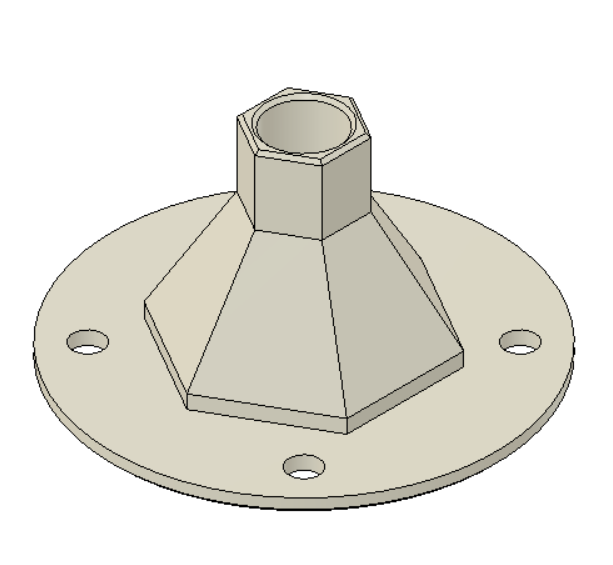

We also utilize a variety of 3D printed parts on our robot.

While we use less 3D printed parts than previous years, that

is due to the particular challenges of this year. Our parts are modelled in PTC

Creo, and we have recently switched over from Creo V.3 to Creo V.4 so that we

can use the more advanced features included in the new program. Our personal 3D

printer can handle a variety of materials, and we have used nylon, ABS,

Filoflex, and Ninjaflex in prior designs to fit various needs. In our current robot,

we have settled on using nylon. Nylon has four qualities that make it more

advantageous than other materials. First, nylon is less brittle and prone to

breaking than materials such as ABS. Second, nylon achieves comparatively high

print quality on our robot as compared to Filoflex and Ninjaflex. Third, nylon

has enough give so that it doesn’t break, but is strong enough to withstand the

forces felt in everyday use of our robot. Finally, nylon can be dyed so that we

can give our parts a distinguishing color, a quality that we have taken

advantage of in prior seasons.

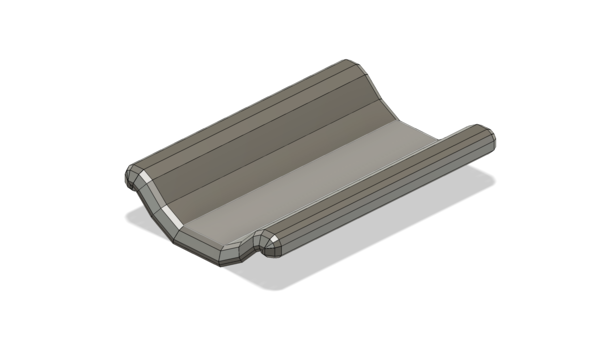

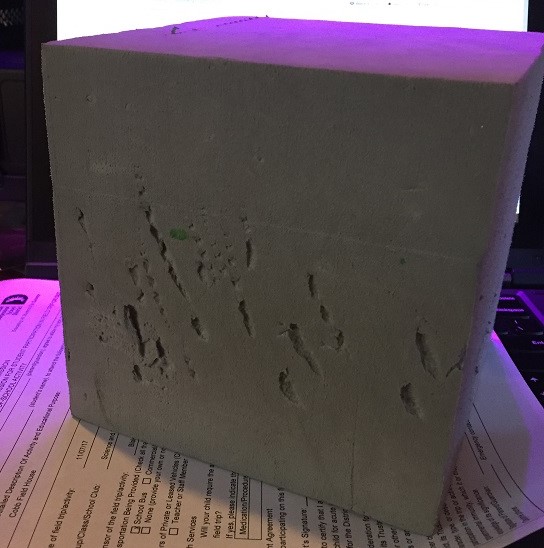

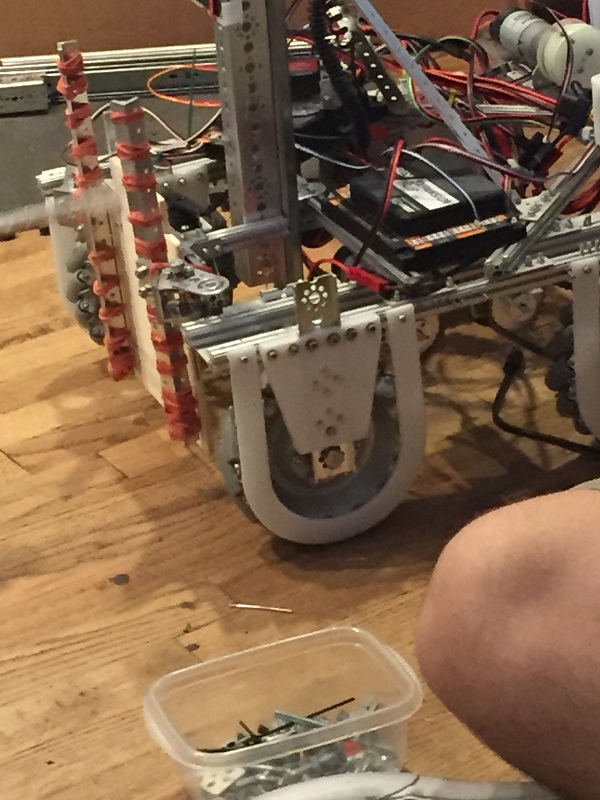

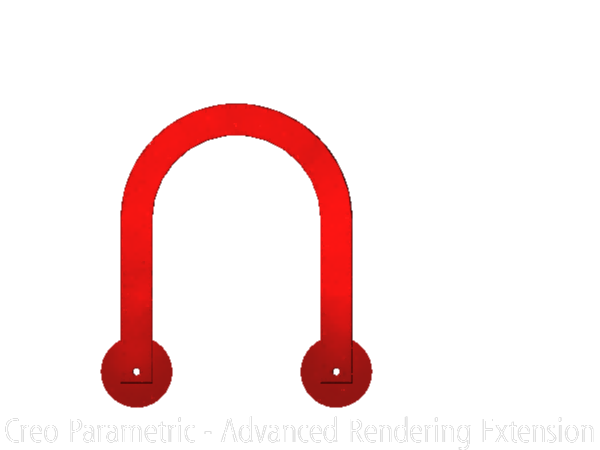

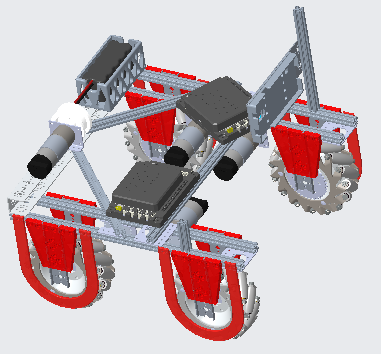

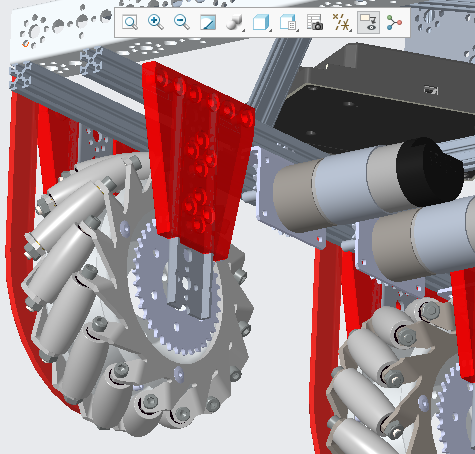

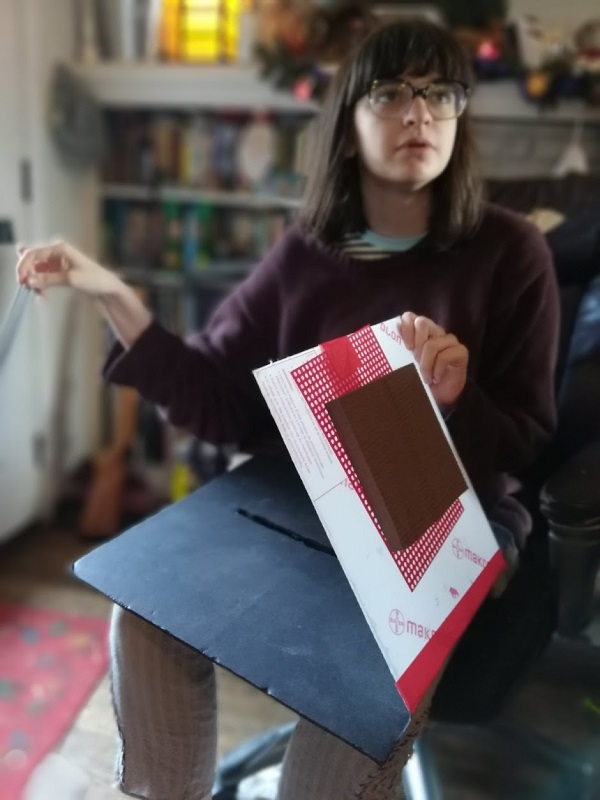

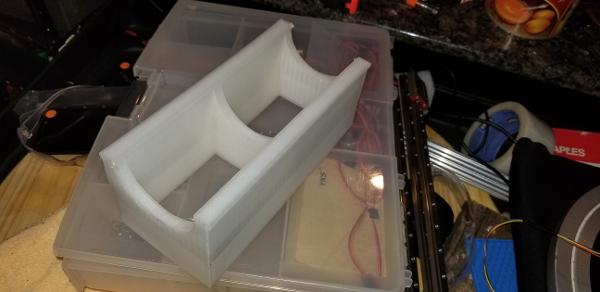

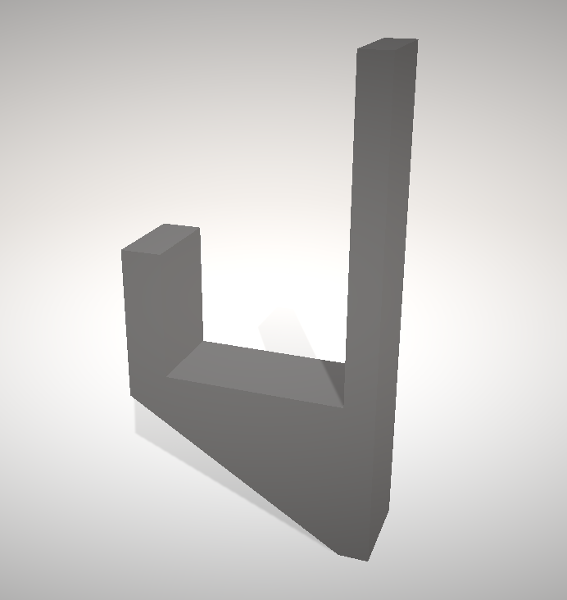

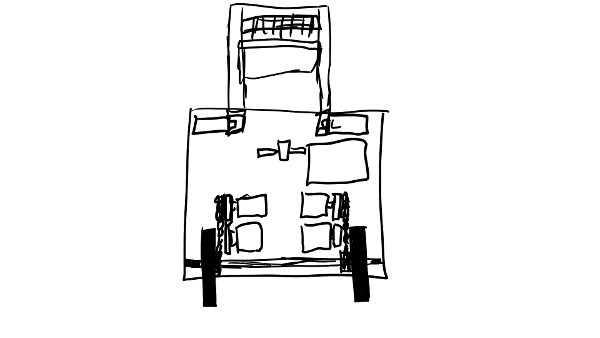

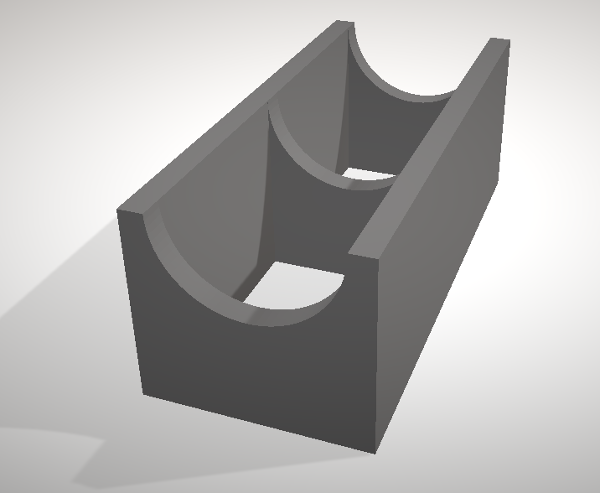

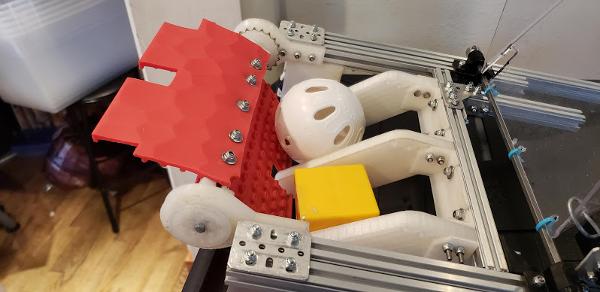

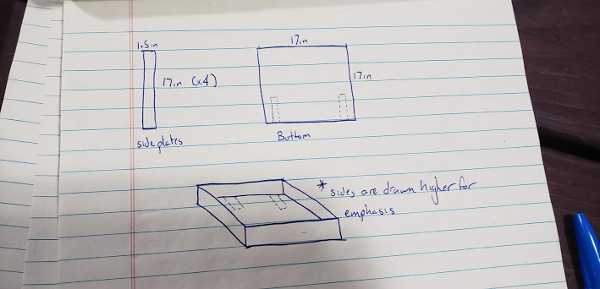

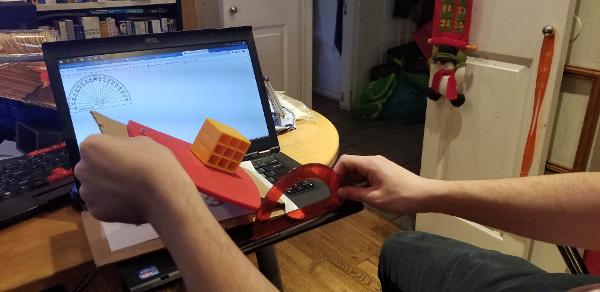

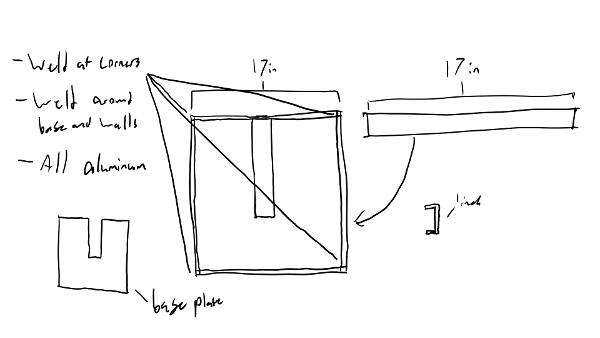

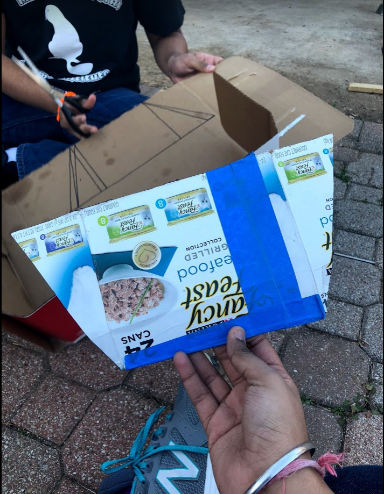

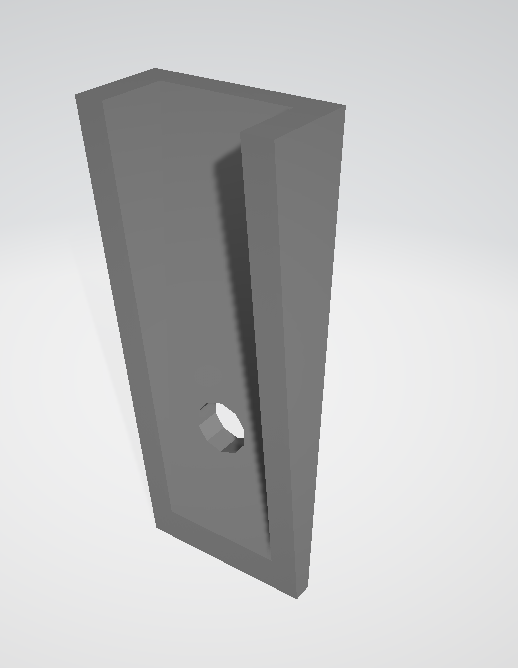

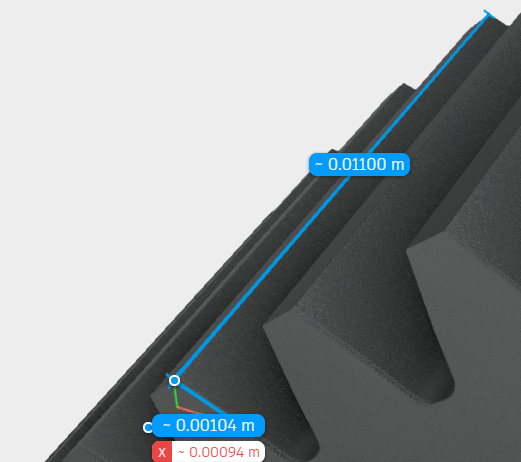

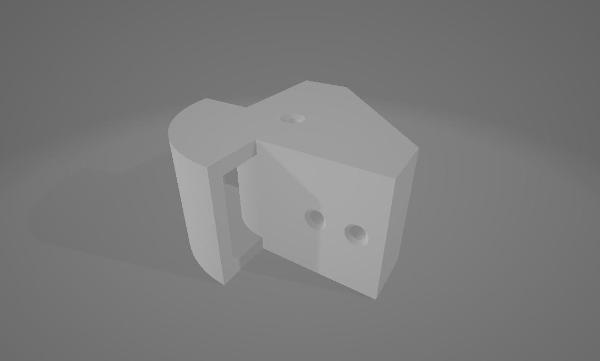

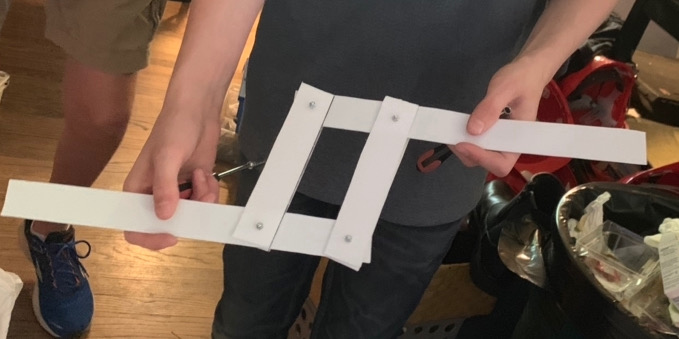

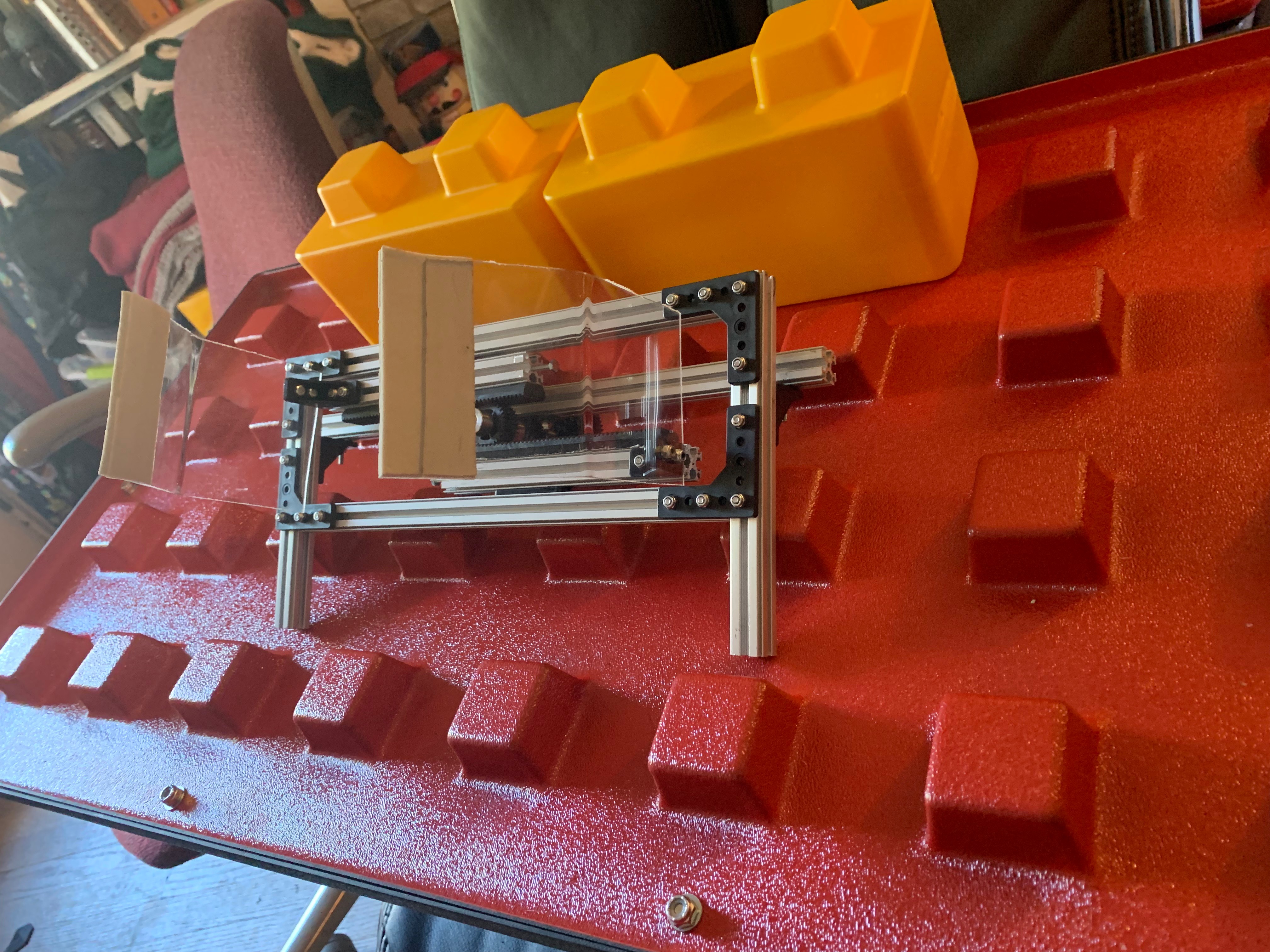

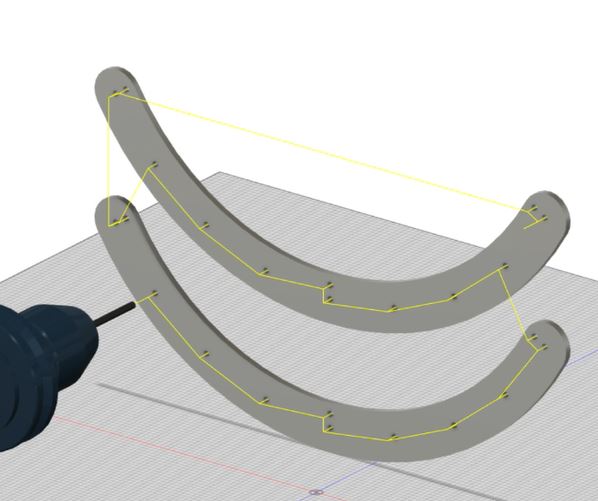

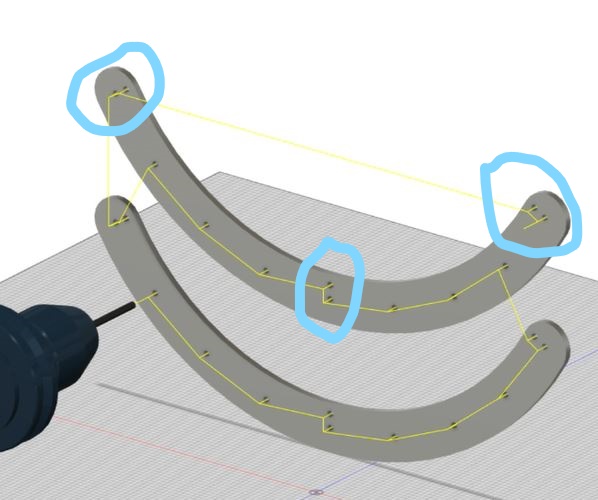

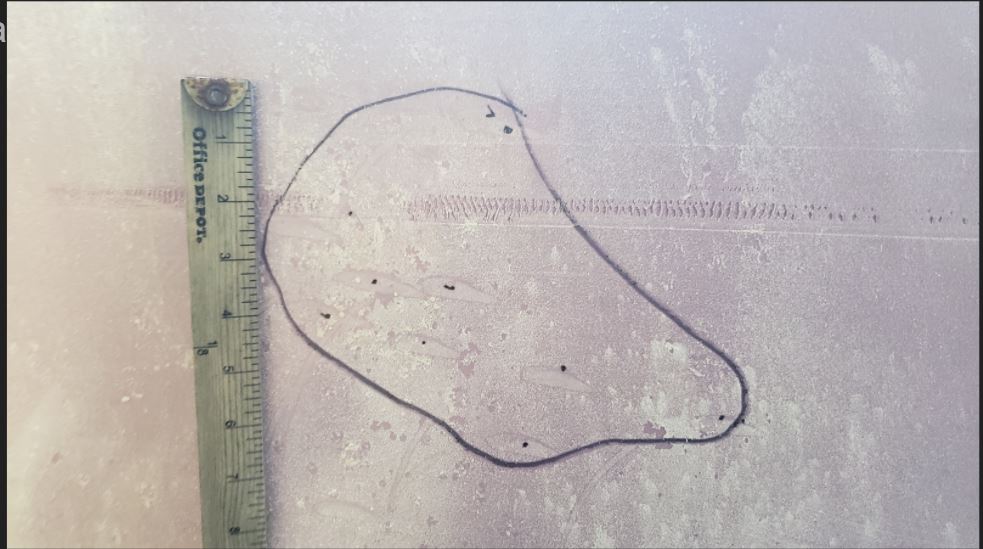

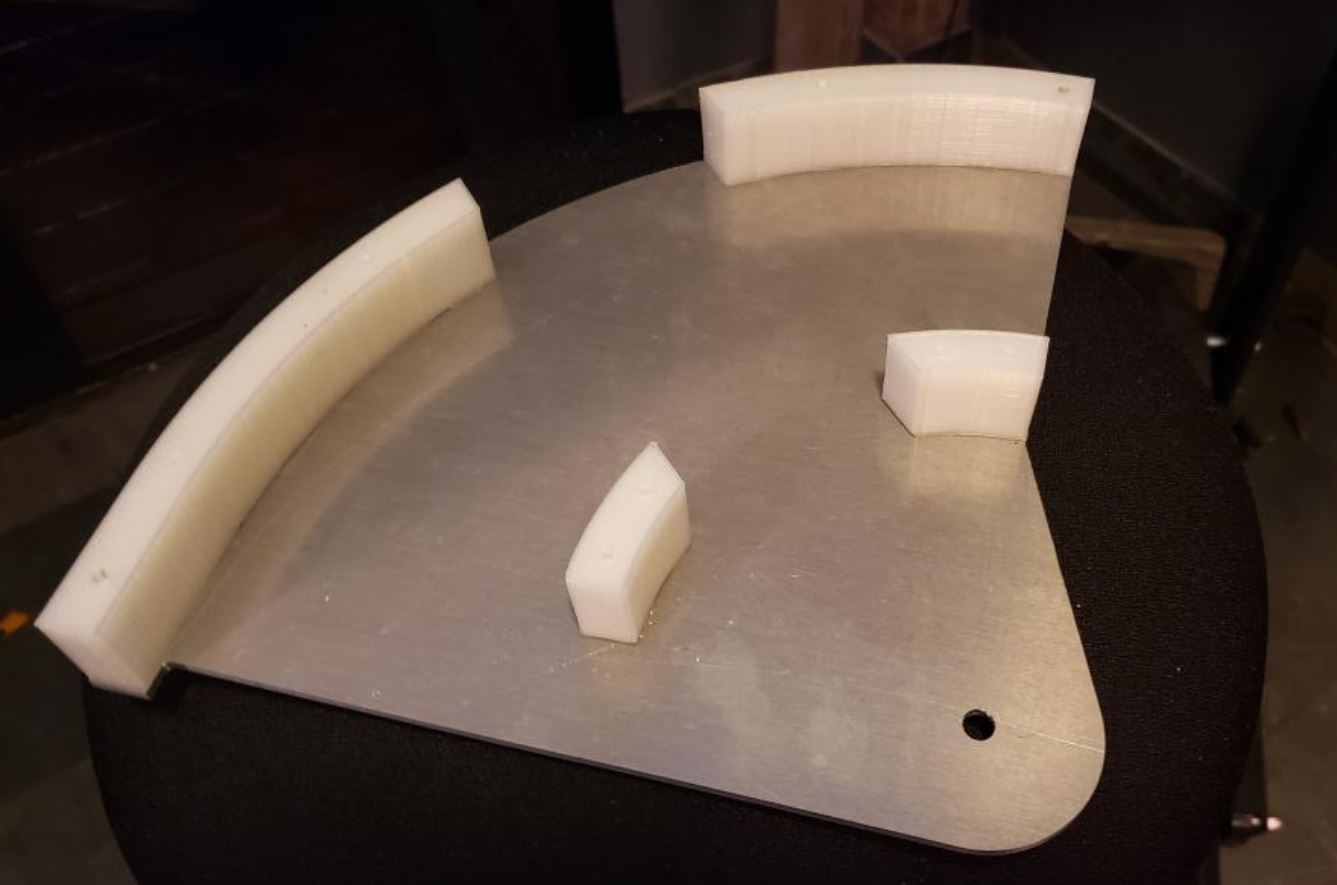

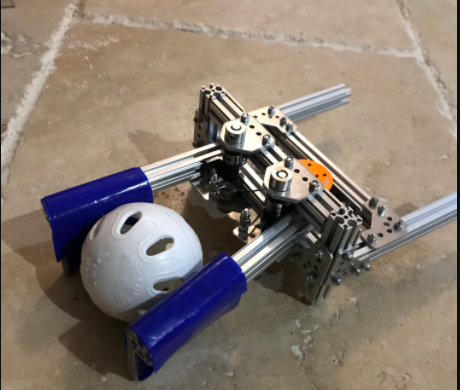

An example of these 3D printed parts are our wheel guards.

In testing, our mecanum drive train tended to cut up the cryptoboxes when we

drove up against them. As a result, we designed various wheel guards and tested

them. We also made mockups with various materials such as cardboard, to

minimize design time and waste parts. We settled on a U-shaped design to

prevent damage to the boxes and other field elements, while not sacrificing

mobility. Then, to guarantee nothing went wrong, we iterated through various

heights of the U-shape so that they would not cut into the mats or bump into

other robots

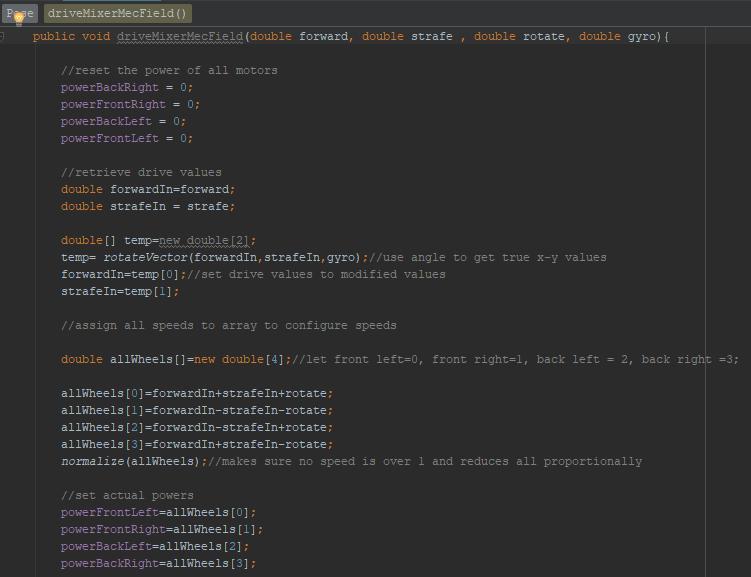

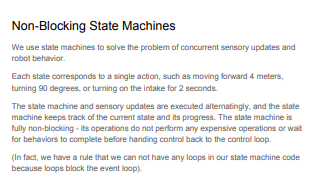

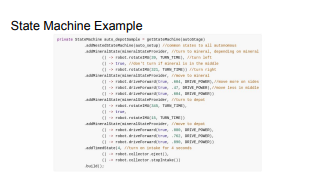

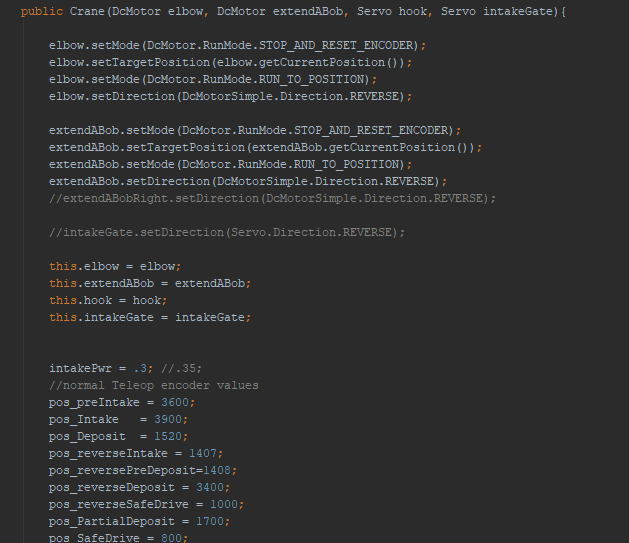

Programming

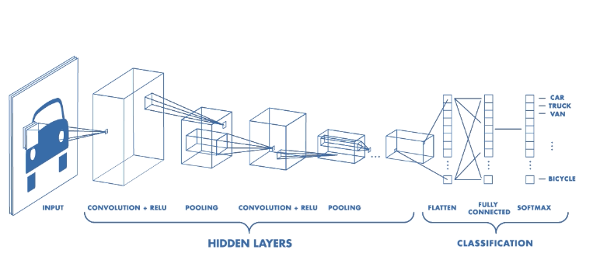

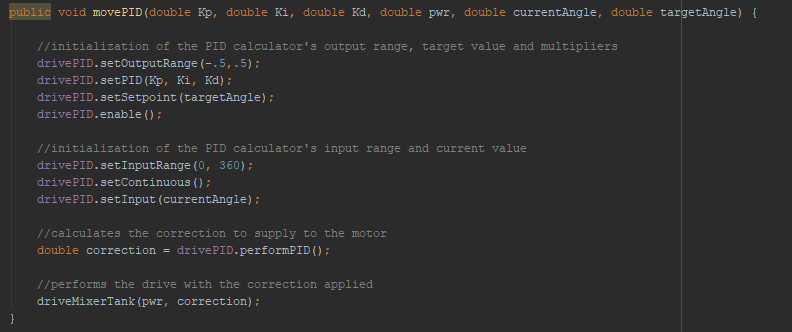

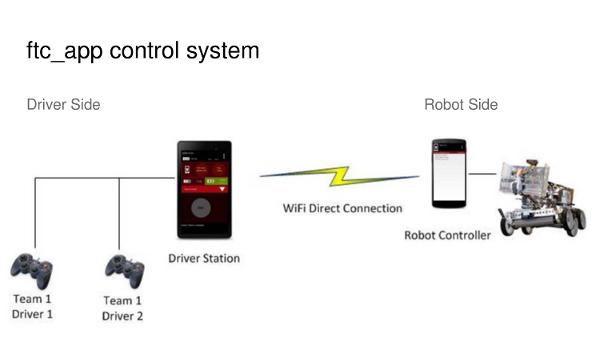

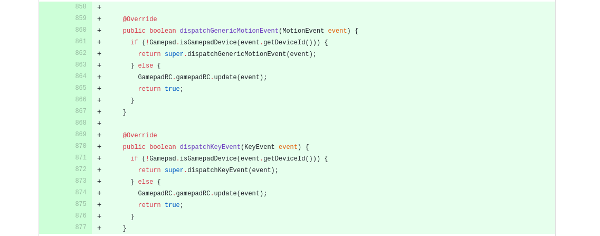

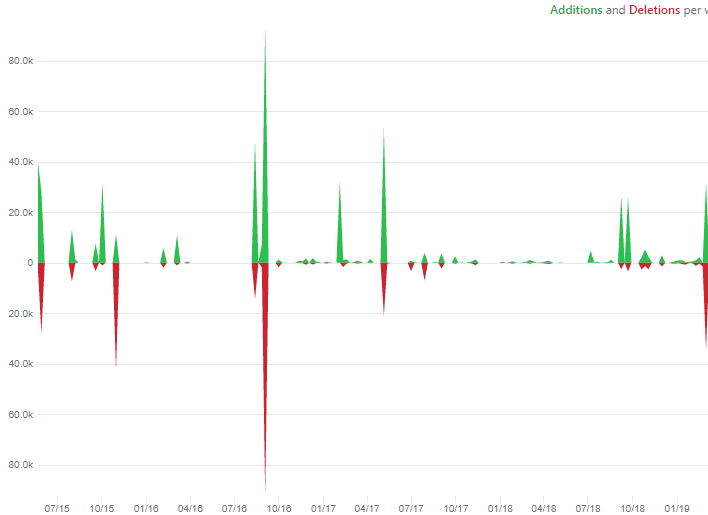

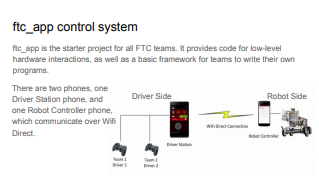

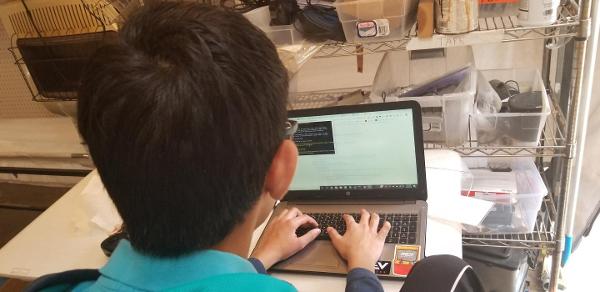

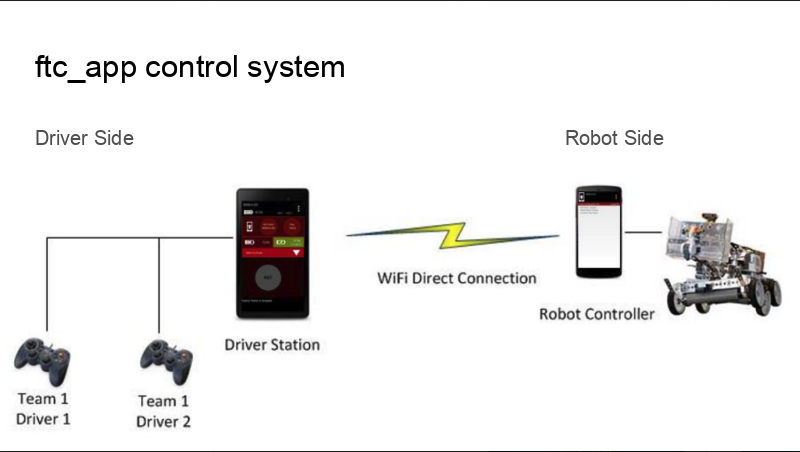

Iron Reign has generated a substantial codebase over the

years. Initially, Iron Reign programmed in RobotC. However, when robot phones

started becoming the main form of control, we transferred our

codebase into Java. We use the Android Studio IDE to code our robot.

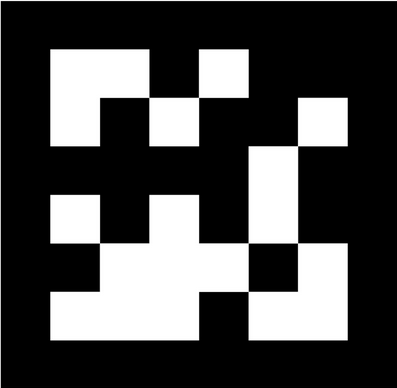

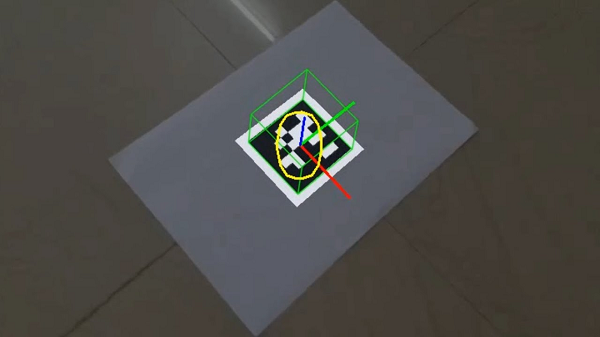

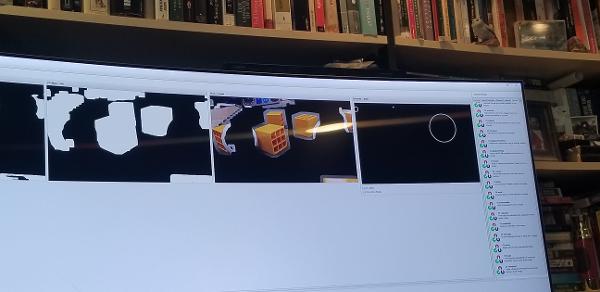

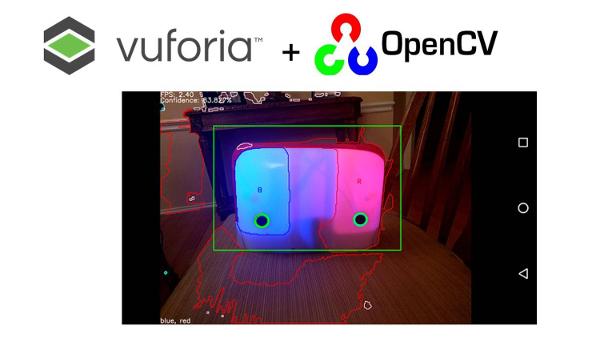

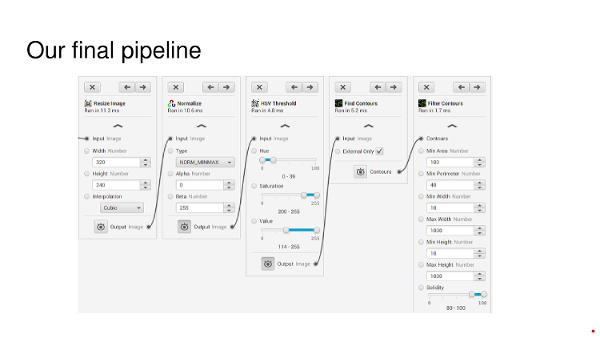

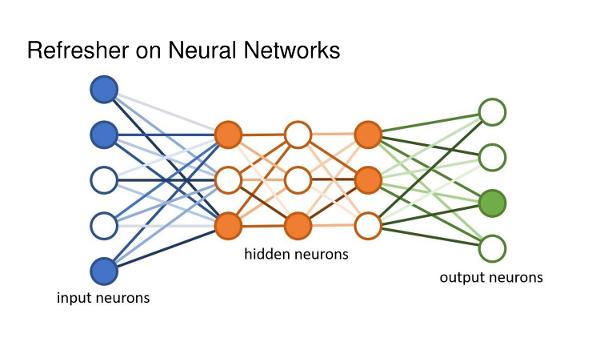

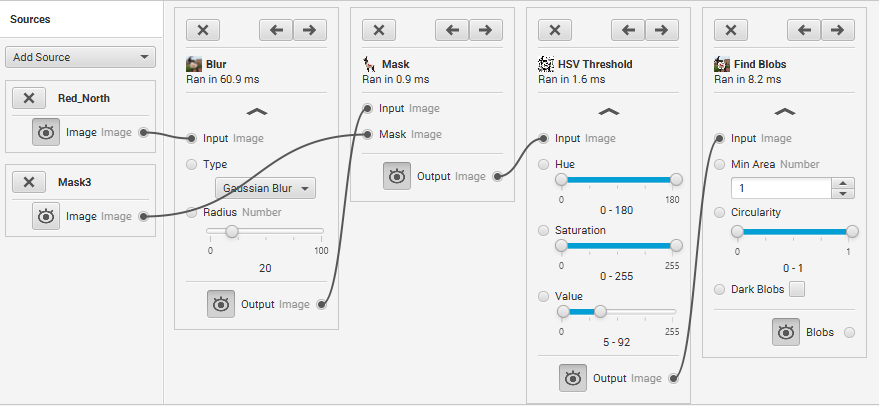

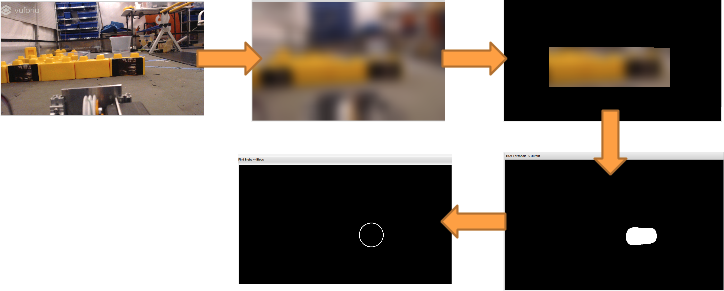

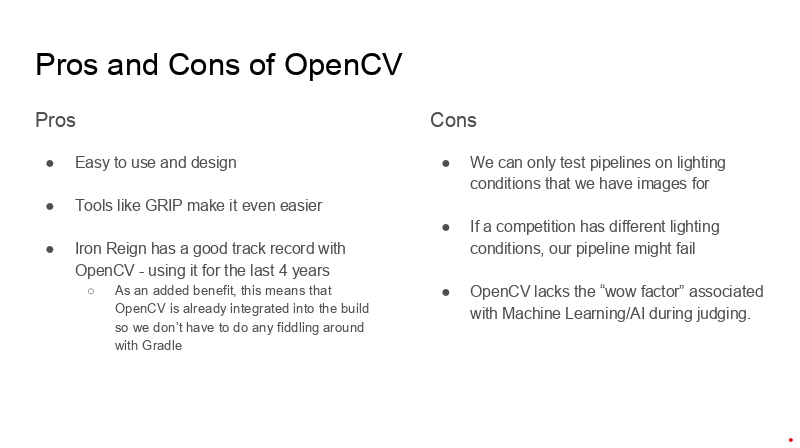

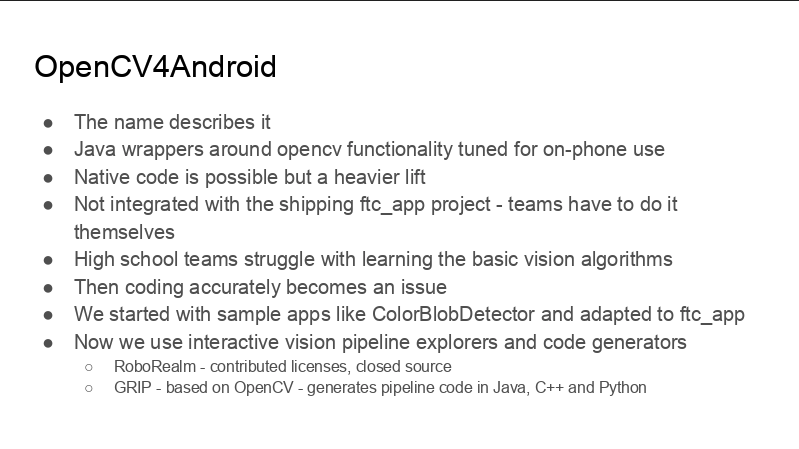

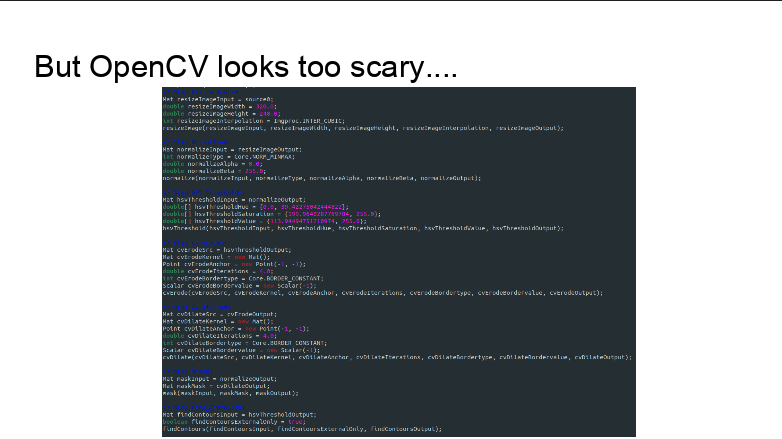

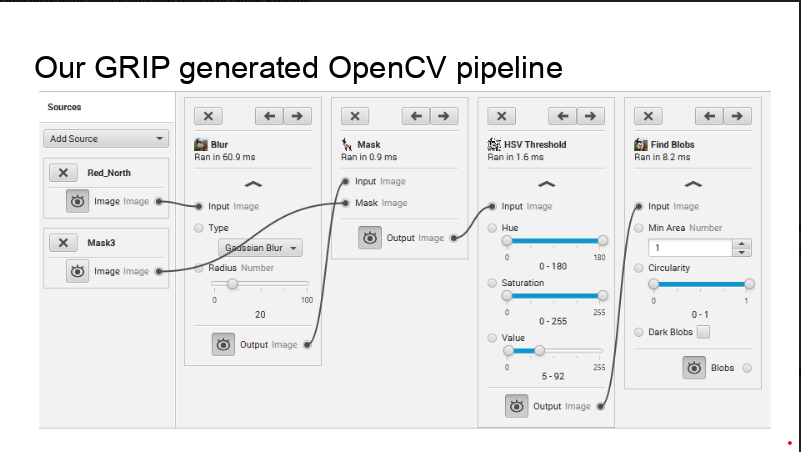

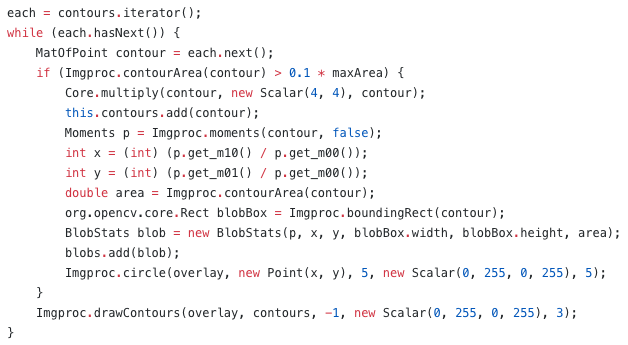

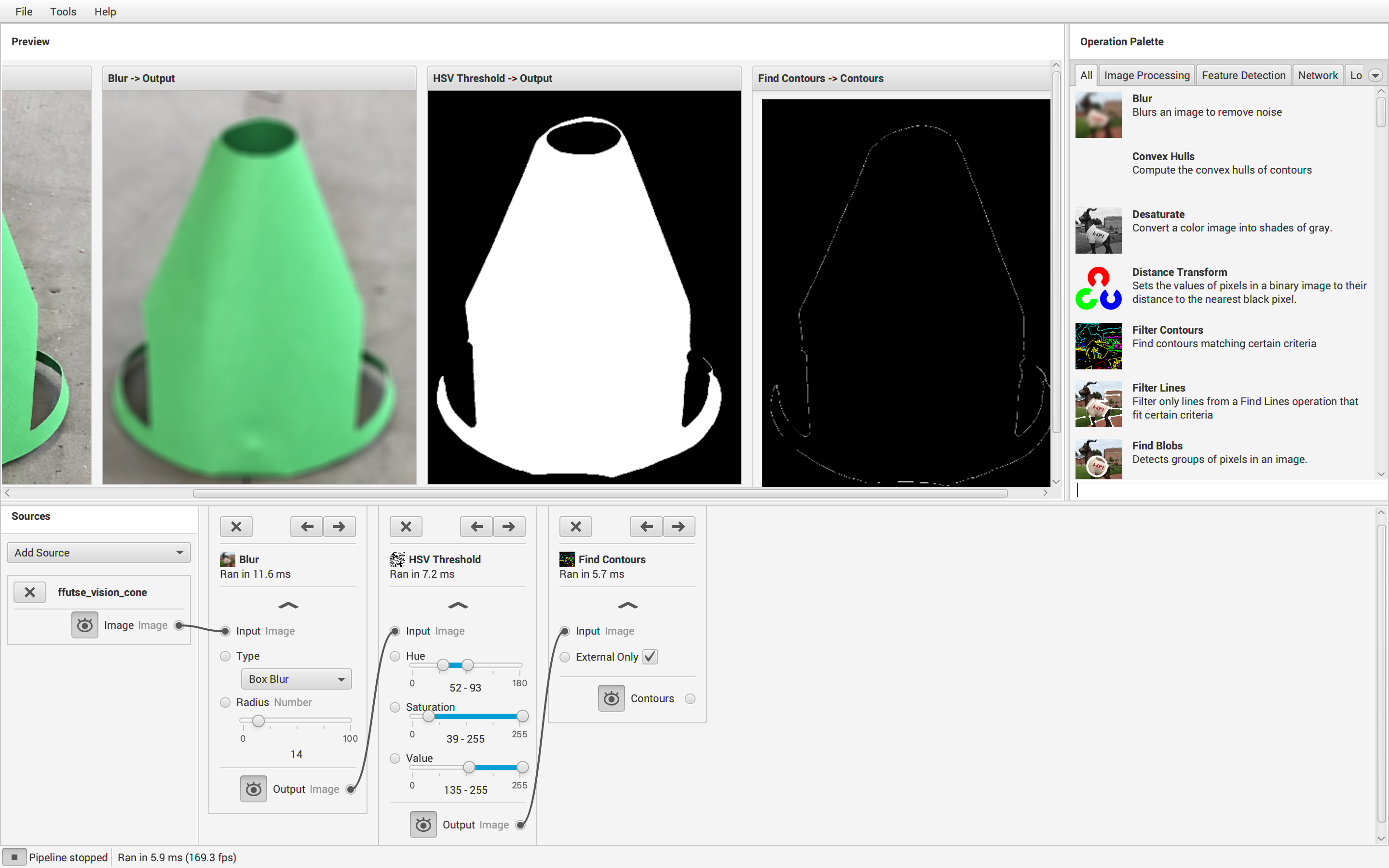

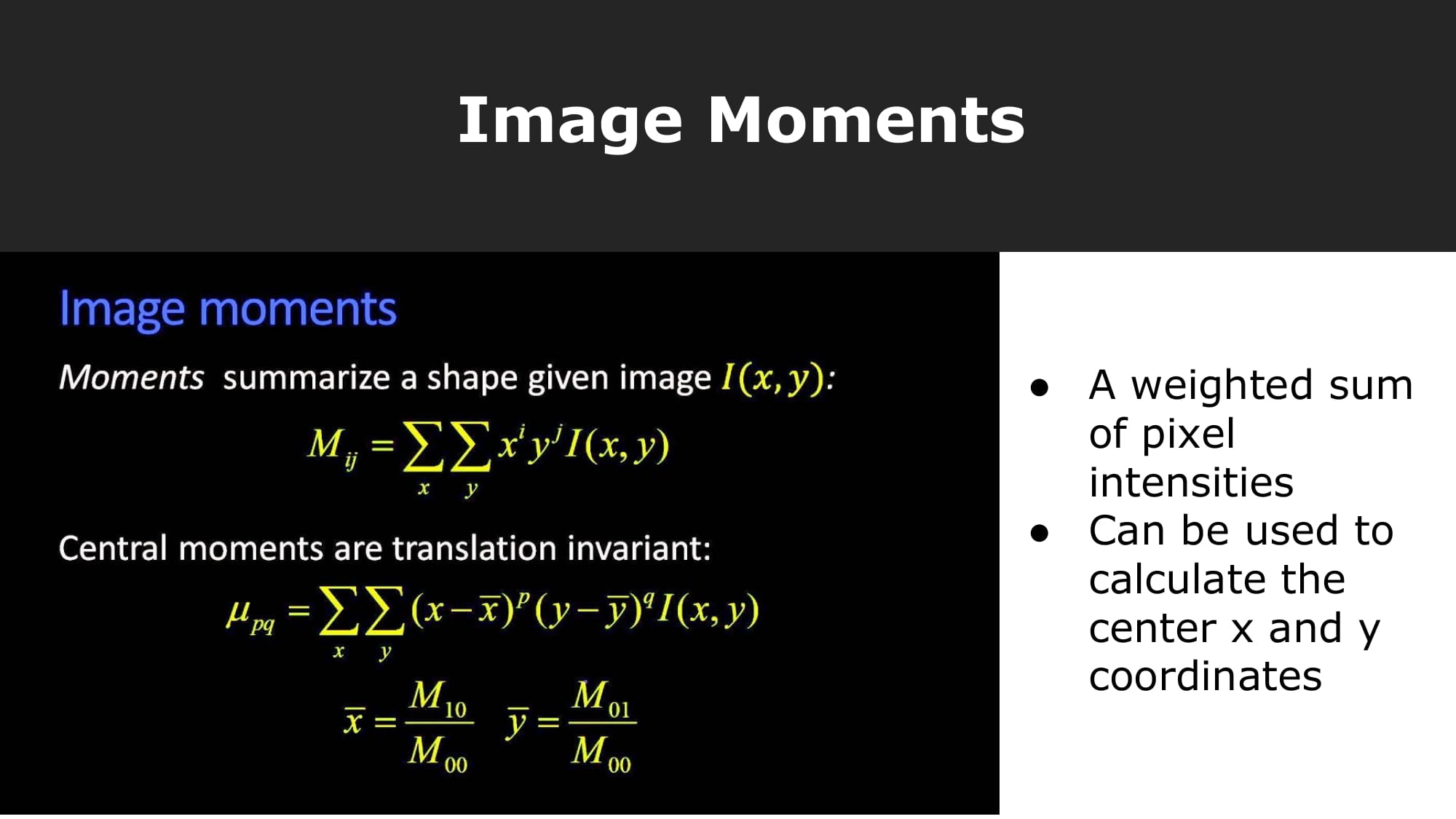

Our most notable programming achievement has been the

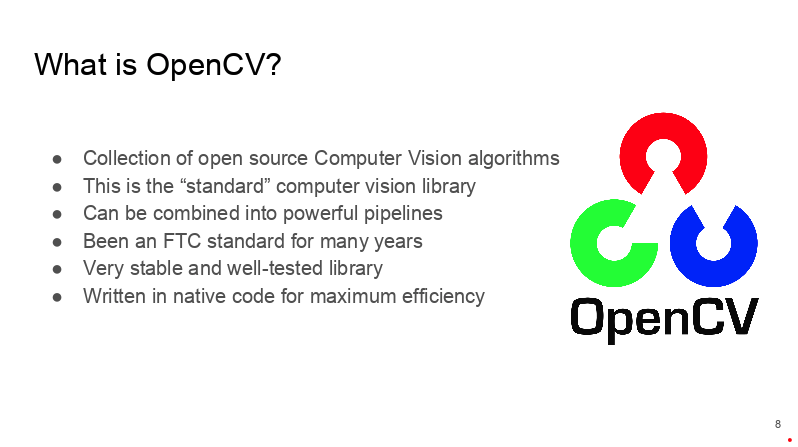

integration of machine vision and augmented reality libraries into our code.

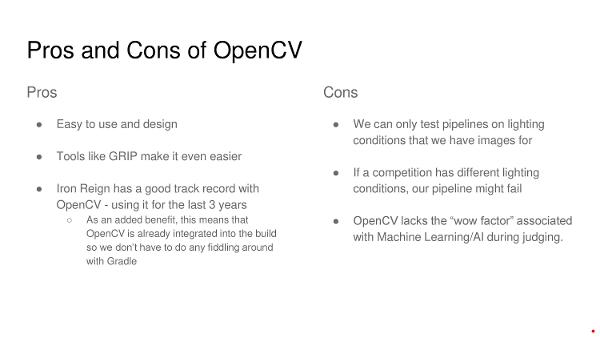

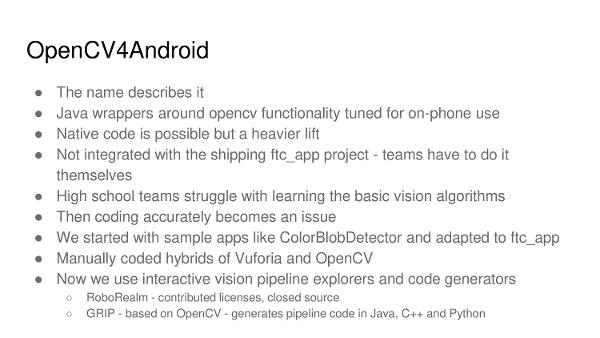

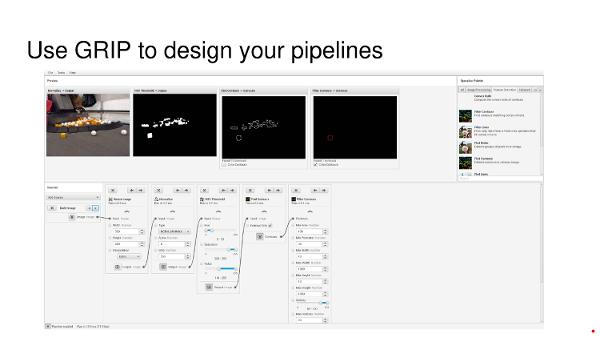

Currently, we use Vuforia in conjunction with OpenCV to identify and score

field elements in autonomous, as well as assist in scoring elements during

TeleOp. Both Vuforia and OpenCV are industrial-level technologies that we have

integrated into our codebase. Vuforia in particular is

currently owned by PTC, one of the sponsors of FIRST.

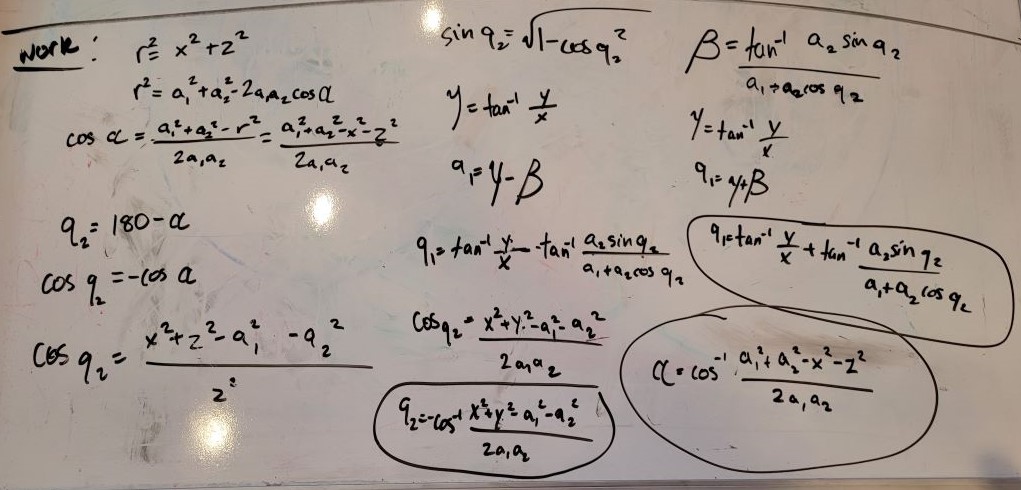

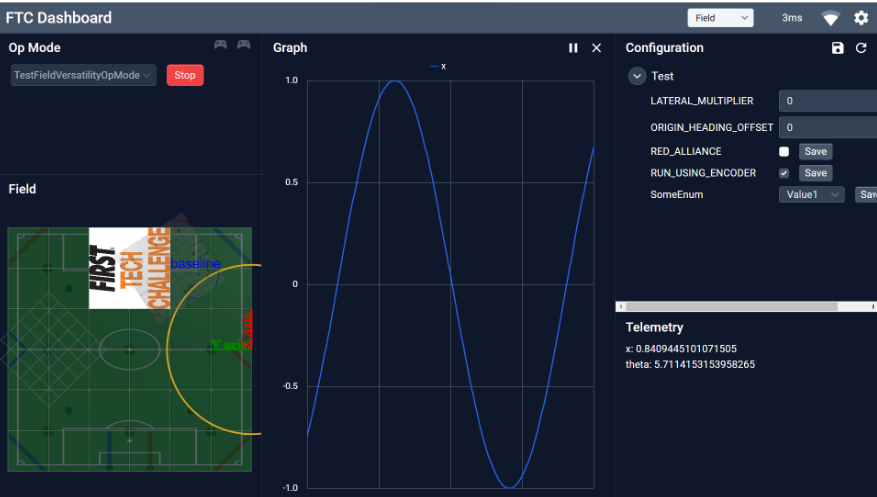

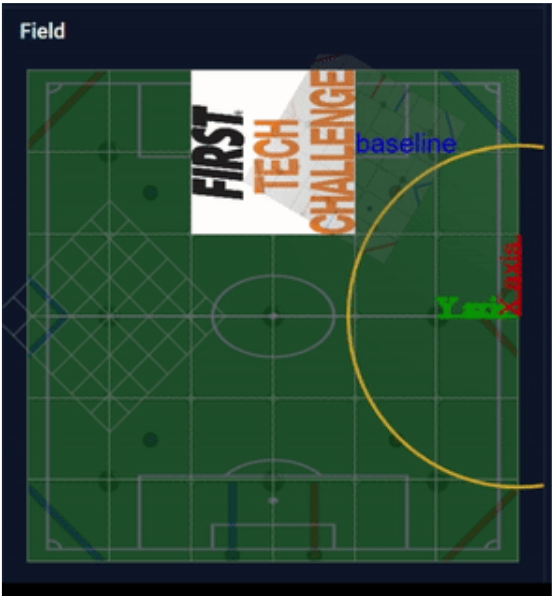

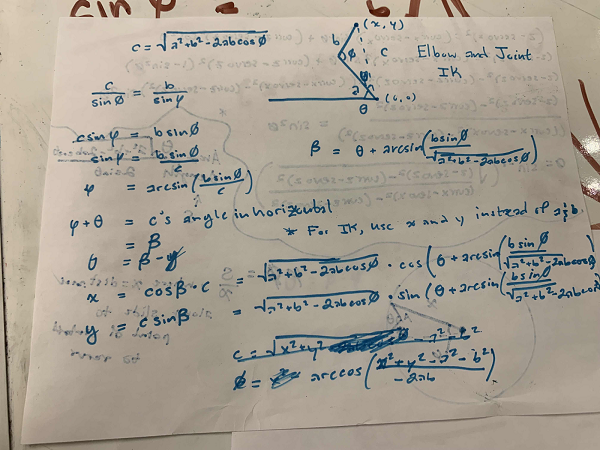

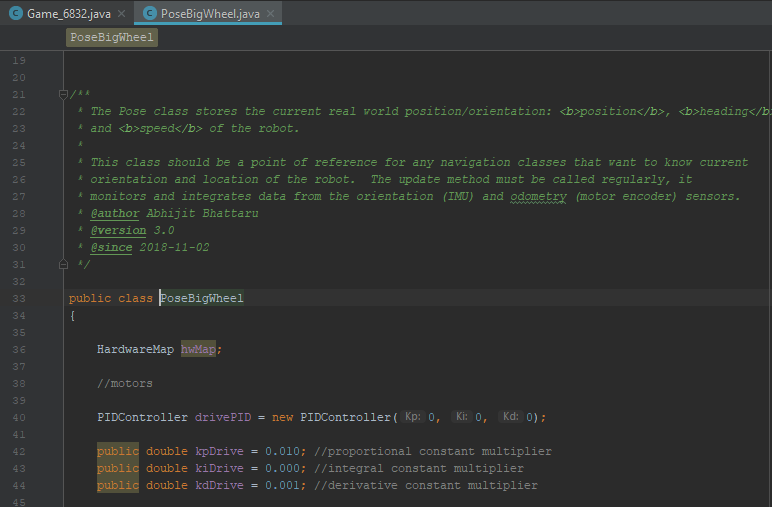

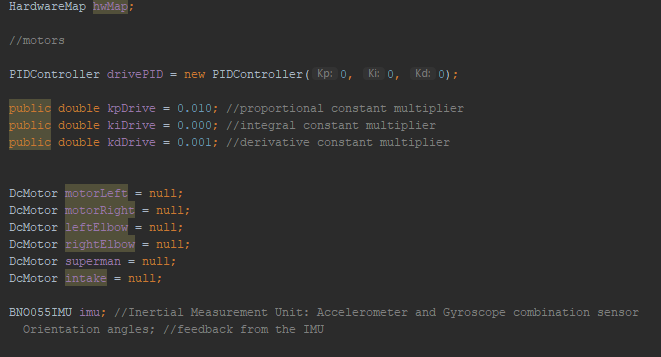

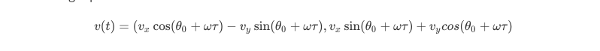

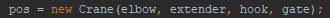

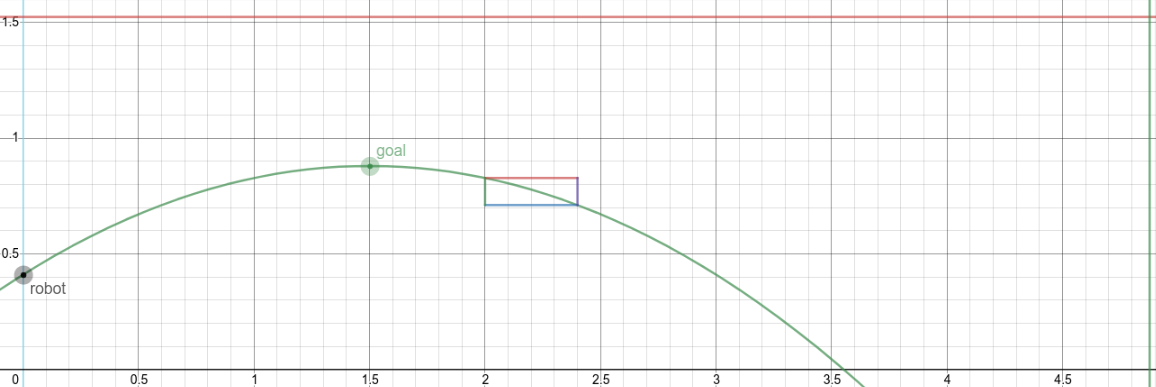

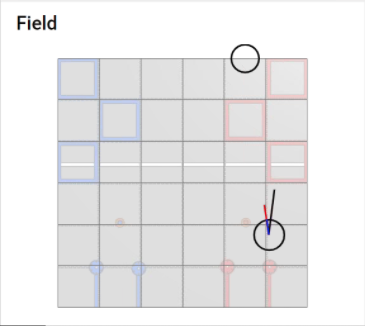

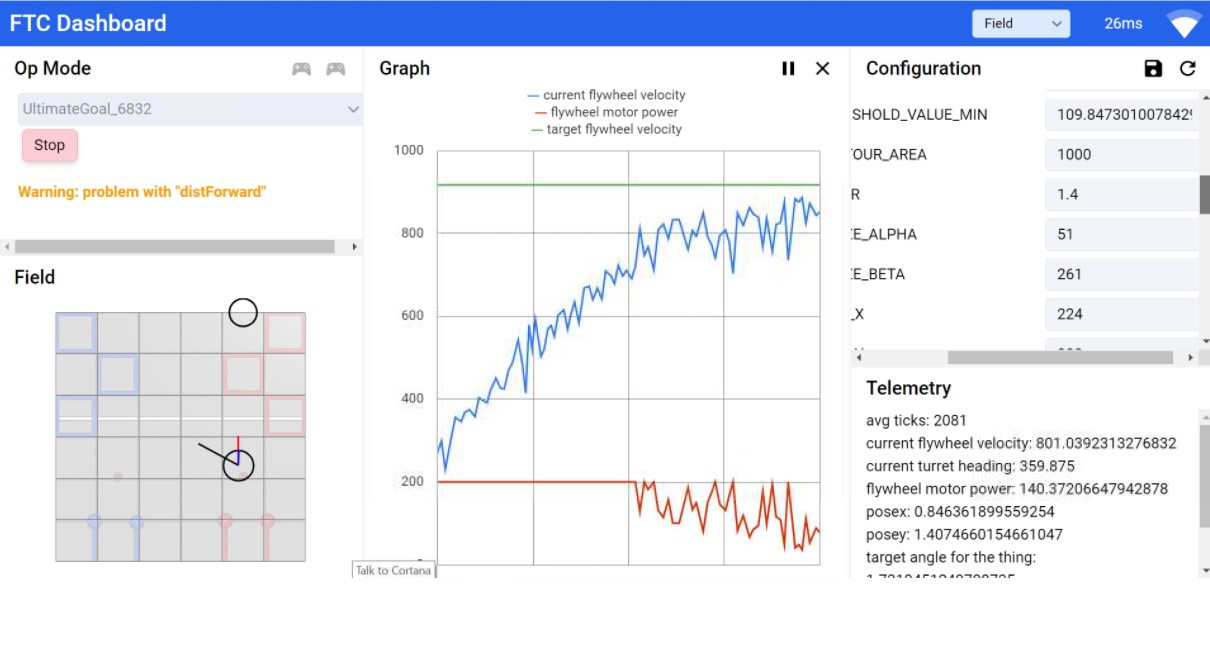

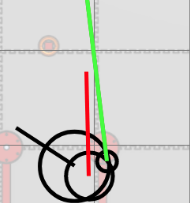

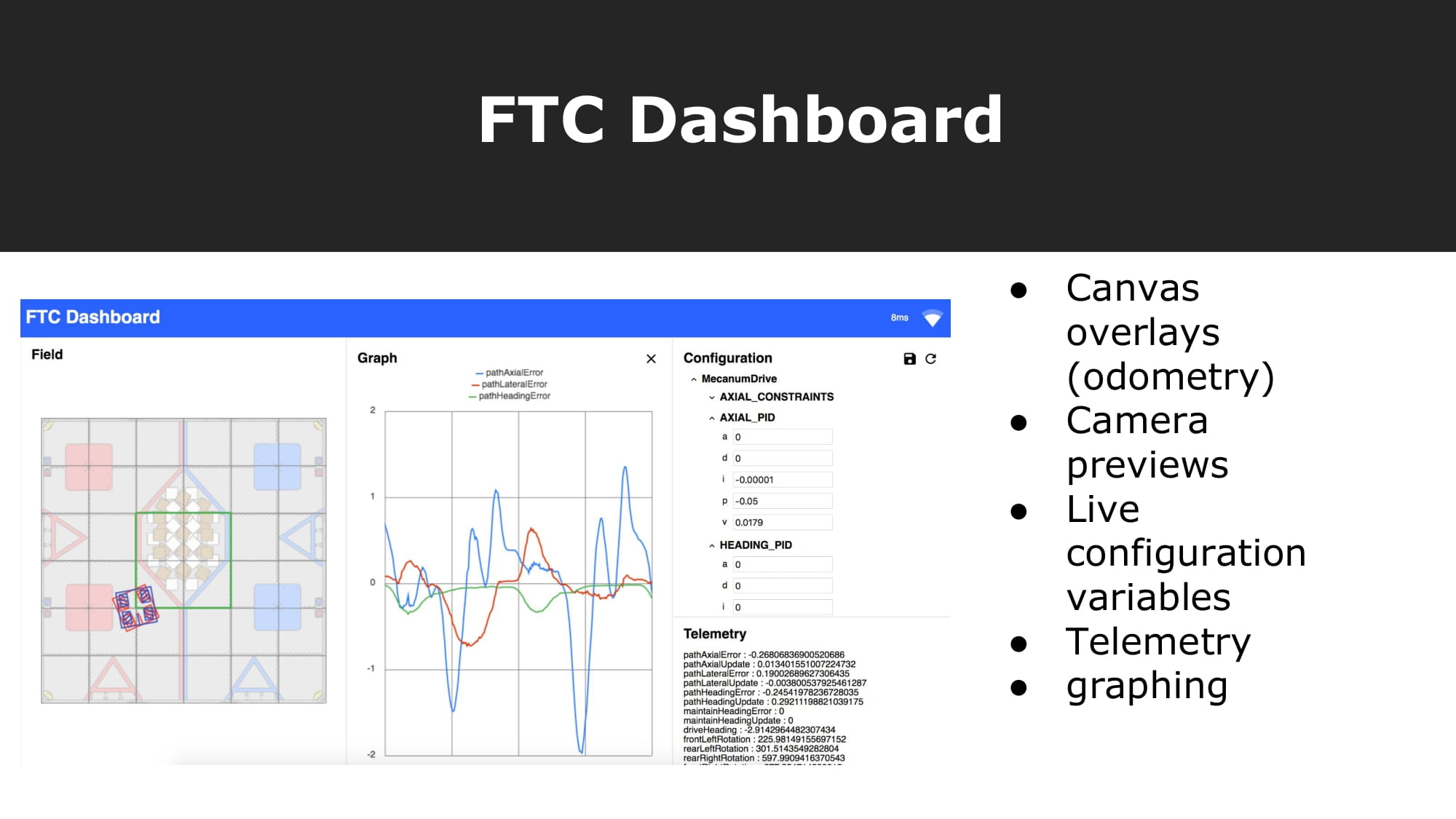

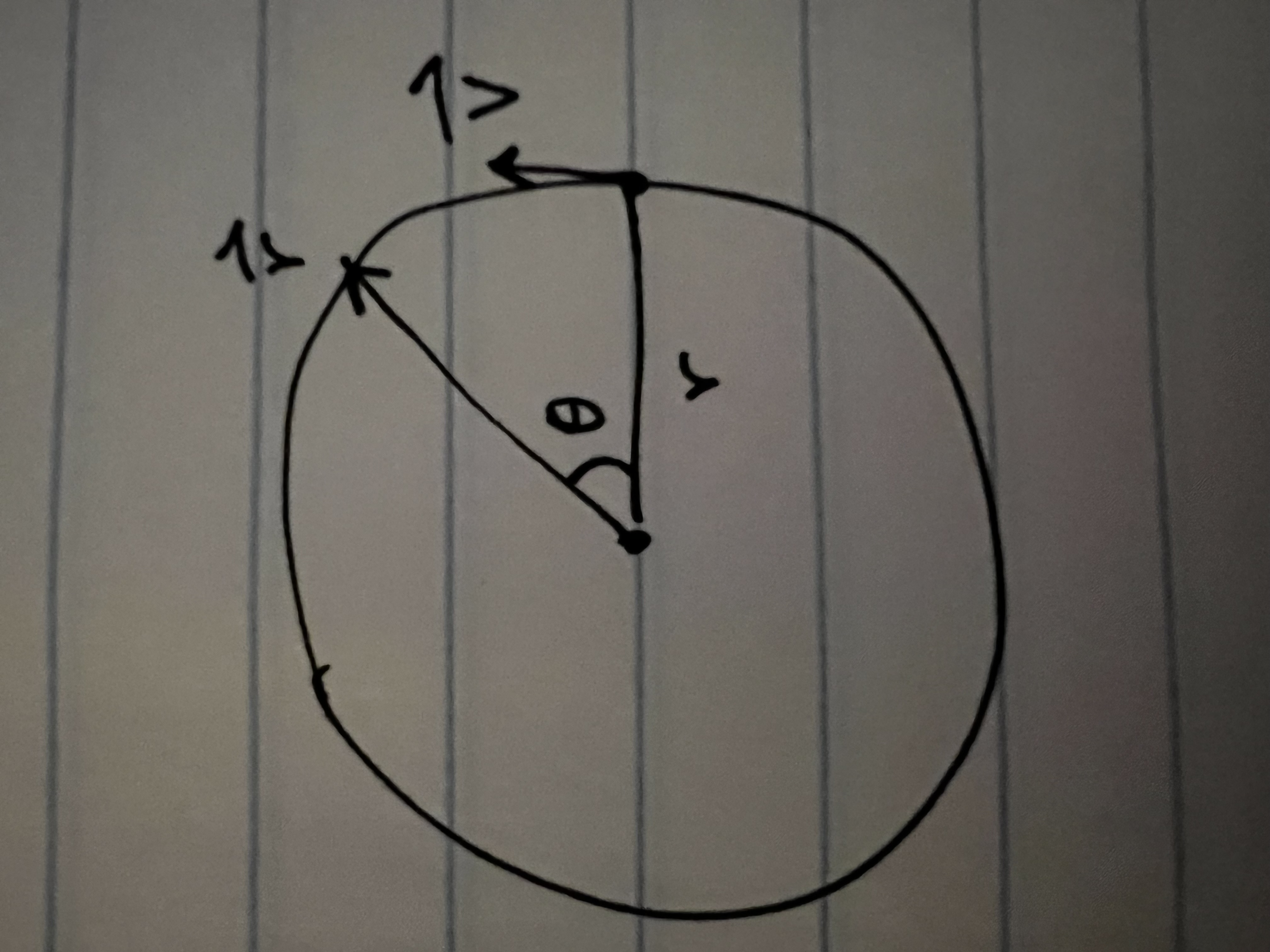

Another notable programming achievement is our Pose class.

We use the class to determine our robot’s current position on the field using

trigonometric functions. While this class currently need updating for the new

season, it can still be used for any small-scale operations on the field.

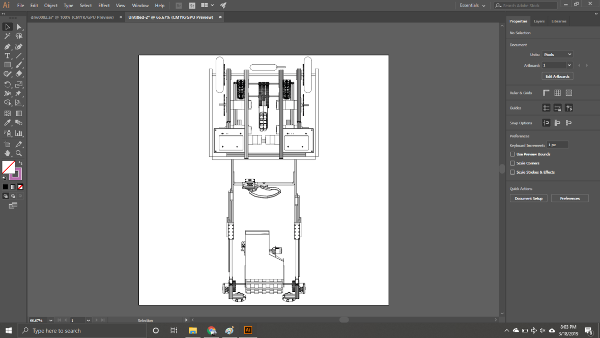

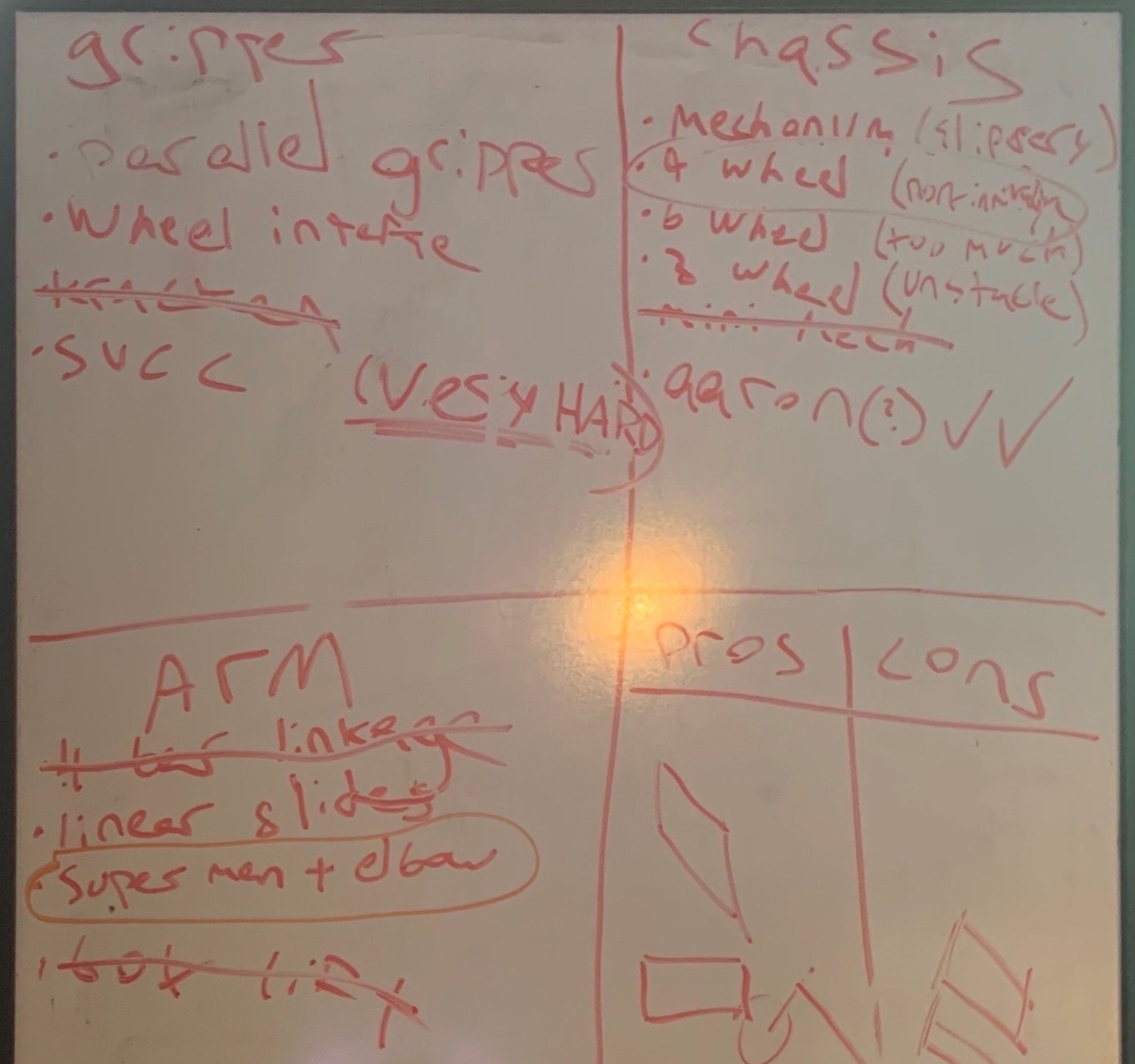

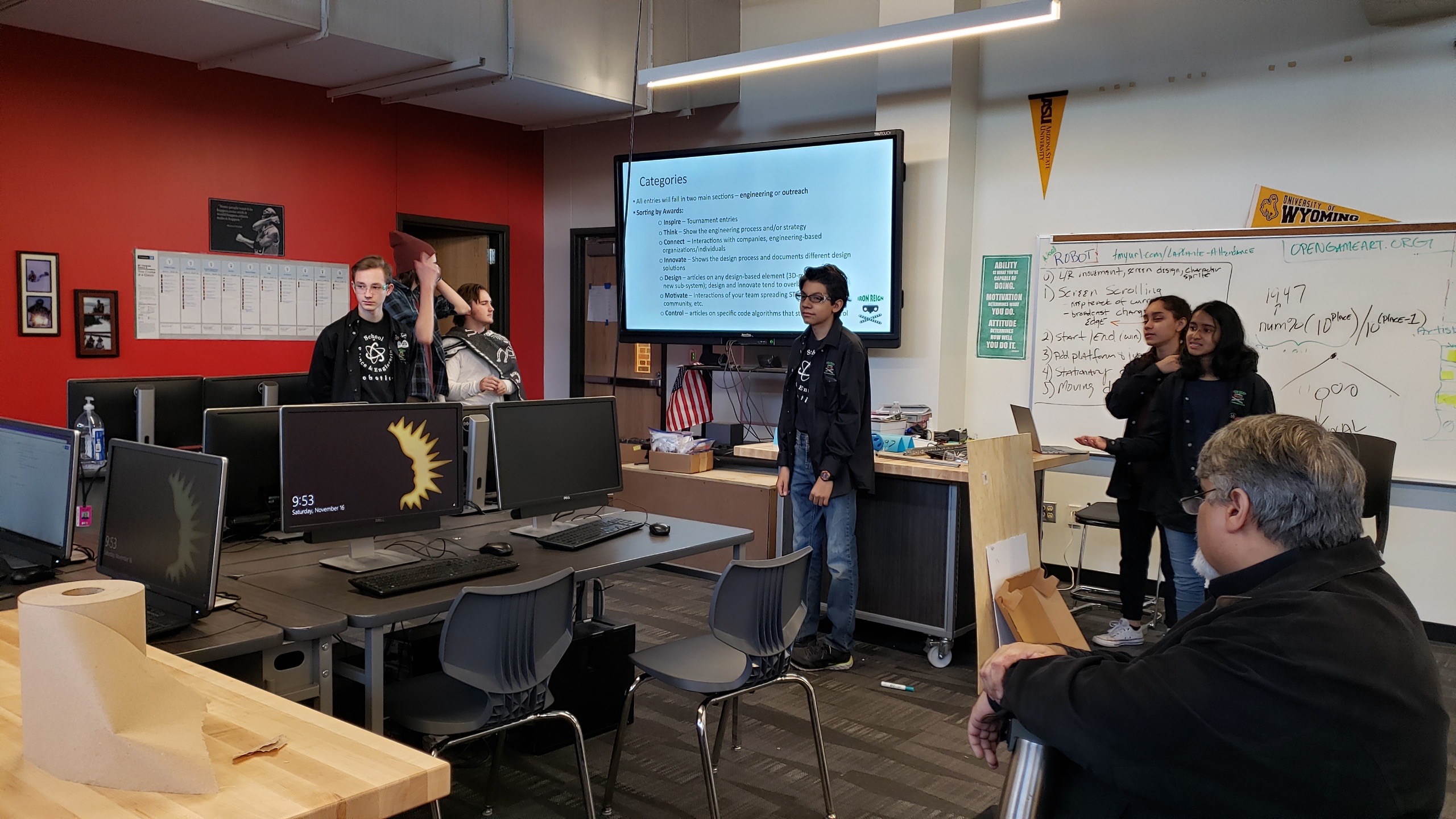

Design Process

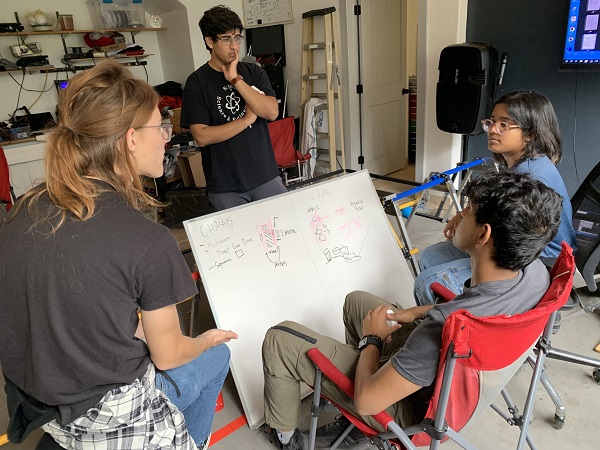

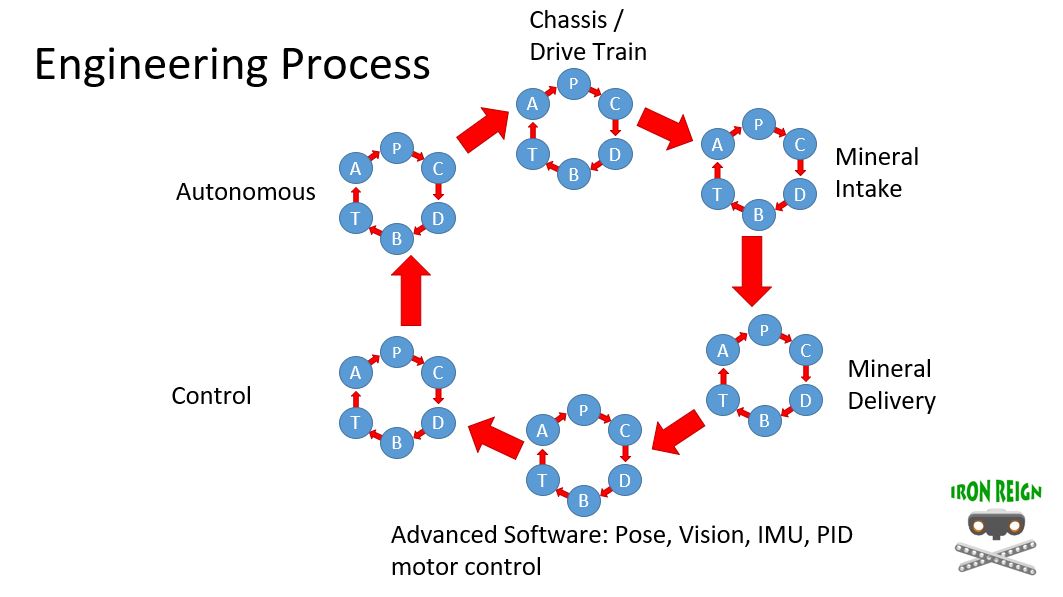

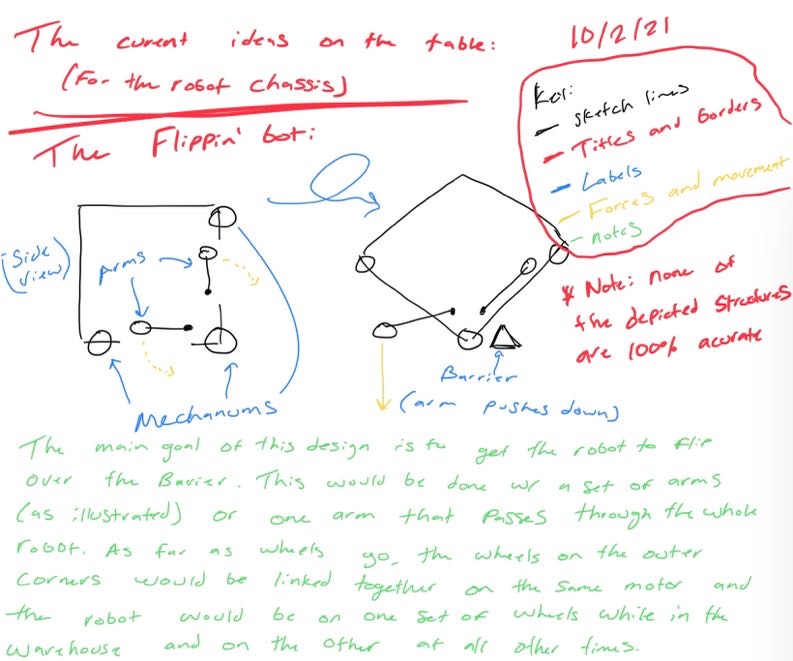

Iron Reign uses two design processes in conjunction with

each other to create efficient and reliable parts. First, we use the Kaizen

design process, also used in industrial corporations such as Toyota. The

philosophy behind Kaizen is the idea of continual improvement, that there is

always some modification to each system on our robot that will make it more

efficient or more reliable. As well, design competitions are a focal point of

Iron Reign’s design process. In these design competitions, team members choose

their favored designs that all complete some field challenge, and build them

individually. Upon completion of each mechanism, the designs are tested against

each other, considering weight, maneuverability, reliability, and efficiency.

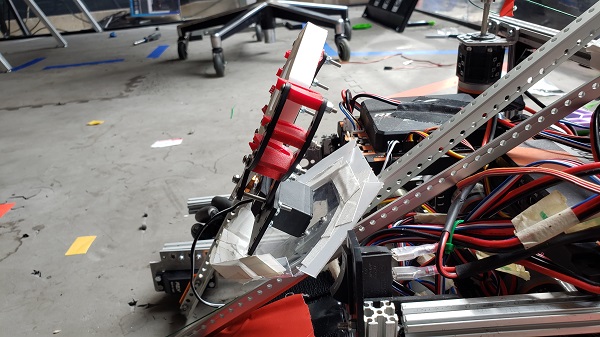

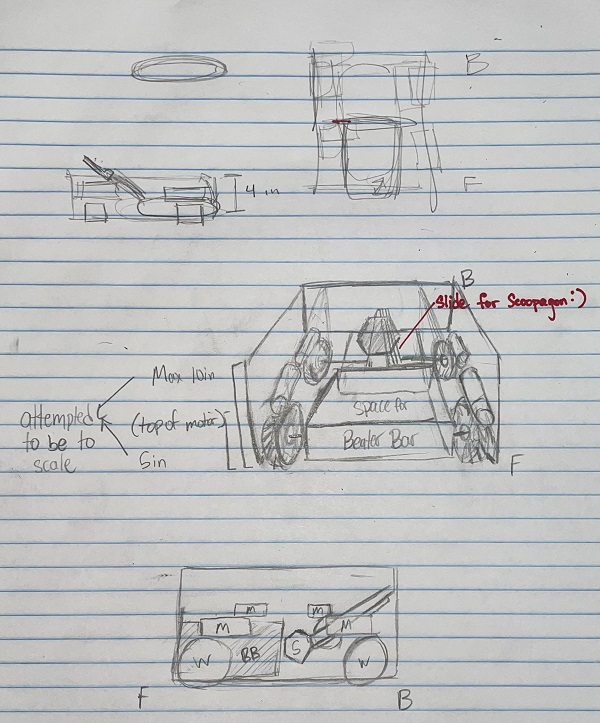

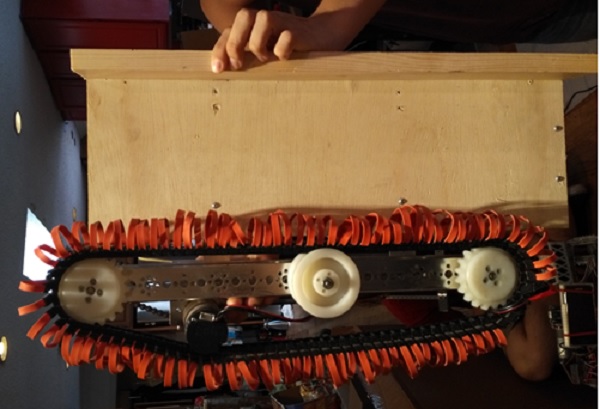

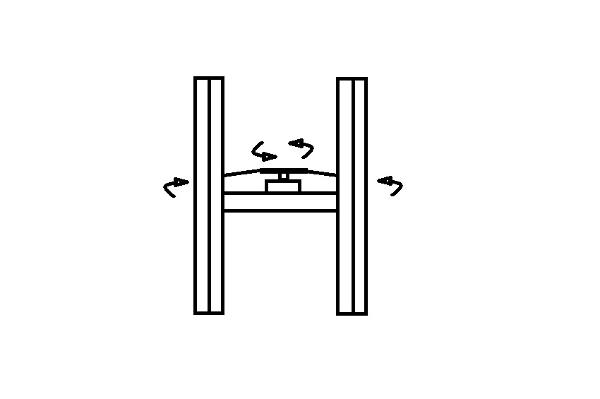

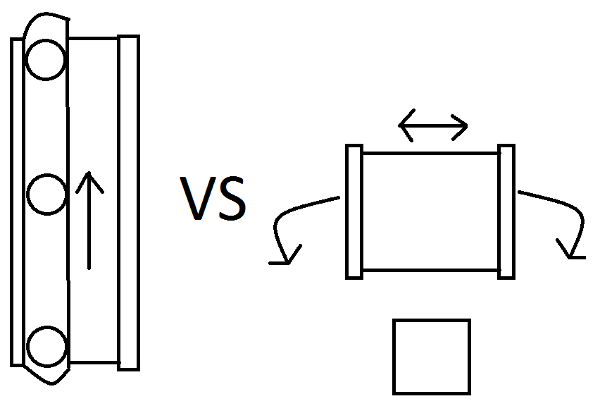

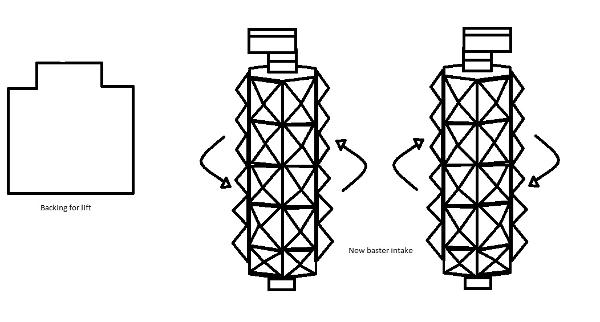

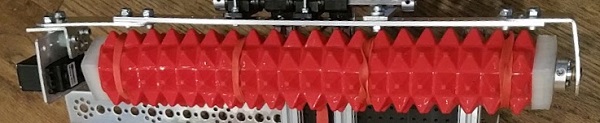

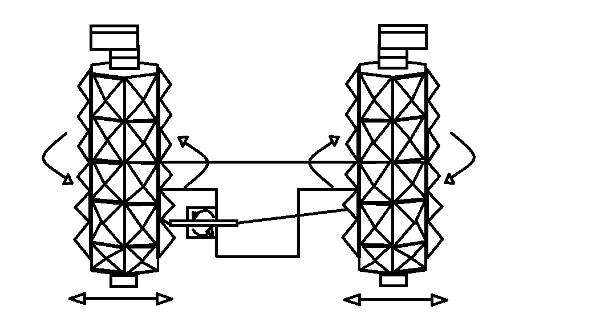

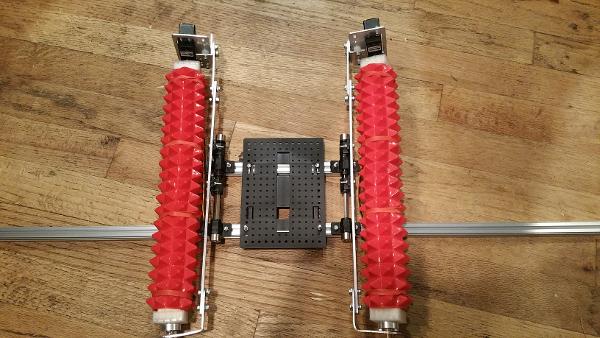

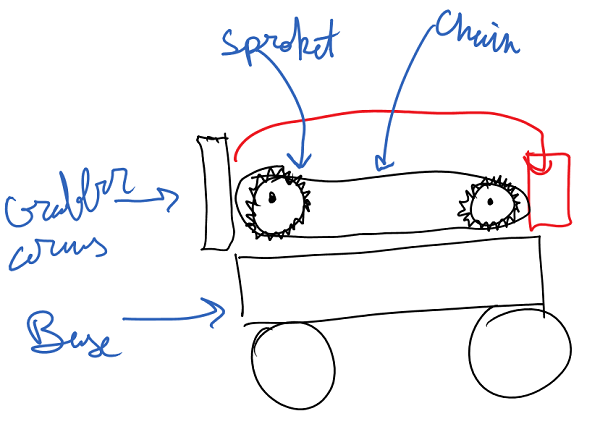

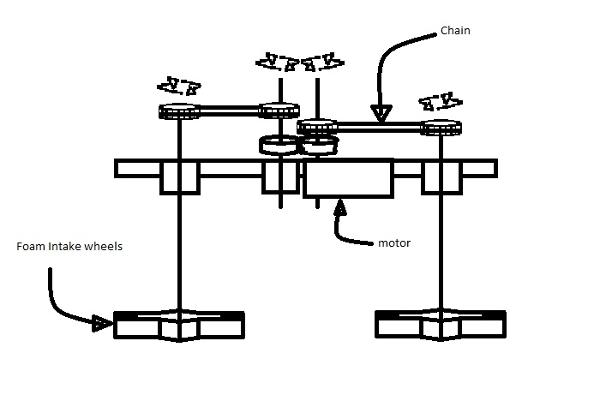

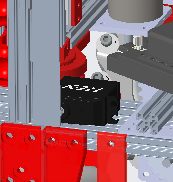

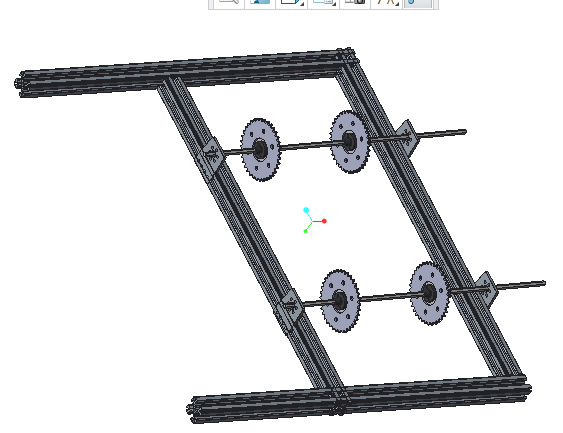

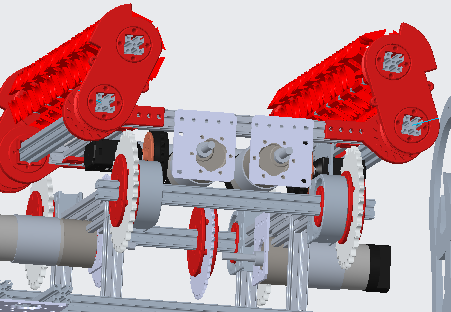

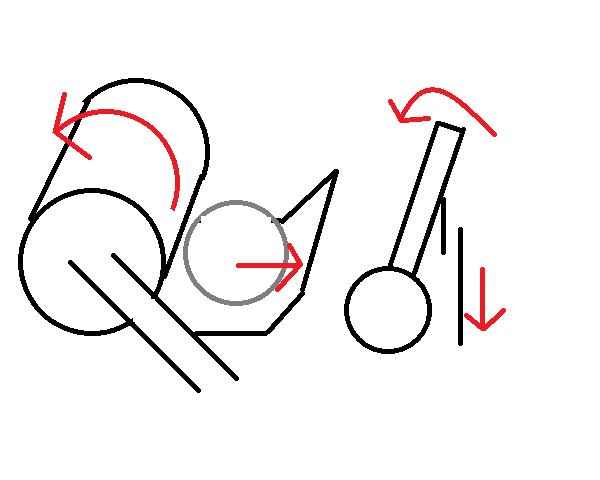

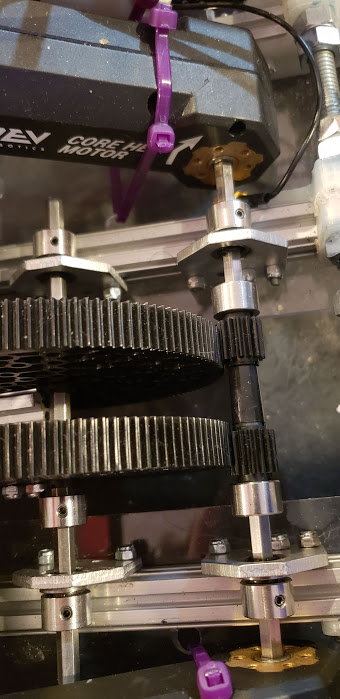

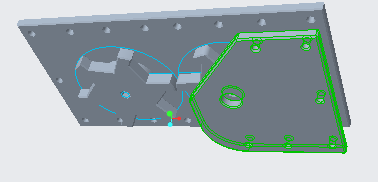

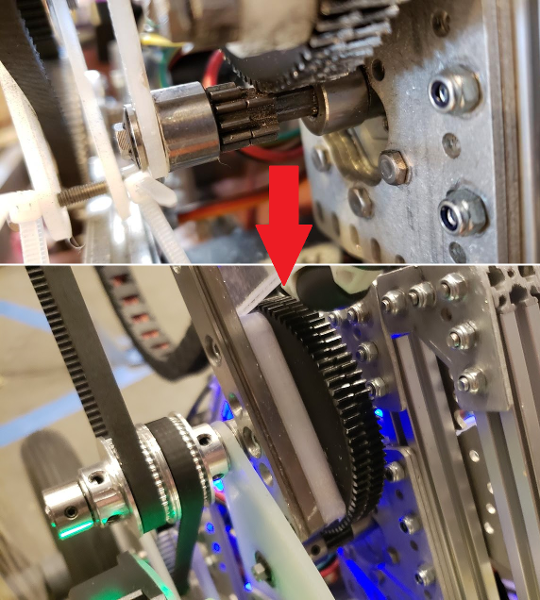

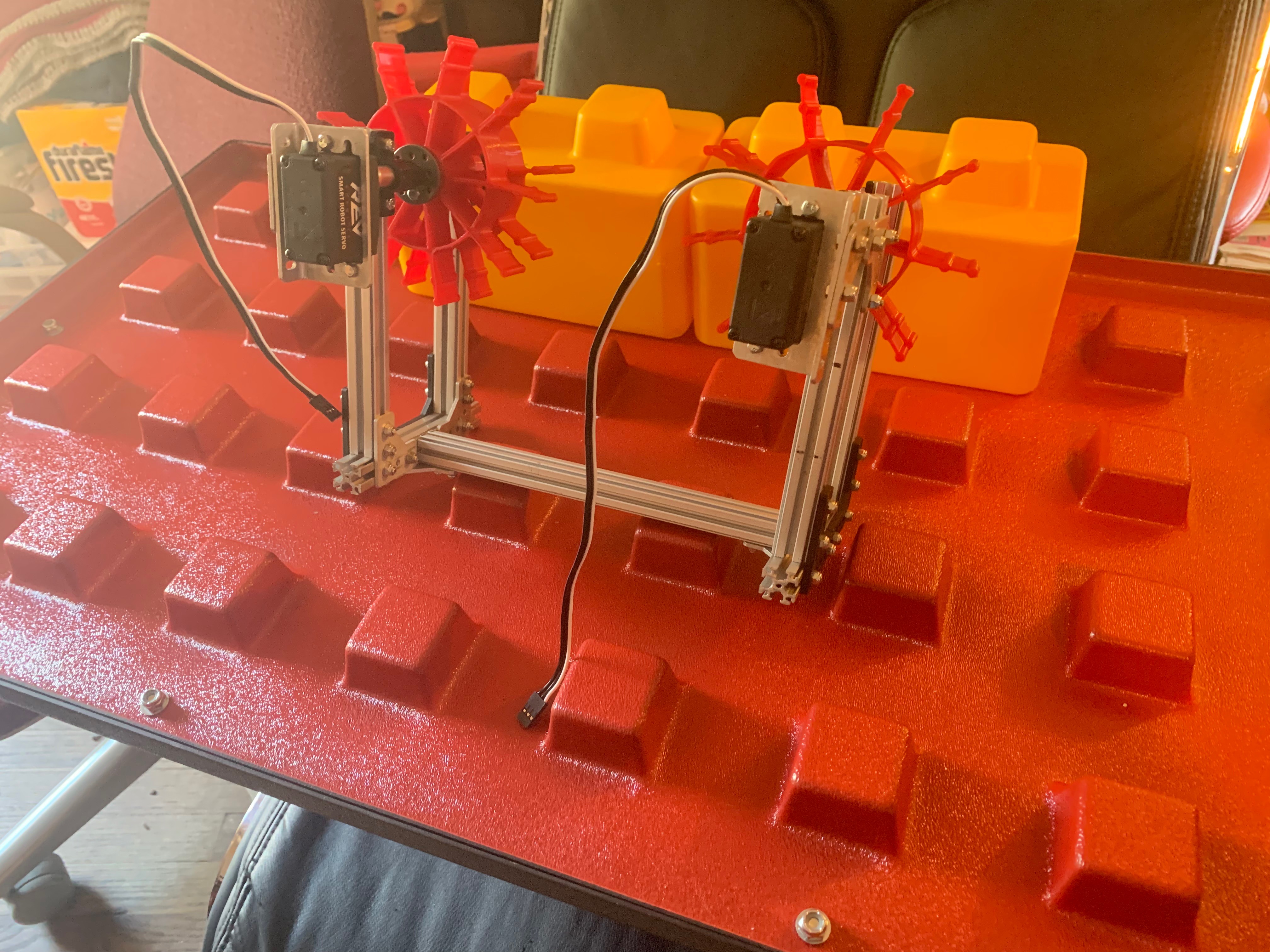

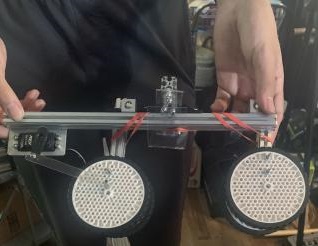

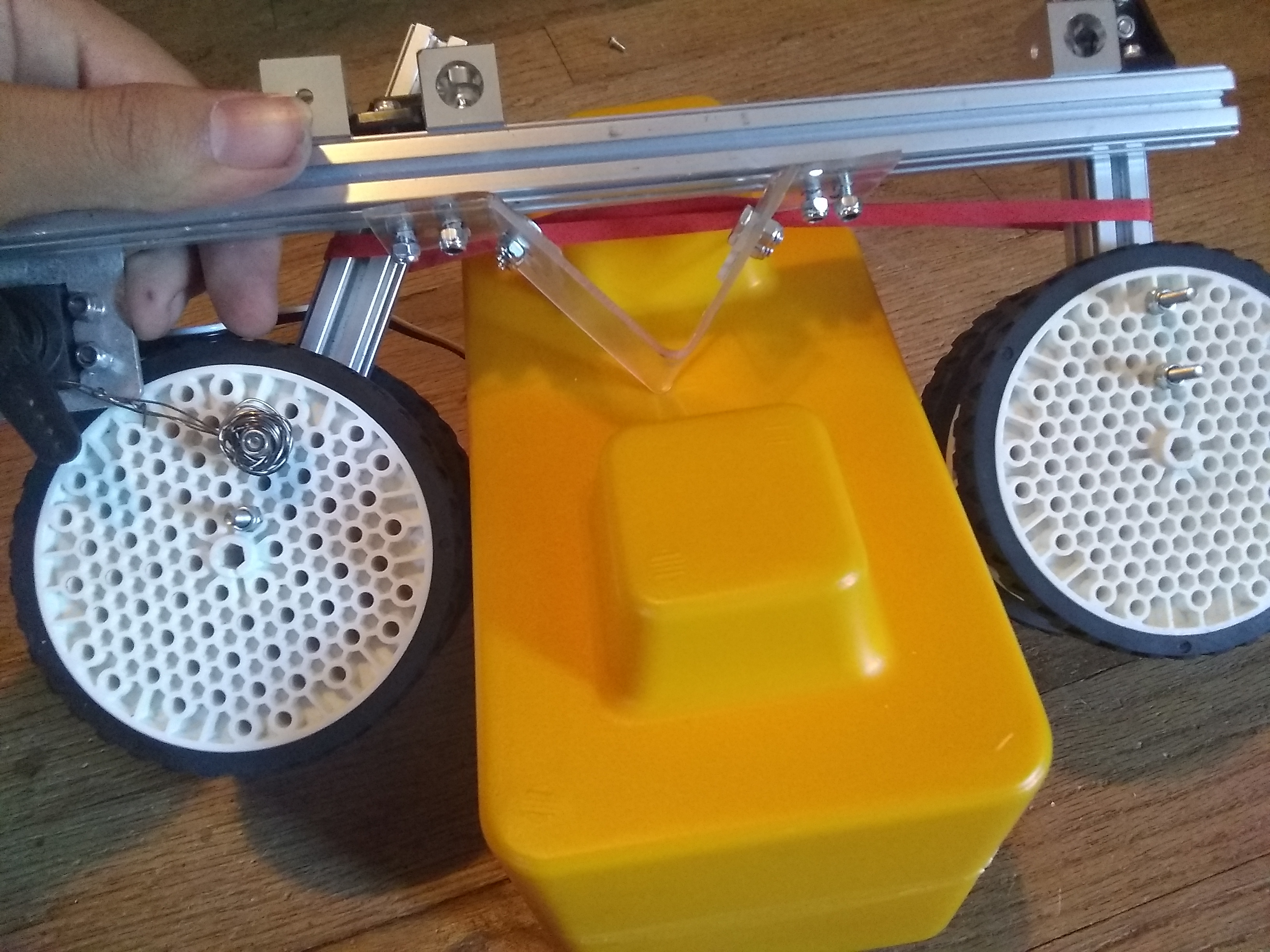

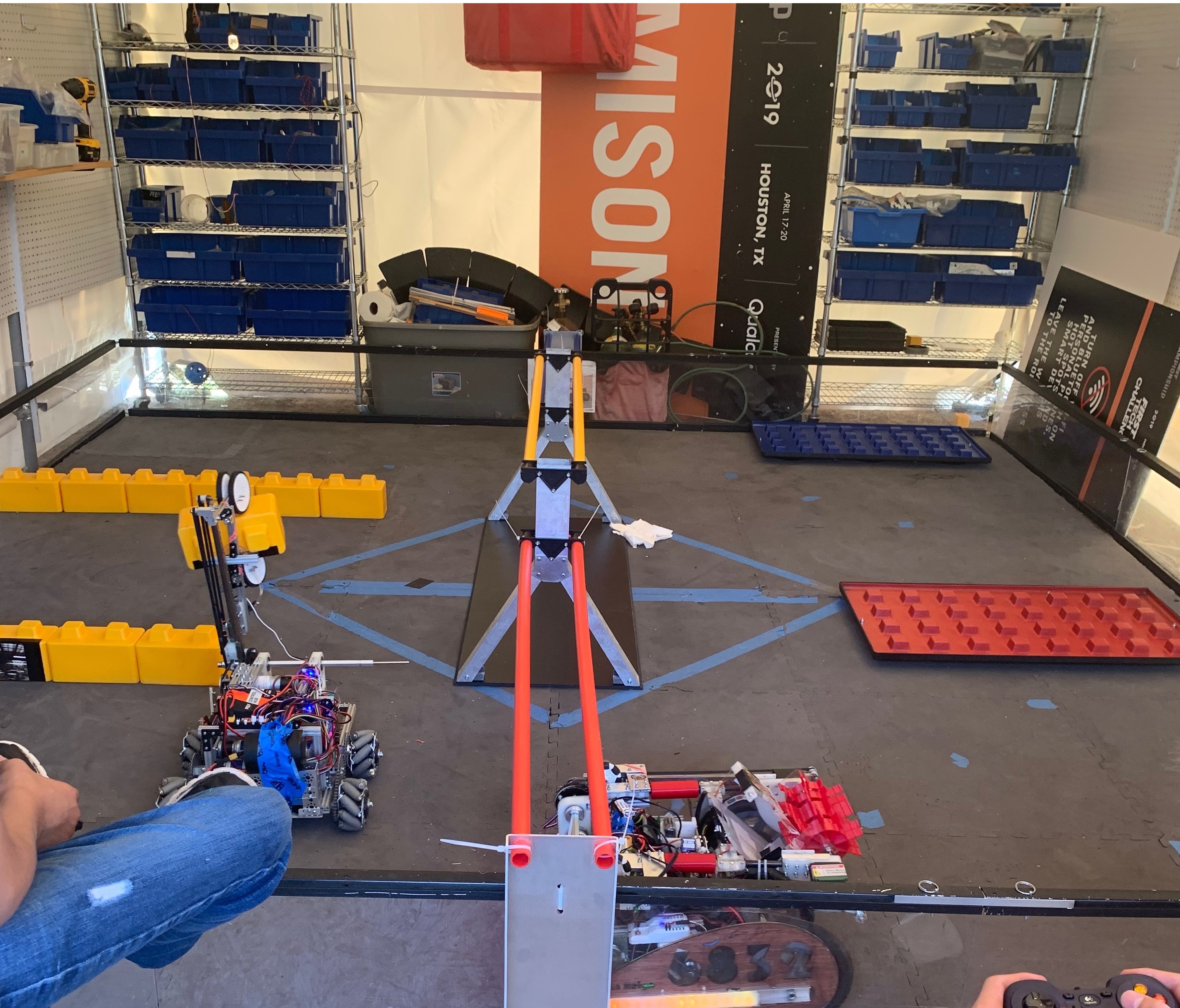

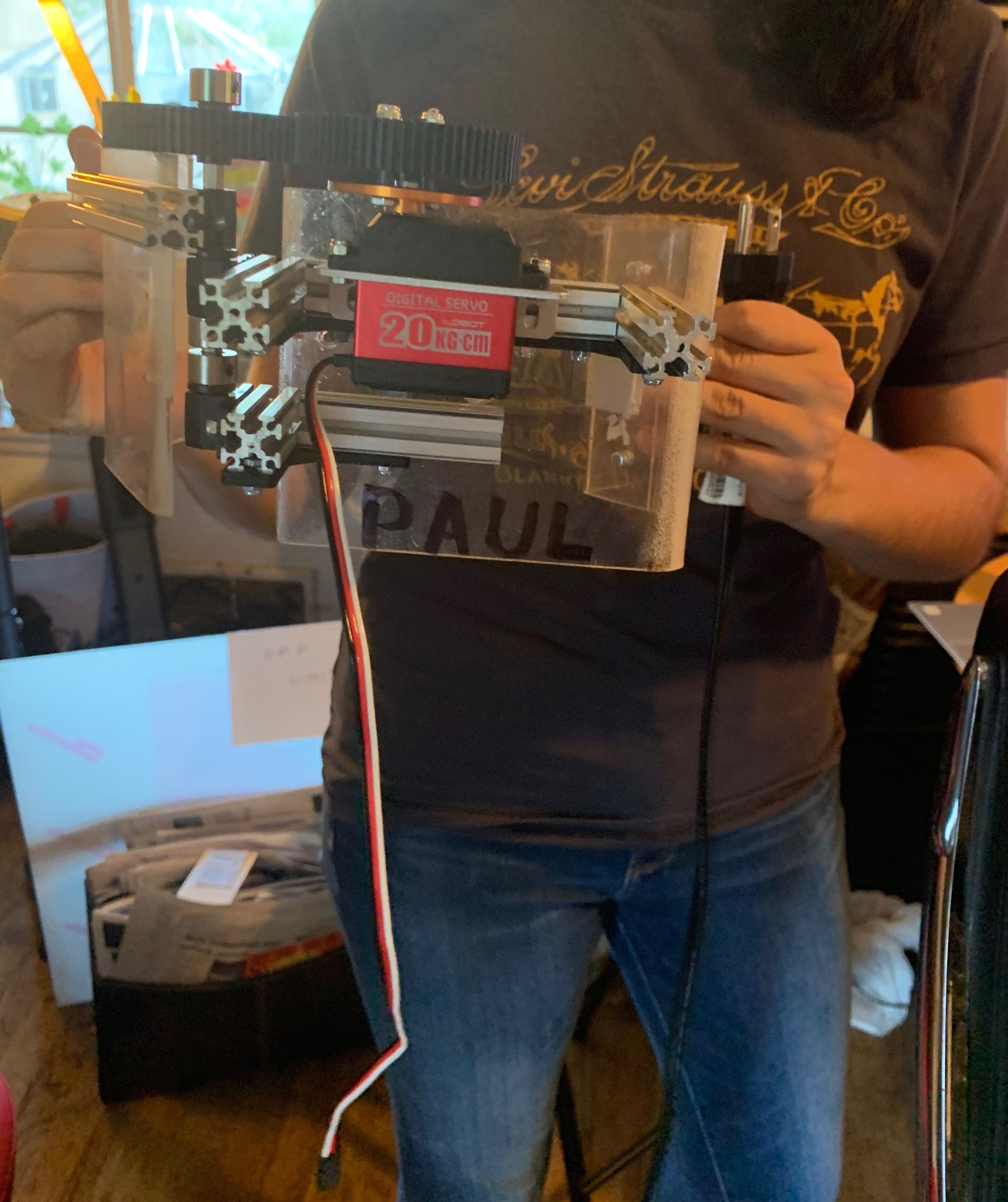

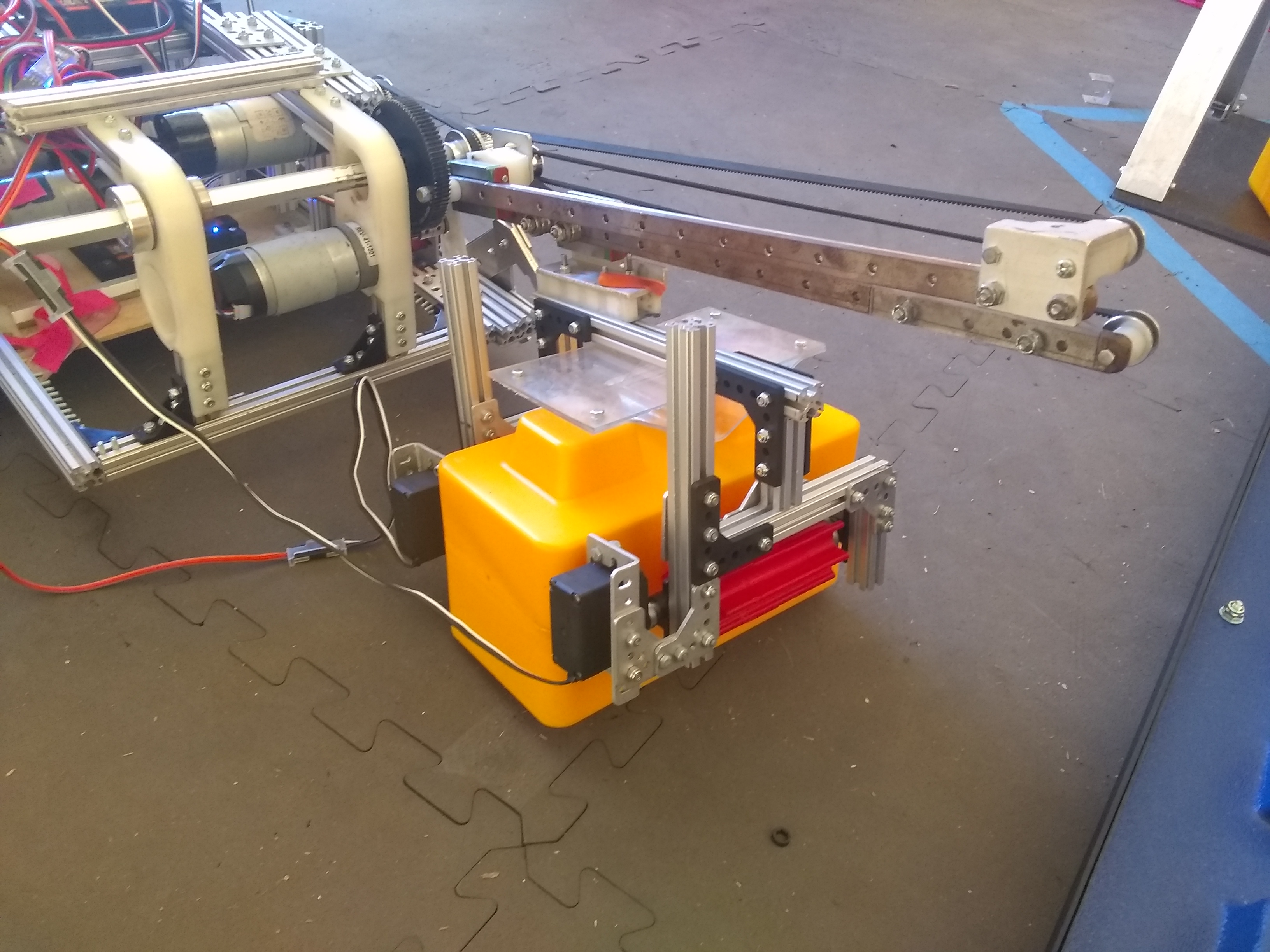

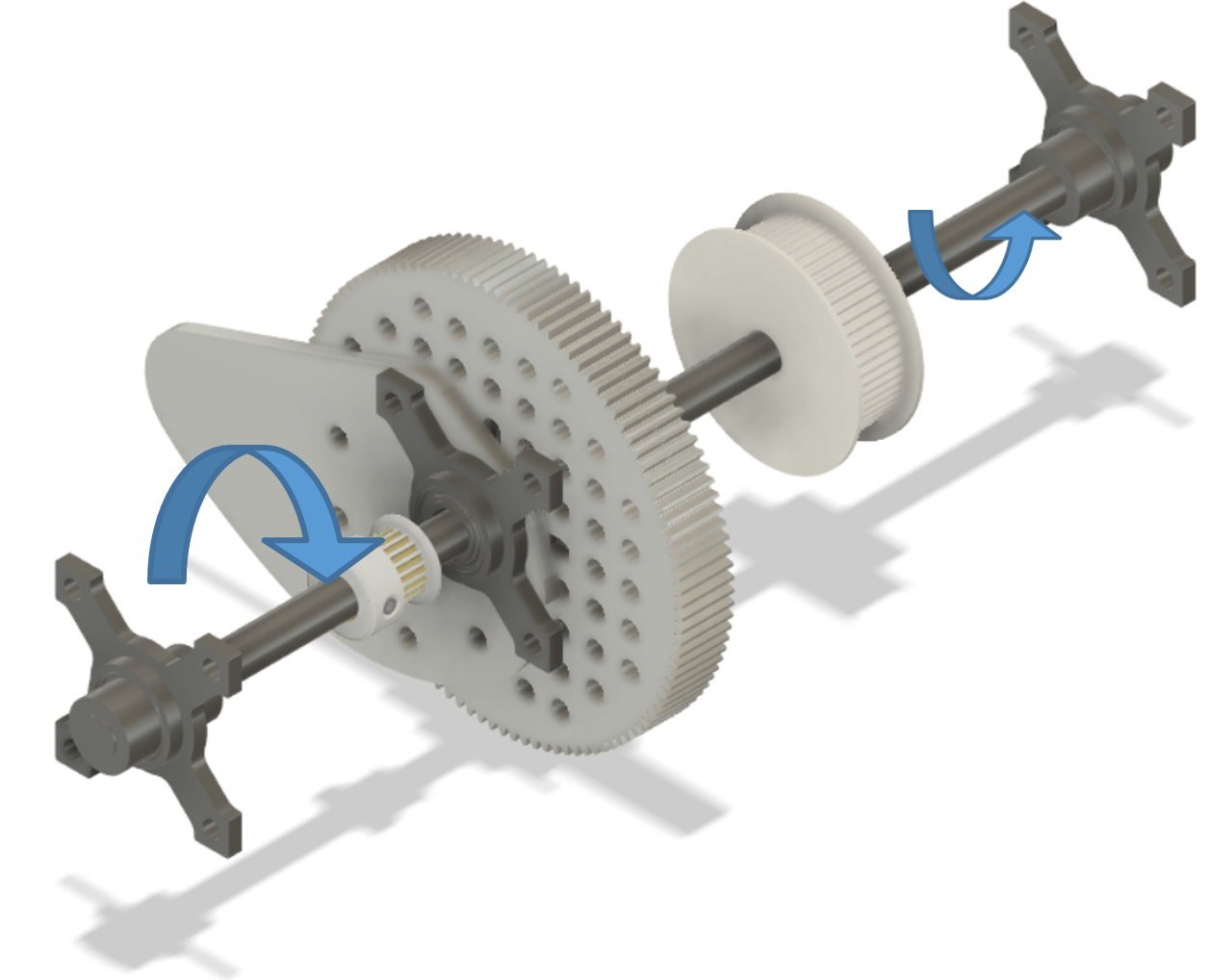

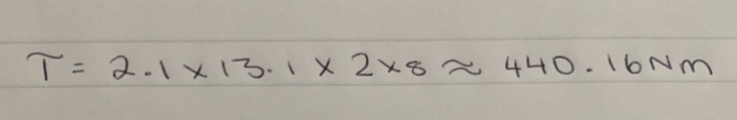

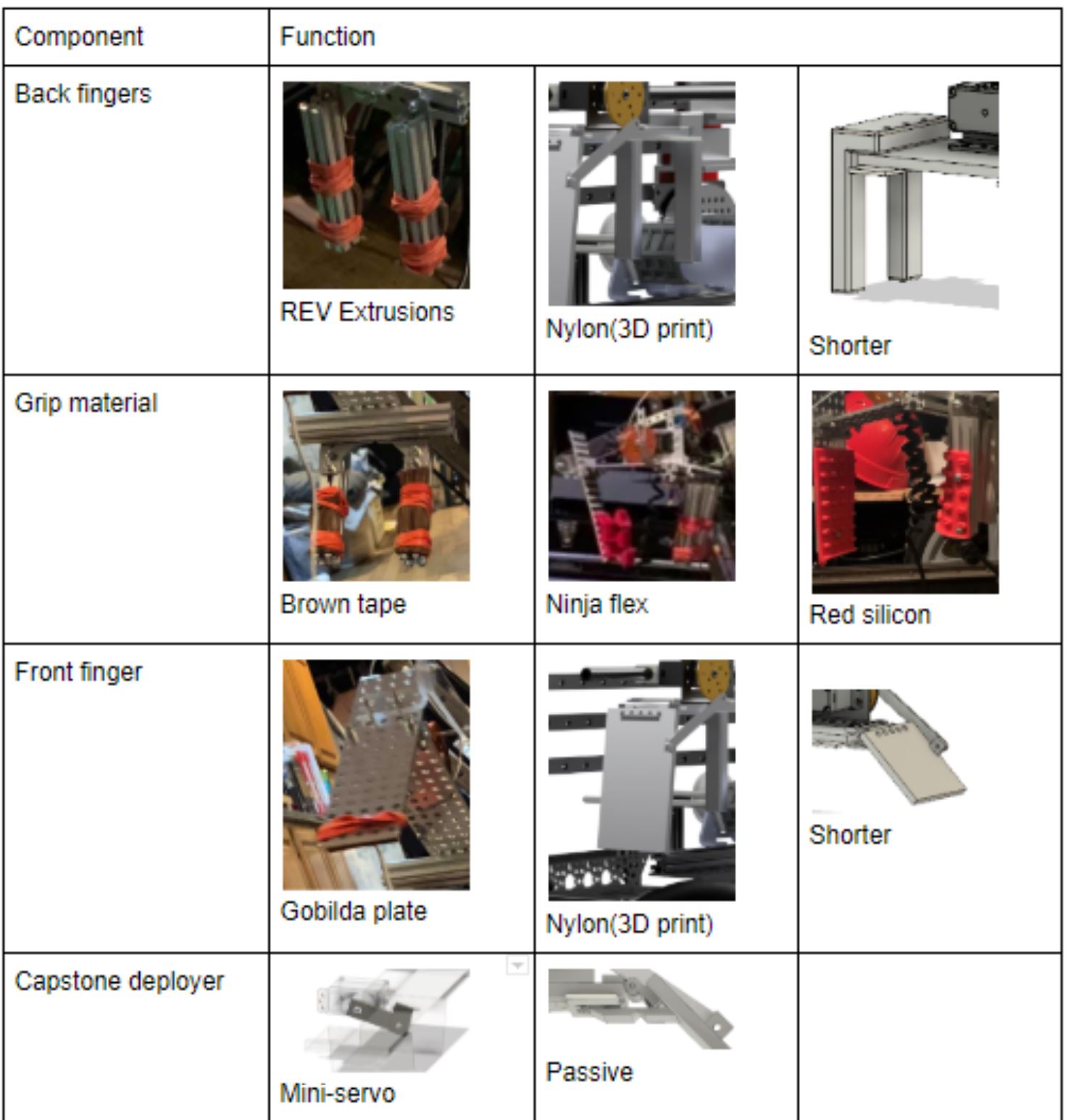

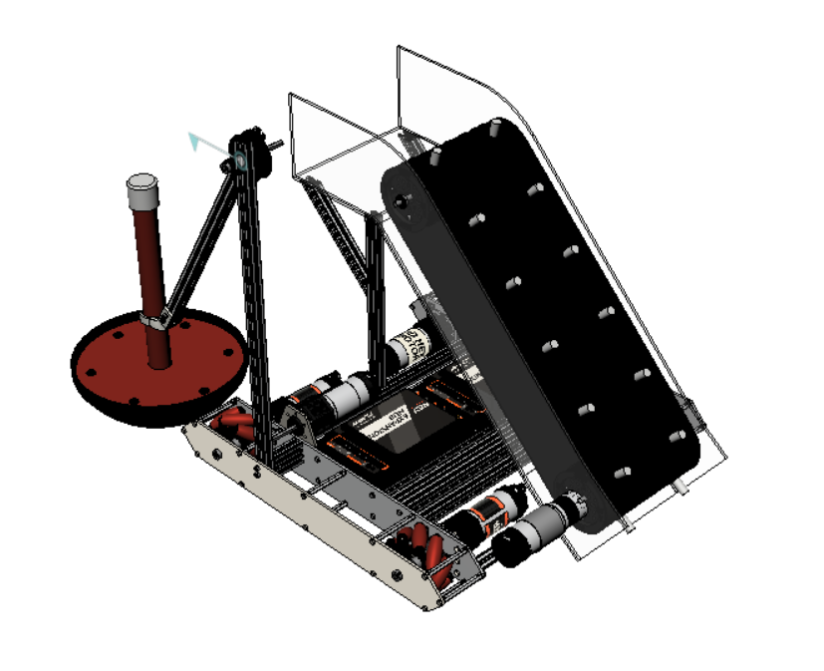

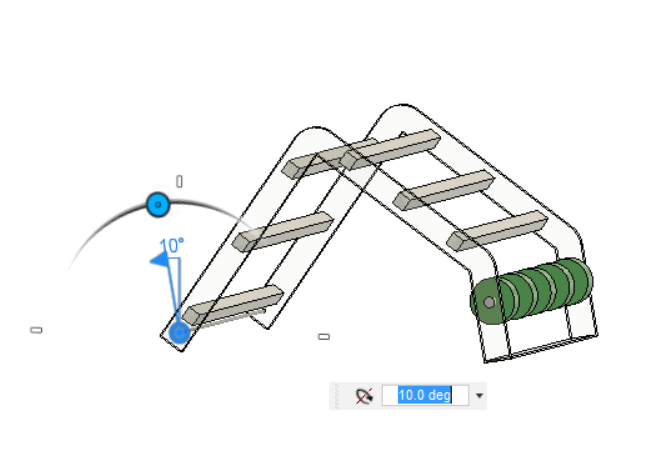

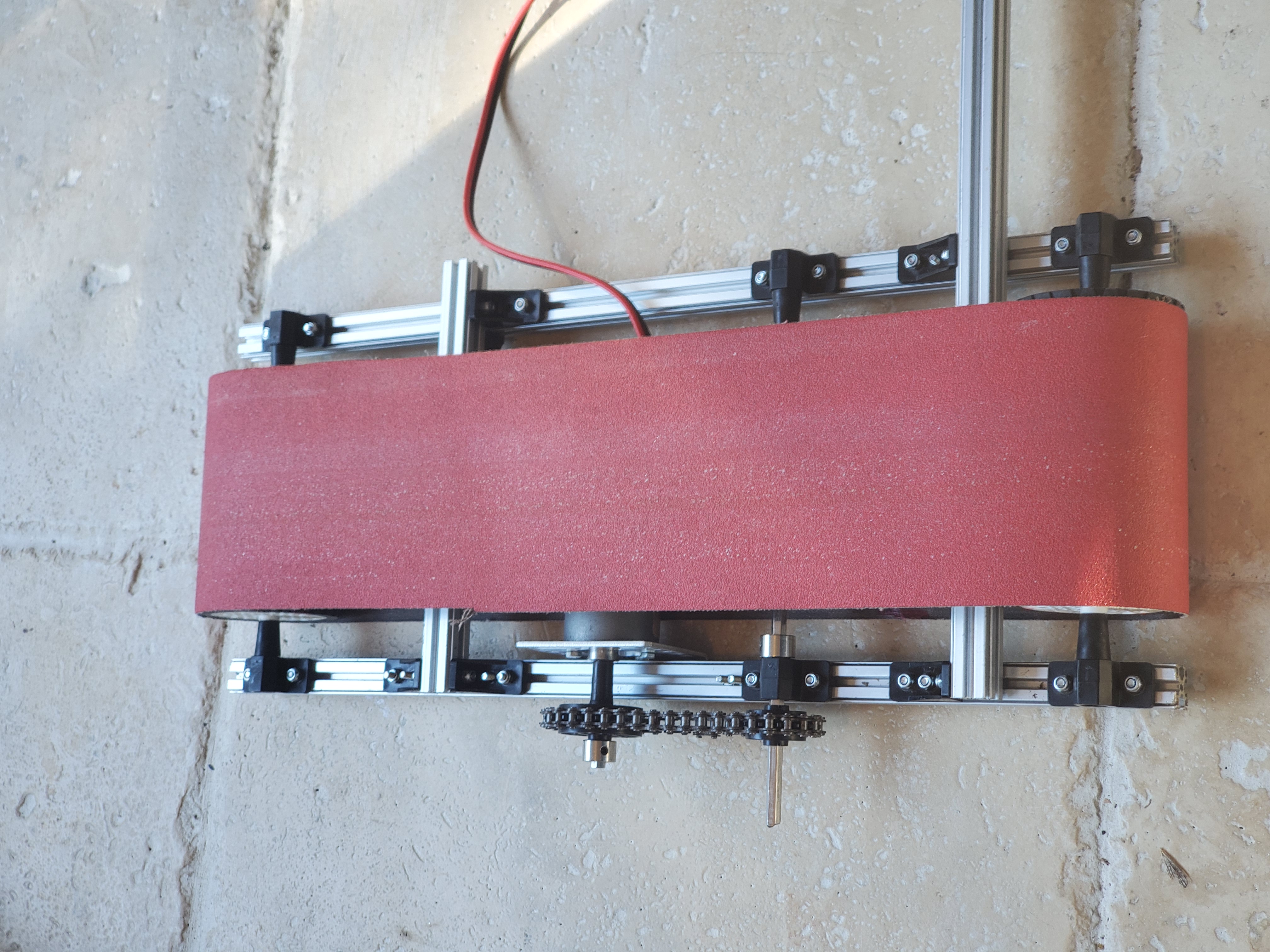

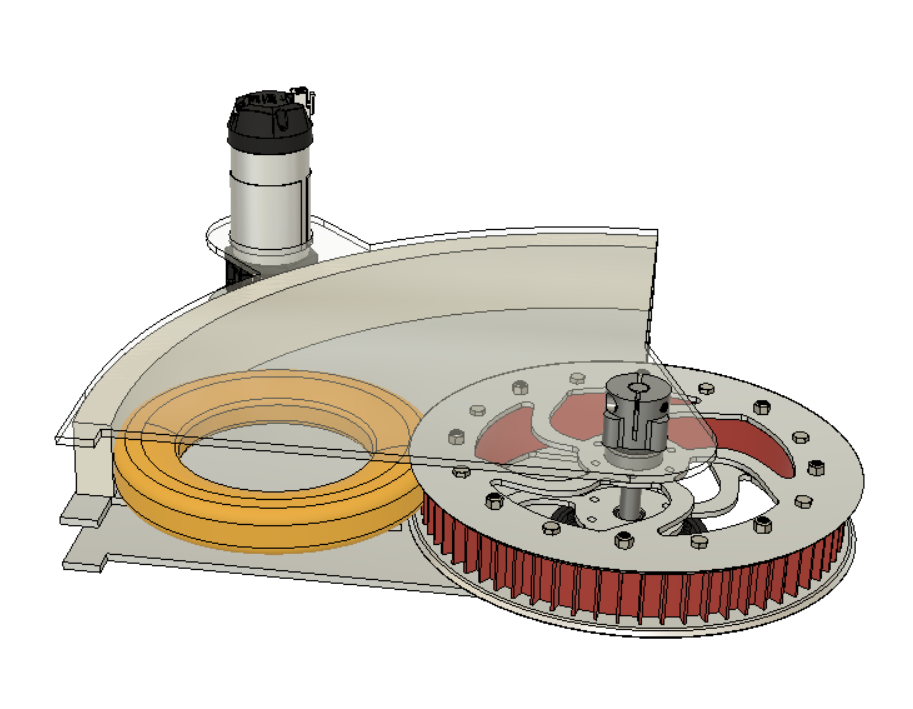

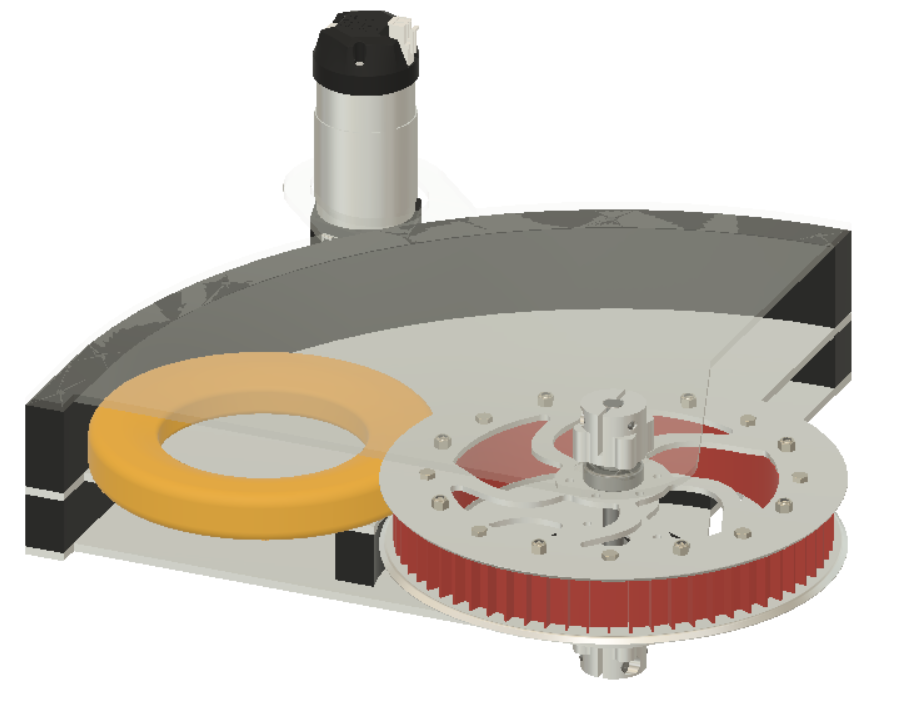

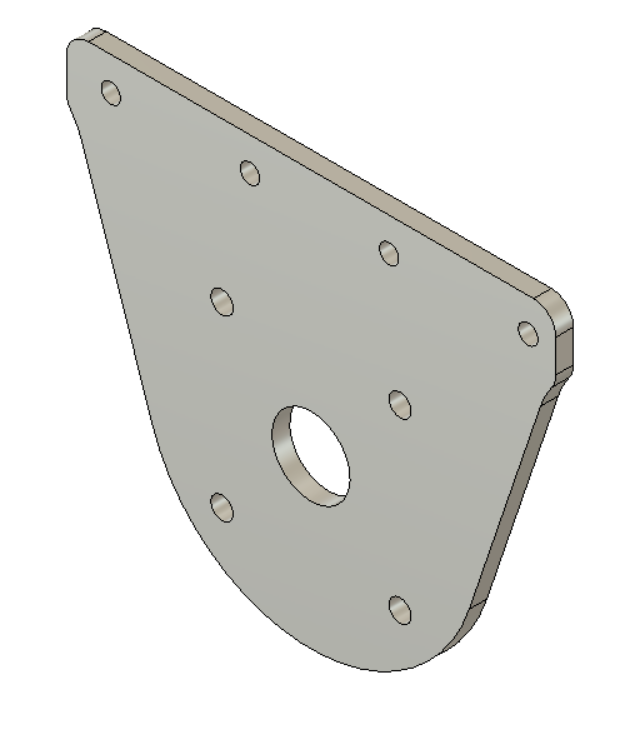

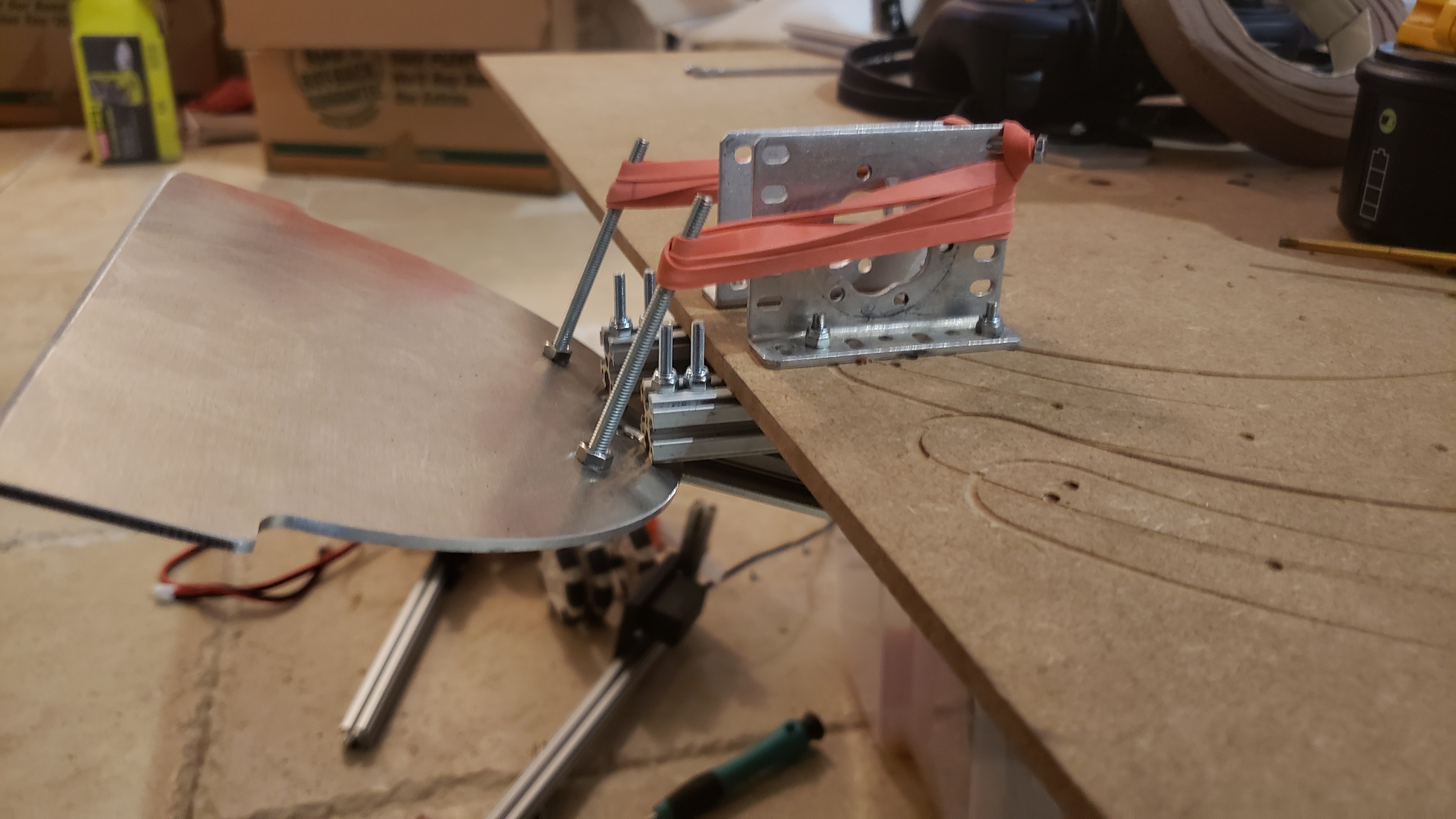

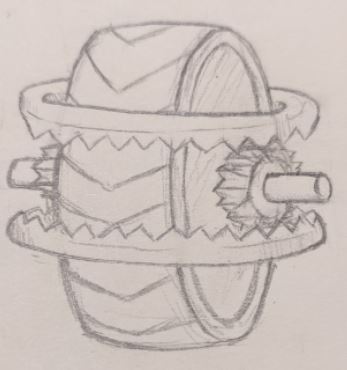

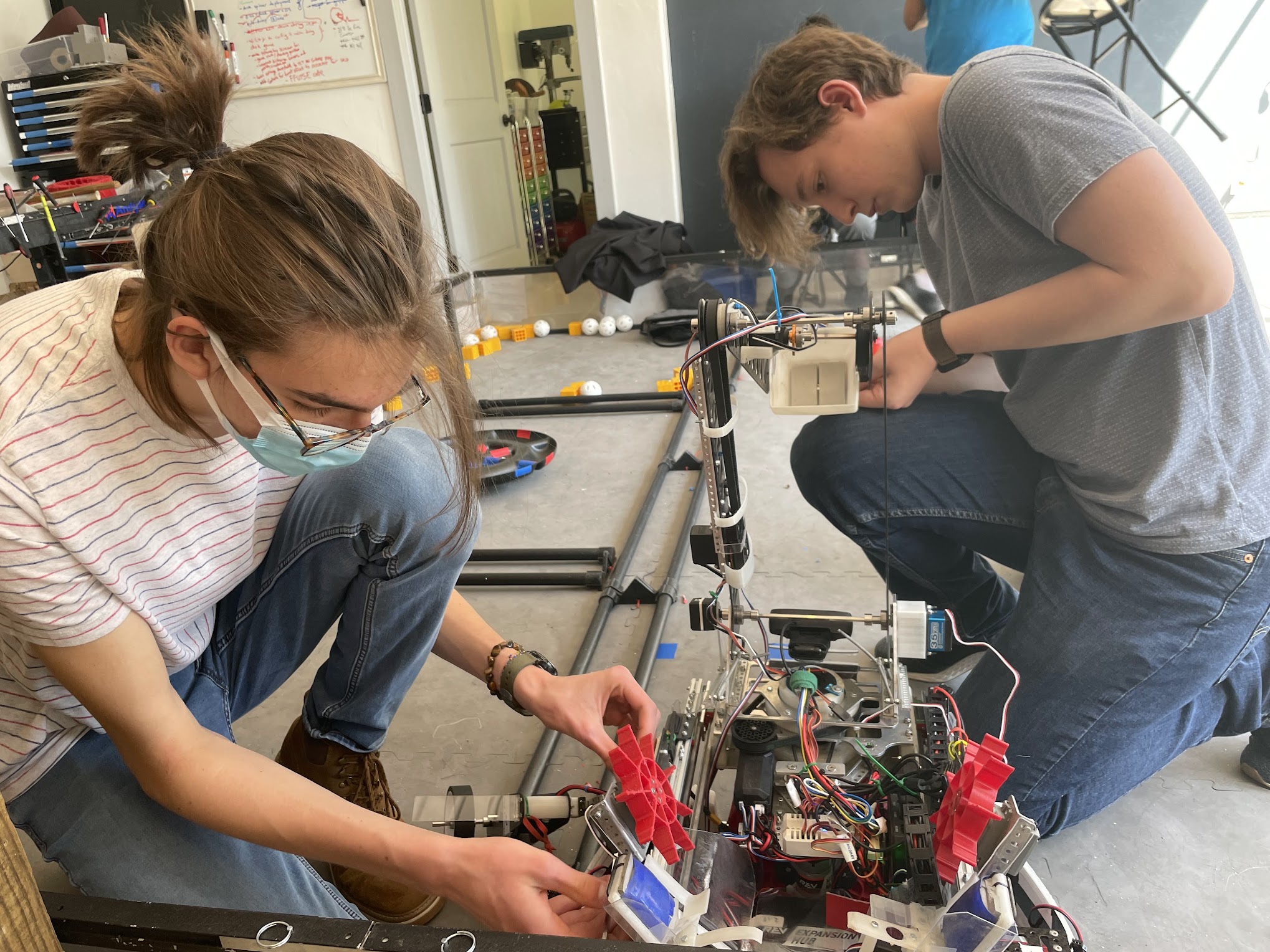

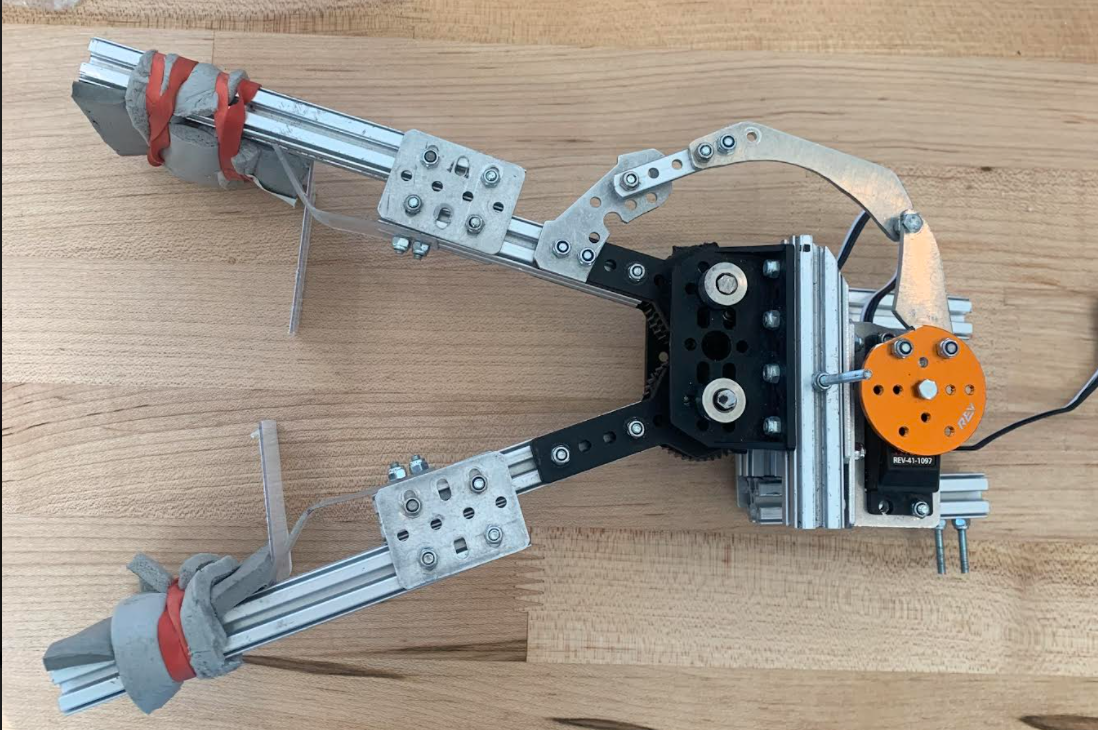

An example of these design processes working in conjunction

is the process of designing our cryptobox intake system. Evan had the idea to

build an arm-style grabber seen on many current competition robots. His design,

however, included shorter arms for space’s sake and a more compact lift system

than normal. Austin decided to build a unique conveyor-belt system which used

friction to hold blocks in space and move them vertically. Through the

competition, we determined that Evan’s design was more efficient and took up

less space than Austin, so we settle on his design, adding in a linear slide for

lifting at the end of the process. Then, Kaizen comes in. Through firsthand

experience in scrimmages, we learned that the grabber system isn’t as reliable

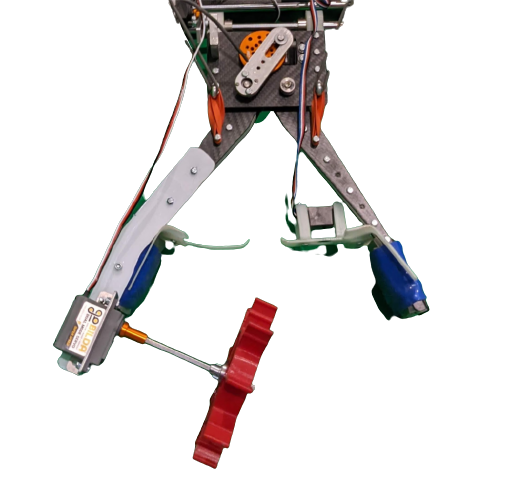

as we thought when first testing. So, we have designed a new grabber system

that moves like the arms did previously, but also rotate with soft spikes

attached to hold blocks with friction better without damaging them.

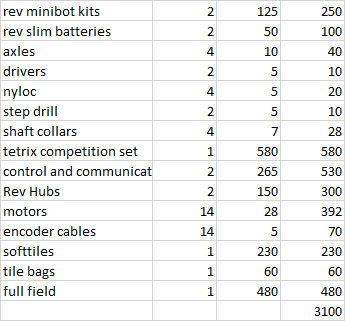

Budget

Bought:

|

REV Minibot Kit

|

2

|

125

|

250

|

|

REV Slim Batteries

|

2

|

50

|

100

|

|

Axles

|

4

|

10

|

40

|

|

Drivers

|

2

|

5

|

10

|

|

Nyloc Parts

|

4

|

5

|

20

|

|

Step Drill

|

2

|

5

|

10

|

|

Shaft Collars

|

4

|

7

|

28

|

|

Tetrix Competition Set

|

1

|

580

|

580

|

|

Control and Communication

|

2

|

265

|

530

|

|

REV Hubs

|

4

|

150

|

600

|

|

Motors

|

14

|

28

|

392

|

|

Encoder Cables

|

14

|

5

|

70

|

|

Soft Tiles

|

28

|

5

|

140

|

|

Tile Bags

|

2

|

60

|

120

|

|

Full Field

|

2

|

480

|

960

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total

|

|

|

3850

|

Wishlist:

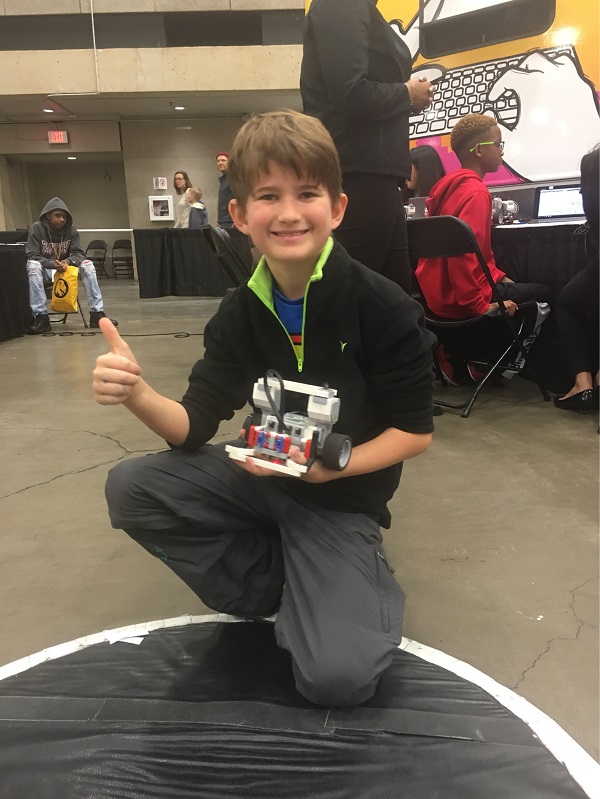

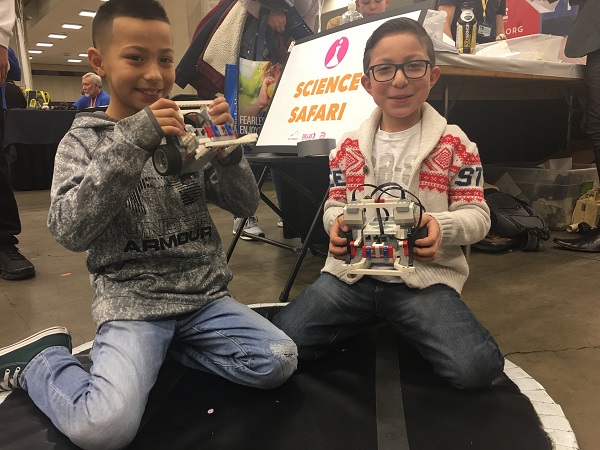

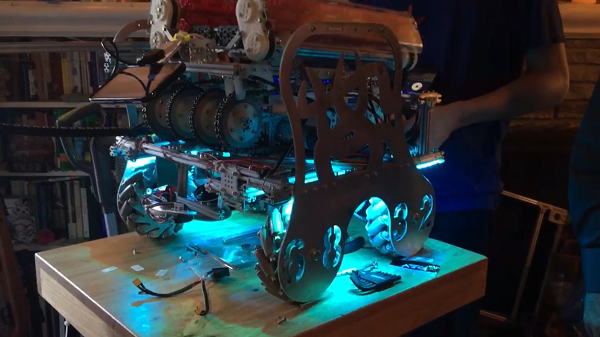

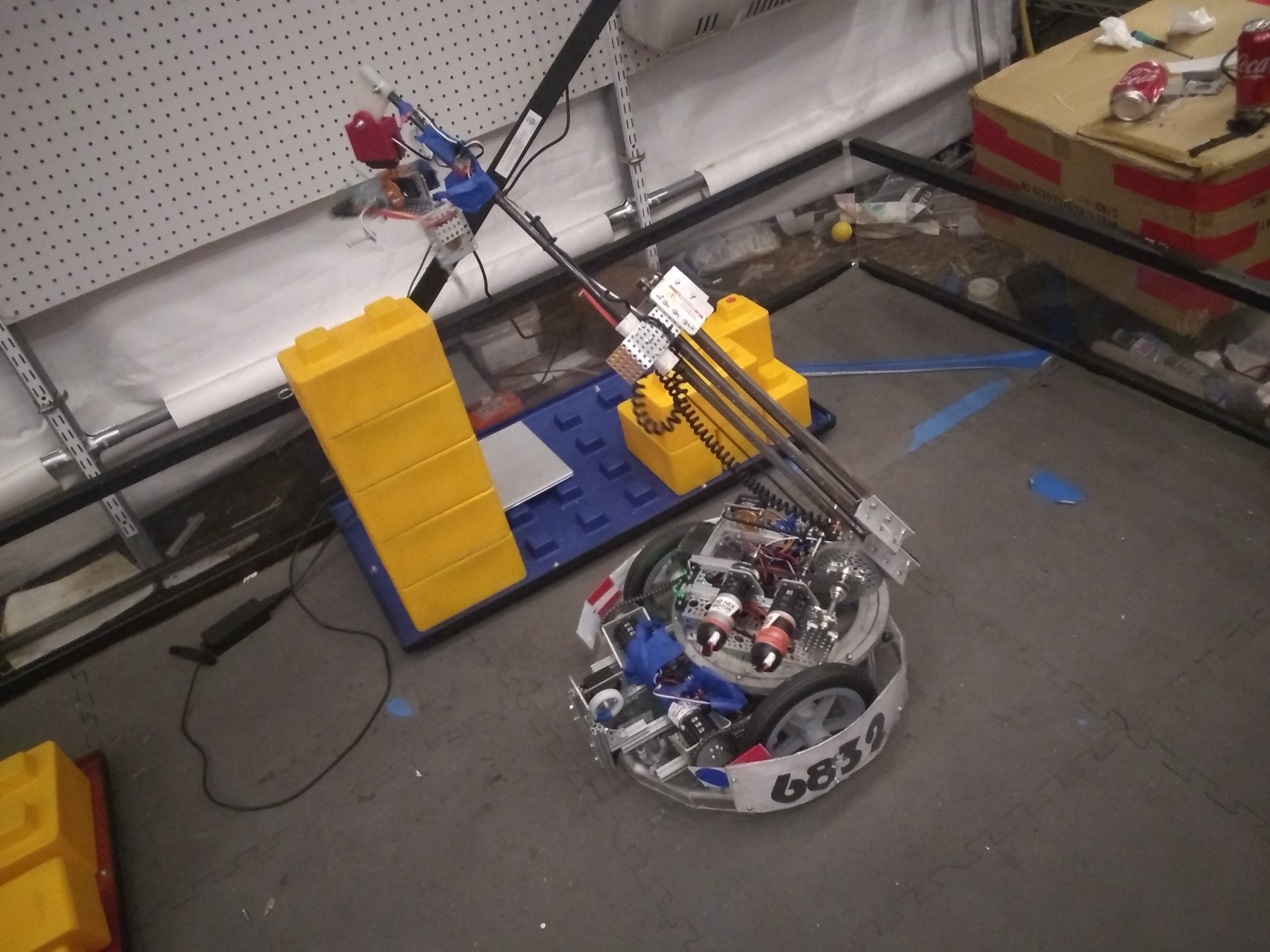

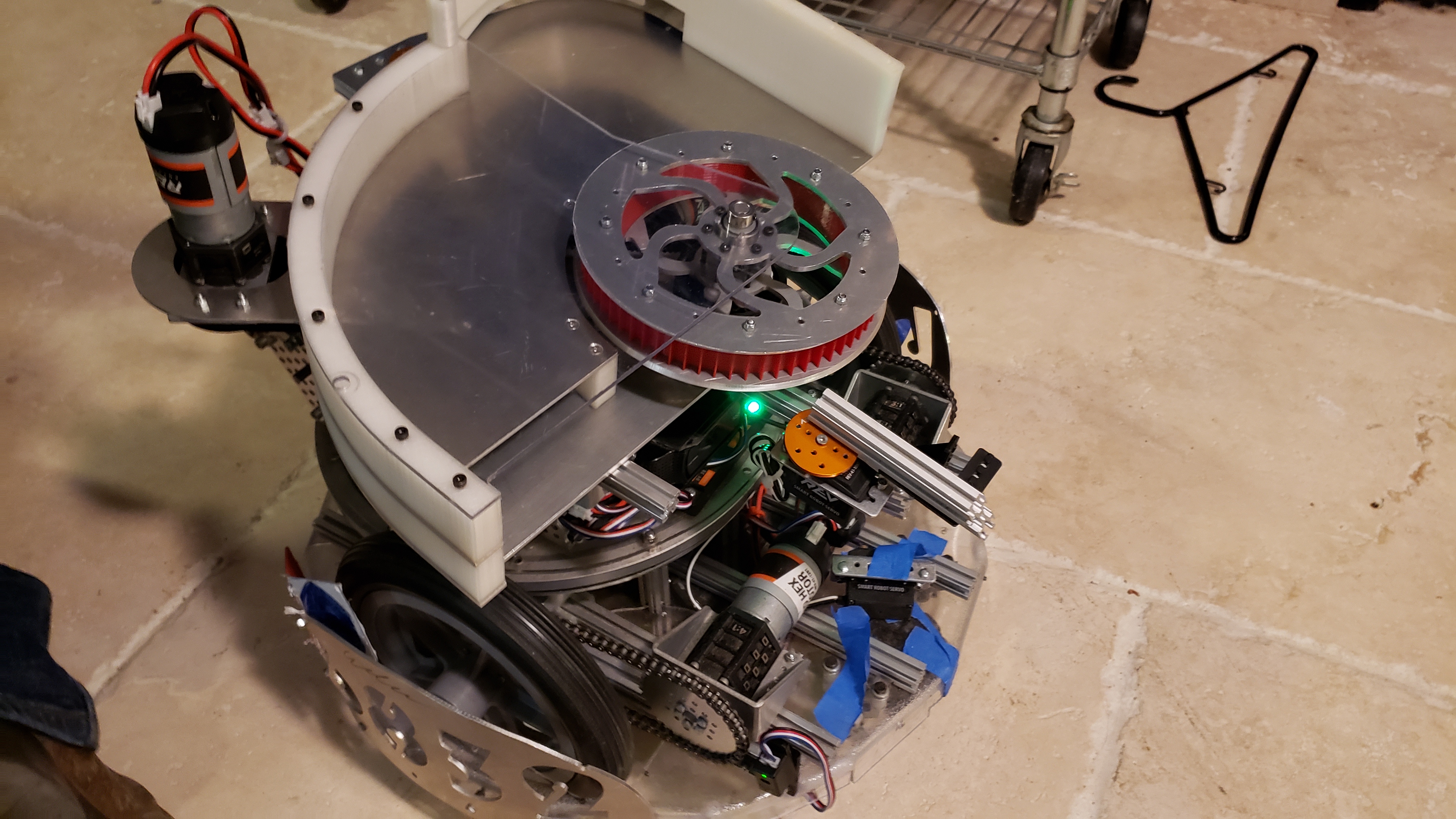

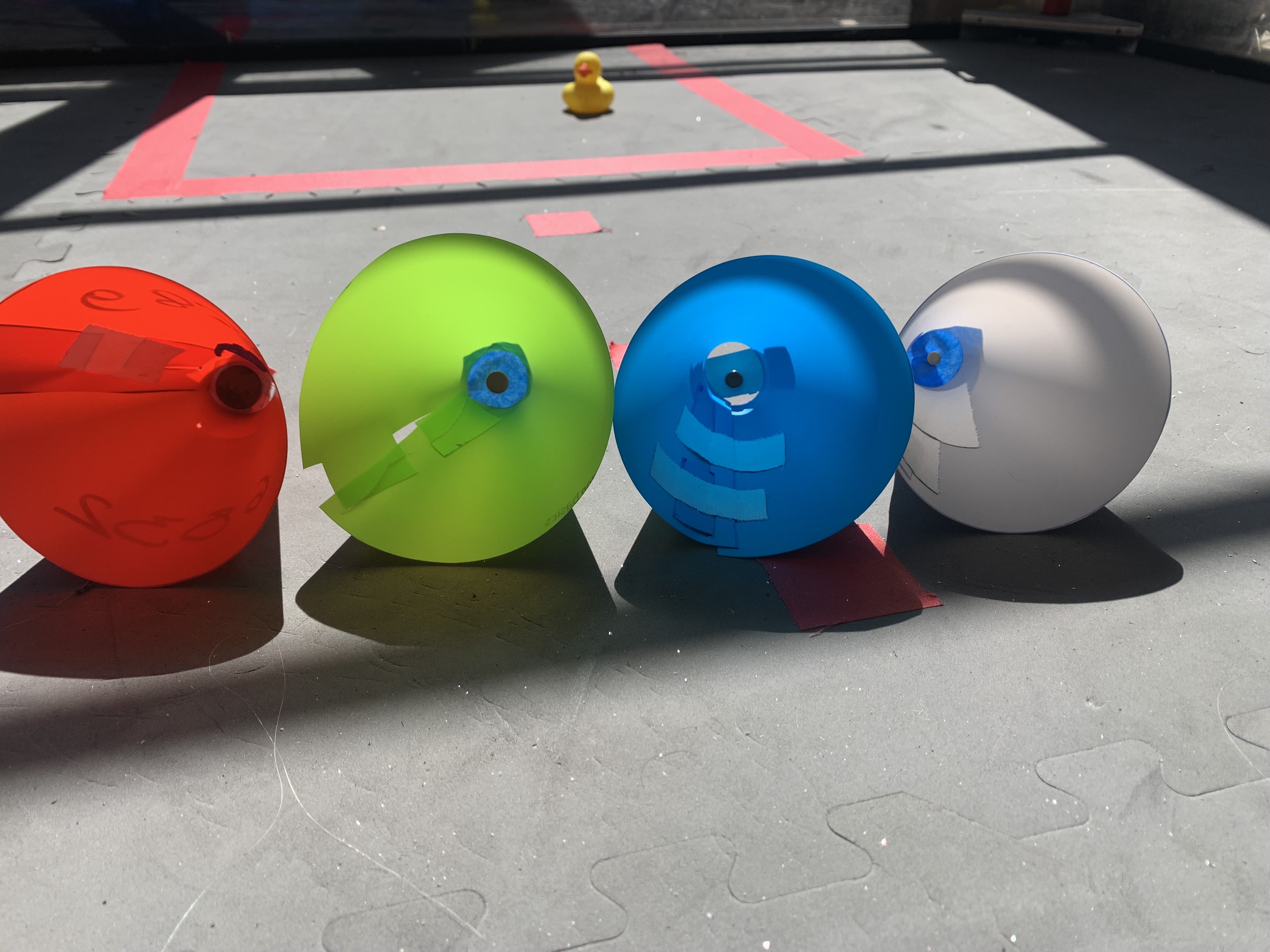

Each year the Frontiers of Flight Museum hosts the Turn Up!, an event that contains STEM exhibits and demonstration to teach kids about the wonders of Science and Math. We brought the Mobile XPerience (MXP) complete with laptops, 3D printers, and LEGO SumoBot to help teach. Outside the RV we had laptops set up where we taught kids how to code EV3 sumo bots and battle them , we also taught kids how to create their own key chains on SketchUp and 3-D print them. Inside the RV we had more SketchUp latops set up as well as the educational Minecraft servers where the kids could learn how to build structures. As well, we demonstrated our FTC competition robot and Argos by driving them around the museum we got younger kids excited about robotics by giving them balls and letting them "feed" the robot.

Each year the Frontiers of Flight Museum hosts the Turn Up!, an event that contains STEM exhibits and demonstration to teach kids about the wonders of Science and Math. We brought the Mobile XPerience (MXP) complete with laptops, 3D printers, and LEGO SumoBot to help teach. Outside the RV we had laptops set up where we taught kids how to code EV3 sumo bots and battle them , we also taught kids how to create their own key chains on SketchUp and 3-D print them. Inside the RV we had more SketchUp latops set up as well as the educational Minecraft servers where the kids could learn how to build structures. As well, we demonstrated our FTC competition robot and Argos by driving them around the museum we got younger kids excited about robotics by giving them balls and letting them "feed" the robot.

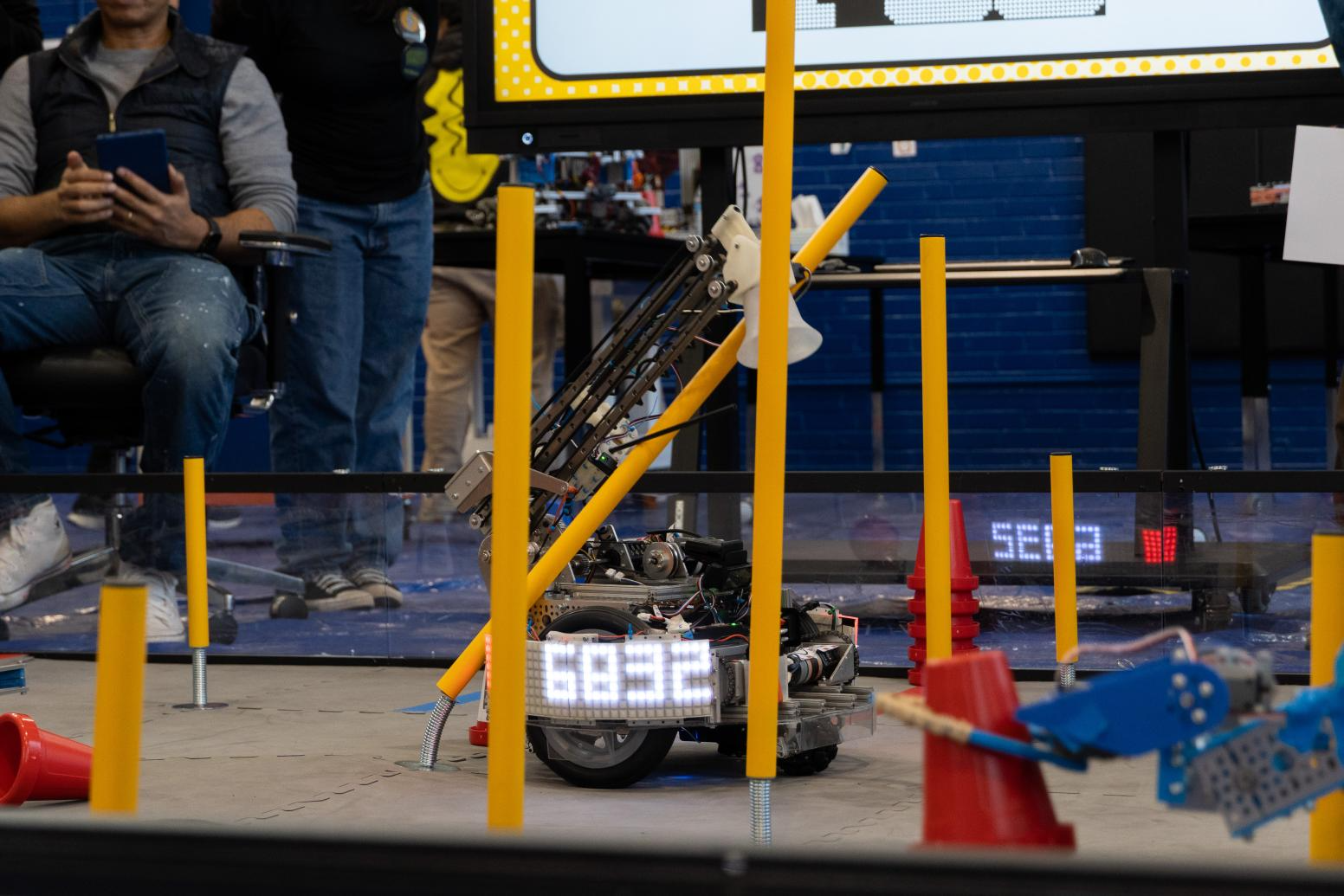

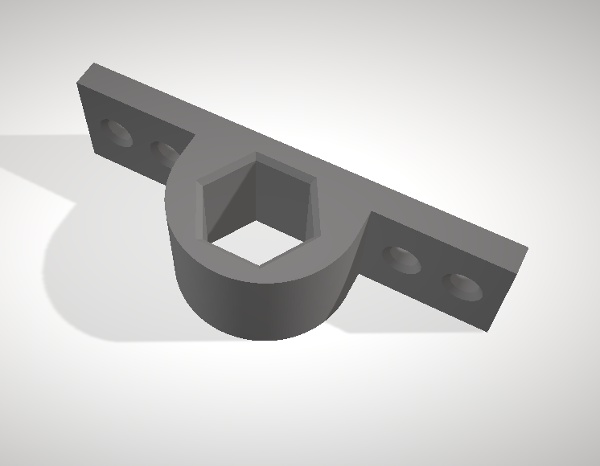

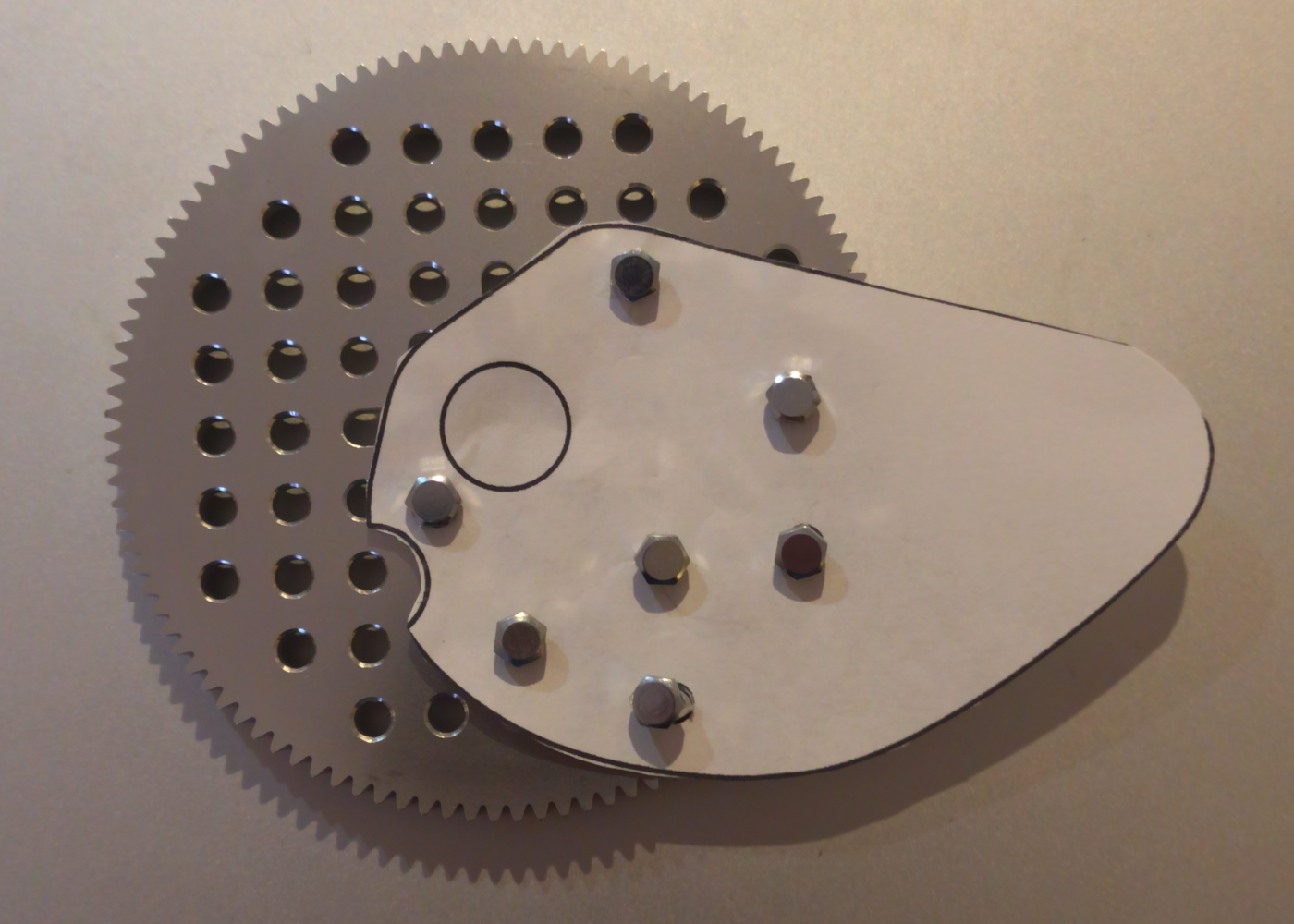

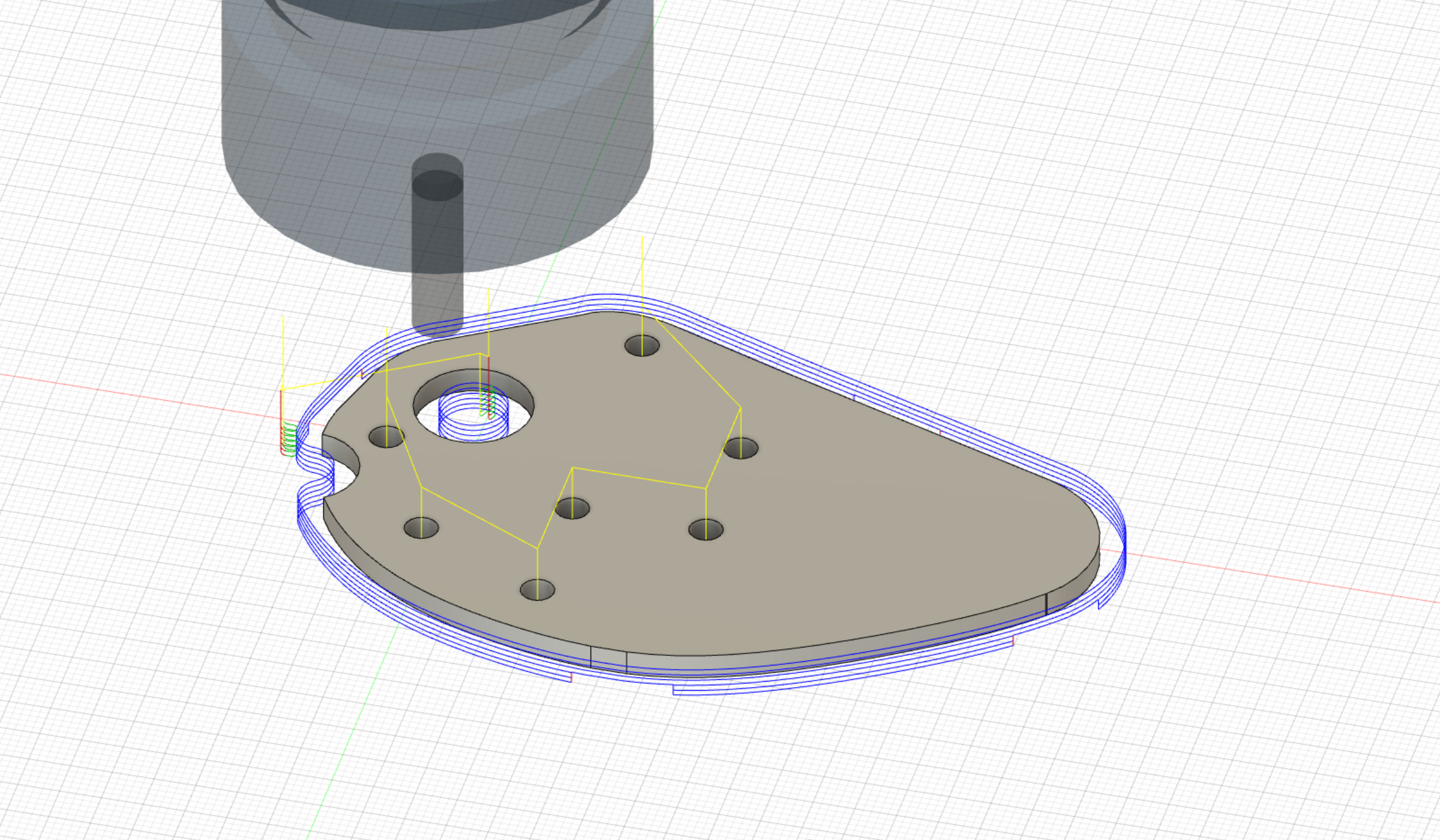

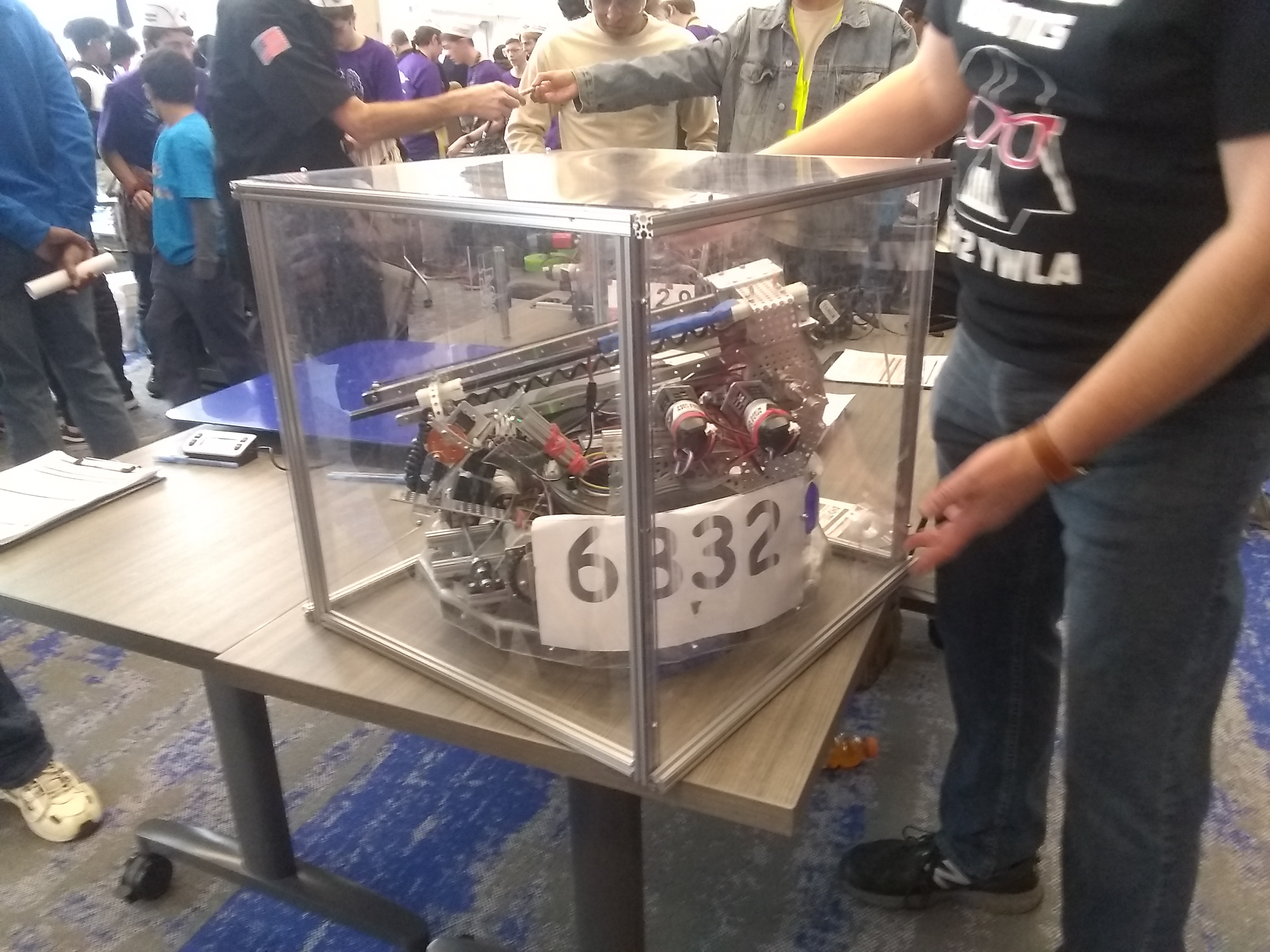

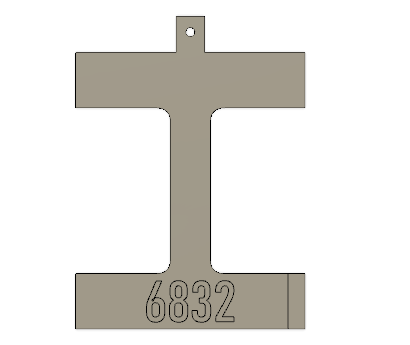

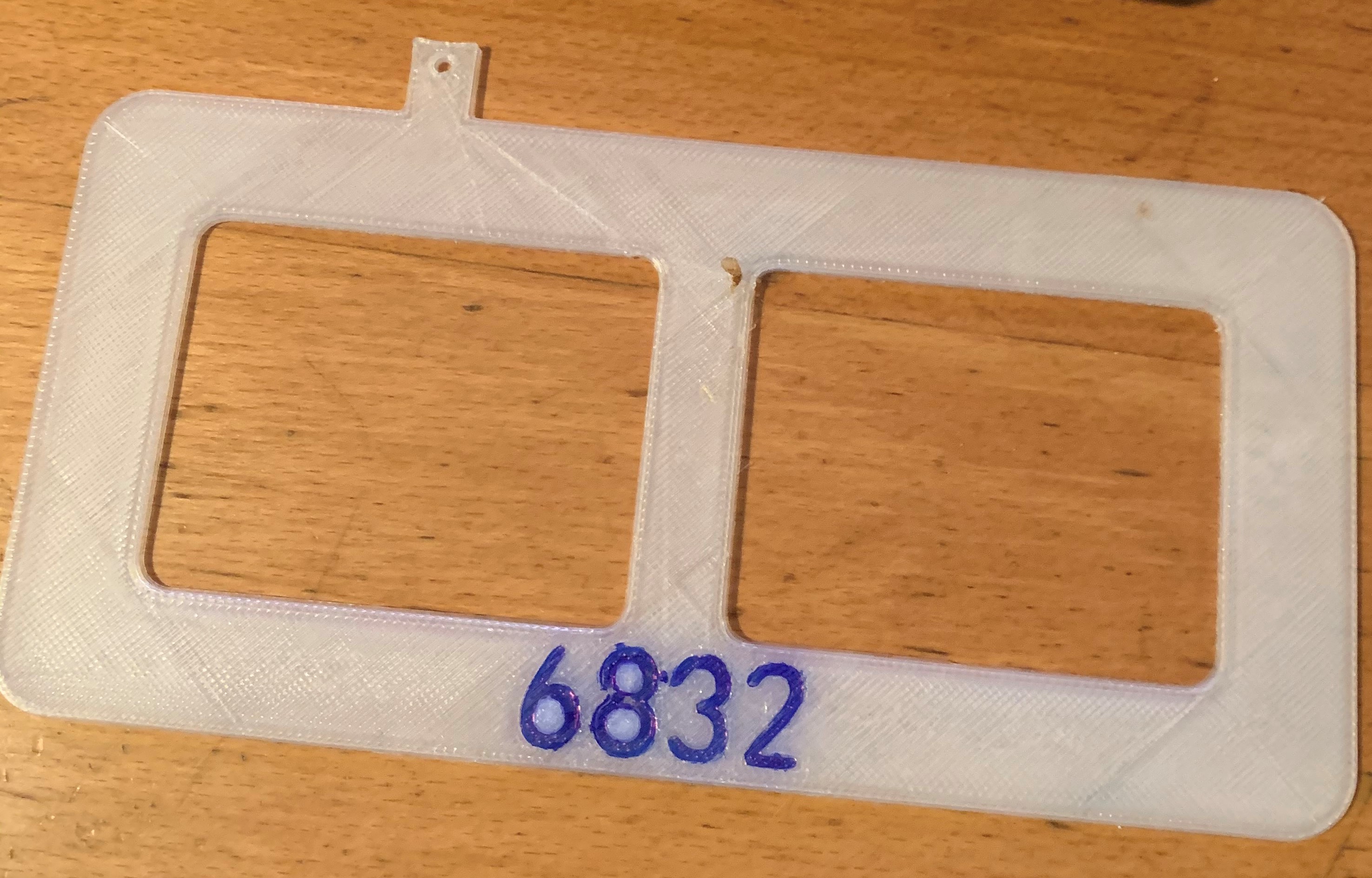

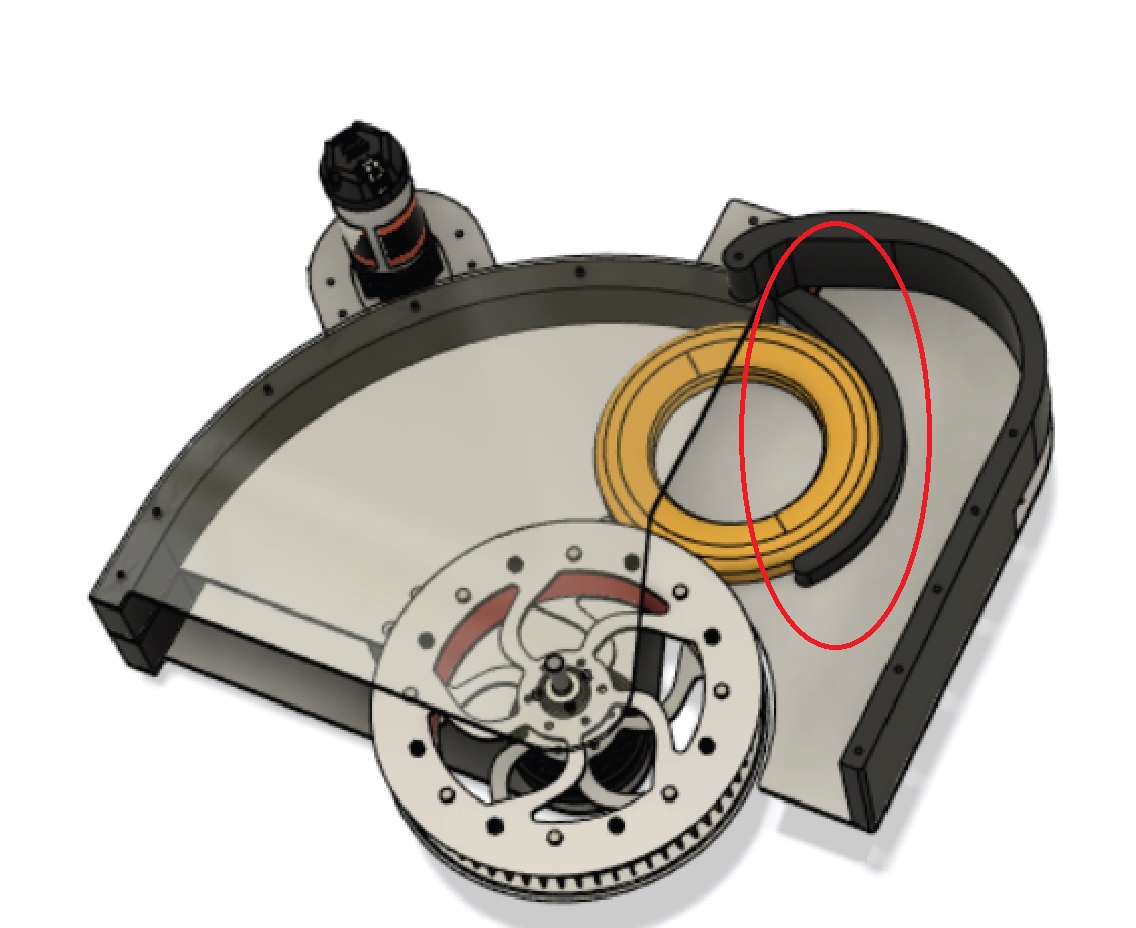

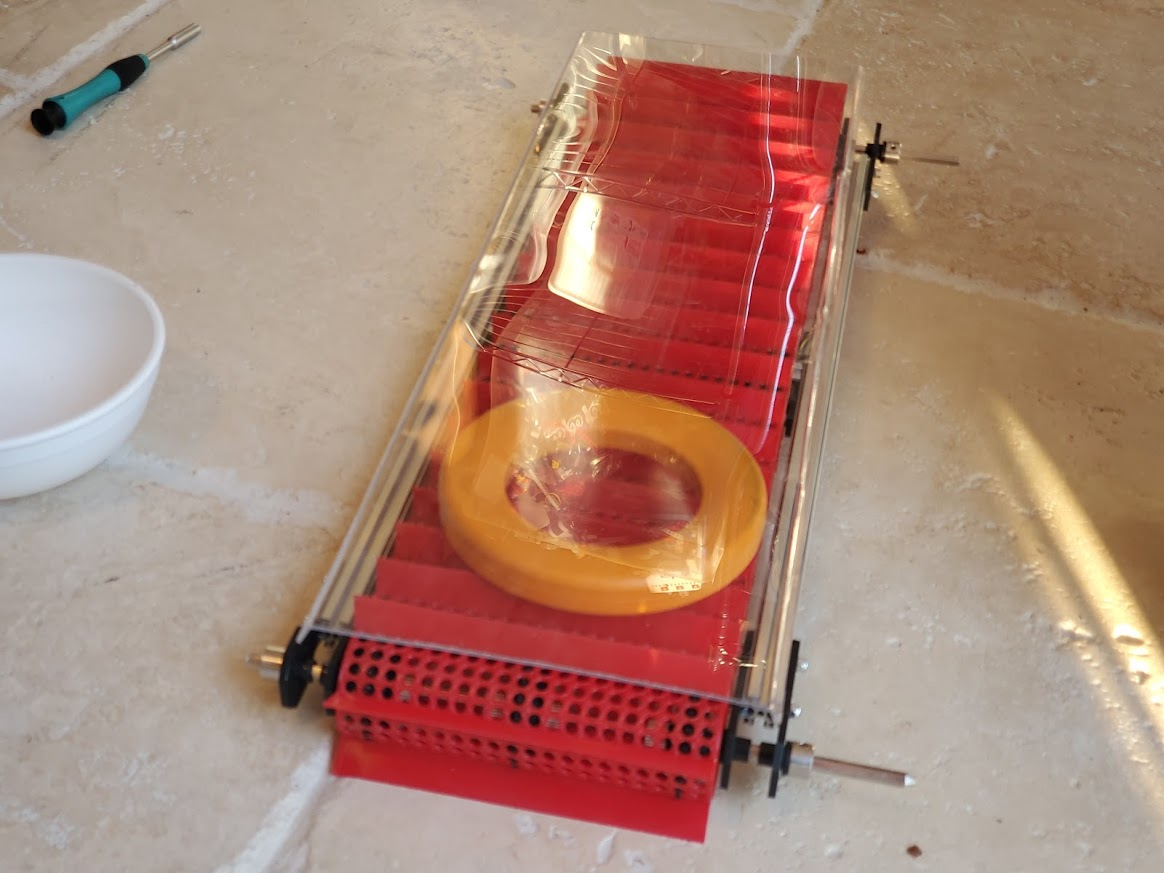

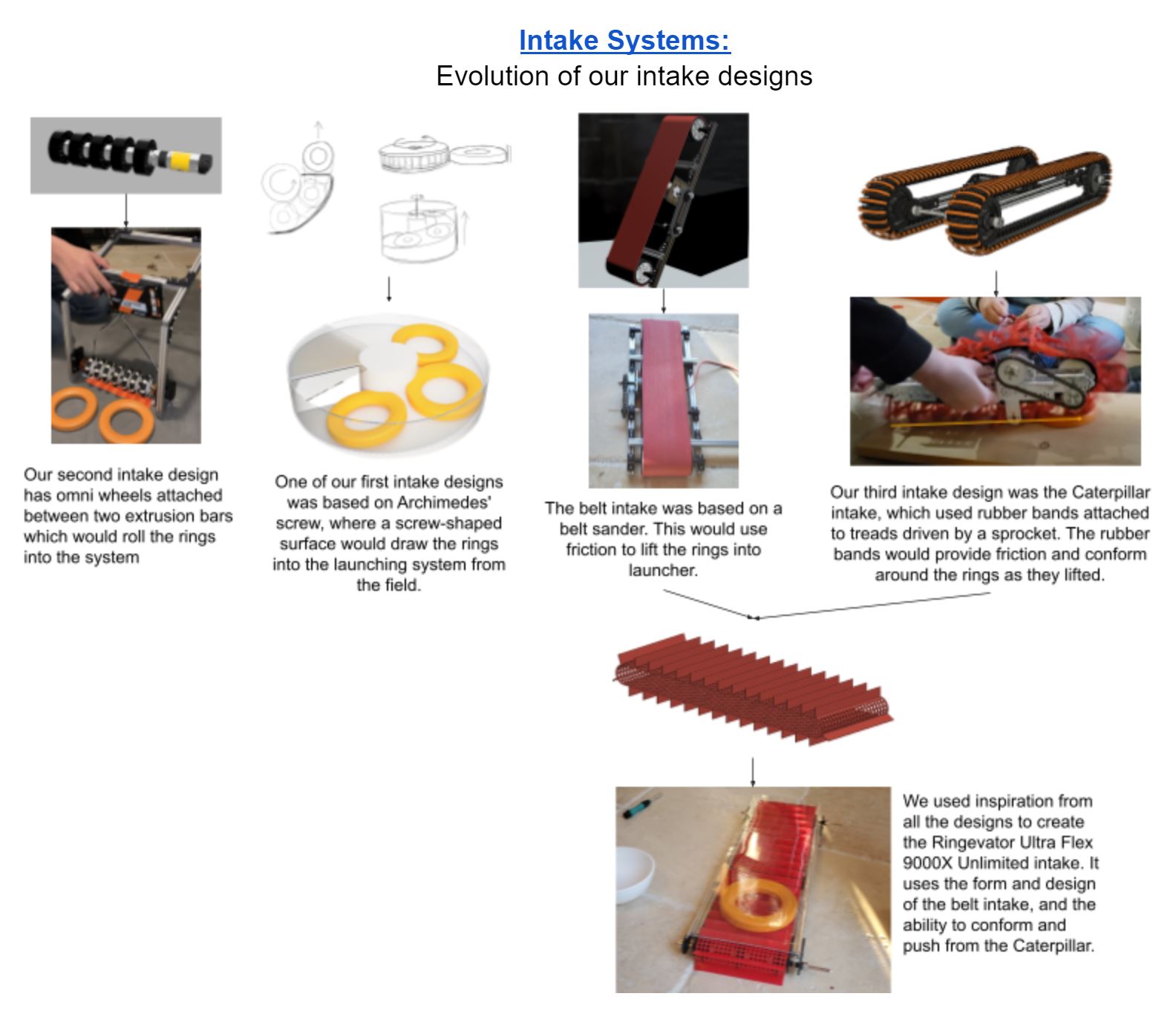

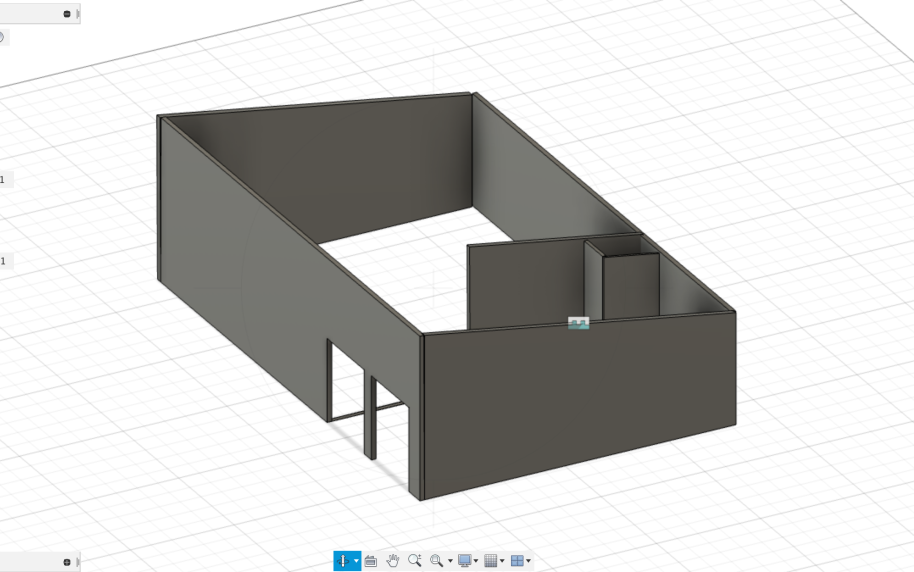

Fig 2

Fig 2

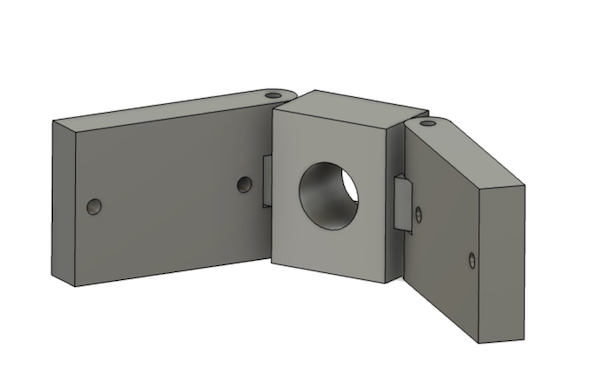

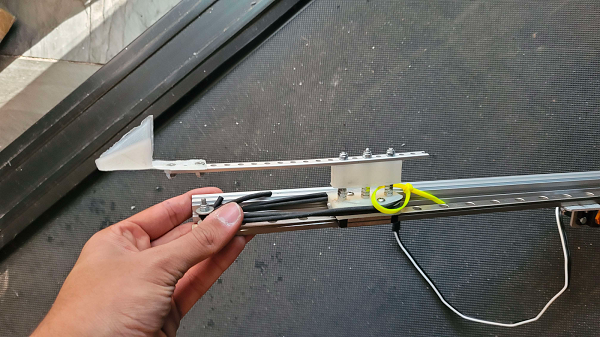

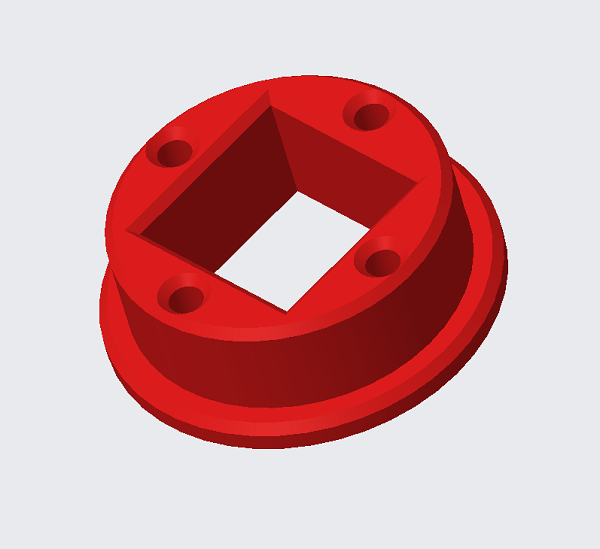

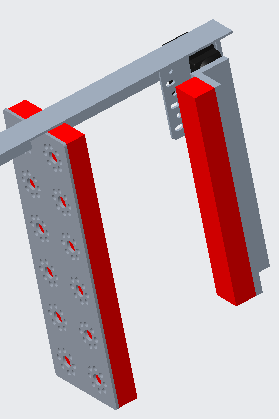

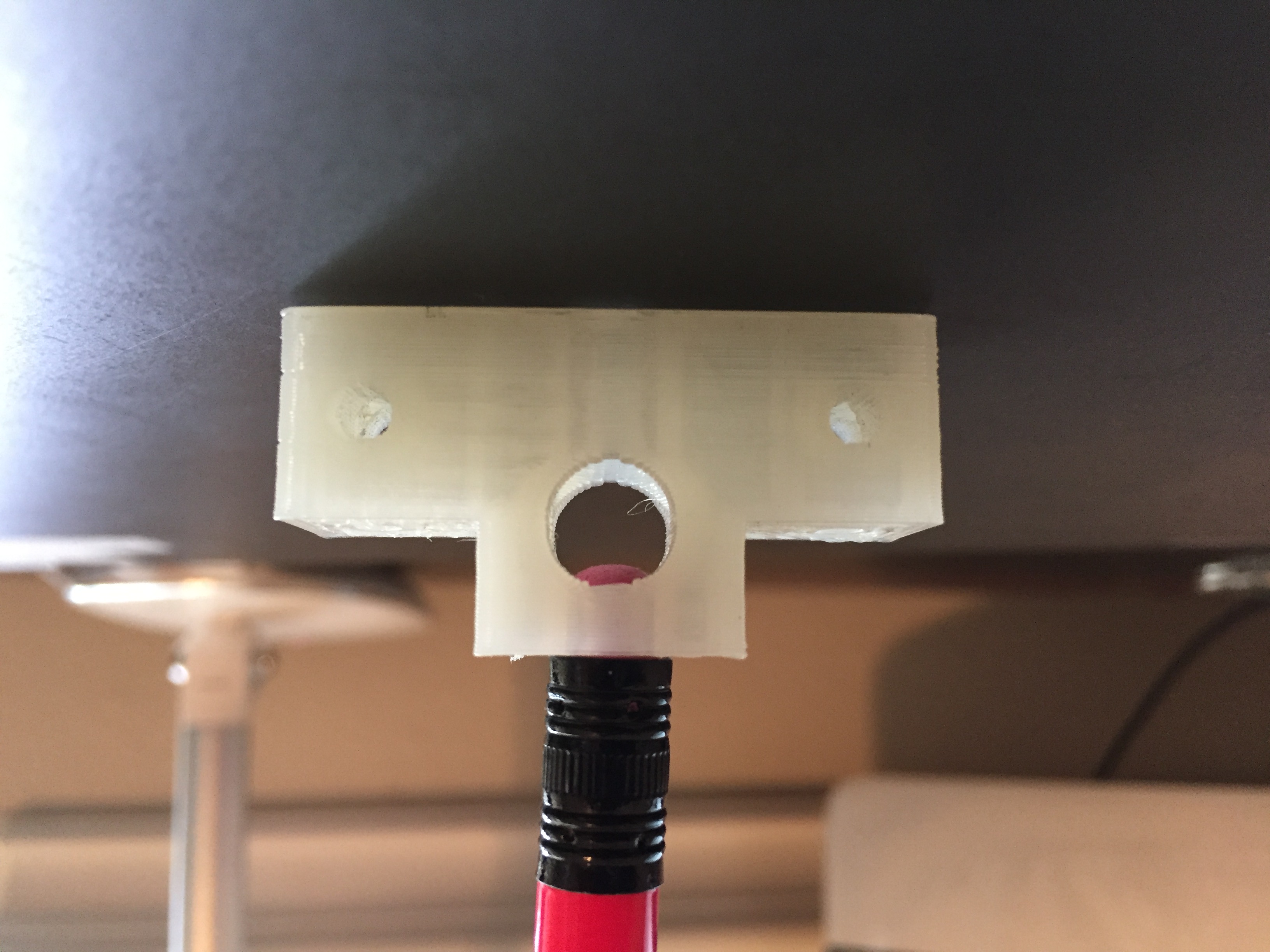

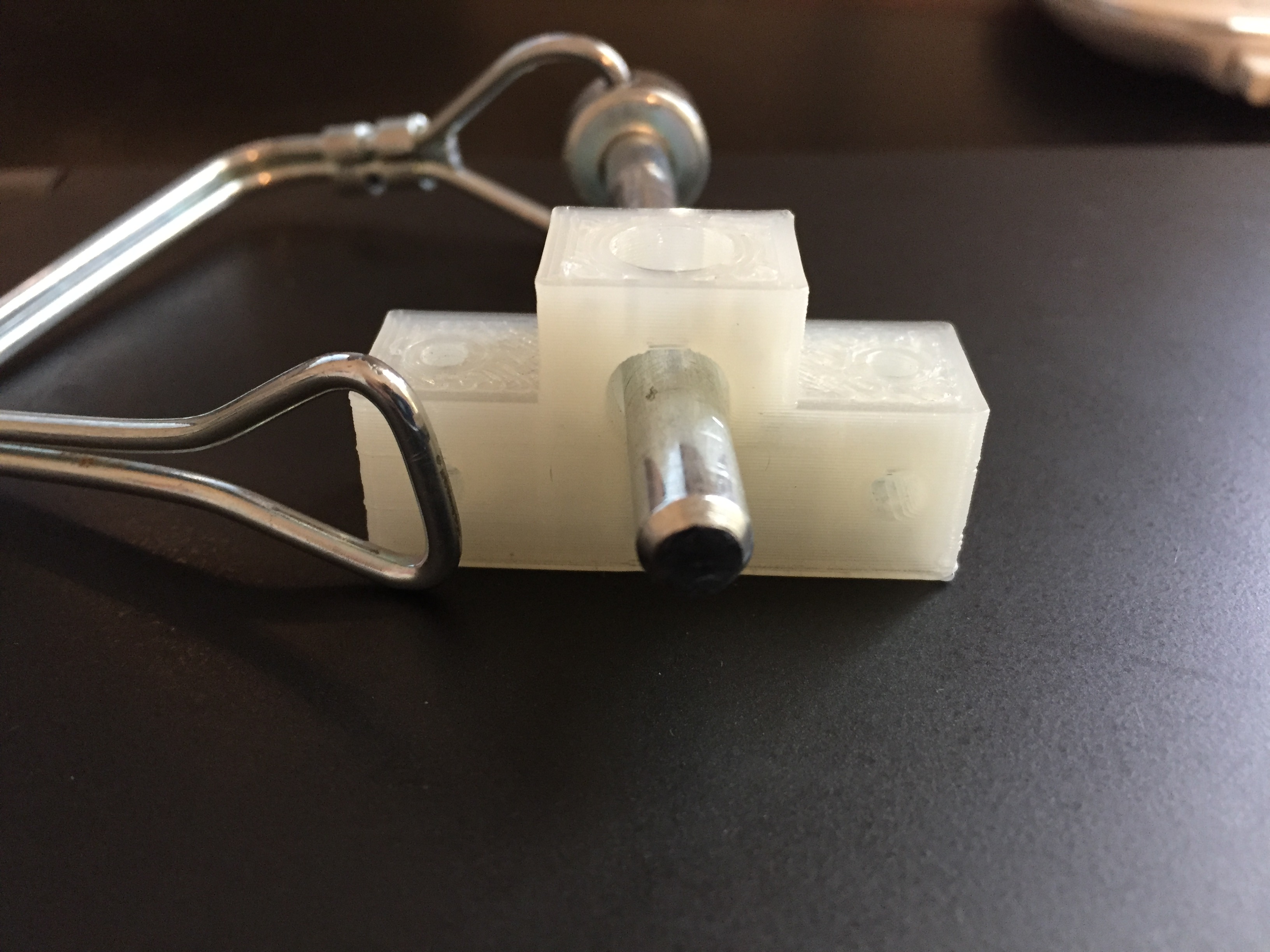

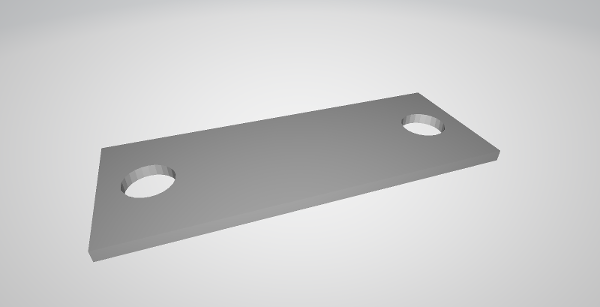

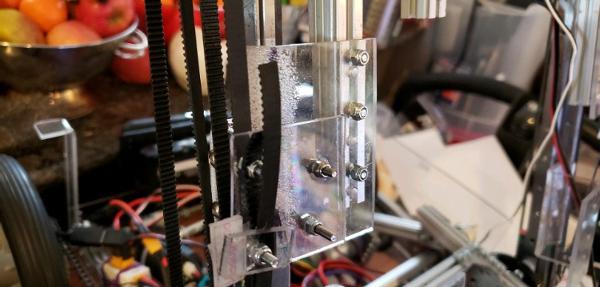

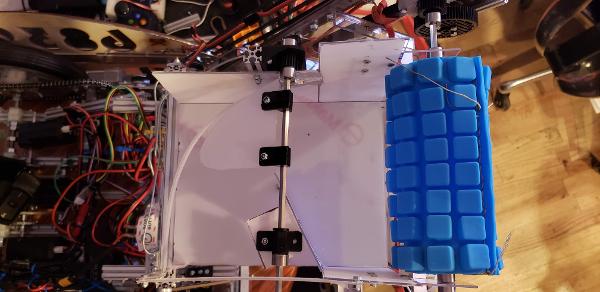

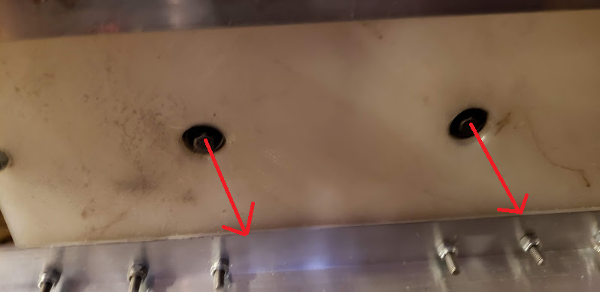

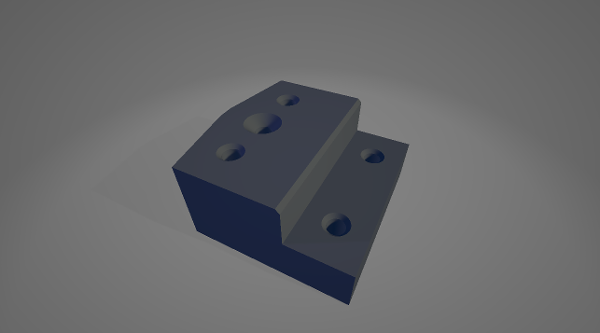

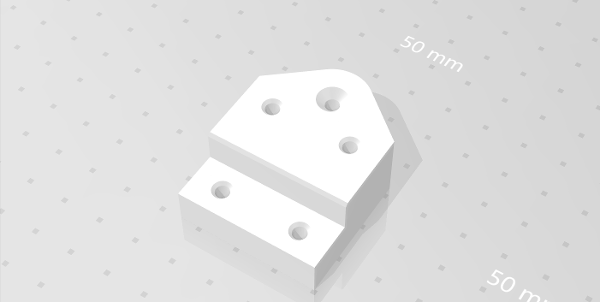

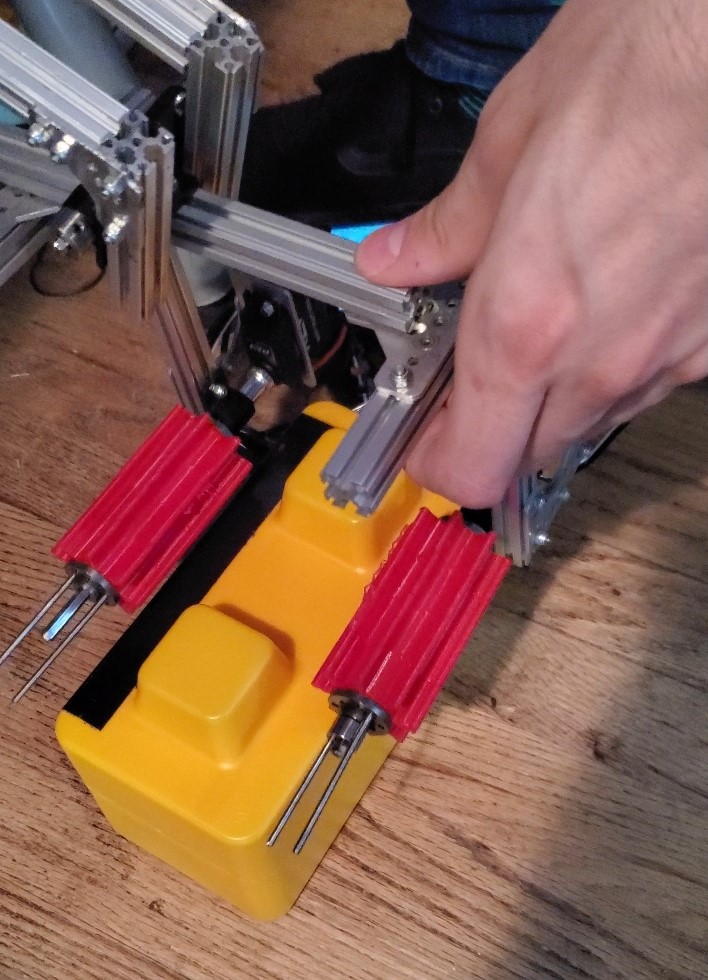

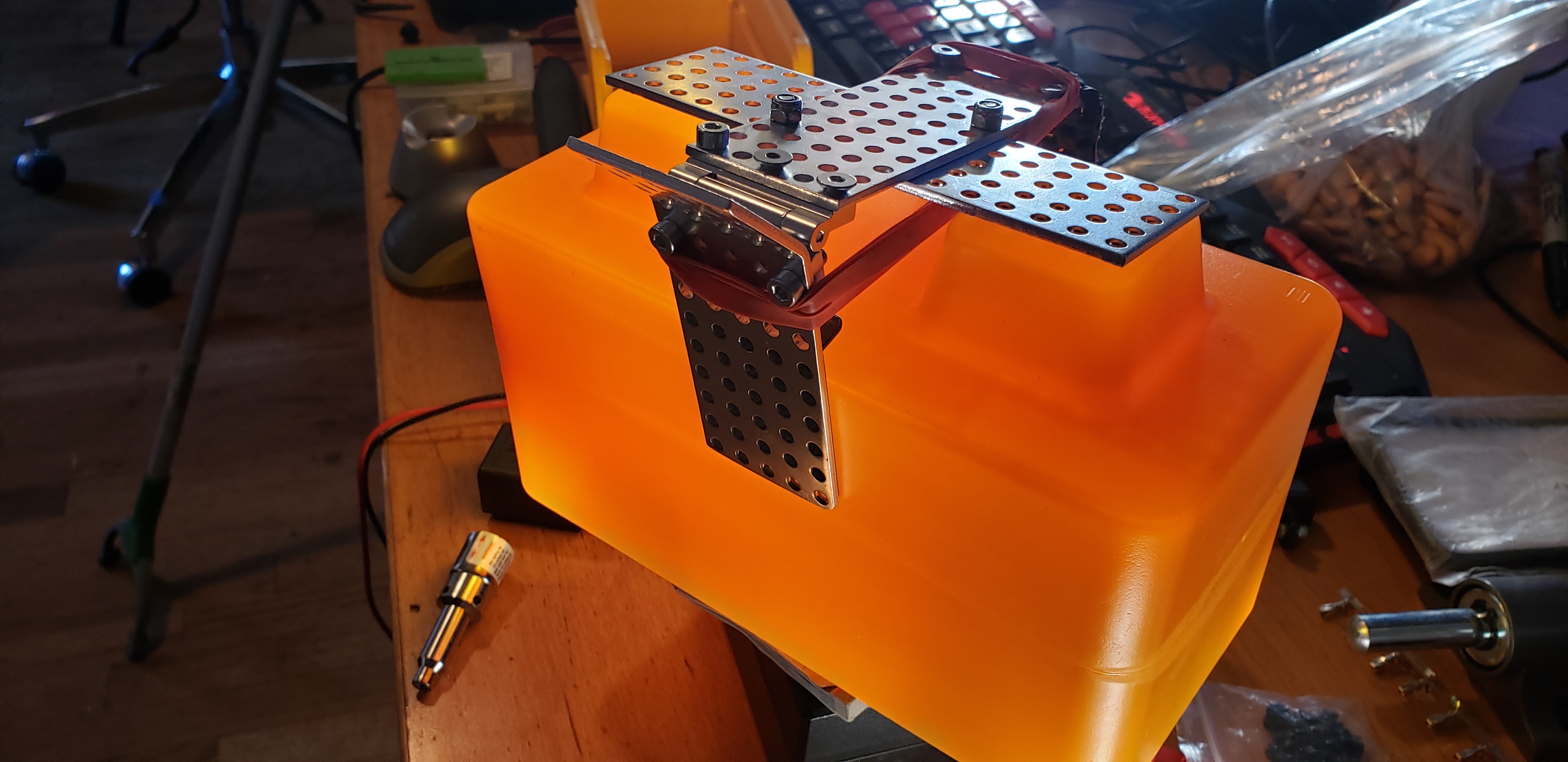

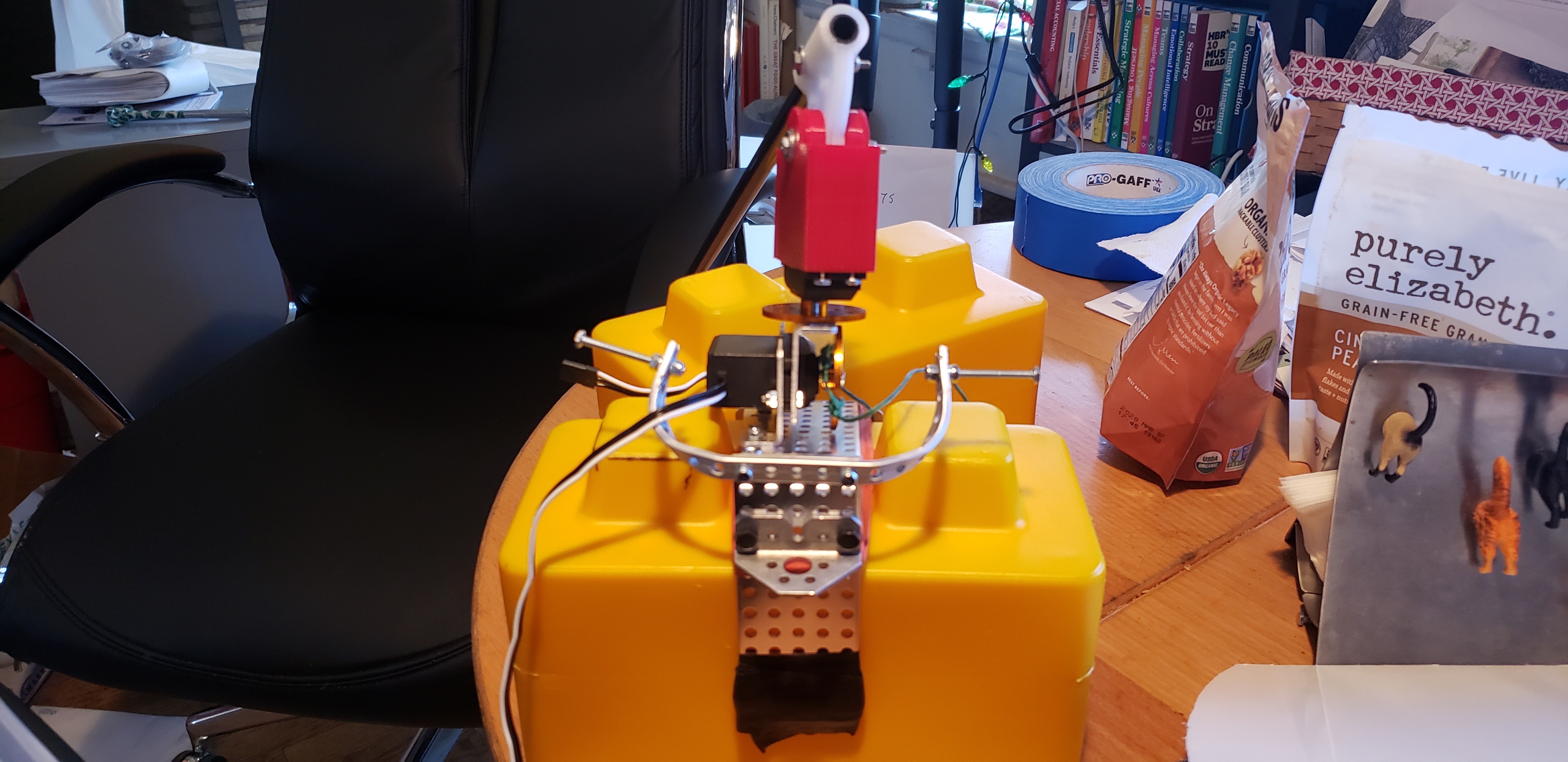

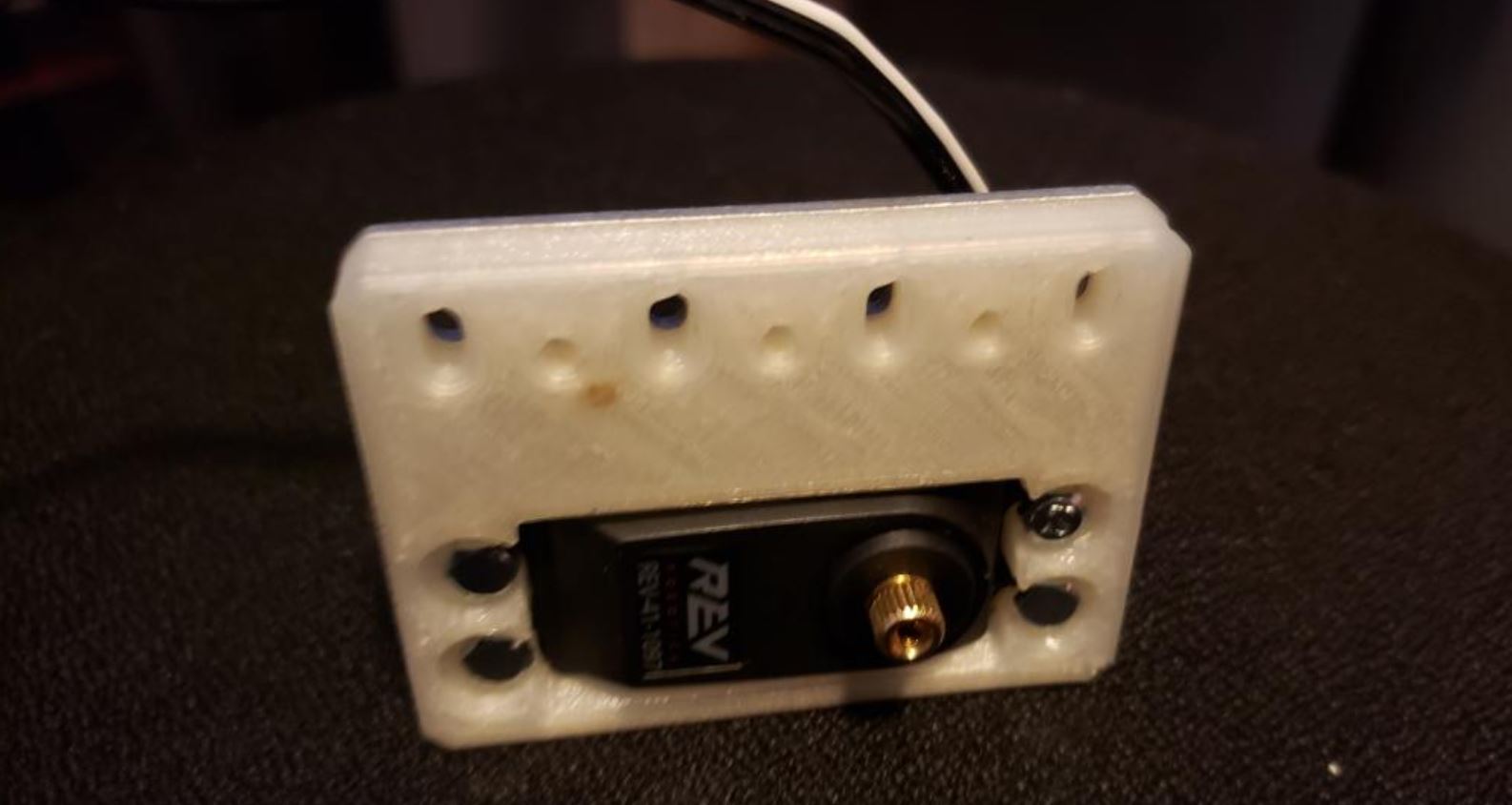

We also designed and printed square pieces to go on the top and bottom of the gripper to keep it in place.

We also designed and printed square pieces to go on the top and bottom of the gripper to keep it in place.

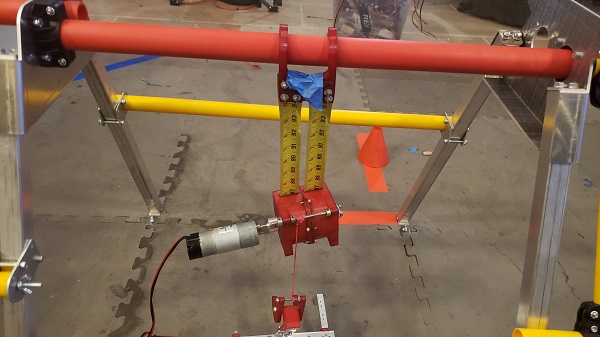

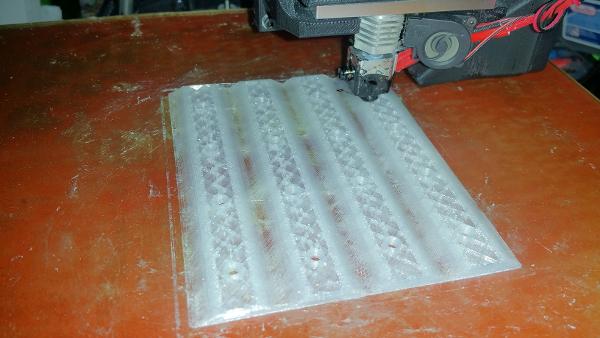

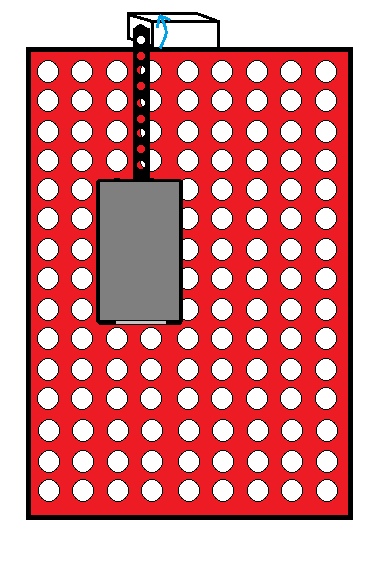

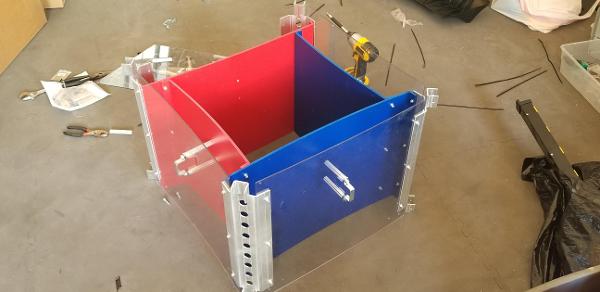

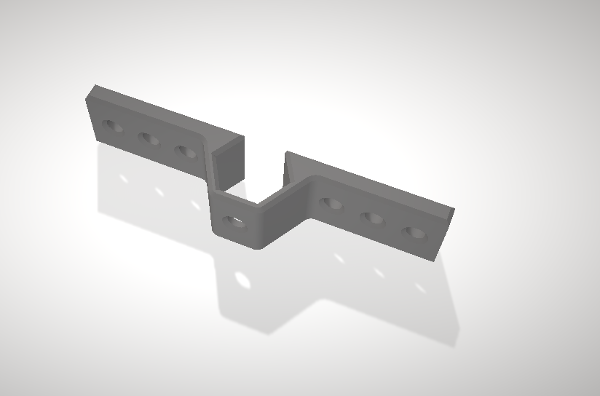

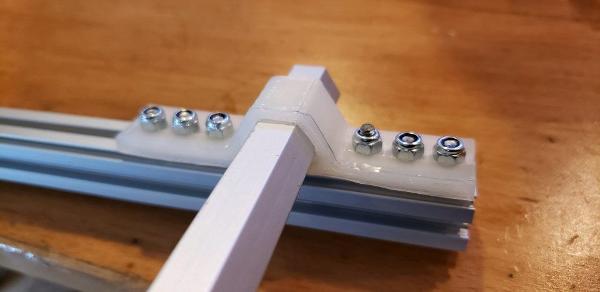

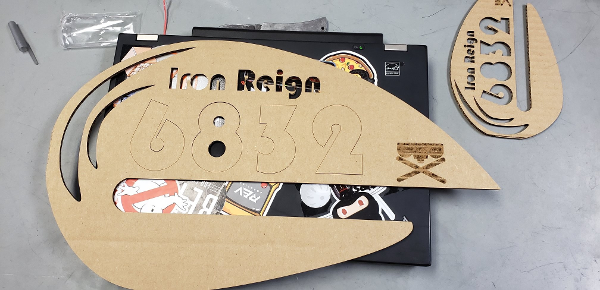

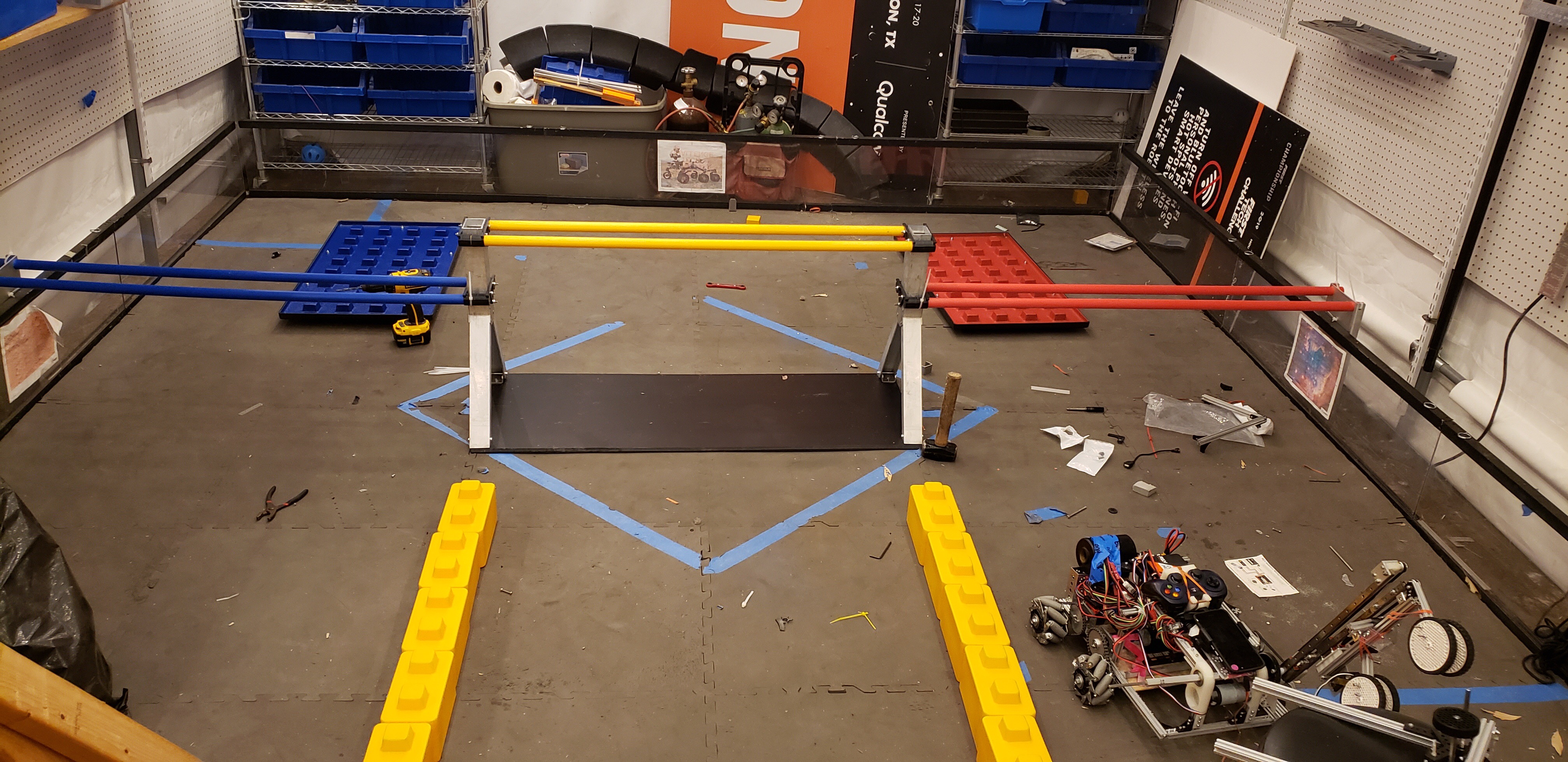

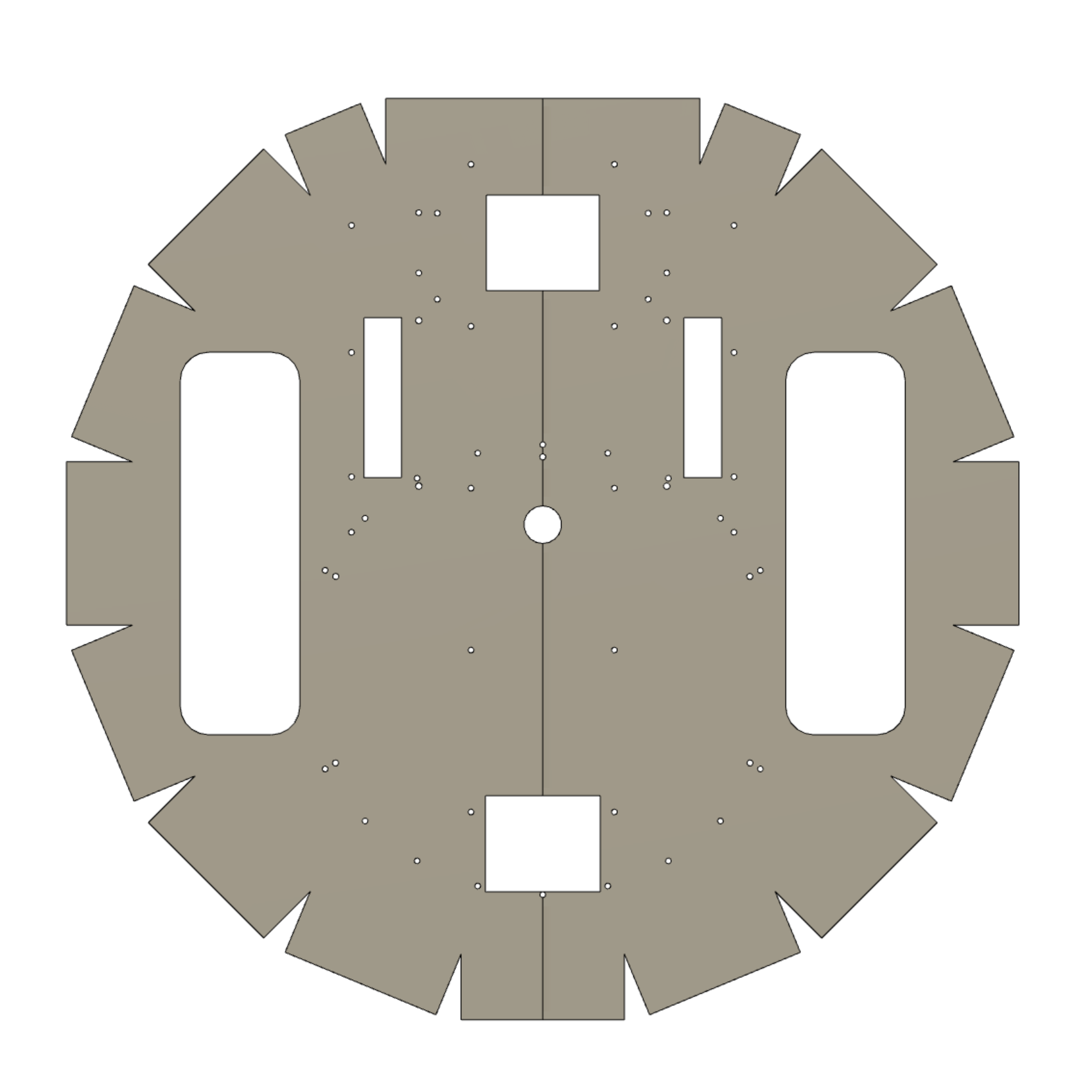

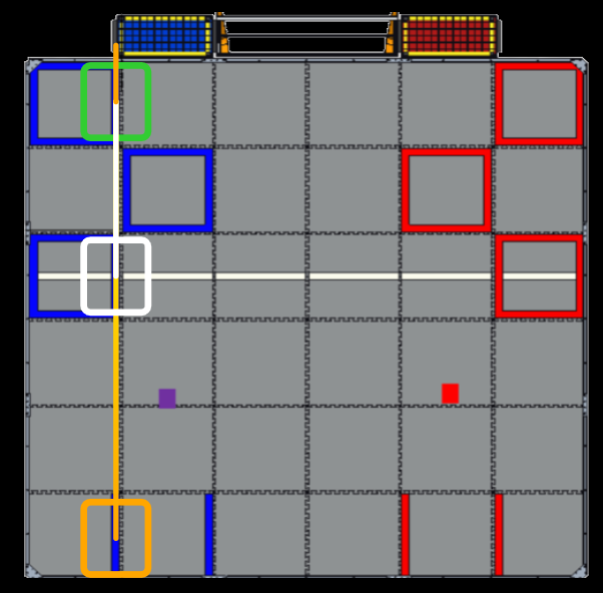

In total, it took us most of practice to finish making all of the field elements and attaching all of the tiles, but we are not finished yet! We still have to set up the field border and attach the field elements, so keep on the look out for a

In total, it took us most of practice to finish making all of the field elements and attaching all of the tiles, but we are not finished yet! We still have to set up the field border and attach the field elements, so keep on the look out for a

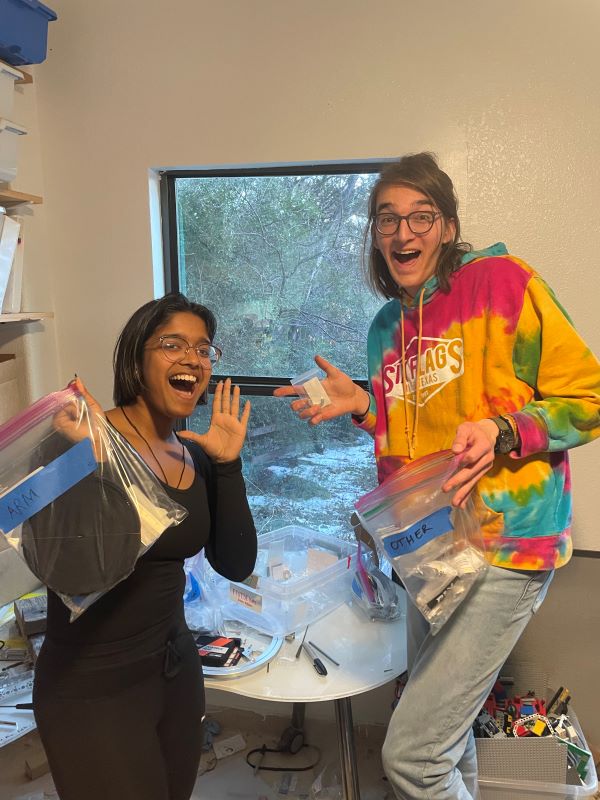

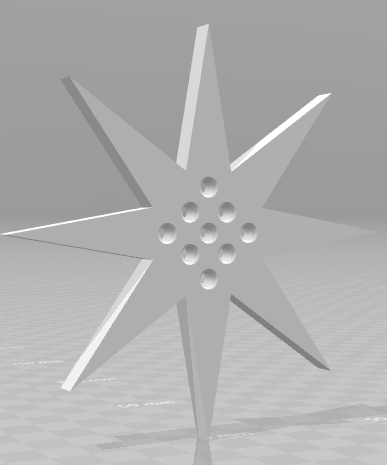

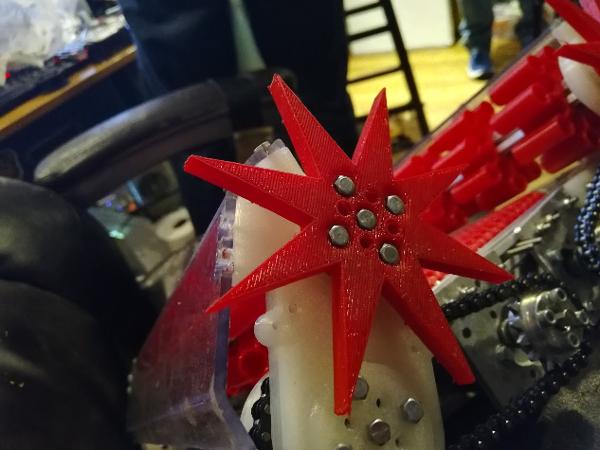

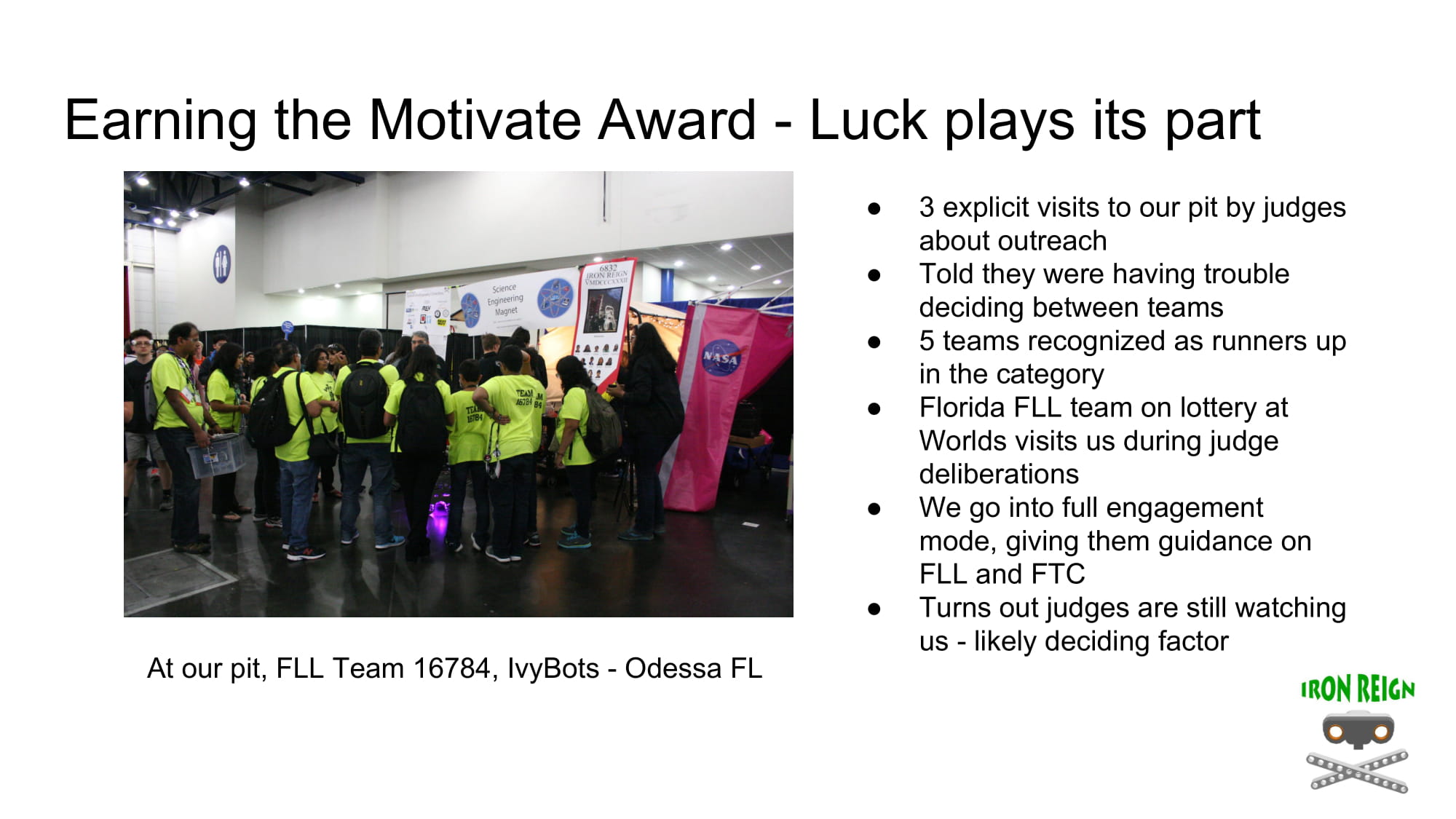

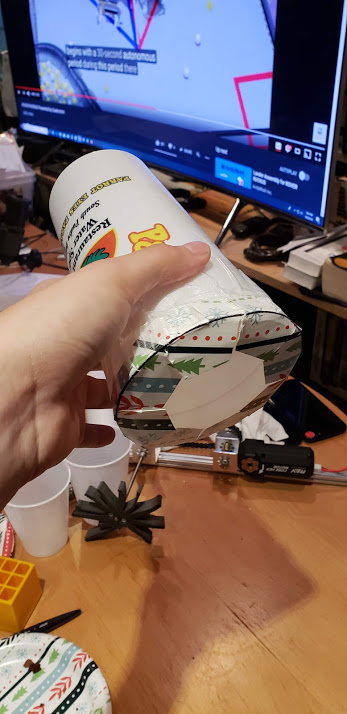

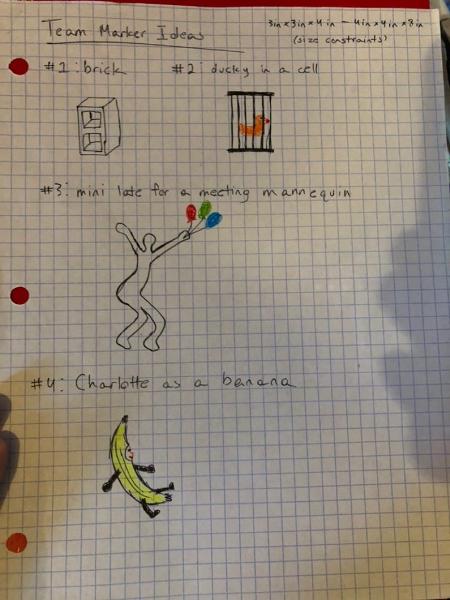

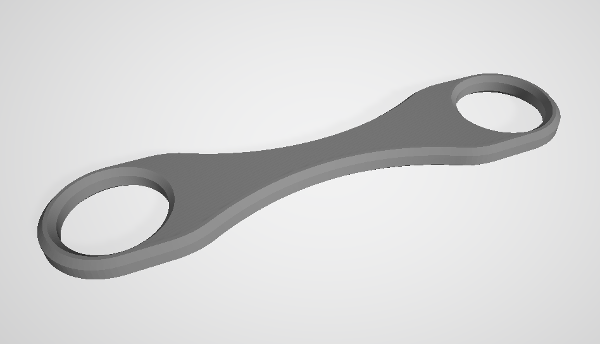

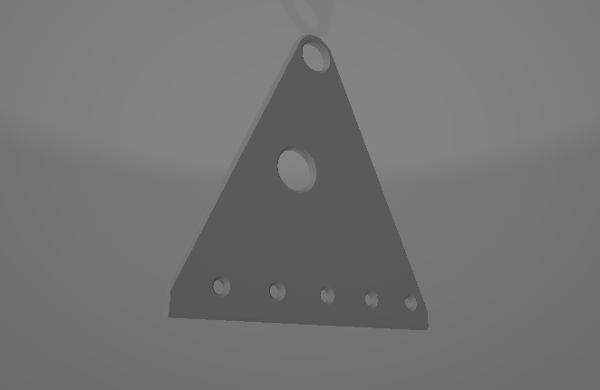

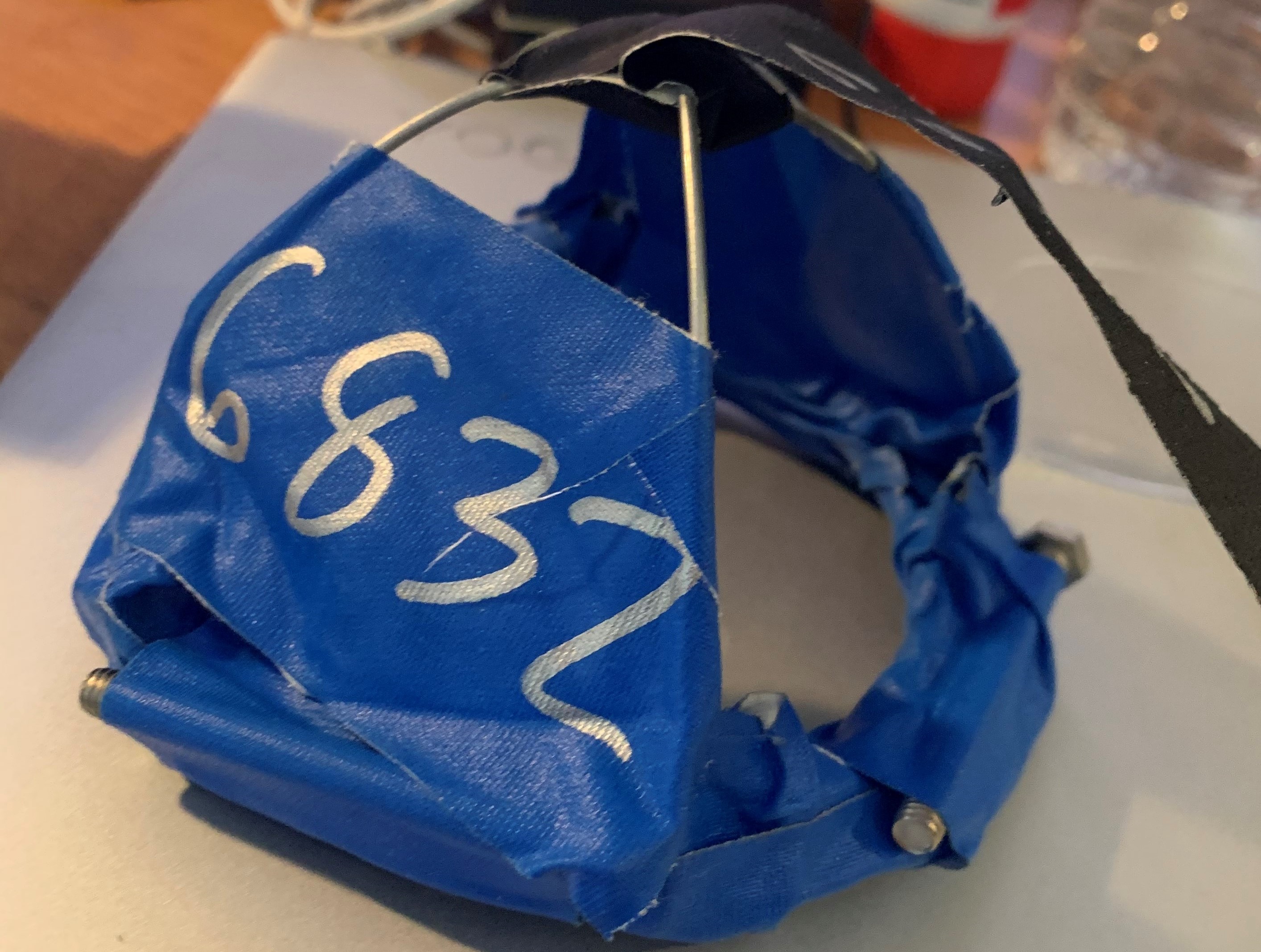

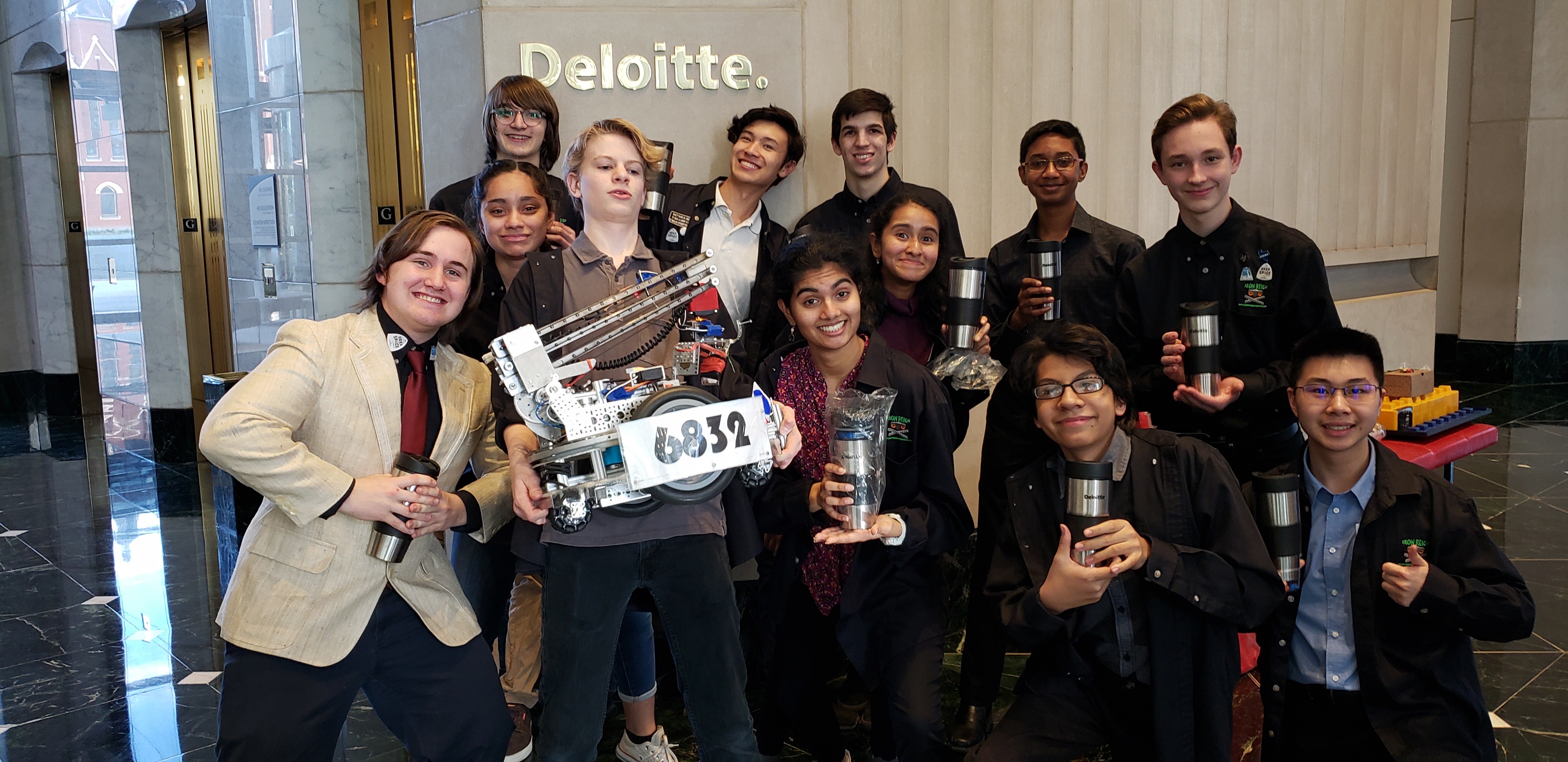

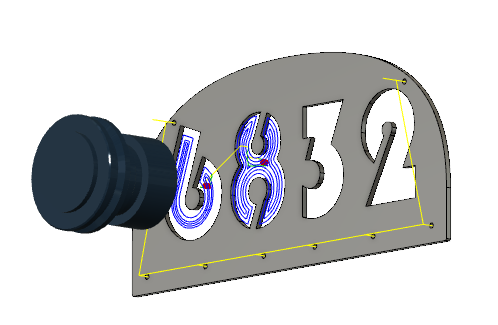

We came to the Oklahoma Regional woefully unprepared for the amount of stuff other teams would give out.

As soon as we arrived, we received every trinket imaginable.

There were keychains, pins, 3D-printed symbols, business cards, patches, and tons of other creative designs. Luckily, the MXP was there and had 4 3D printers on board.

Normally, we use them to print out keychains for kids during our outreach in Dallas, but this time it was for our own use.

We whipped up a quick design on SketchUP and started printing. The design wasn't especially memorable

(something we want to improve on for Supers), but it was nice to have something to give out to passing teams.

We came to the Oklahoma Regional woefully unprepared for the amount of stuff other teams would give out.

As soon as we arrived, we received every trinket imaginable.

There were keychains, pins, 3D-printed symbols, business cards, patches, and tons of other creative designs. Luckily, the MXP was there and had 4 3D printers on board.

Normally, we use them to print out keychains for kids during our outreach in Dallas, but this time it was for our own use.

We whipped up a quick design on SketchUP and started printing. The design wasn't especially memorable

(something we want to improve on for Supers), but it was nice to have something to give out to passing teams.

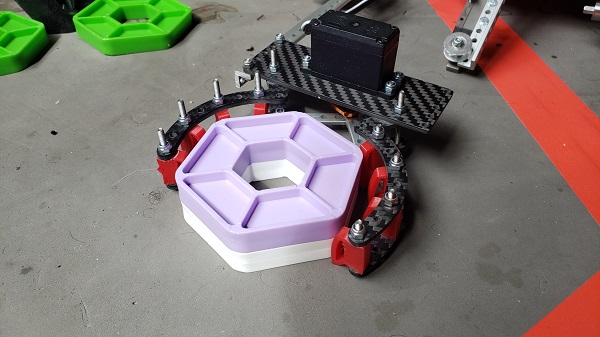

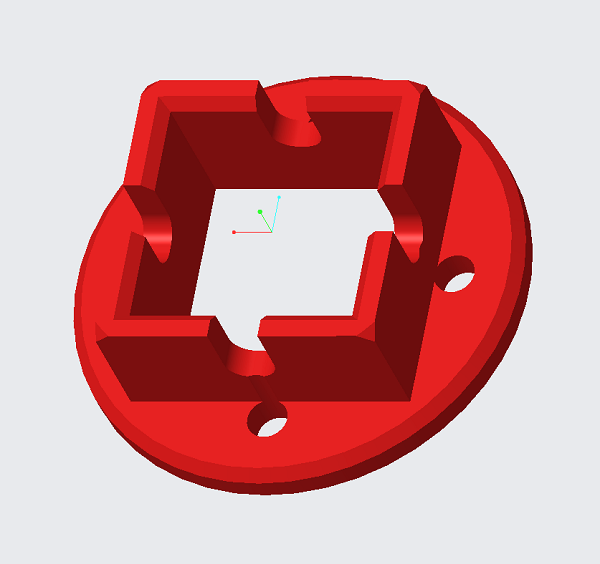

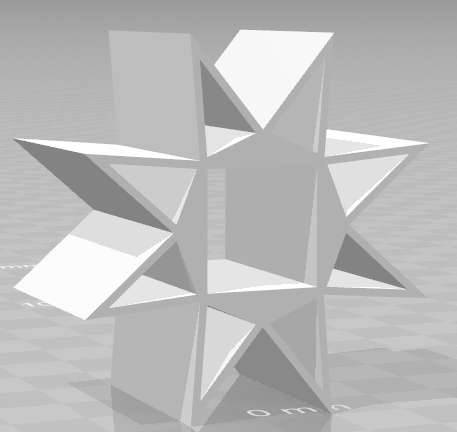

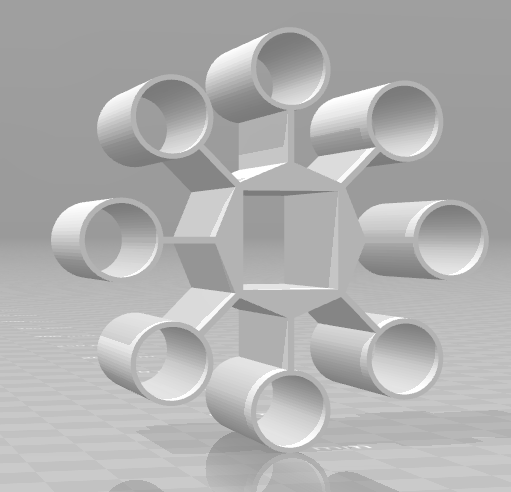

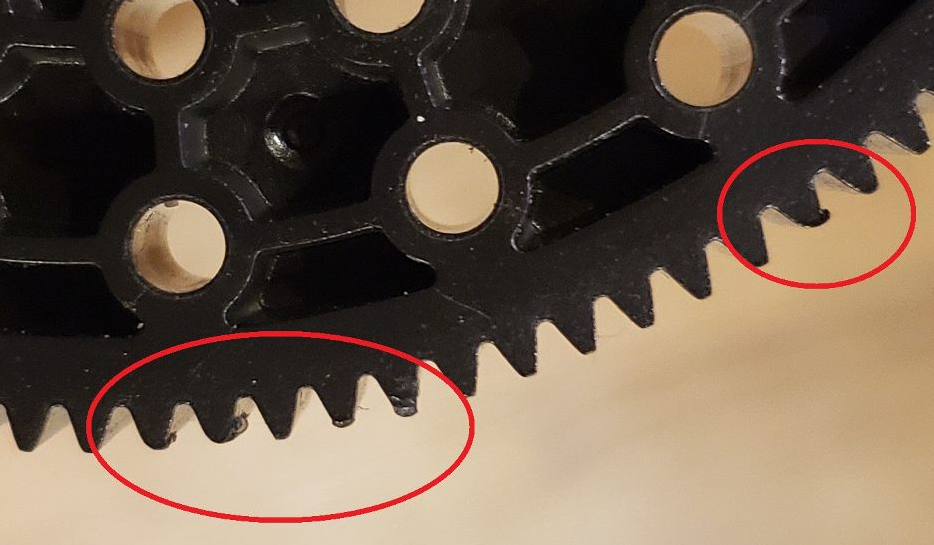

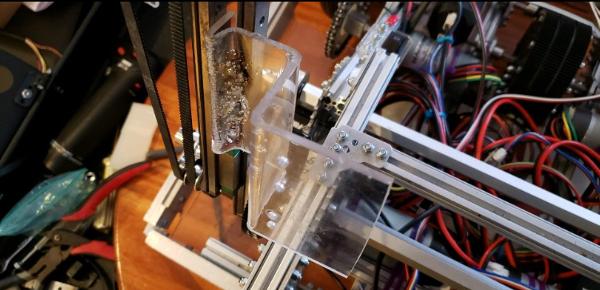

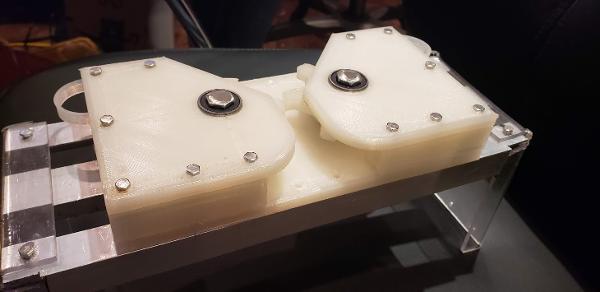

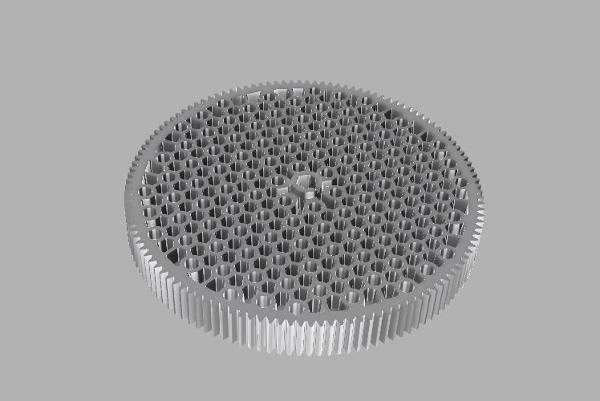

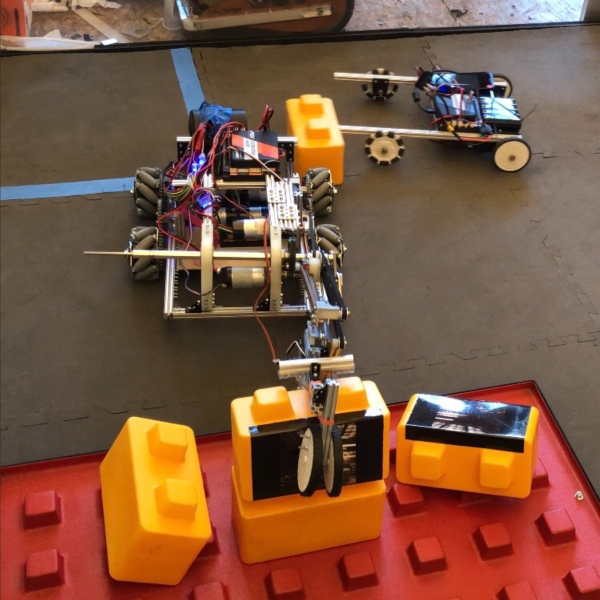

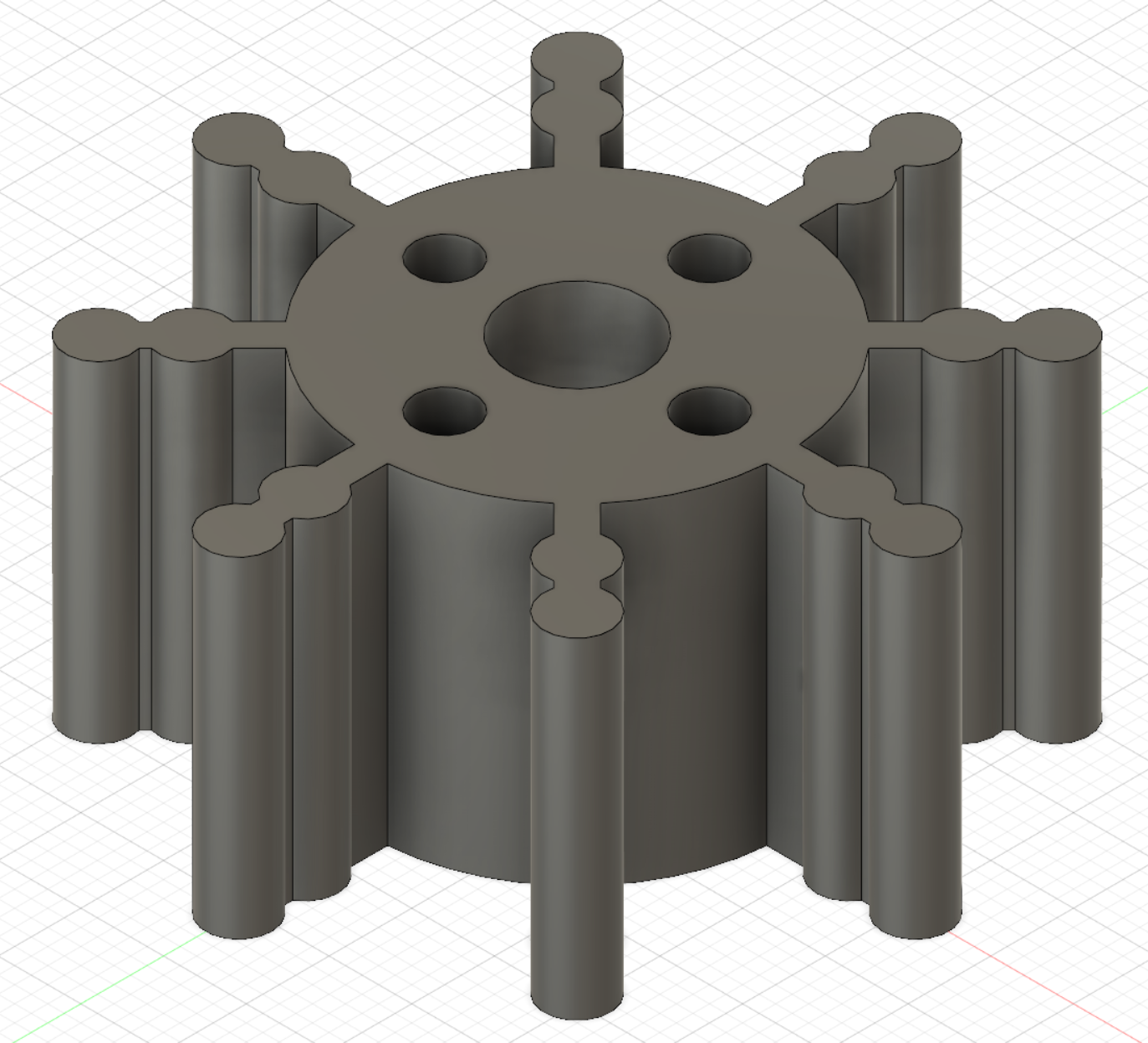

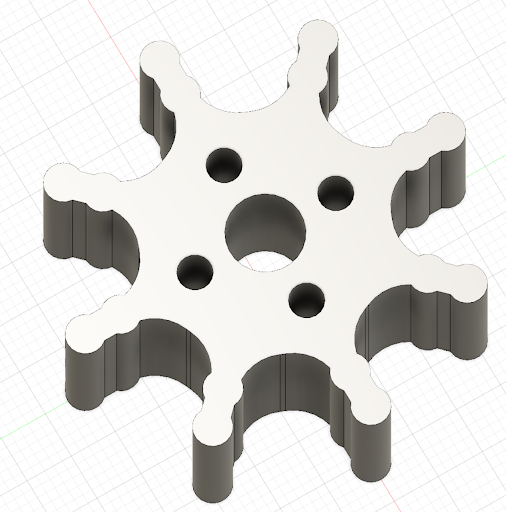

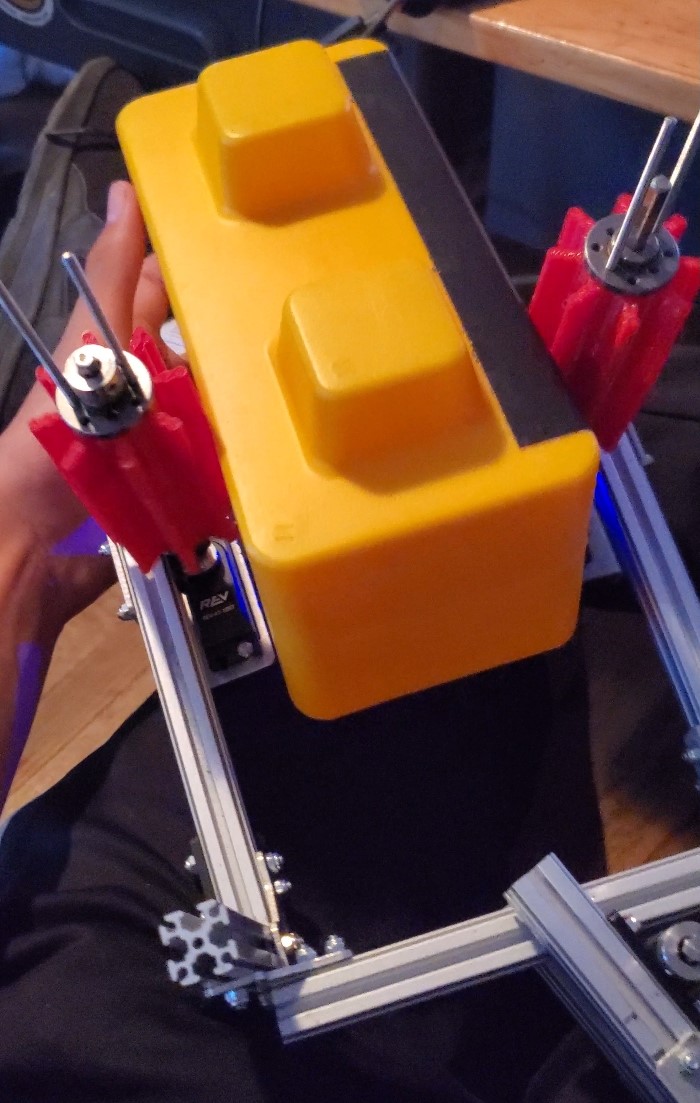

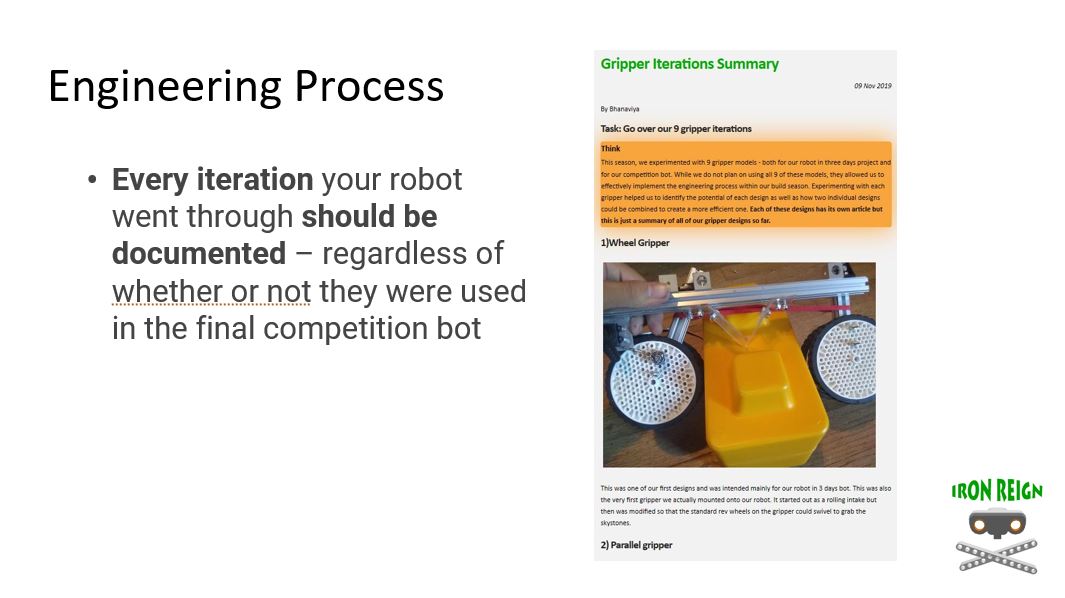

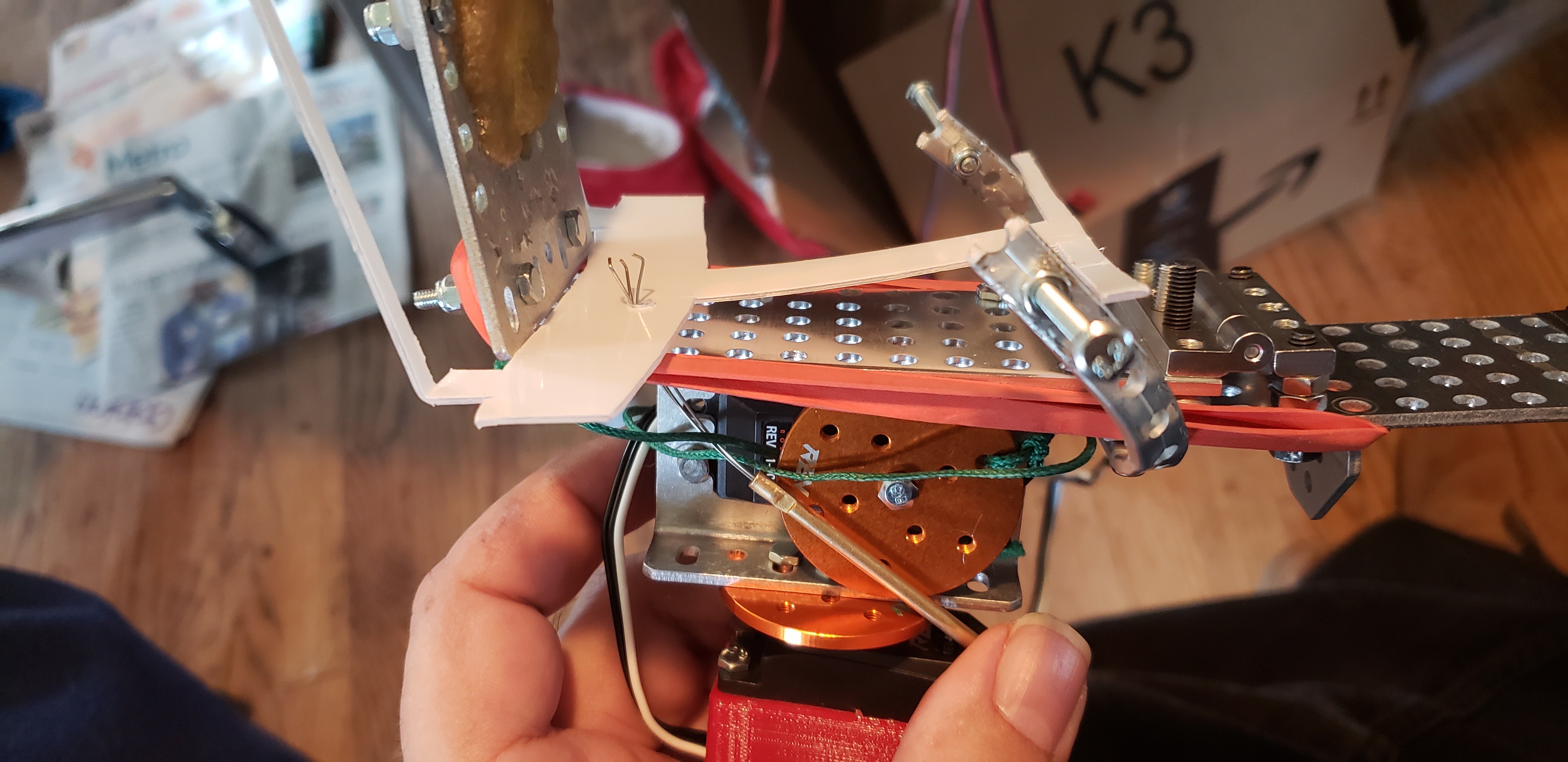

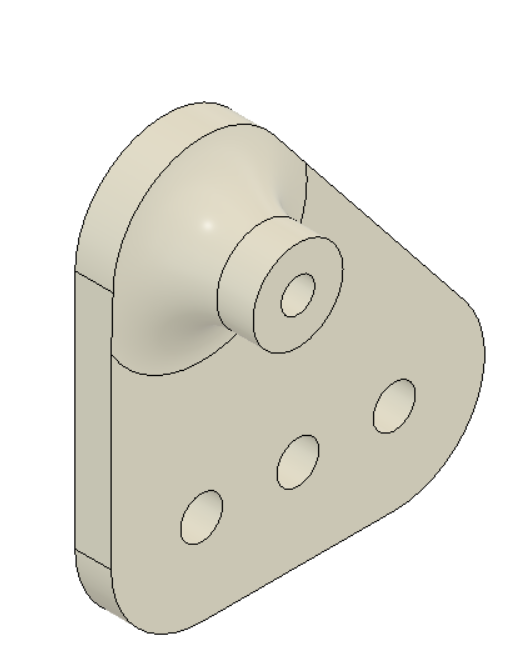

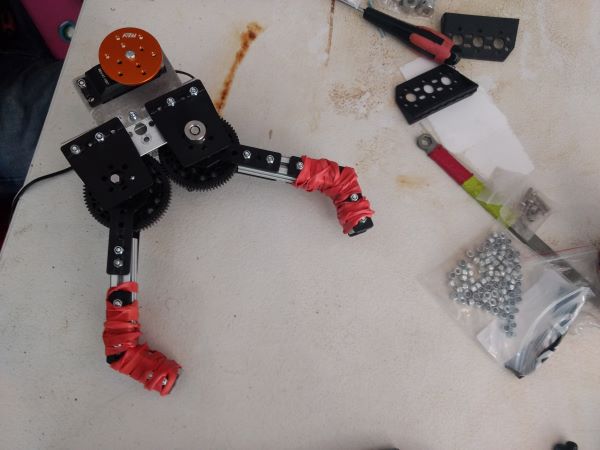

This design was too rigid, we overlooked the fact that triangles tend to be the strongest shape, and therefore this octopucker wasn't as compliant as we wanted, damaging the blocks.

This design was too rigid, we overlooked the fact that triangles tend to be the strongest shape, and therefore this octopucker wasn't as compliant as we wanted, damaging the blocks.

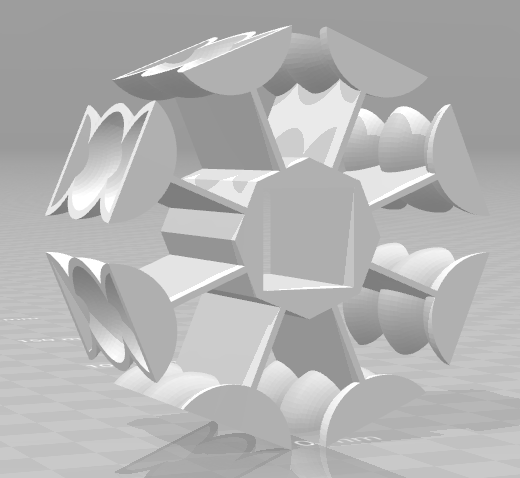

This design was really good, and we used it for 3-4 tournaments. Our initial design of these wouldn't damage the blocks significantly at the levels we used, but at extraordinary conditions they would gouge the blocks, and under normal conditions they would leave superficial scratches.

This design was really good, and we used it for 3-4 tournaments. Our initial design of these wouldn't damage the blocks significantly at the levels we used, but at extraordinary conditions they would gouge the blocks, and under normal conditions they would leave superficial scratches.

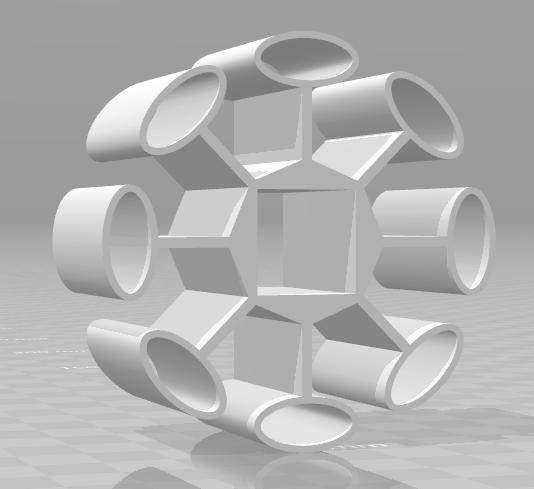

This design was really bad. They would catch on each other and get stuck on themselves, and as a result wouldn't pick up blocks. However, they did not damage the blocks in any conditions. We never brought these to tournament.

This design was really bad. They would catch on each other and get stuck on themselves, and as a result wouldn't pick up blocks. However, they did not damage the blocks in any conditions. We never brought these to tournament.

This was a step in the right direction. They didn't grip the blocks that well, but they worked and didn't get stuck on each other or jam.

This was a step in the right direction. They didn't grip the blocks that well, but they worked and didn't get stuck on each other or jam.

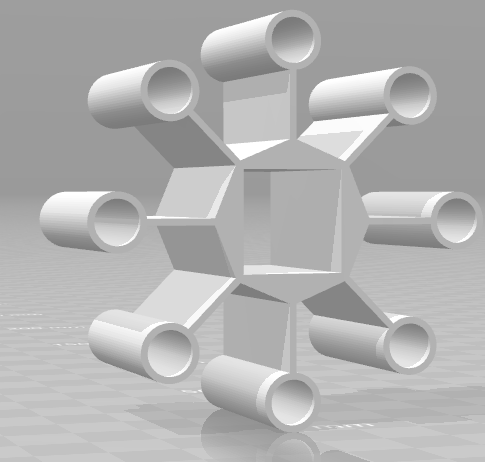

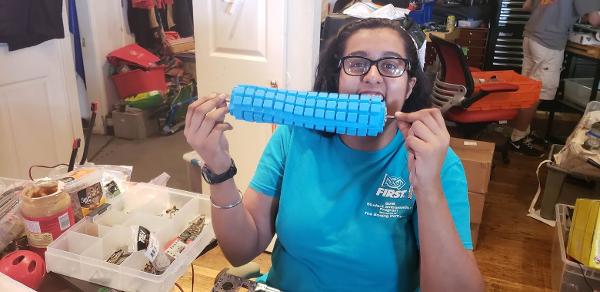

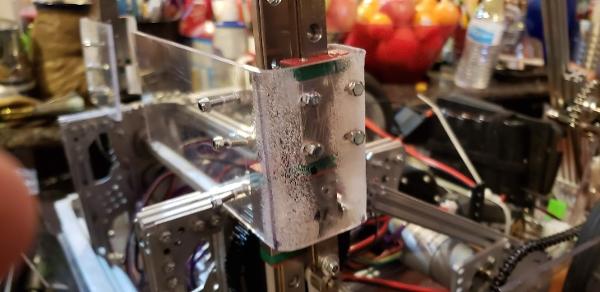

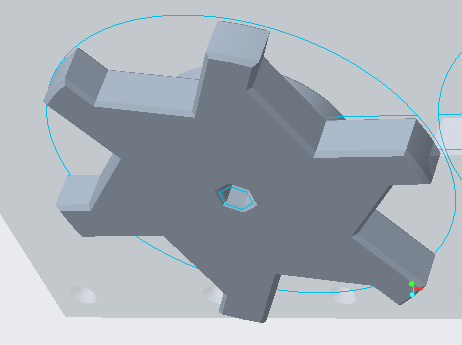

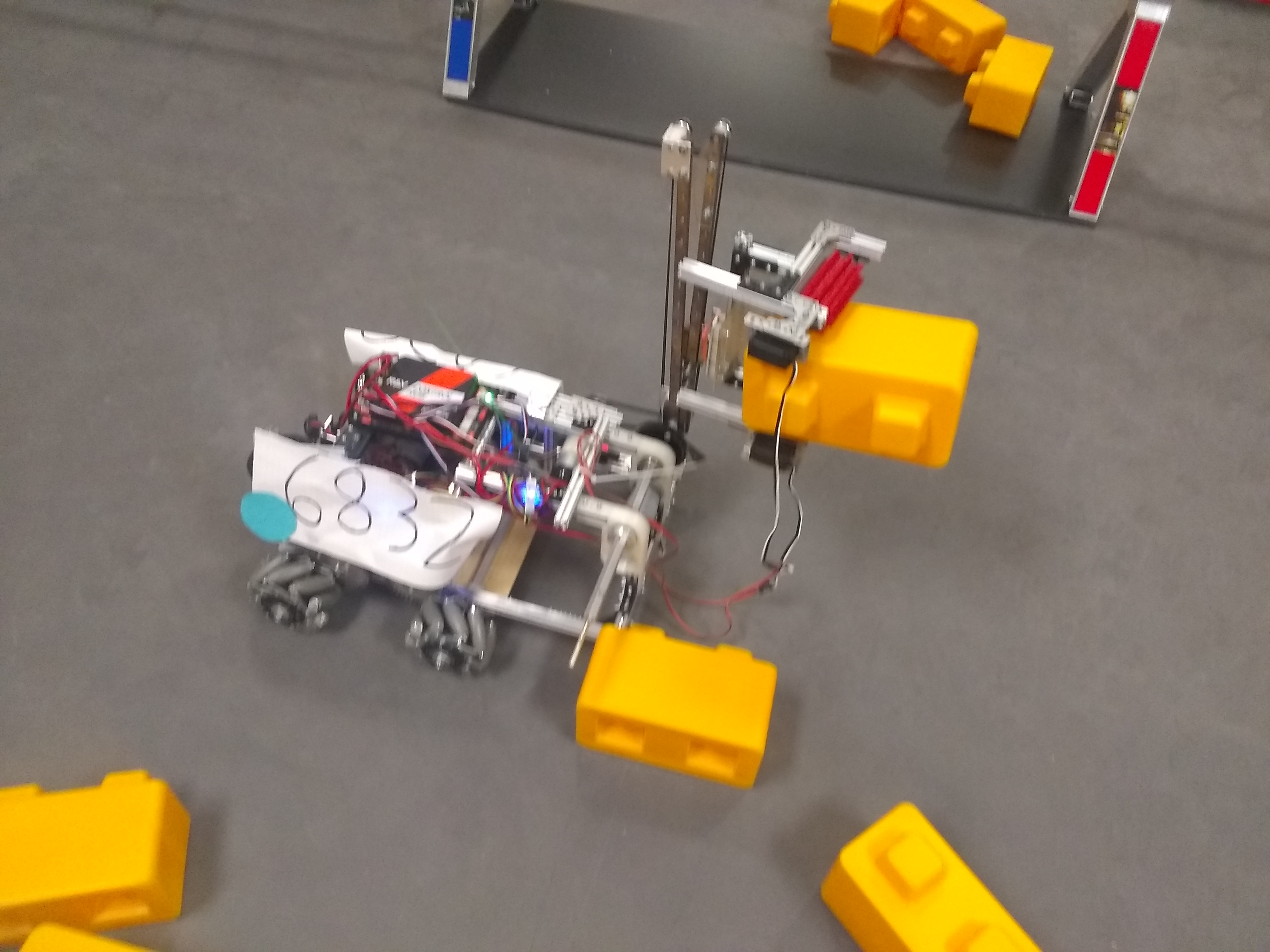

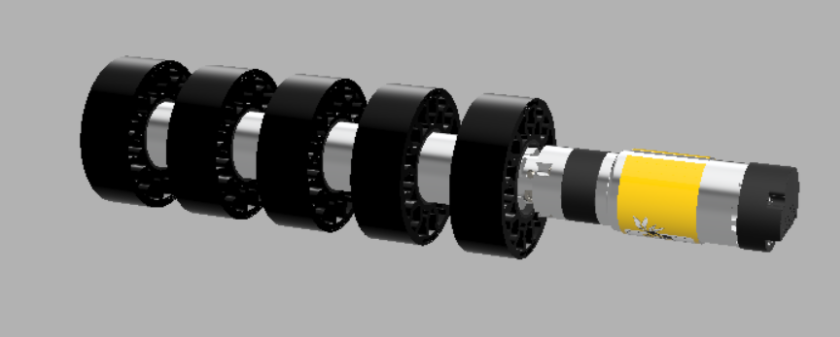

This is the design we're currently using. It's impossible to damage the blocks with them, and with the slightly larger cylinders, they grip the block really well. We're going to use these going into the South Super Regionals.

This is the design we're currently using. It's impossible to damage the blocks with them, and with the slightly larger cylinders, they grip the block really well. We're going to use these going into the South Super Regionals.

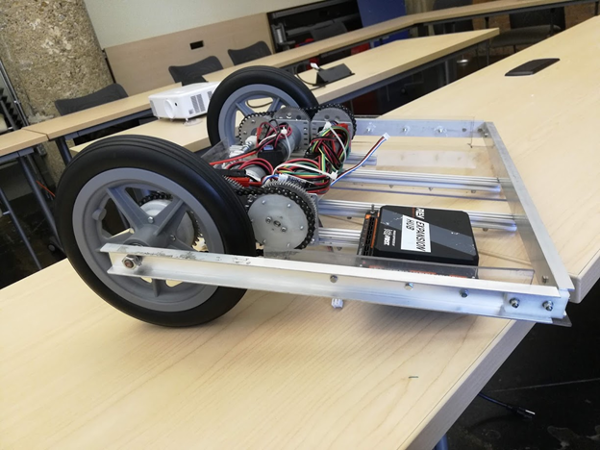

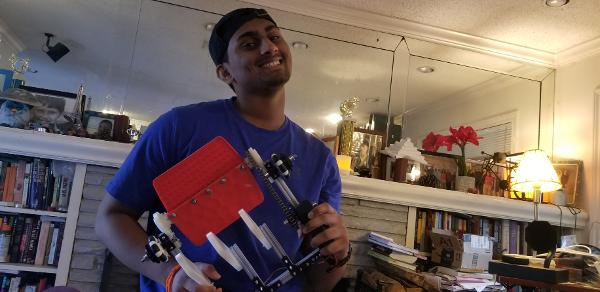

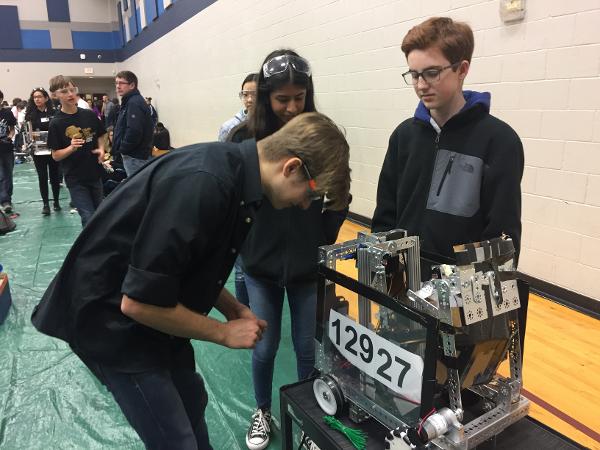

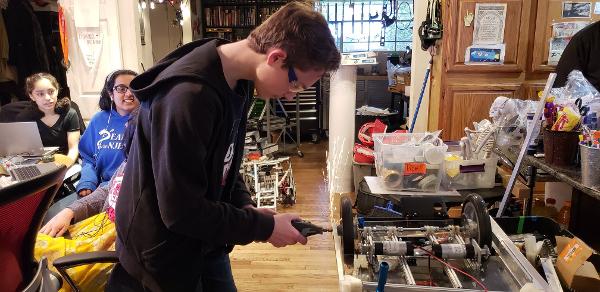

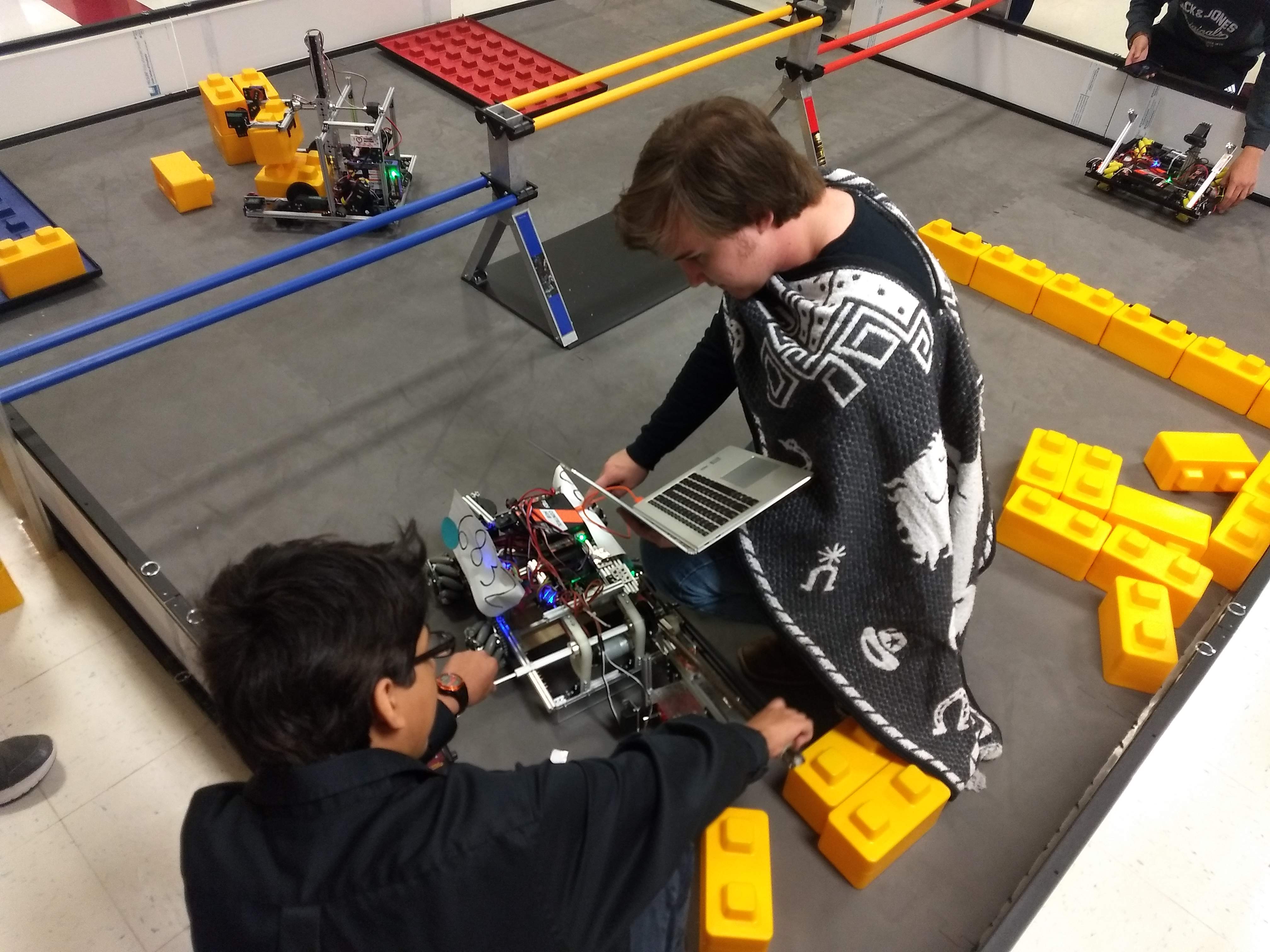

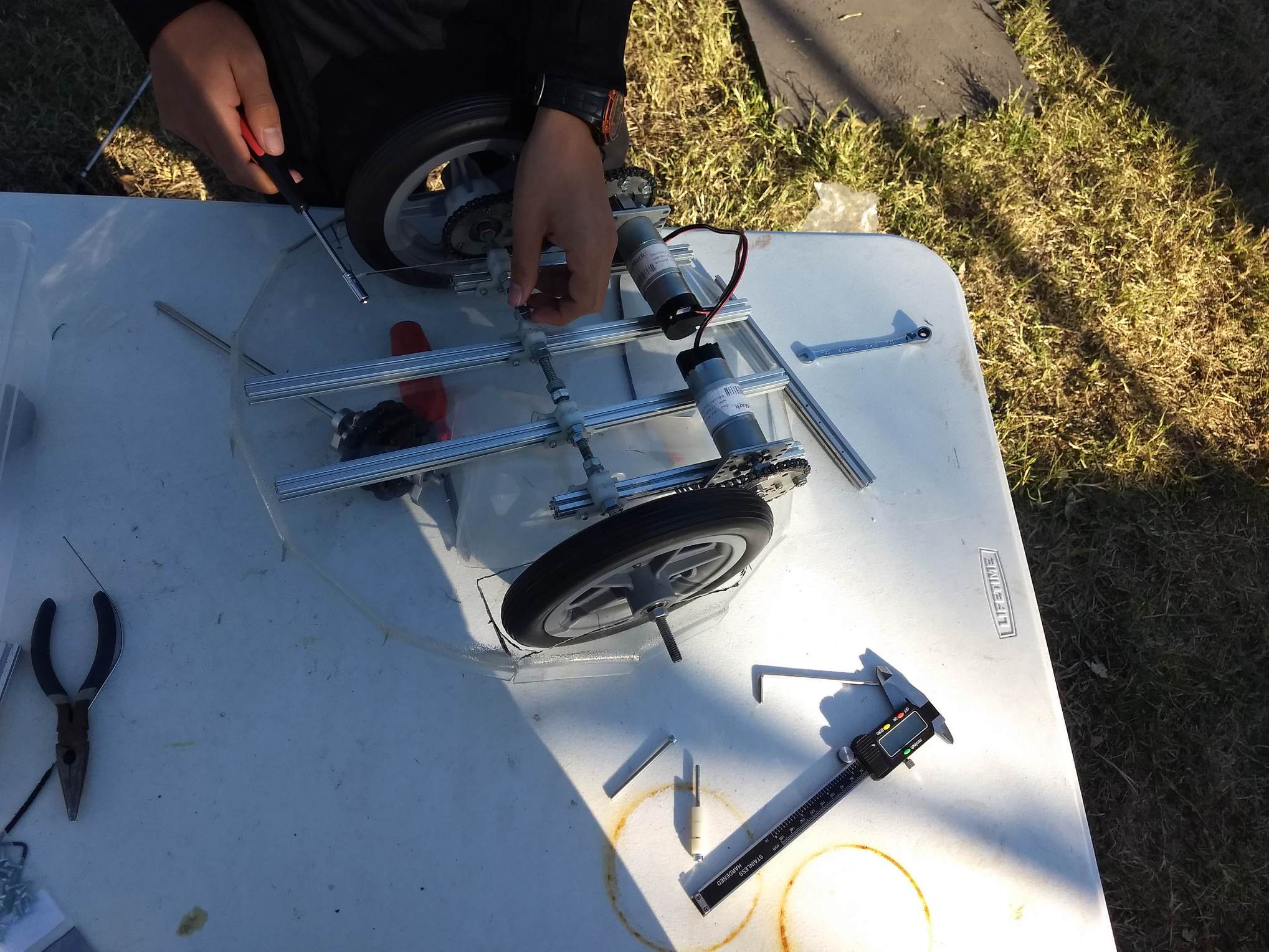

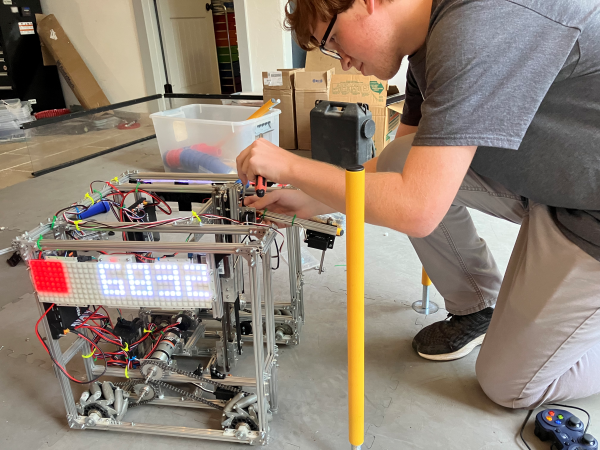

Austin Lui of Technicbots gets their chassis ready for testing.

Austin Lui of Technicbots gets their chassis ready for testing.

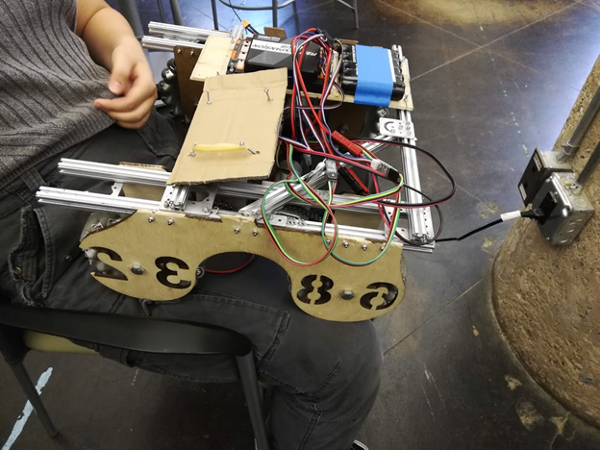

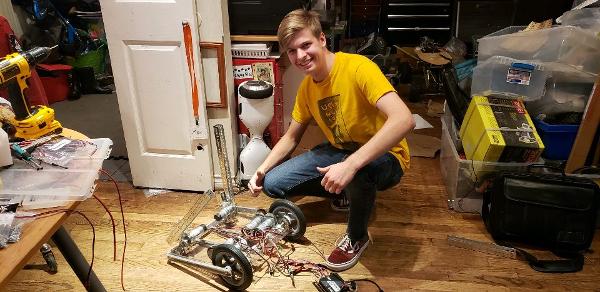

Connor Mihelic of EFFoRT adds some finishing touches.

Connor Mihelic of EFFoRT adds some finishing touches.

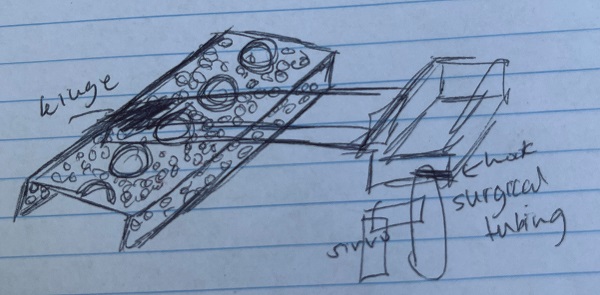

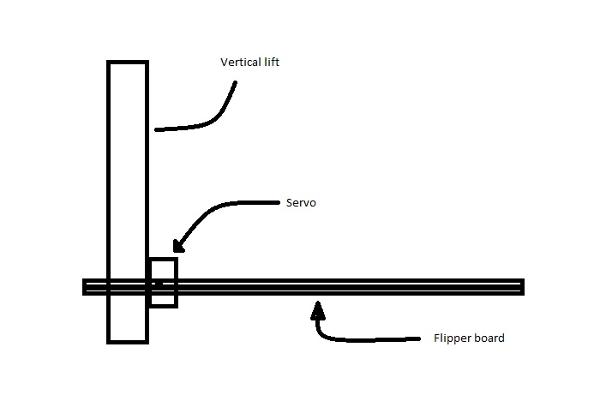

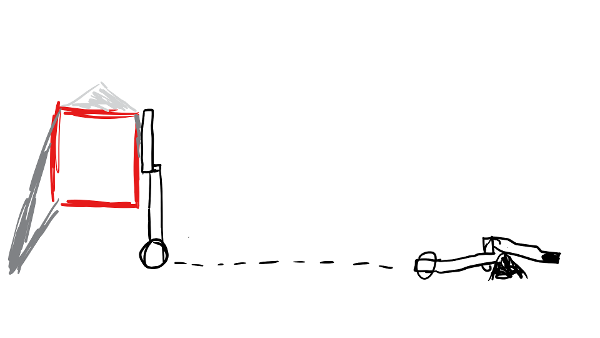

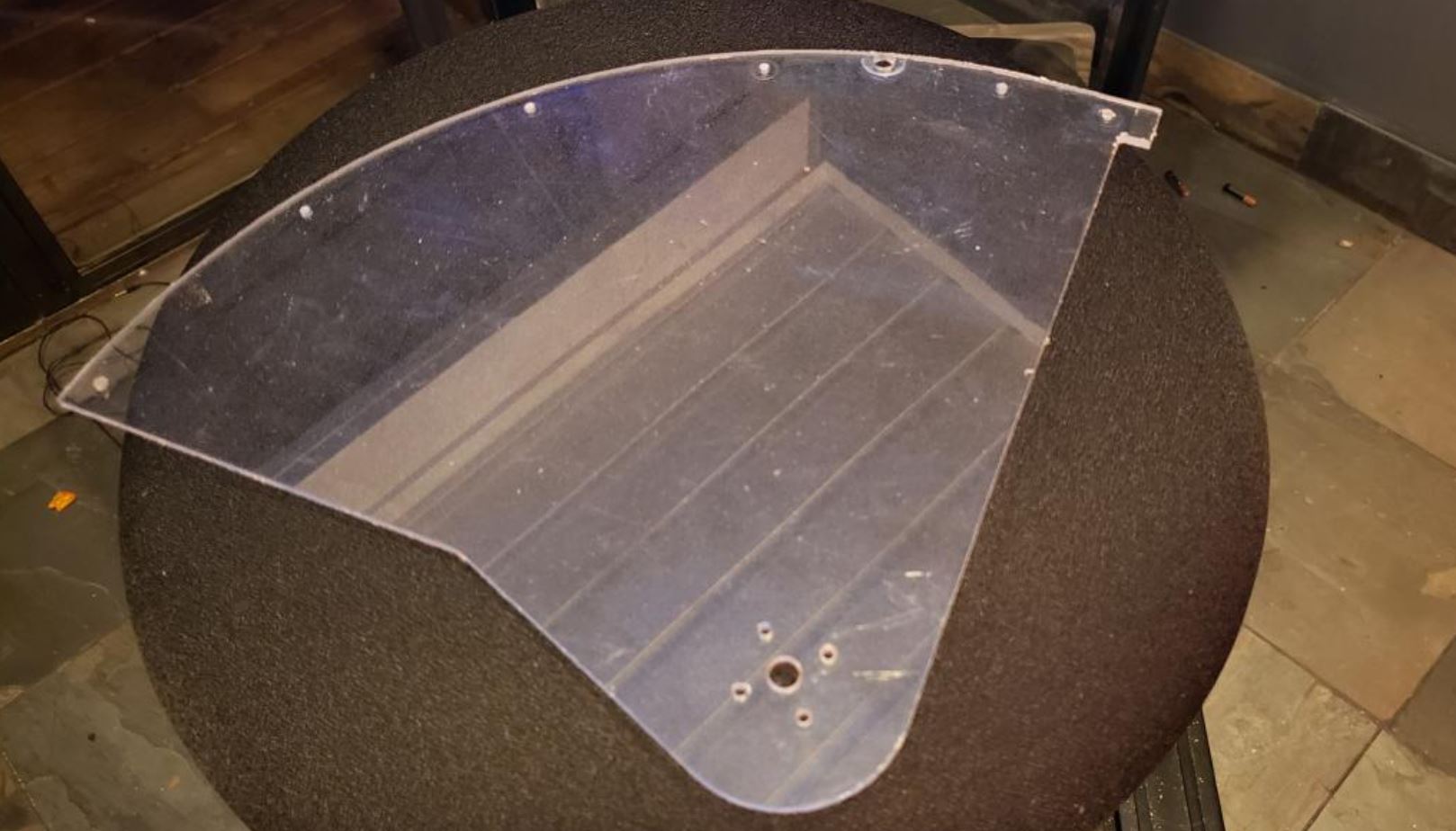

This suggestion uses a plastic flap to "trap" game elements inside it, similar to the lid of a soda cup. You can put marbles through the straw-hole, but you can't easily get them back out.

This suggestion uses a plastic flap to "trap" game elements inside it, similar to the lid of a soda cup. You can put marbles through the straw-hole, but you can't easily get them back out.

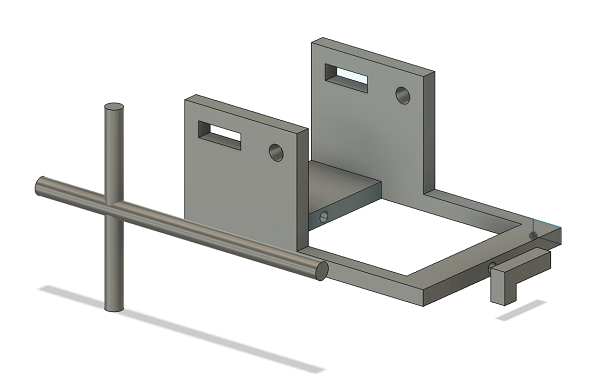

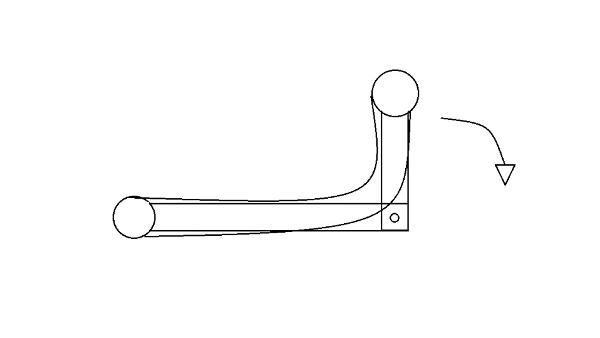

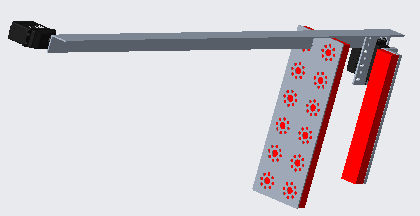

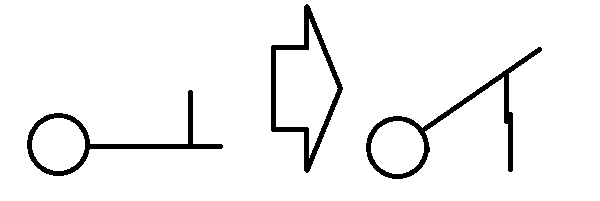

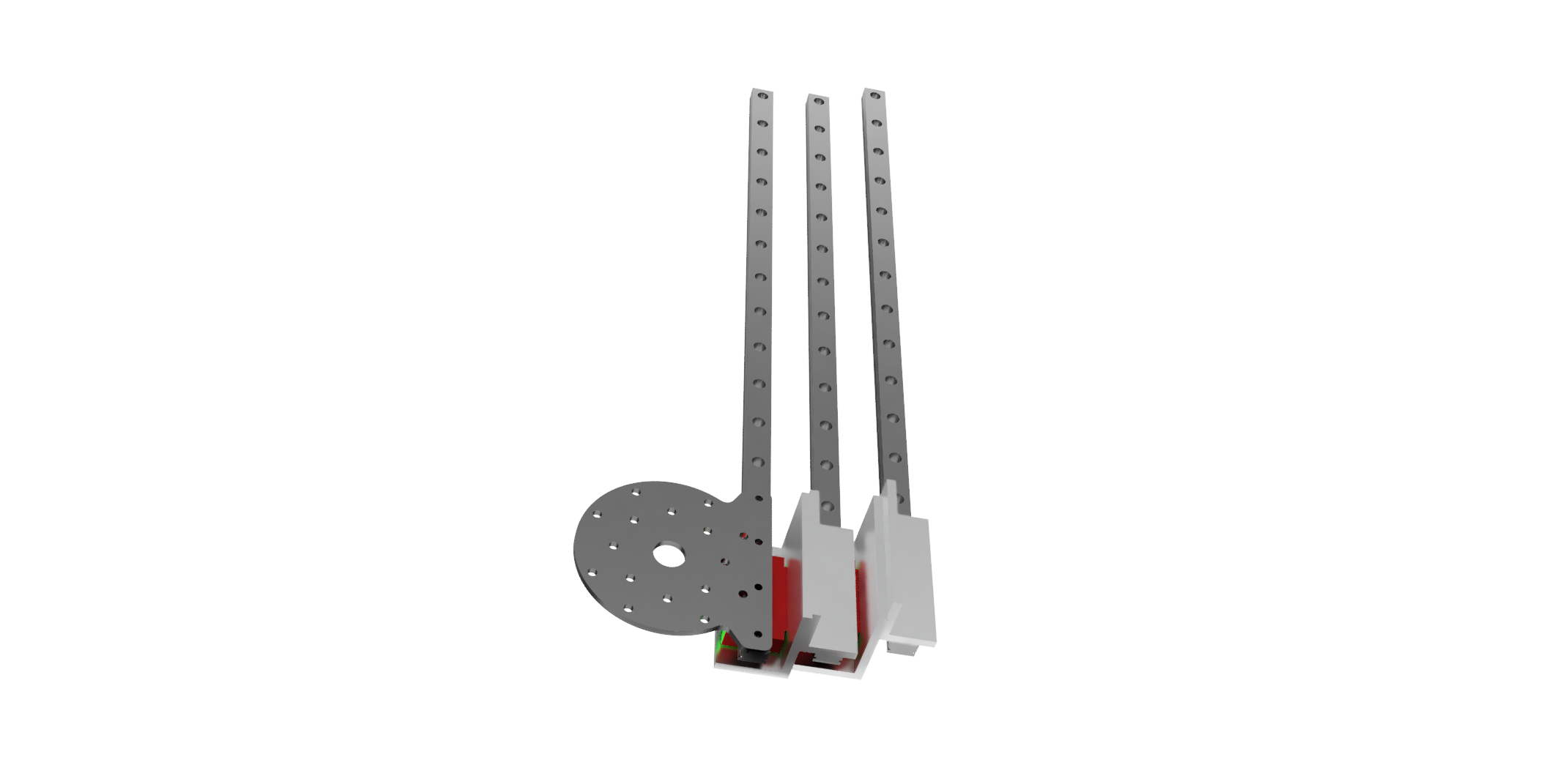

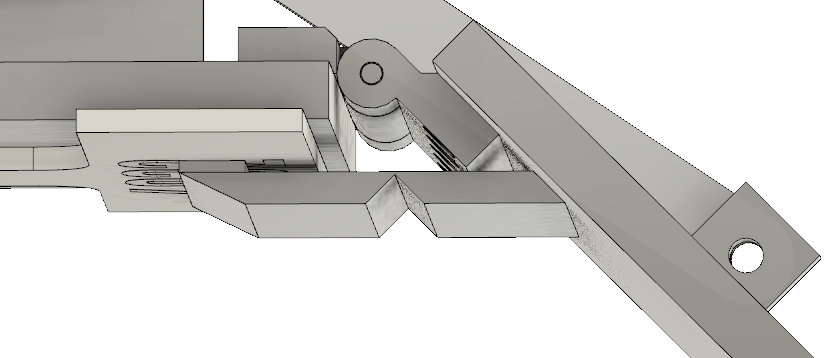

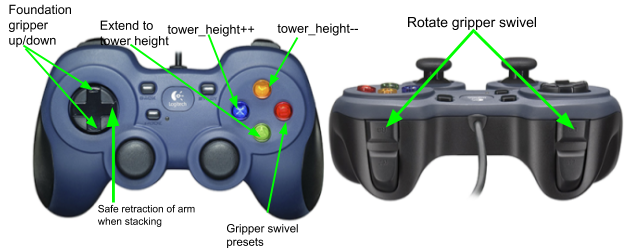

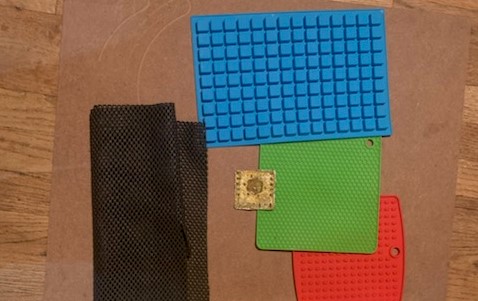

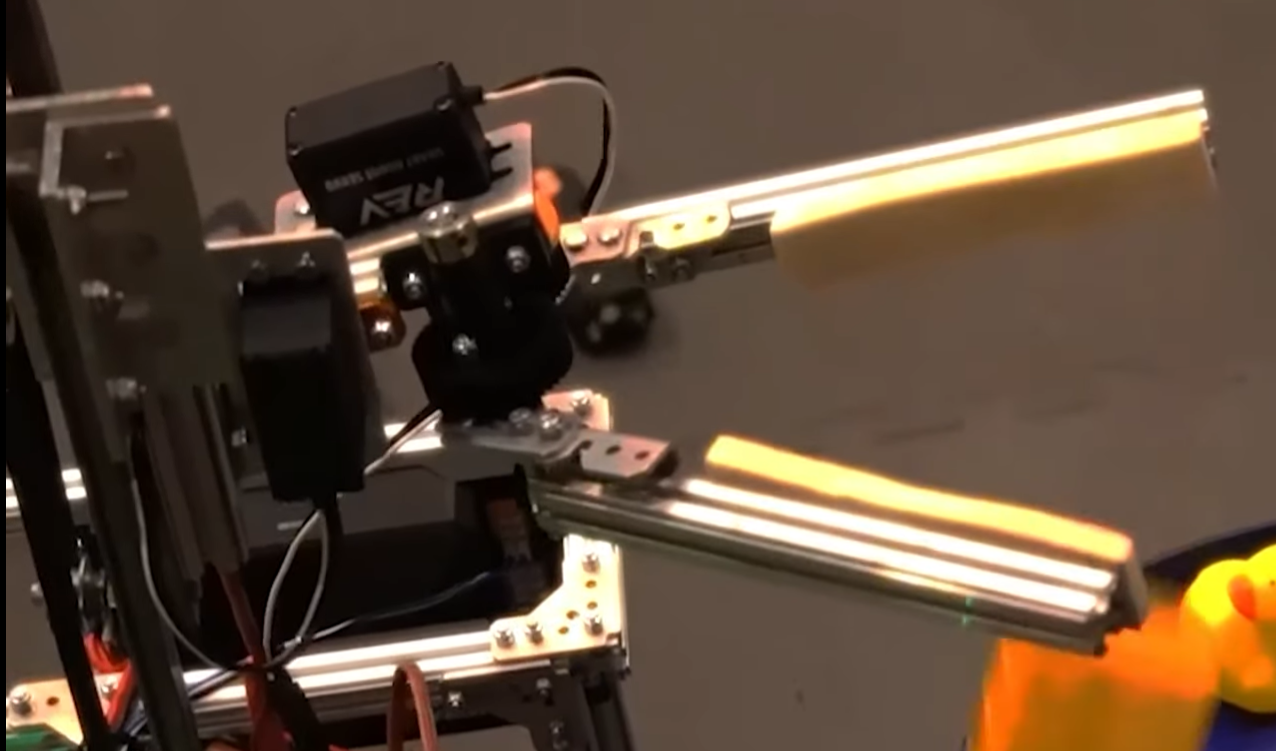

This one is simple - a linear slide arm attached to a motor so that it can pick up game elements and rotate. We fear, however, that many teams will adopt this strategy, so we probably won't do it. One unique part of our design would be the silicone grips, so that the "claws" can firmly grasp the silver and gold.

This one is simple - a linear slide arm attached to a motor so that it can pick up game elements and rotate. We fear, however, that many teams will adopt this strategy, so we probably won't do it. One unique part of our design would be the silicone grips, so that the "claws" can firmly grasp the silver and gold.

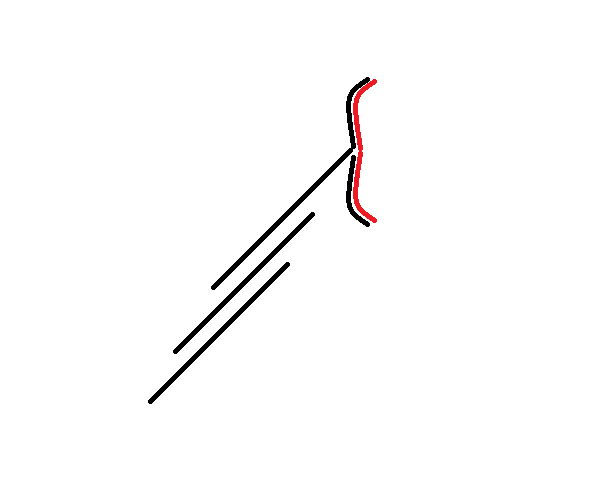

When we did Res-Q, we dropped our robot more times than we'd like to admit. To prevent that, we're designing an interlocking mechanism that the robot can use to hang. It'll have an indent and a corresponding recess that resists lateral force by nature of the indent, but can be opened easily.

When we did Res-Q, we dropped our robot more times than we'd like to admit. To prevent that, we're designing an interlocking mechanism that the robot can use to hang. It'll have an indent and a corresponding recess that resists lateral force by nature of the indent, but can be opened easily.

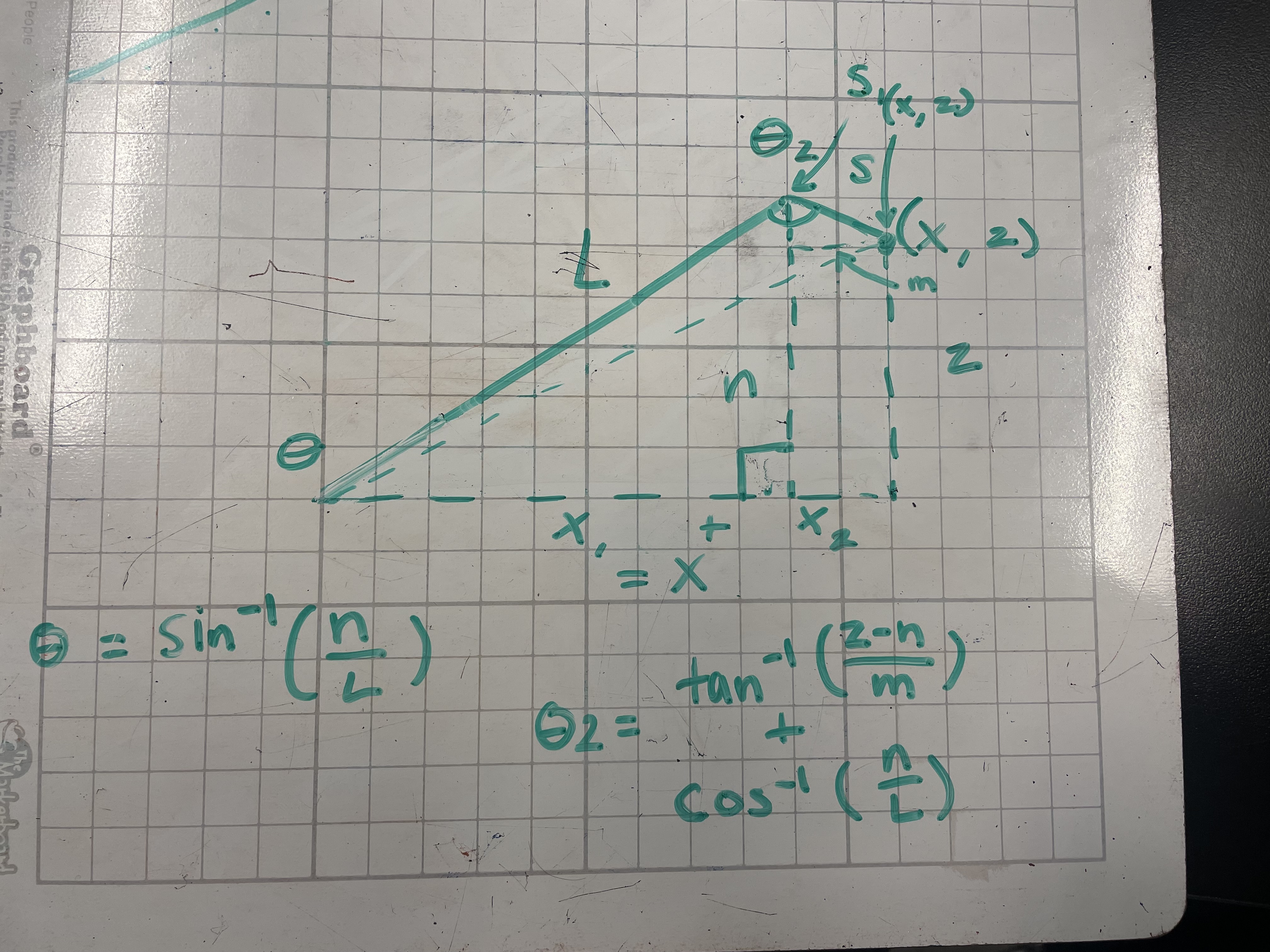

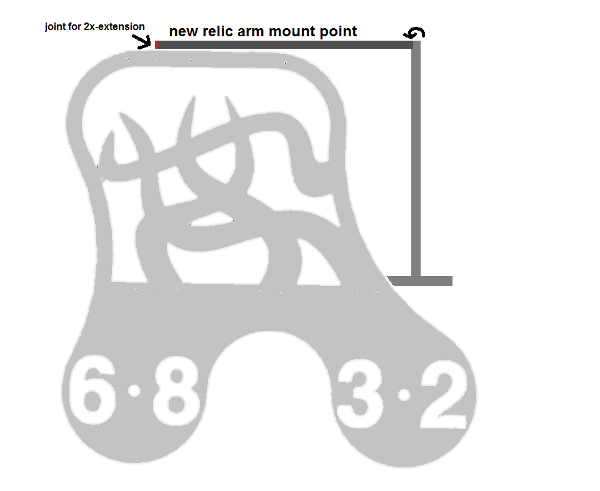

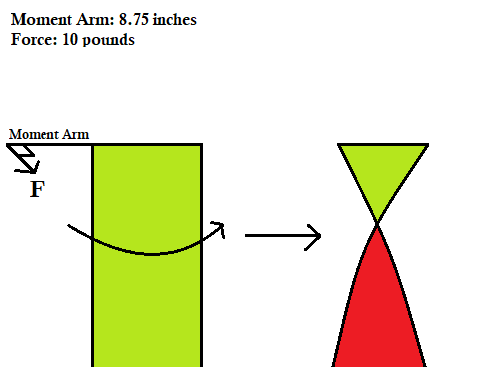

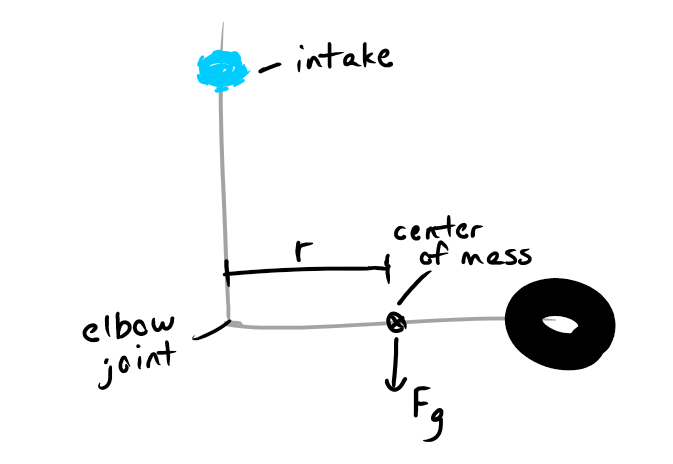

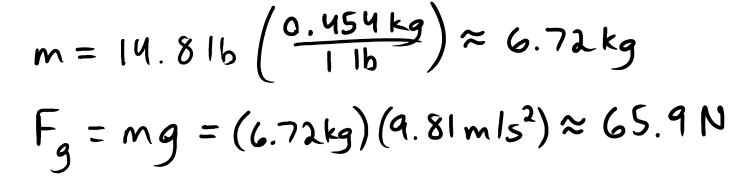

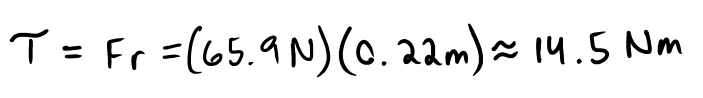

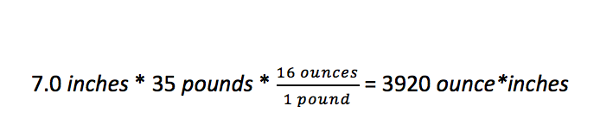

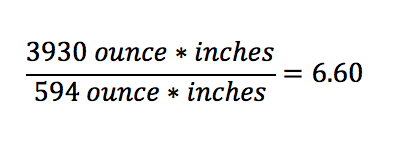

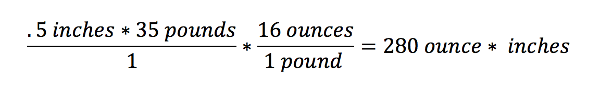

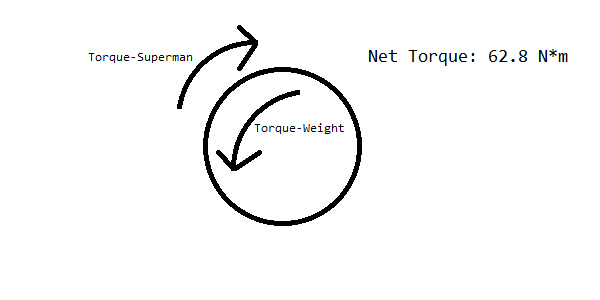

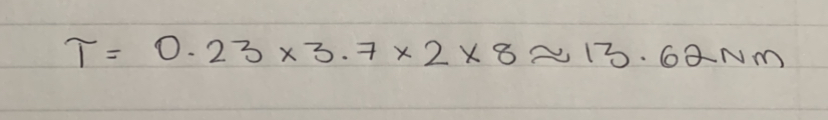

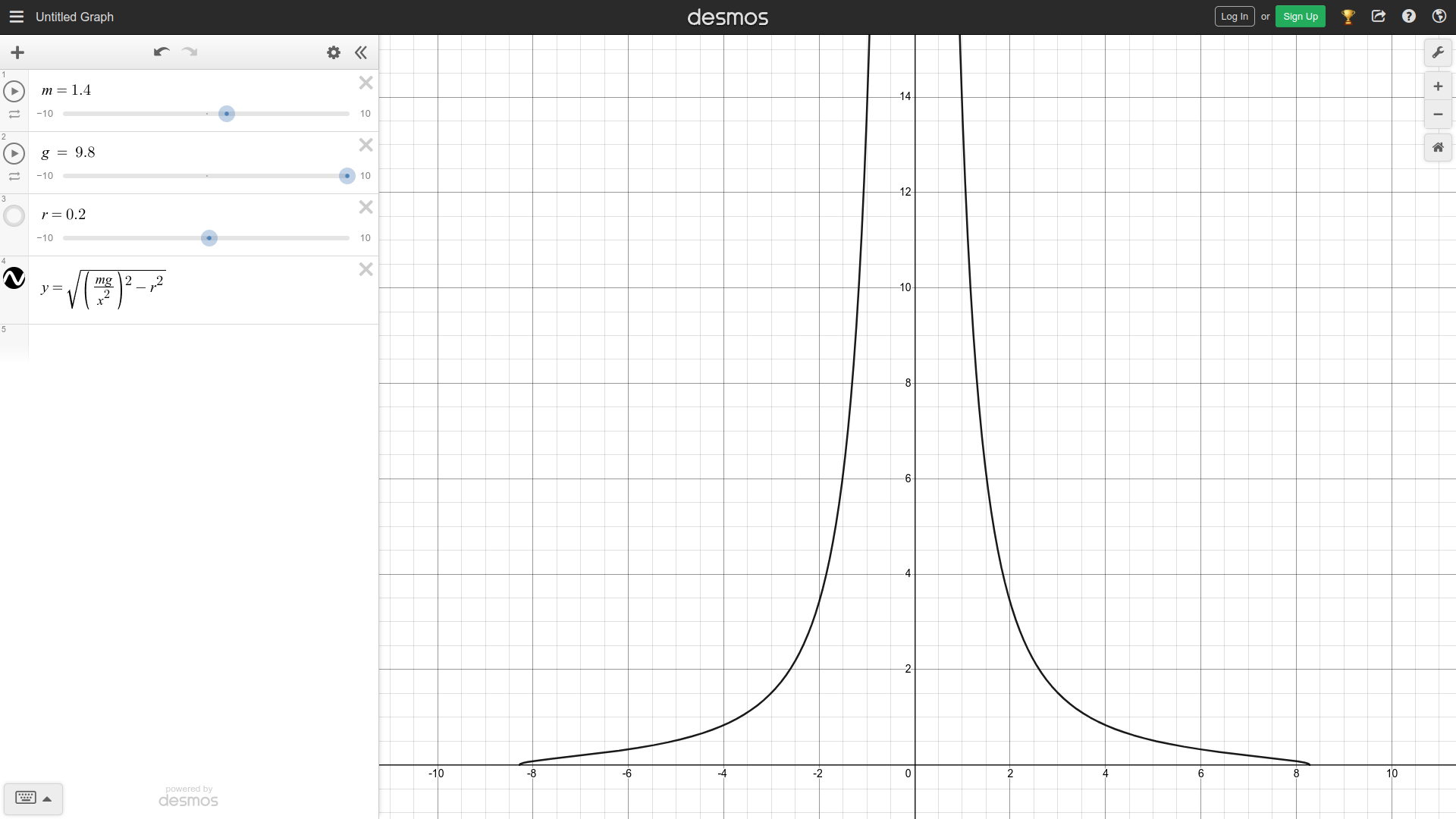

Then we realized a more pressing issue. Since torque is equal to force * arm length (T=FR), and the force on our robot is only the force due to gravity (F=mg), we had a torque on the lift equal to T=mgR. Then, as the lift was mounted at the very end, the torque on the arm was at its absolute maximum. And, while we're confident in our building ability, we're not that confident. So, we realized that we'd have to move the lift closer to the middle to minimize torque.

Then we realized a more pressing issue. Since torque is equal to force * arm length (T=FR), and the force on our robot is only the force due to gravity (F=mg), we had a torque on the lift equal to T=mgR. Then, as the lift was mounted at the very end, the torque on the arm was at its absolute maximum. And, while we're confident in our building ability, we're not that confident. So, we realized that we'd have to move the lift closer to the middle to minimize torque.

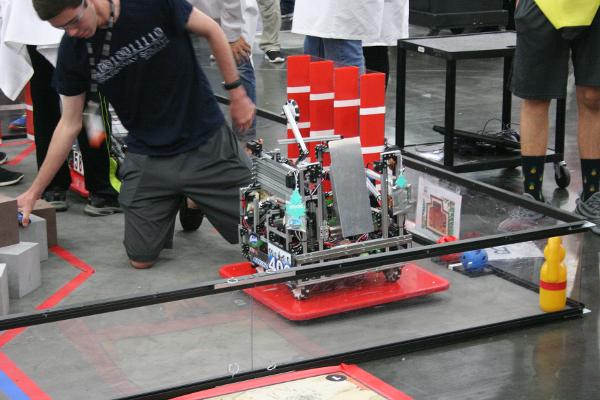

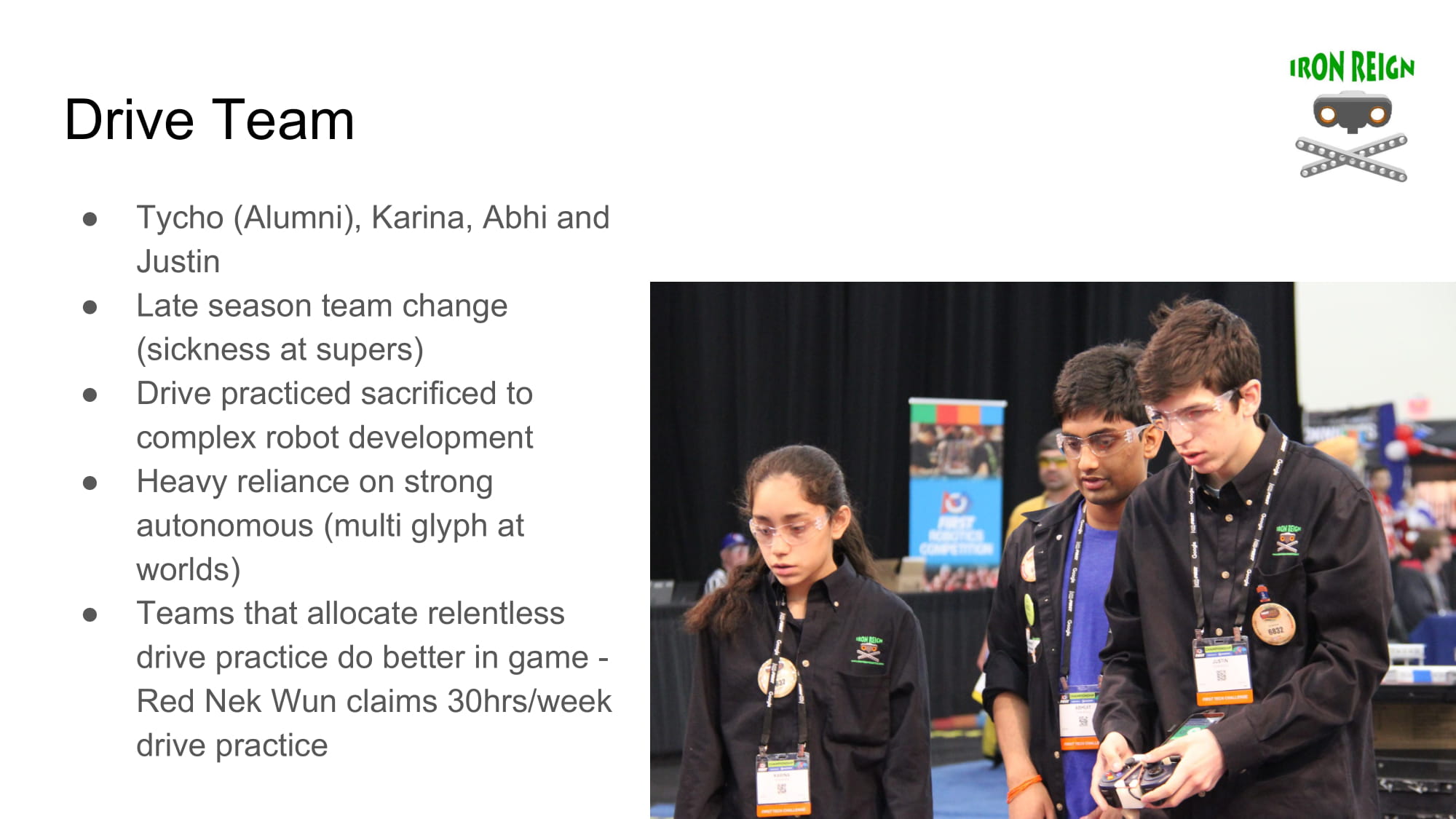

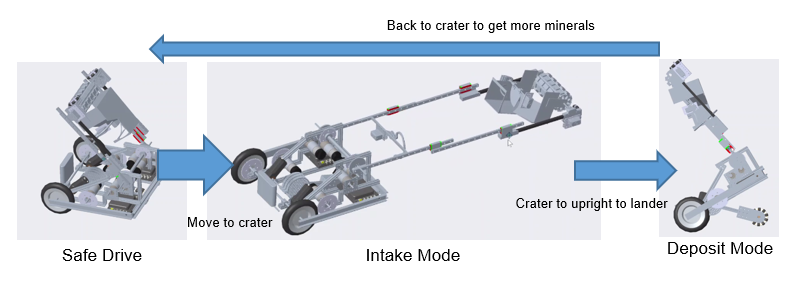

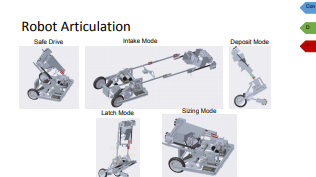

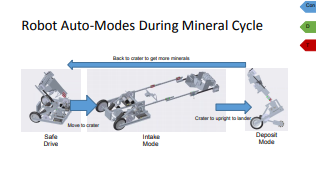

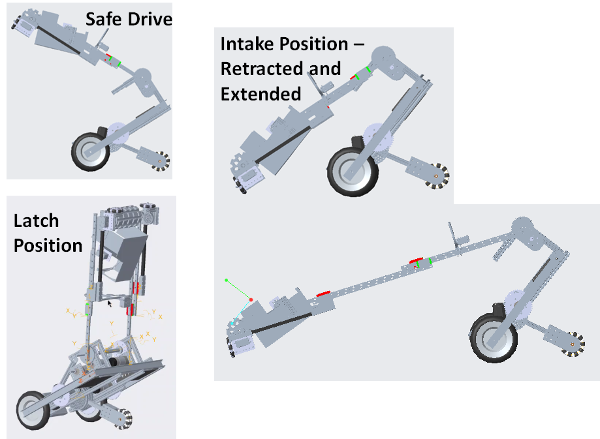

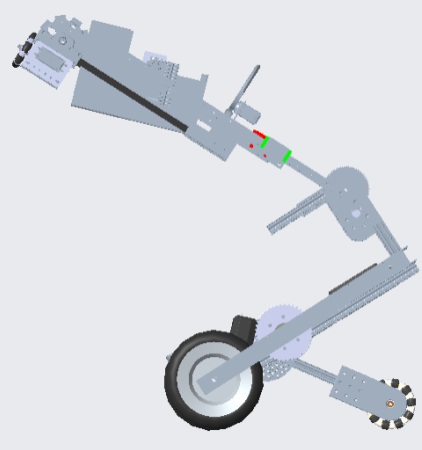

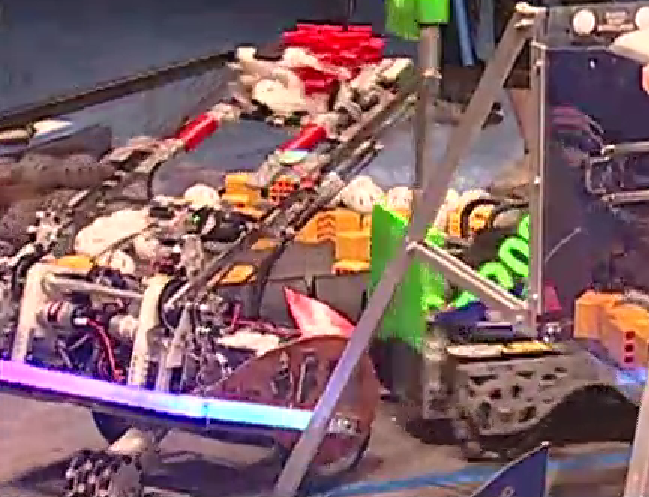

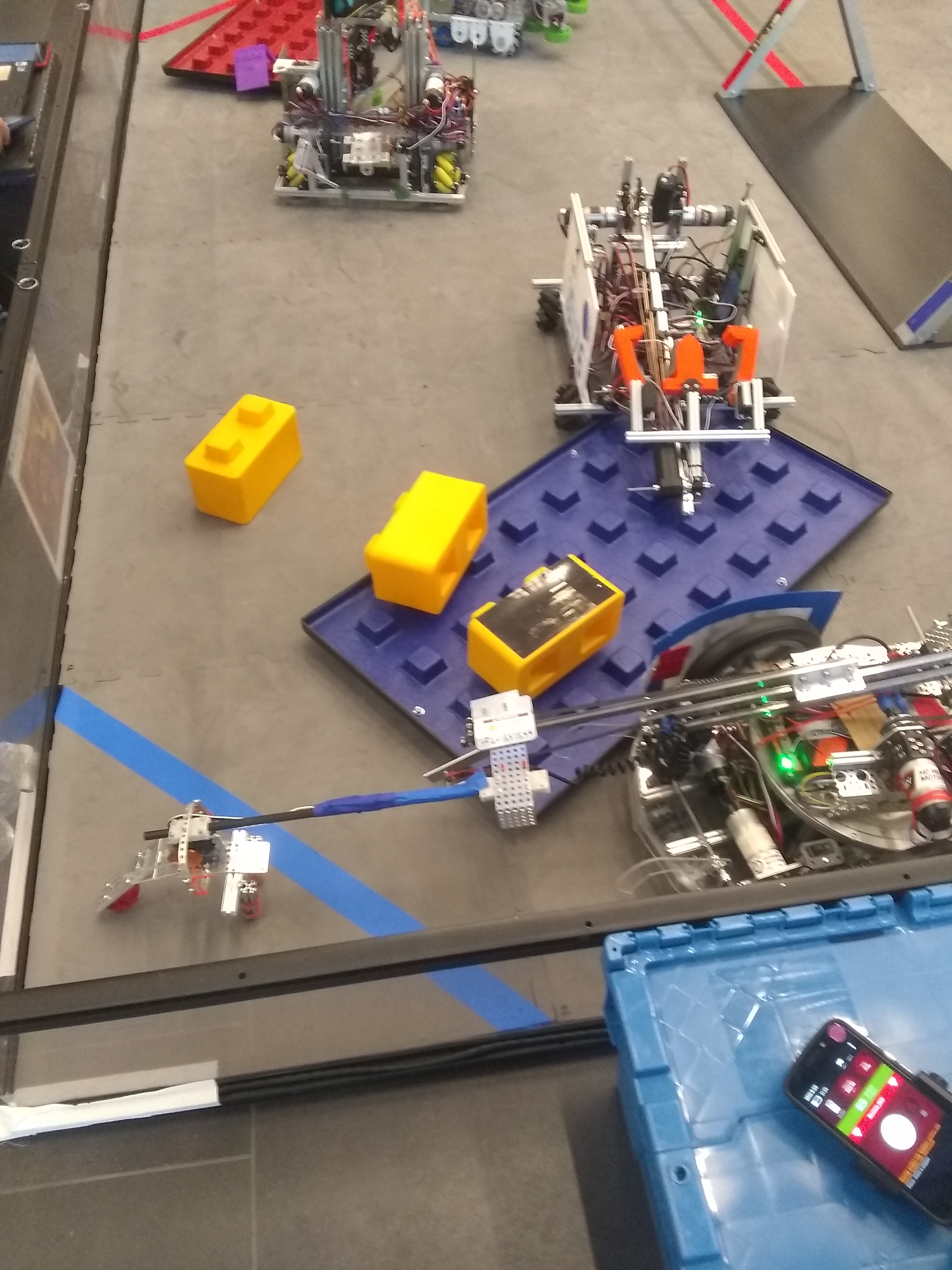

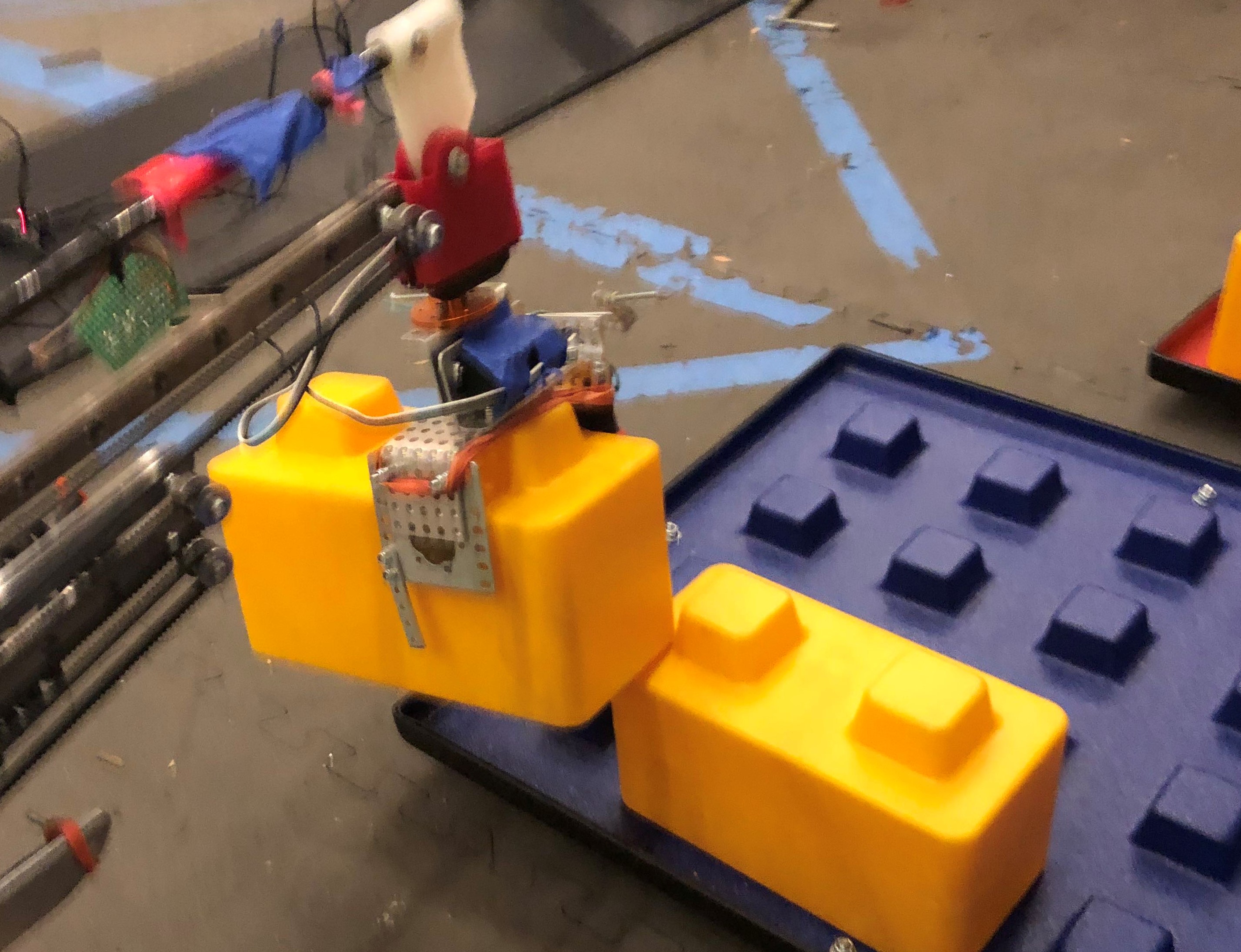

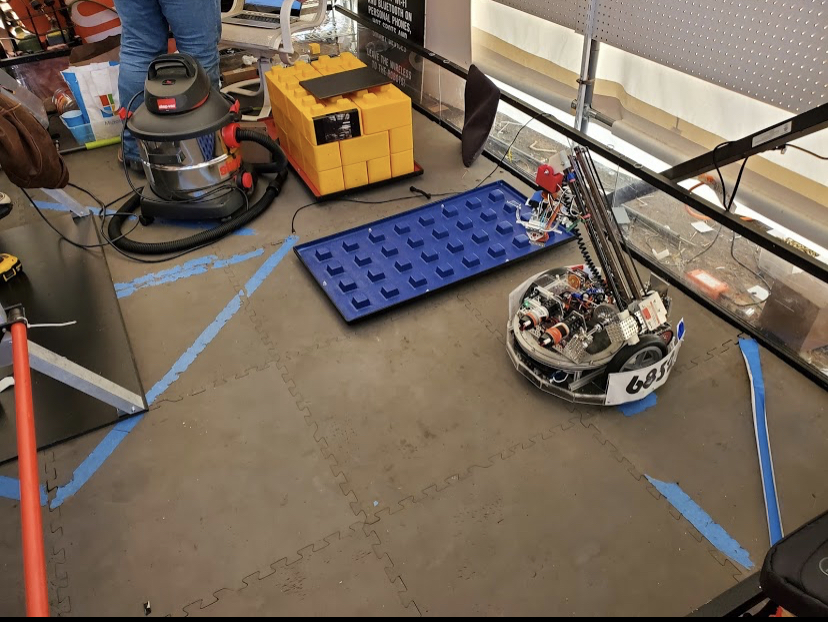

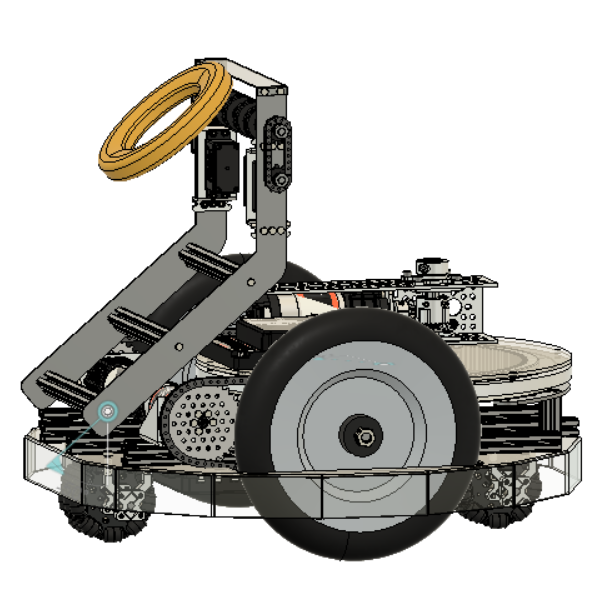

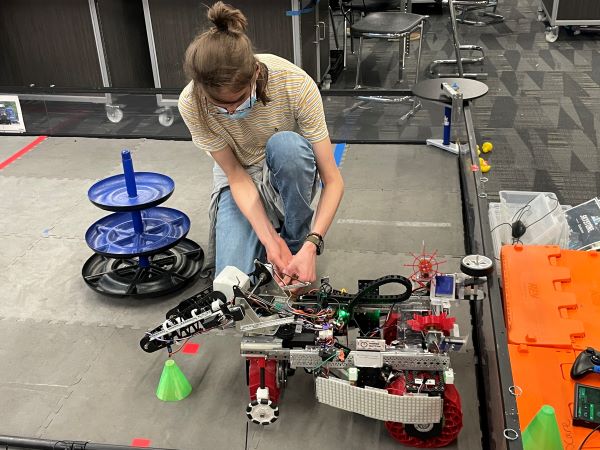

Karina, Justin, and Jose practiced driving the robot. We discovered that the robot latches extremely well with the new hook and that the autonomous delatch works. We also tested the articulation, or poses, of our robot. The only issue that popped up was when the robot moves into deposit mode, it tips toward the side with linear slides, but Karina discovered that if she drives the robot forward at the same time, she can ram the robot into the correct position. Karina got to 4-5 cycles per match with the new updates. This practice was a way to test the strength of our robt - we've had our robot break under stressful situations previously - and this time nothing broke. The biggest issue was that a servo wire on our intake came unplugged, but even with that, our robot still worked.

Karina, Justin, and Jose practiced driving the robot. We discovered that the robot latches extremely well with the new hook and that the autonomous delatch works. We also tested the articulation, or poses, of our robot. The only issue that popped up was when the robot moves into deposit mode, it tips toward the side with linear slides, but Karina discovered that if she drives the robot forward at the same time, she can ram the robot into the correct position. Karina got to 4-5 cycles per match with the new updates. This practice was a way to test the strength of our robt - we've had our robot break under stressful situations previously - and this time nothing broke. The biggest issue was that a servo wire on our intake came unplugged, but even with that, our robot still worked.

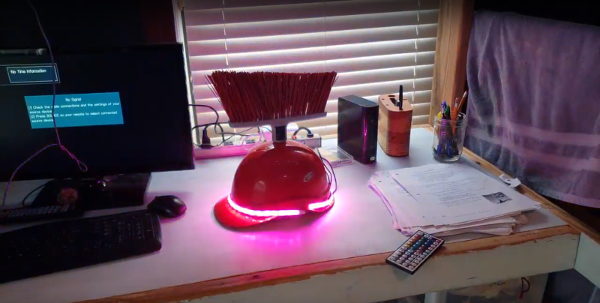

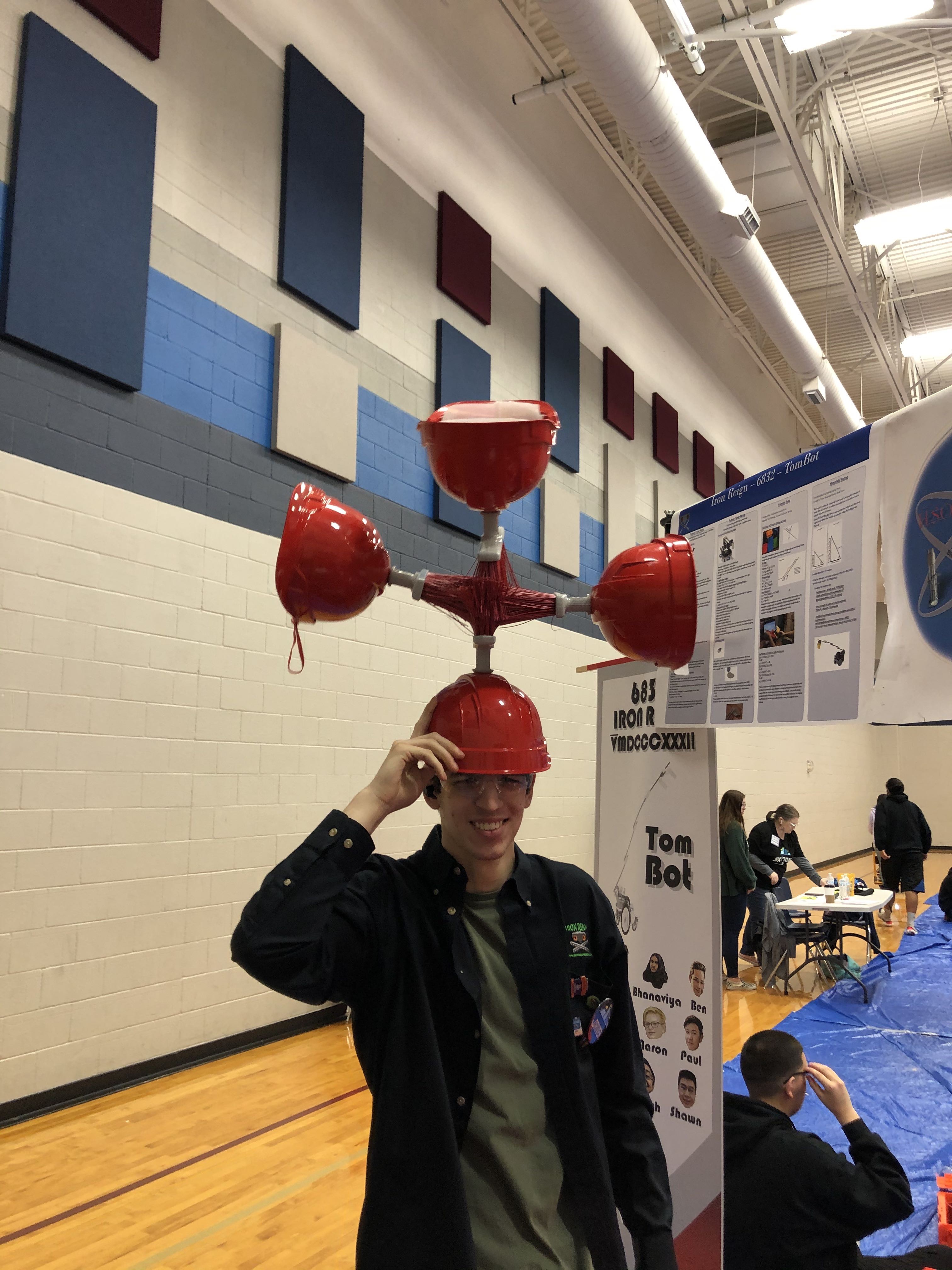

We finished the light-up LED hat.

We finished the light-up LED hat.

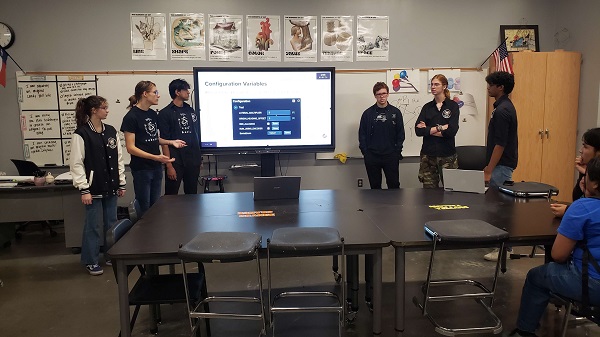

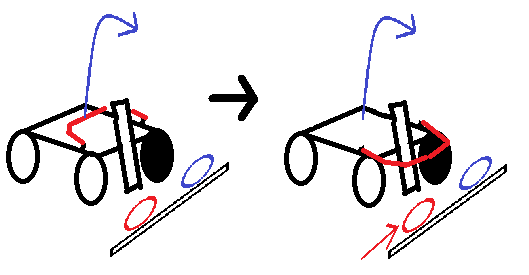

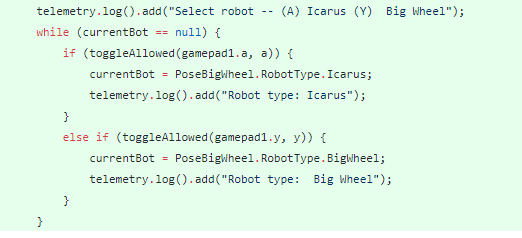

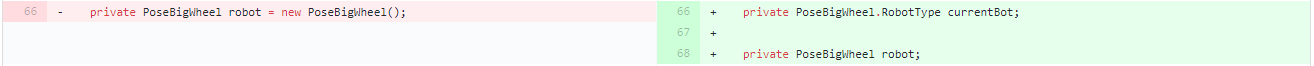

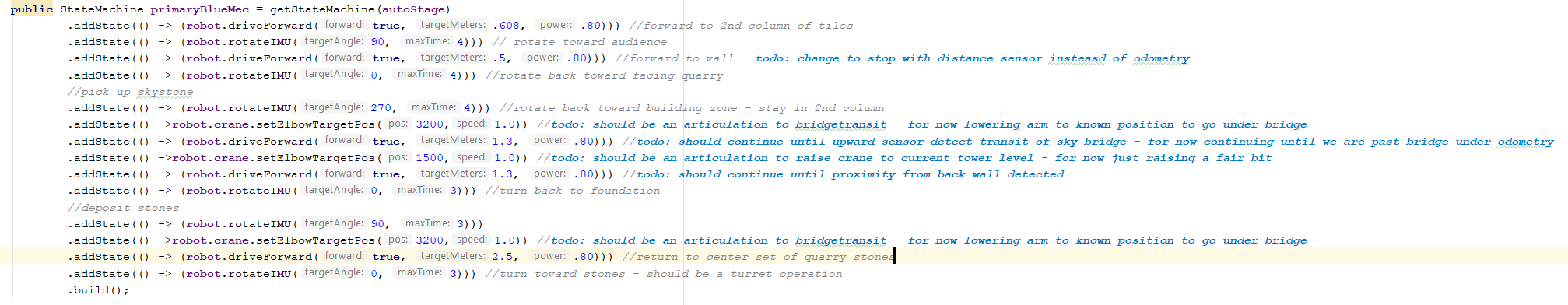

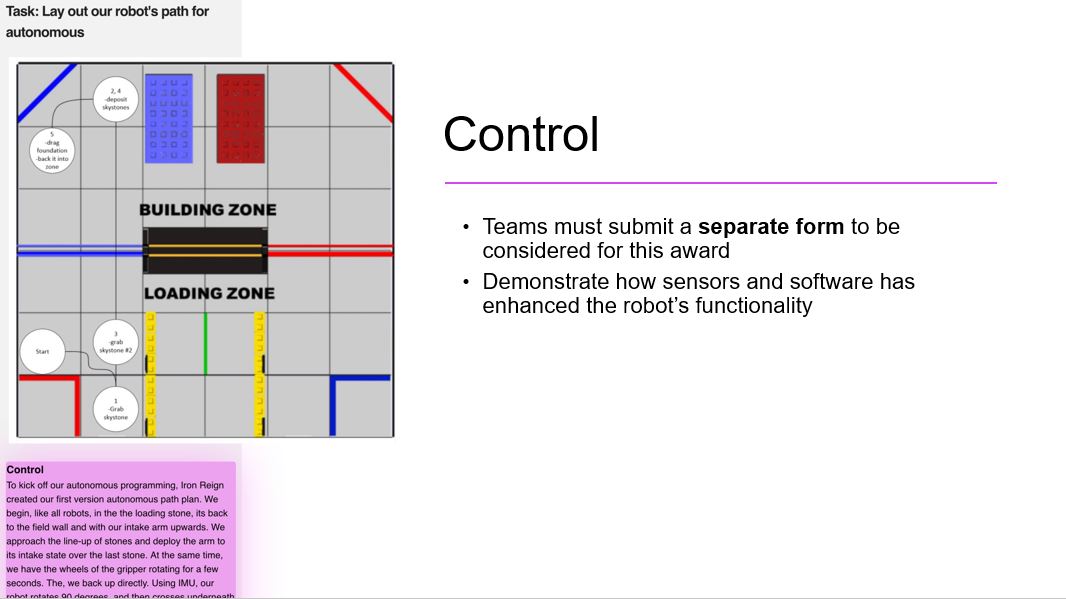

Arjun continued writing the Control Award submission, adding in the new articulations and poses of the driver enhancements. Janavi created state diagrams for the code to add to the submission.

Arjun continued writing the Control Award submission, adding in the new articulations and poses of the driver enhancements. Janavi created state diagrams for the code to add to the submission.

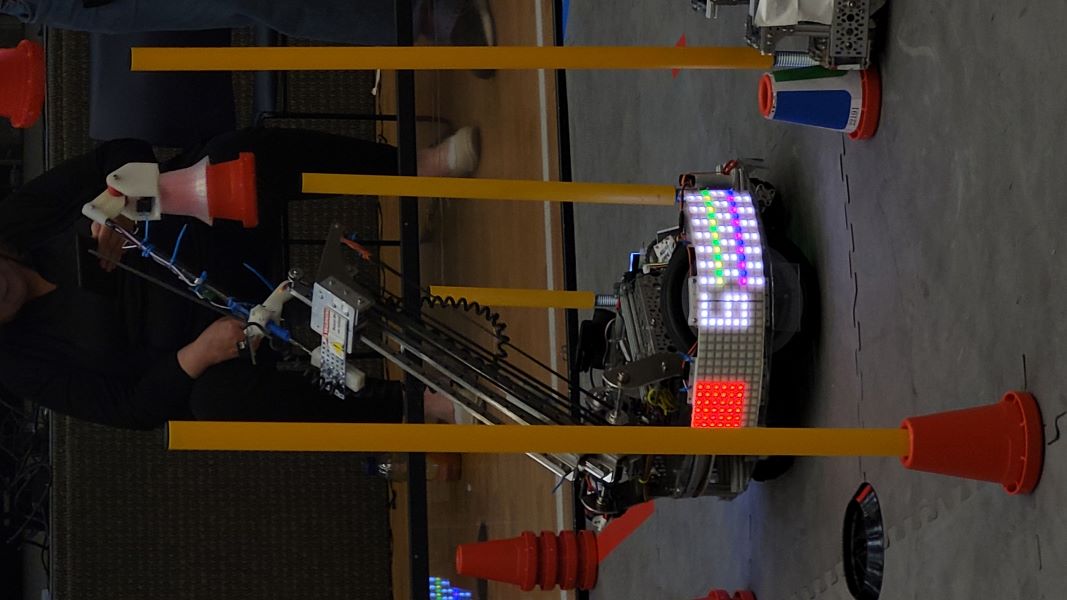

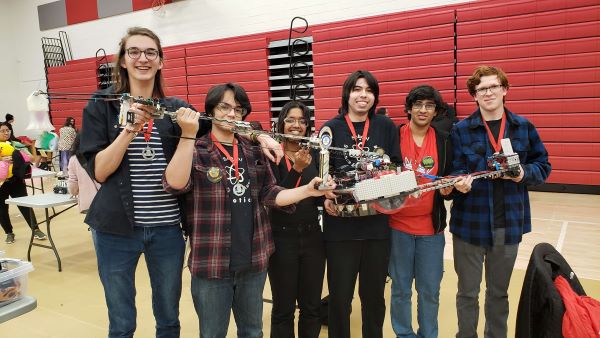

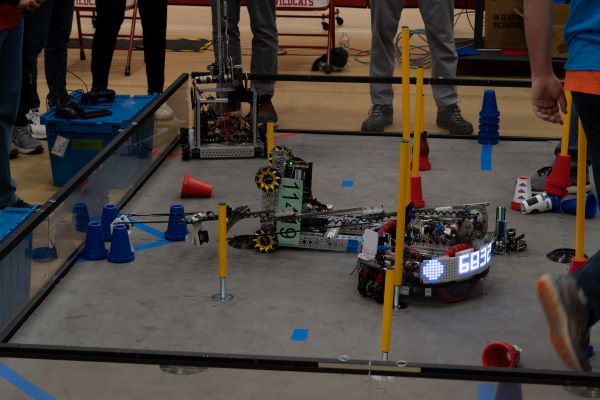

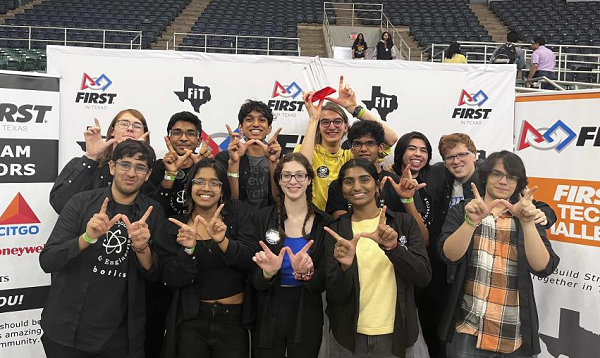

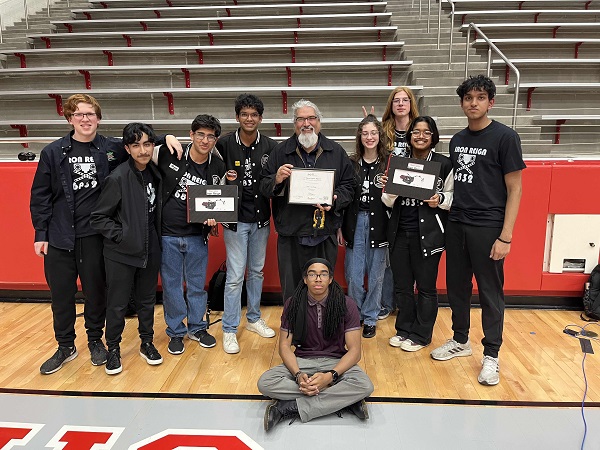

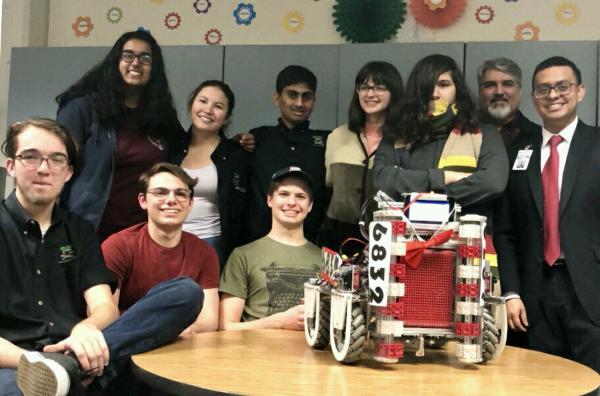

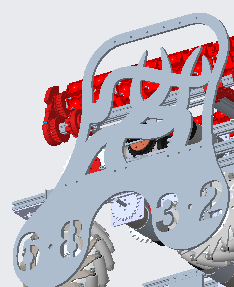

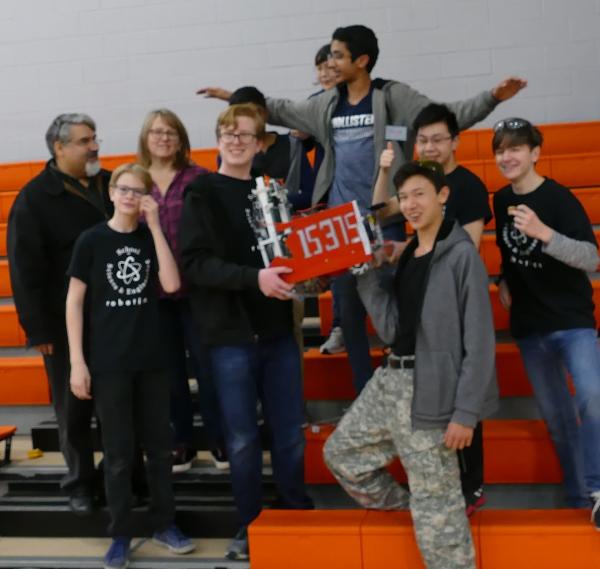

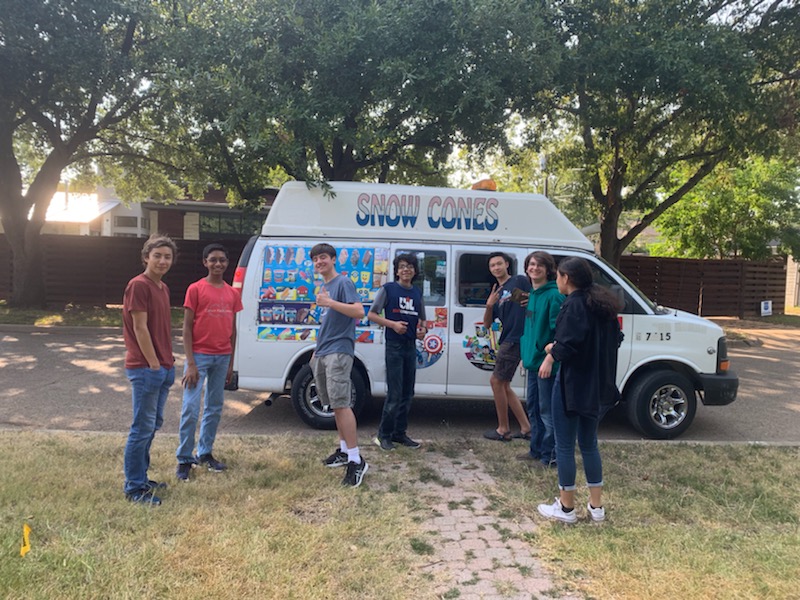

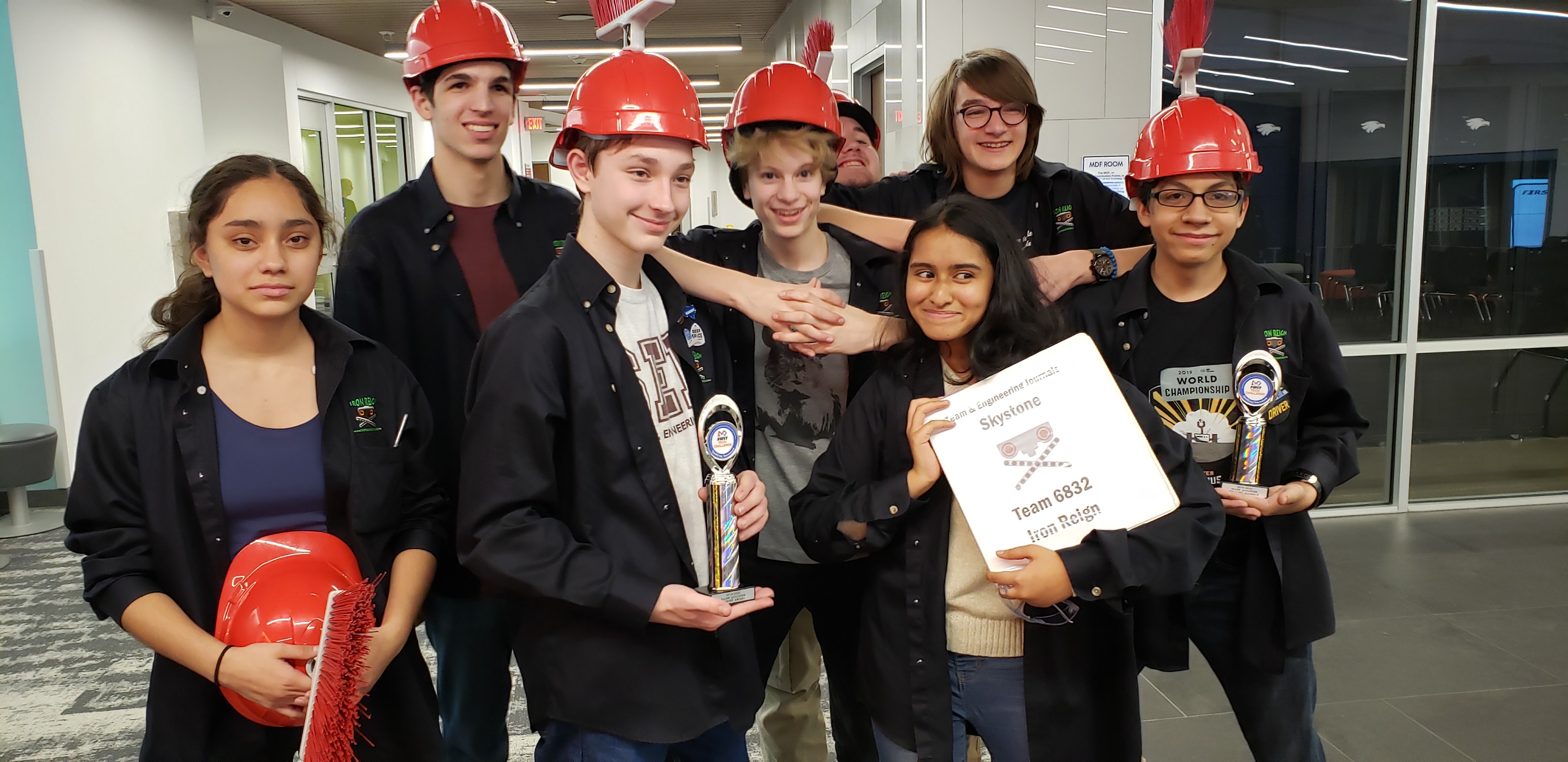

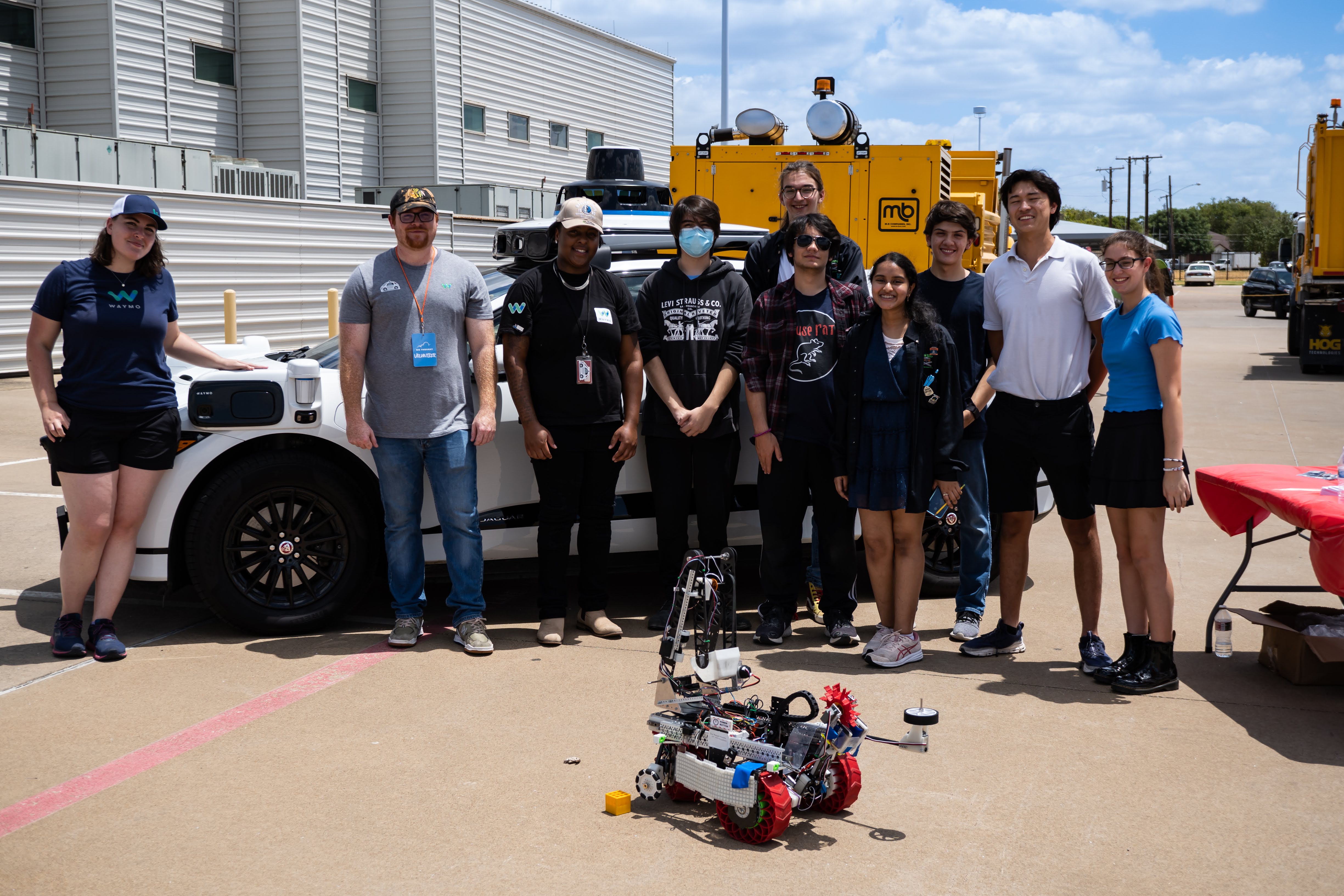

Members included: Trey Davis, Samuel Adler, Rohit Shankar, Christian Saldana, Hudson Shields and Blaine Wells (not shown)

Members included: Trey Davis, Samuel Adler, Rohit Shankar, Christian Saldana, Hudson Shields and Blaine Wells (not shown)

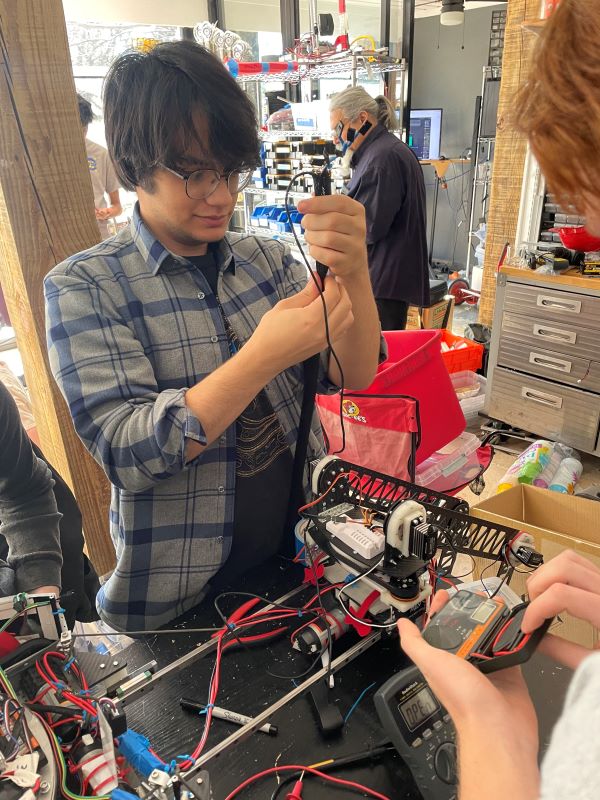

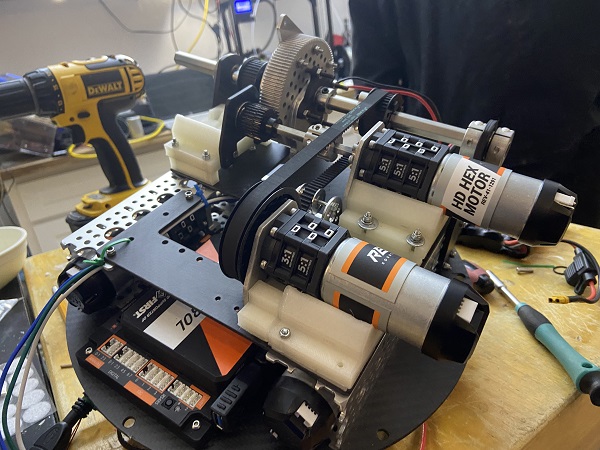

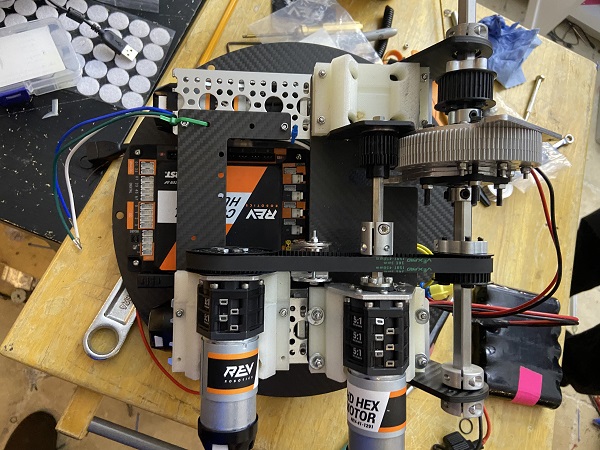

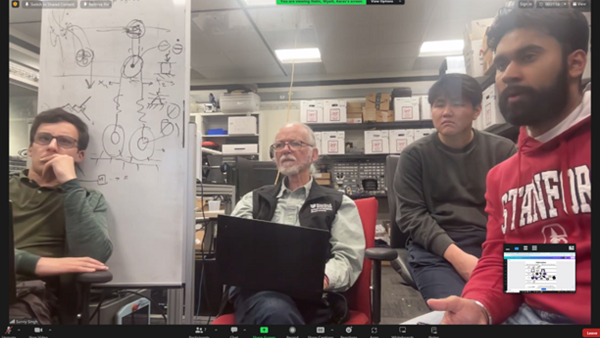

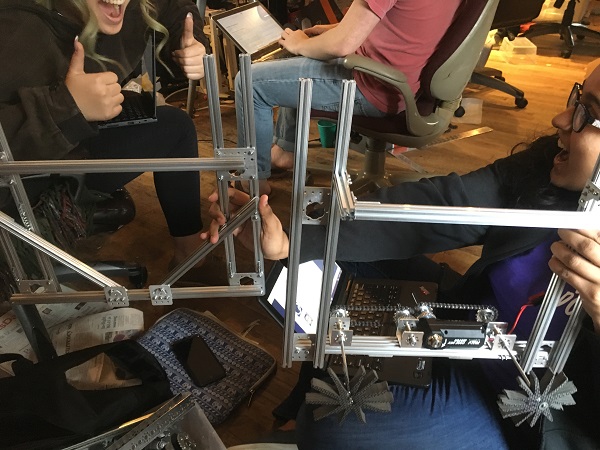

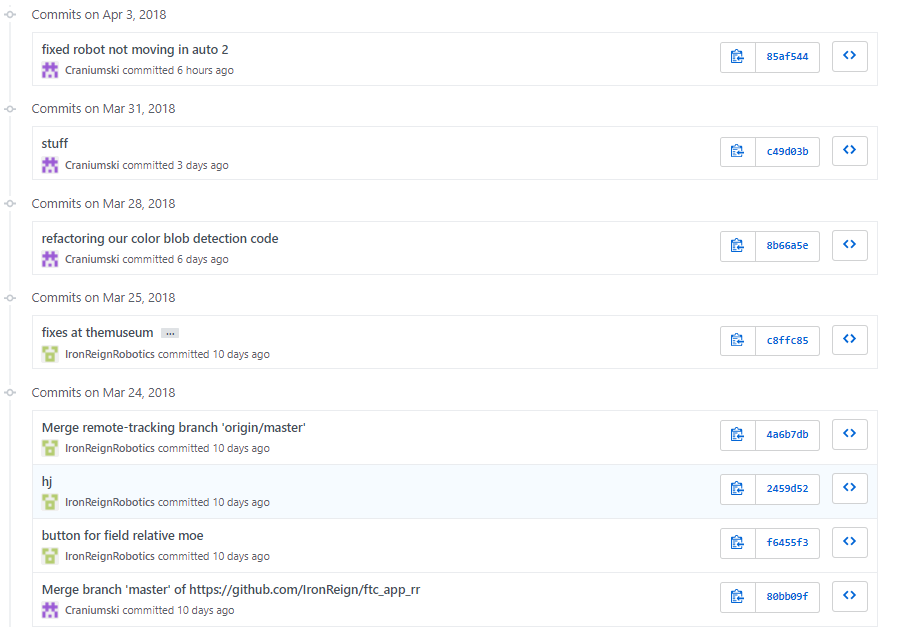

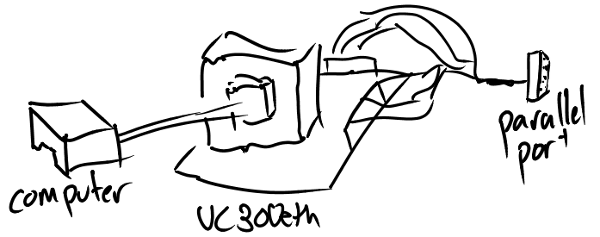

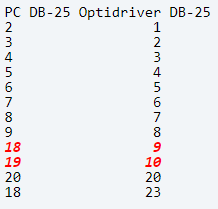

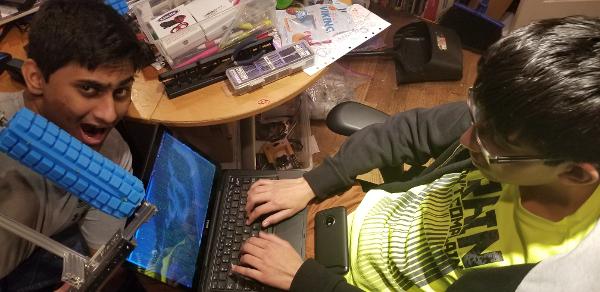

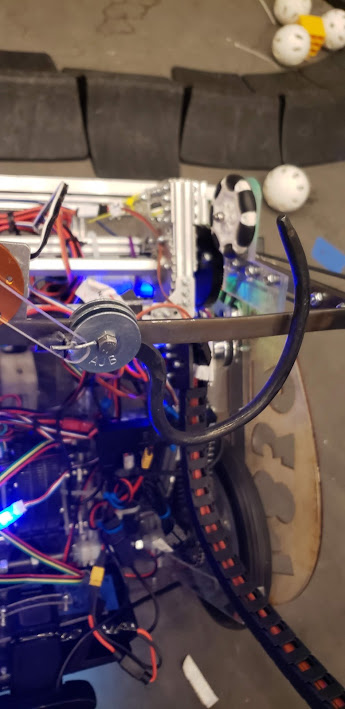

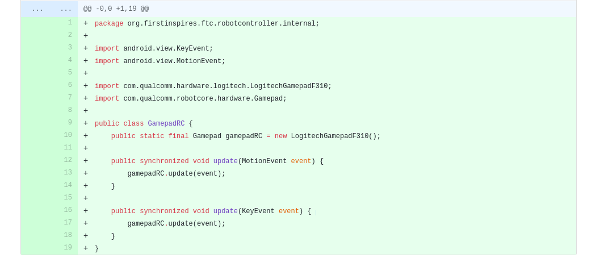

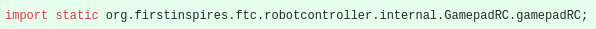

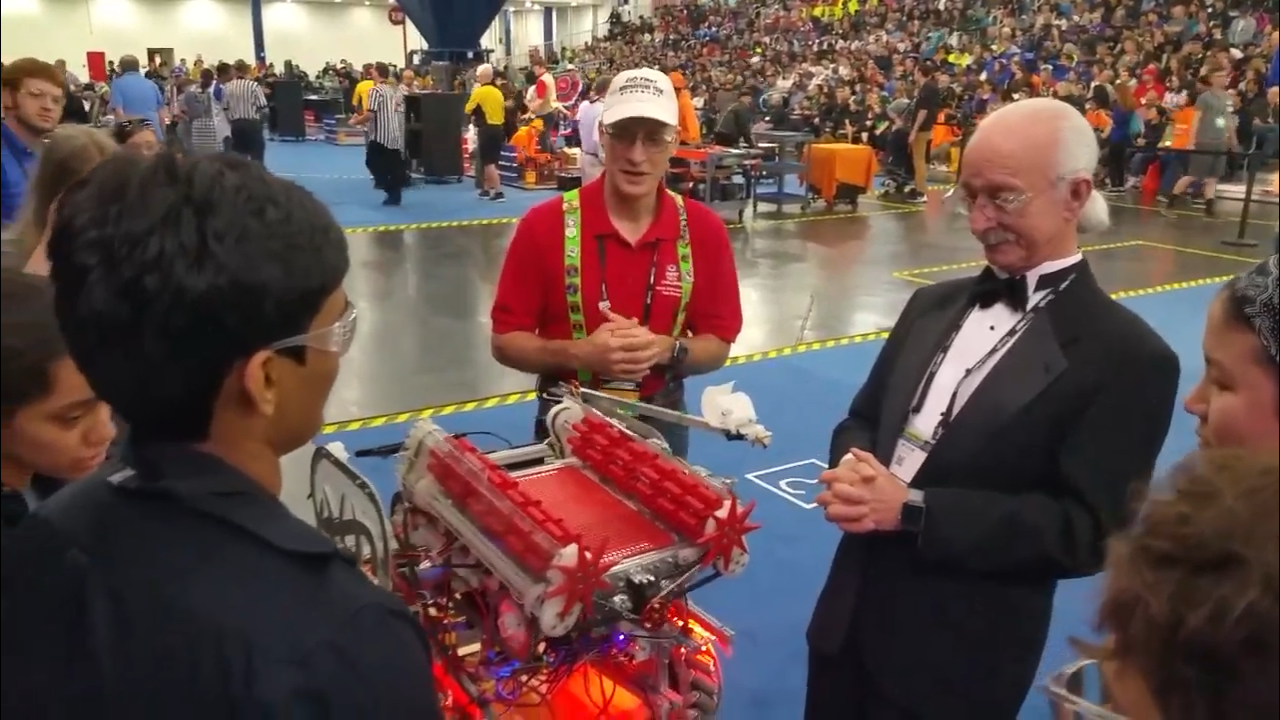

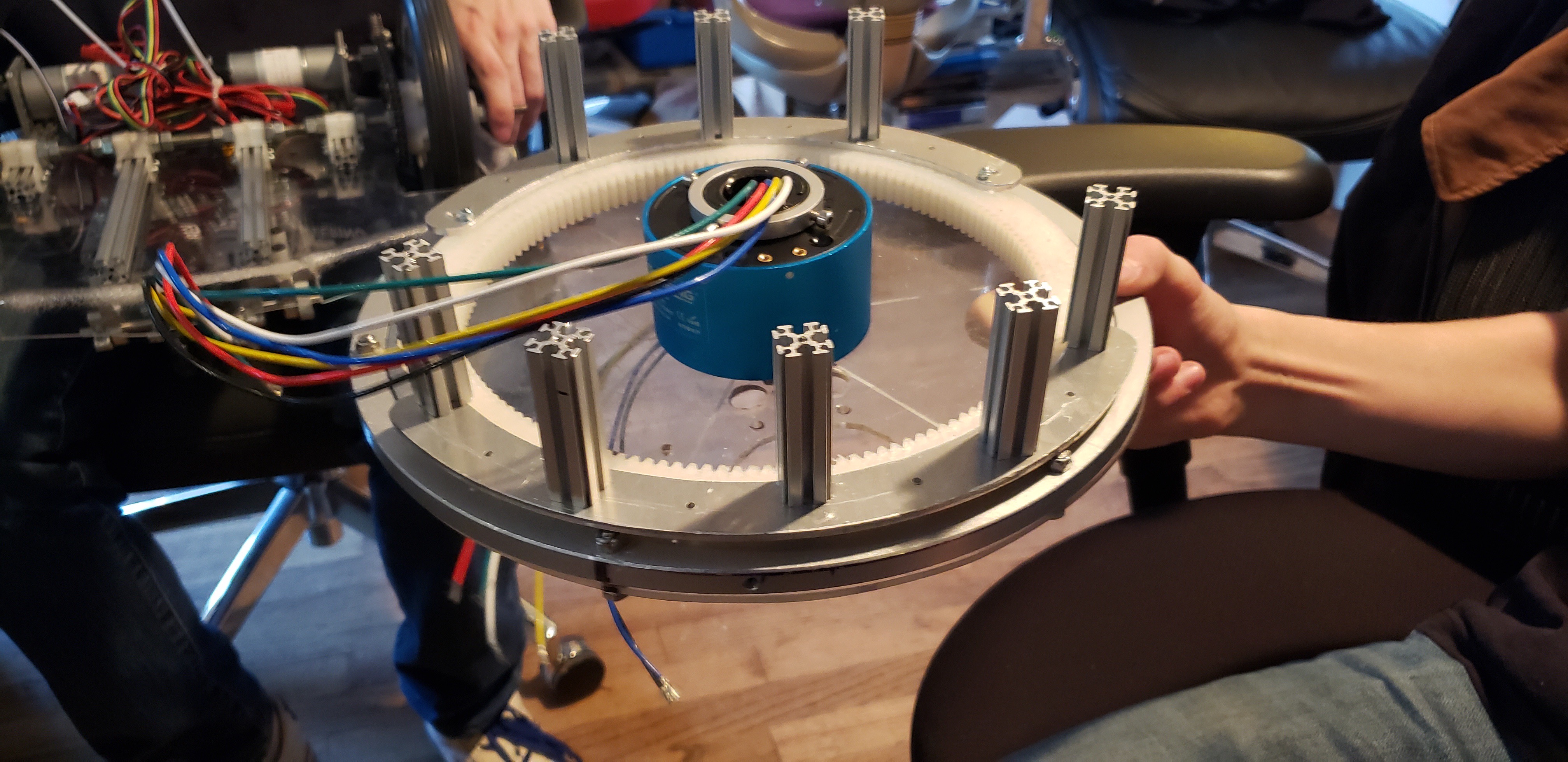

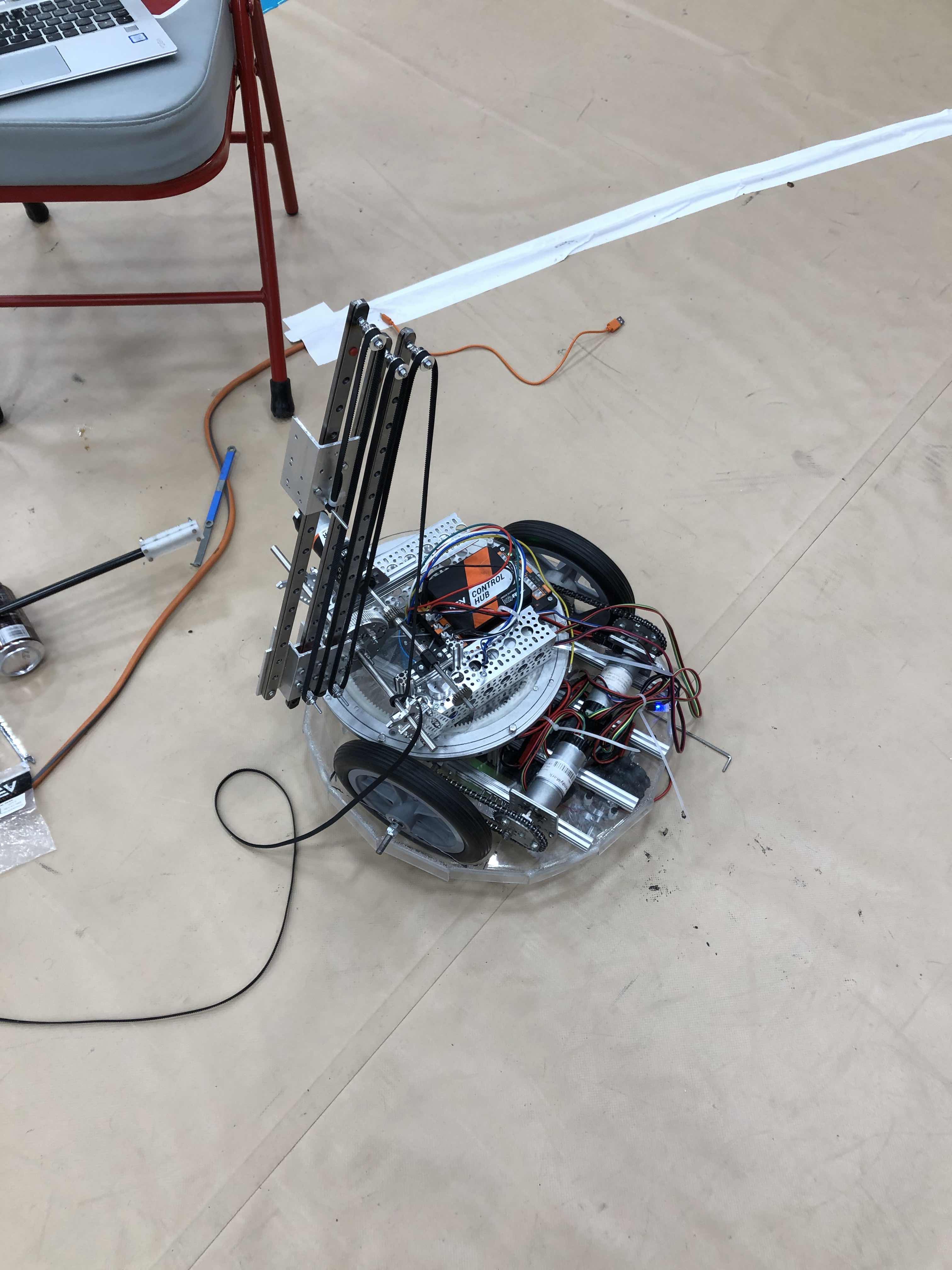

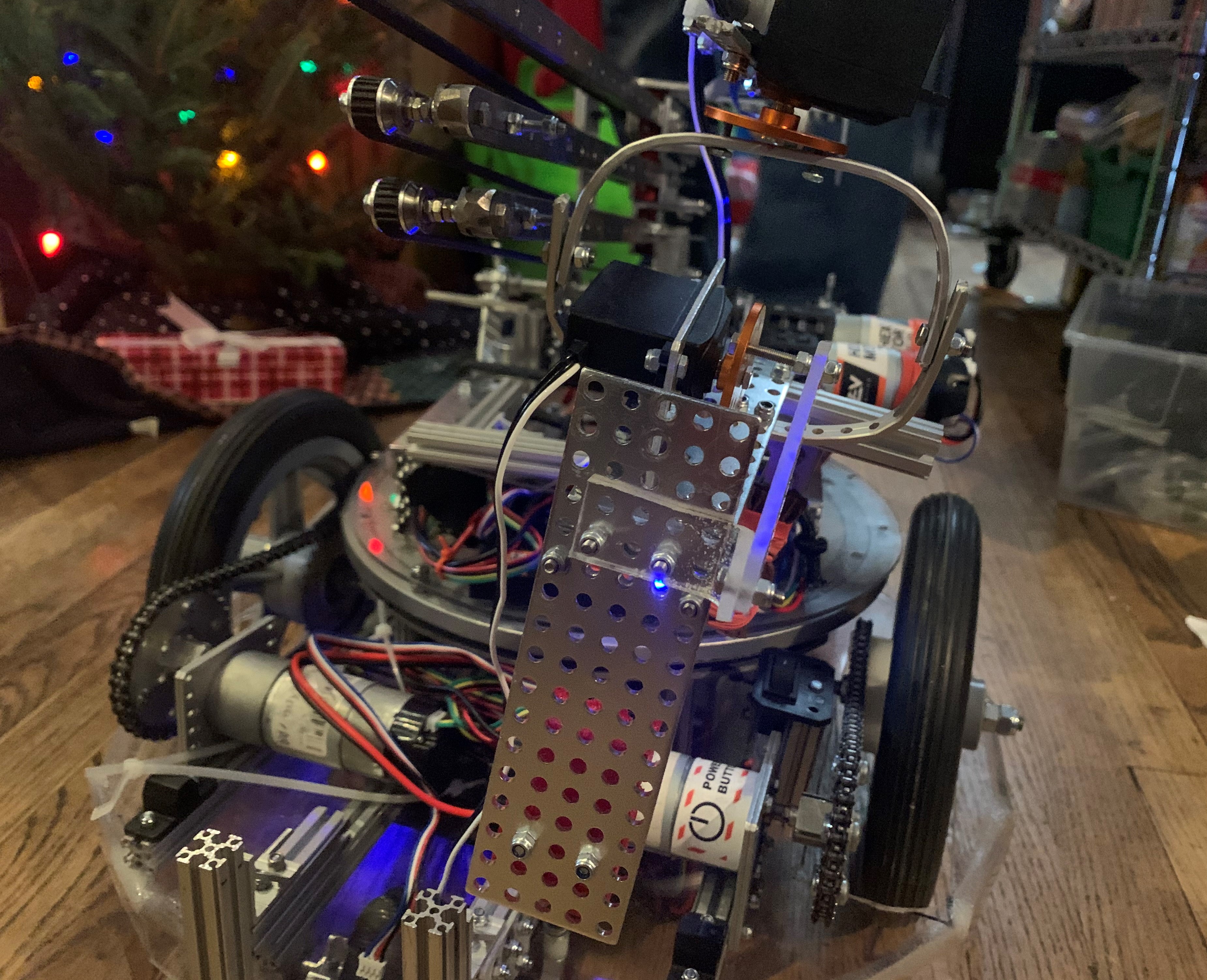

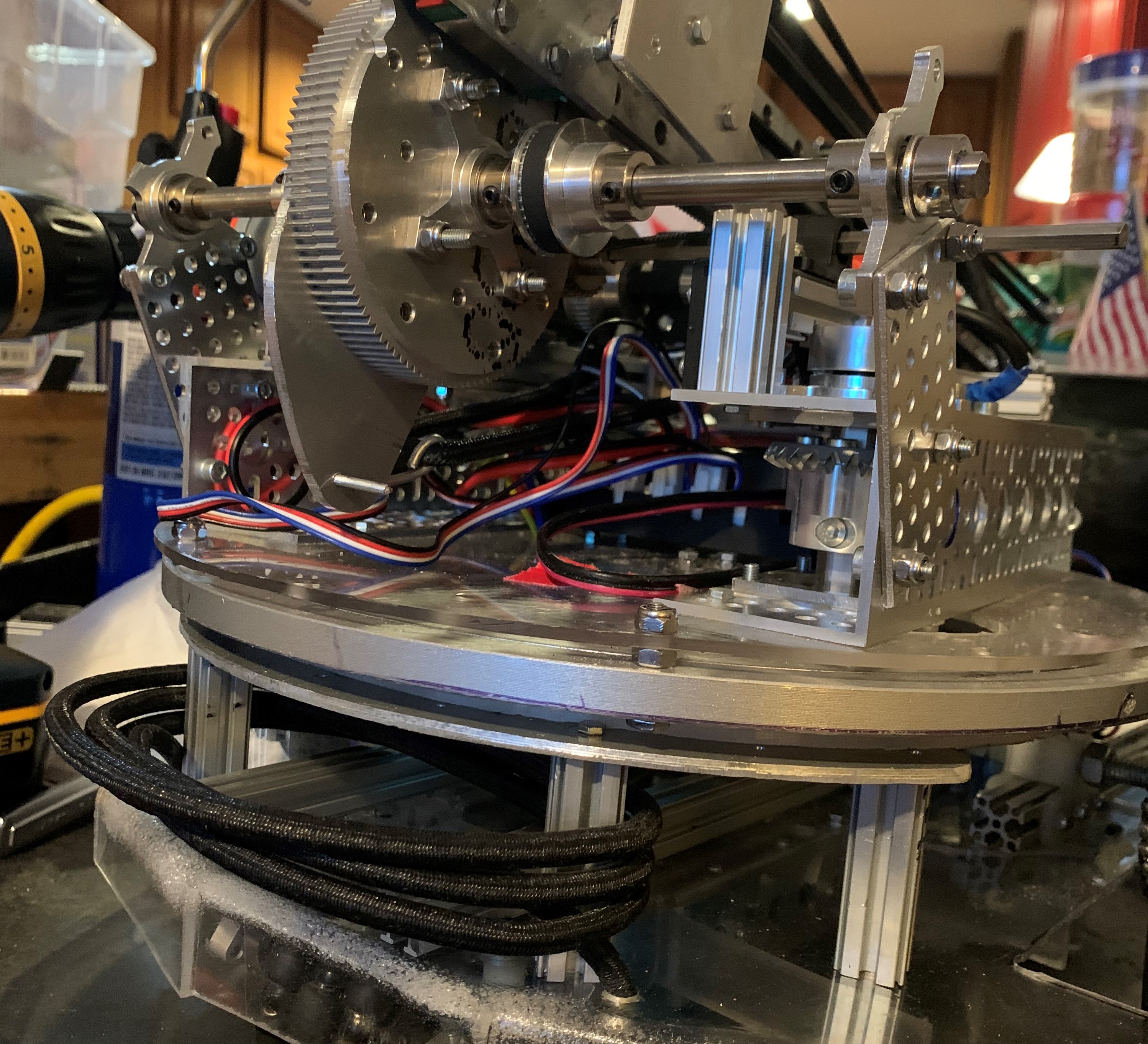

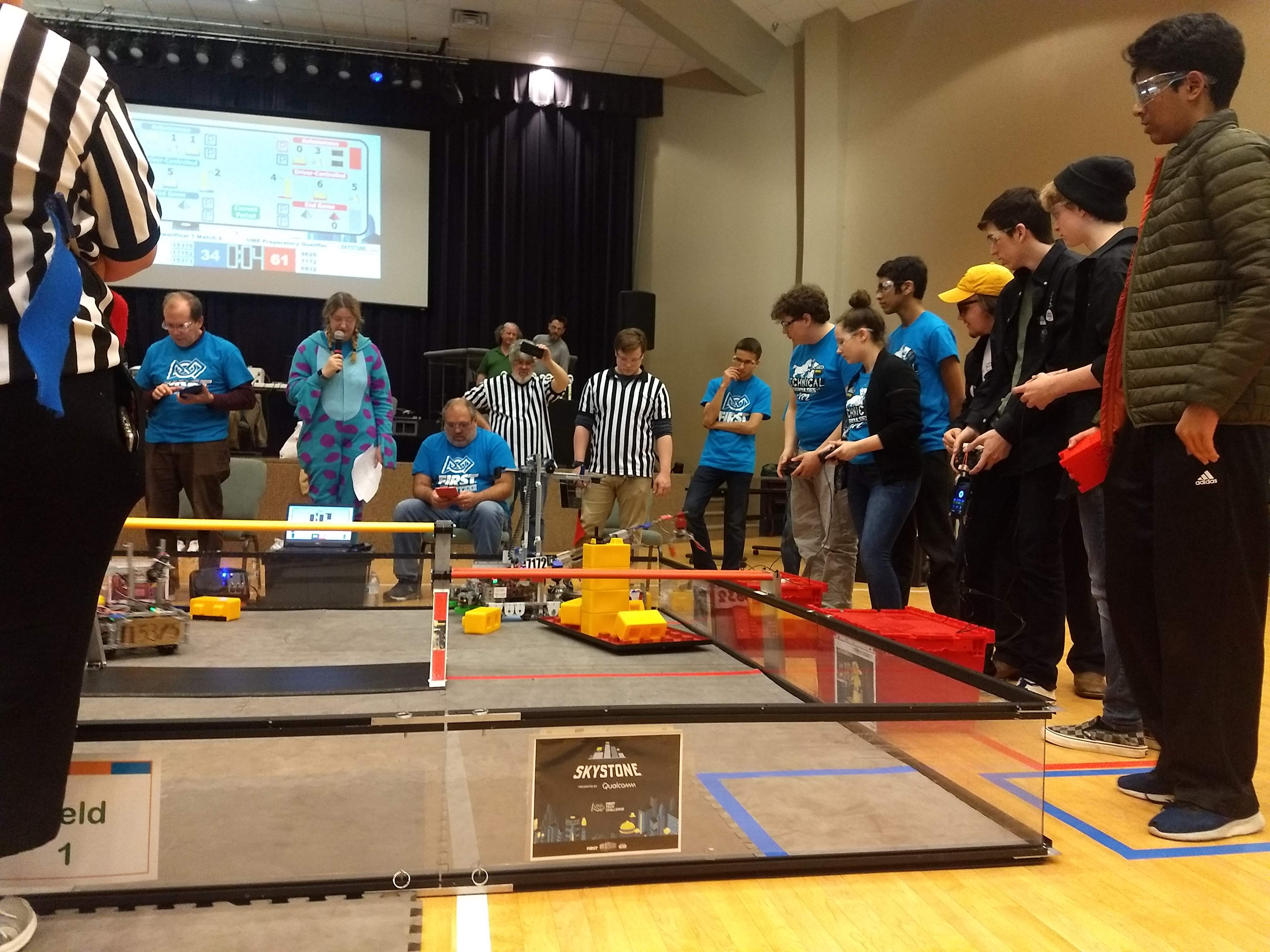

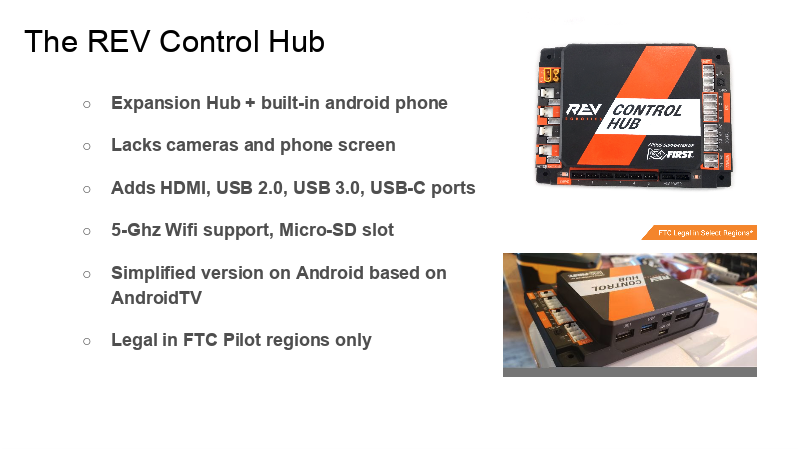

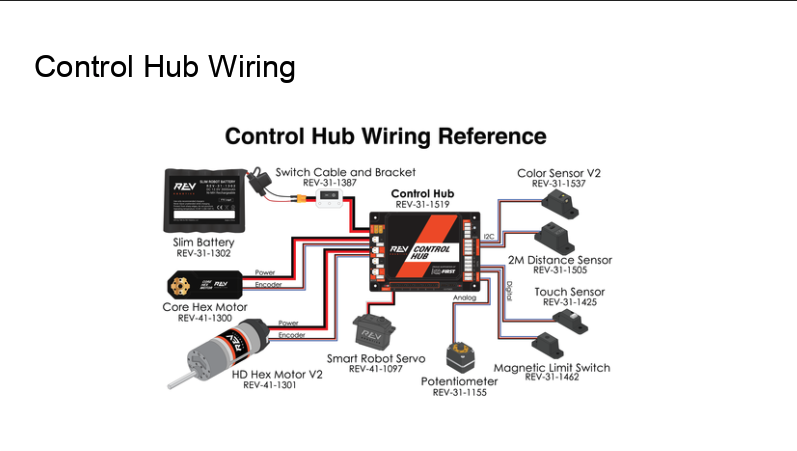

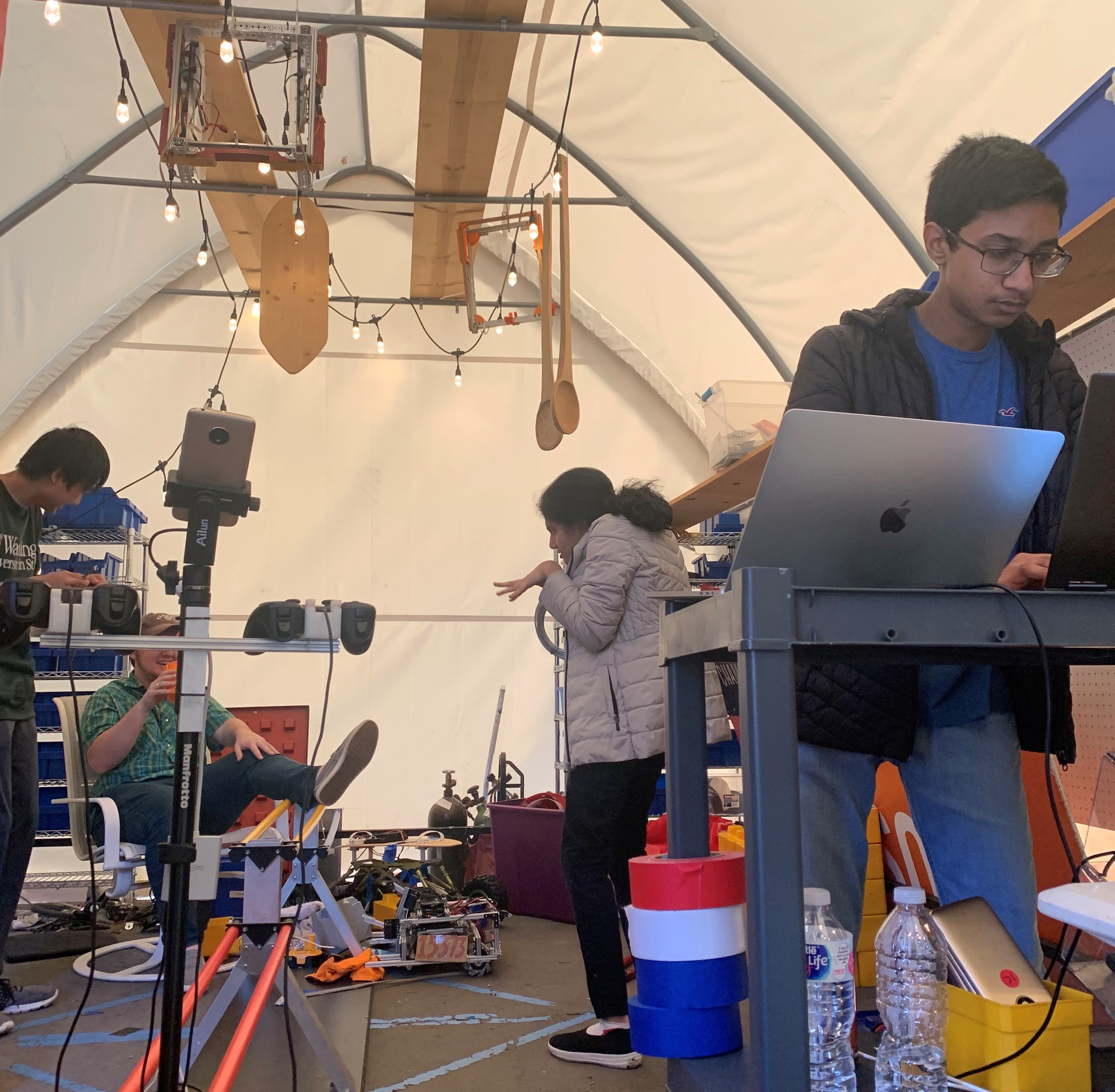

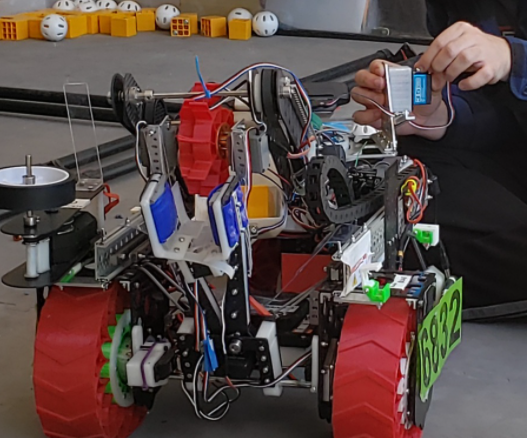

Iron Reign was recently selected to attend a REV Control Hub trial along with select other teams in the region. We wanted to do this so that we could get a good look at the control system that FTC would likely be switching to in the near future, as well as get another chance to test our robot in tournament conditions before Worlds.

Iron Reign was recently selected to attend a REV Control Hub trial along with select other teams in the region. We wanted to do this so that we could get a good look at the control system that FTC would likely be switching to in the near future, as well as get another chance to test our robot in tournament conditions before Worlds.

While testing it, we didn't have time to copy over our entire codebase, so we made a quick OpMode that moved one wheel of one of our old robots. Because the provided SDK is almost identical to ftc_app, no changes were needed to the existing sample OpModes. We successfully tested our OpMode, proving that it works fine with the new system.

While testing it, we didn't have time to copy over our entire codebase, so we made a quick OpMode that moved one wheel of one of our old robots. Because the provided SDK is almost identical to ftc_app, no changes were needed to the existing sample OpModes. We successfully tested our OpMode, proving that it works fine with the new system.

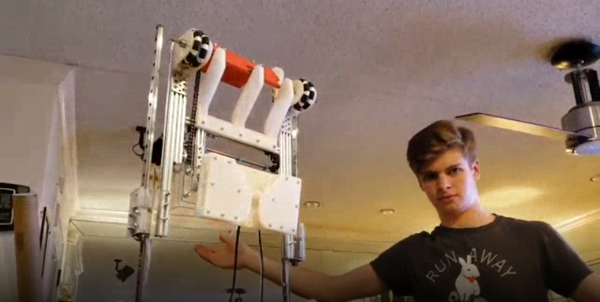

Founders of REV working with our team

Founders of REV working with our team

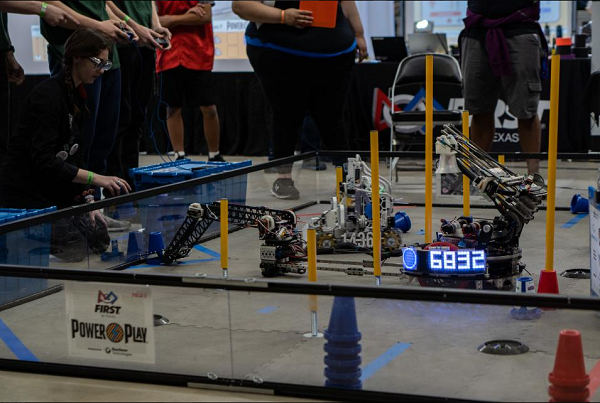

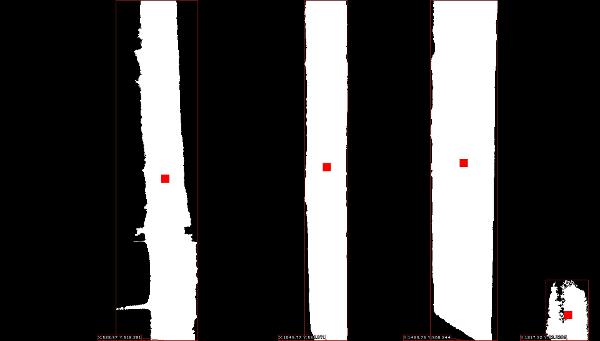

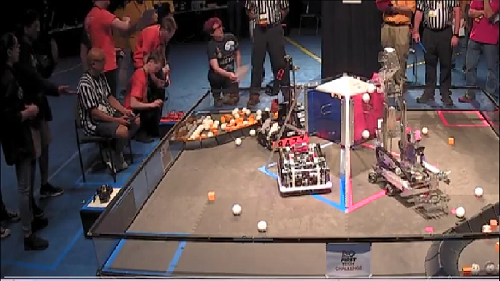

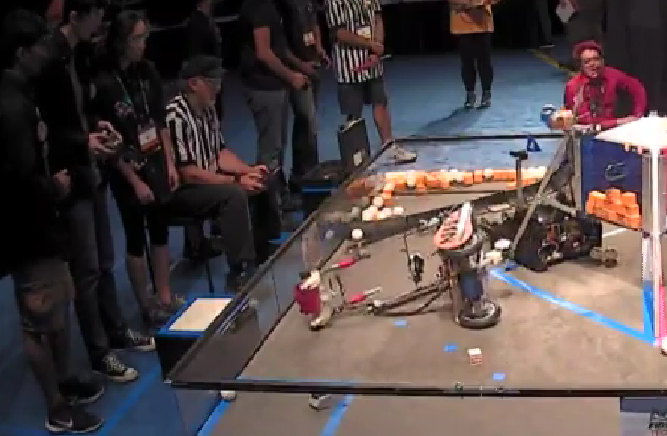

Match 7(Q121)

Match 7(Q121)

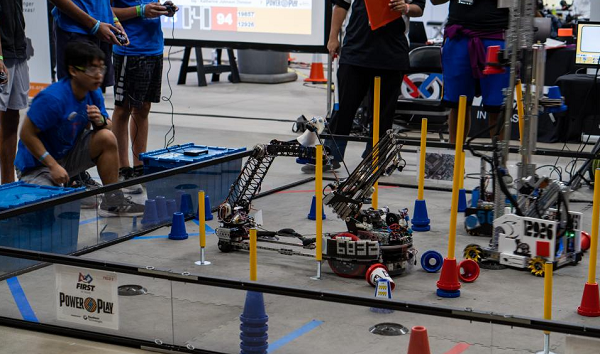

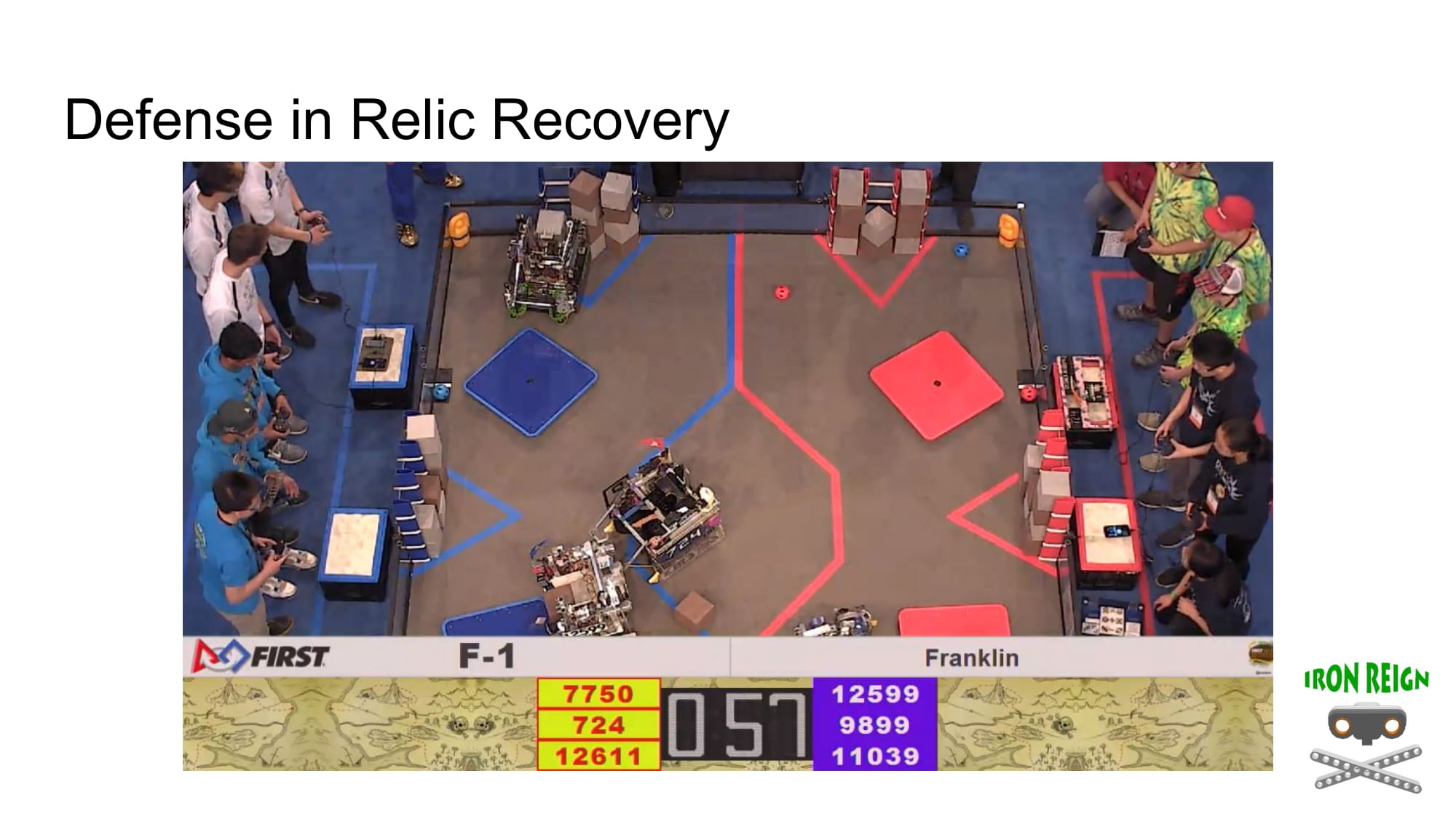

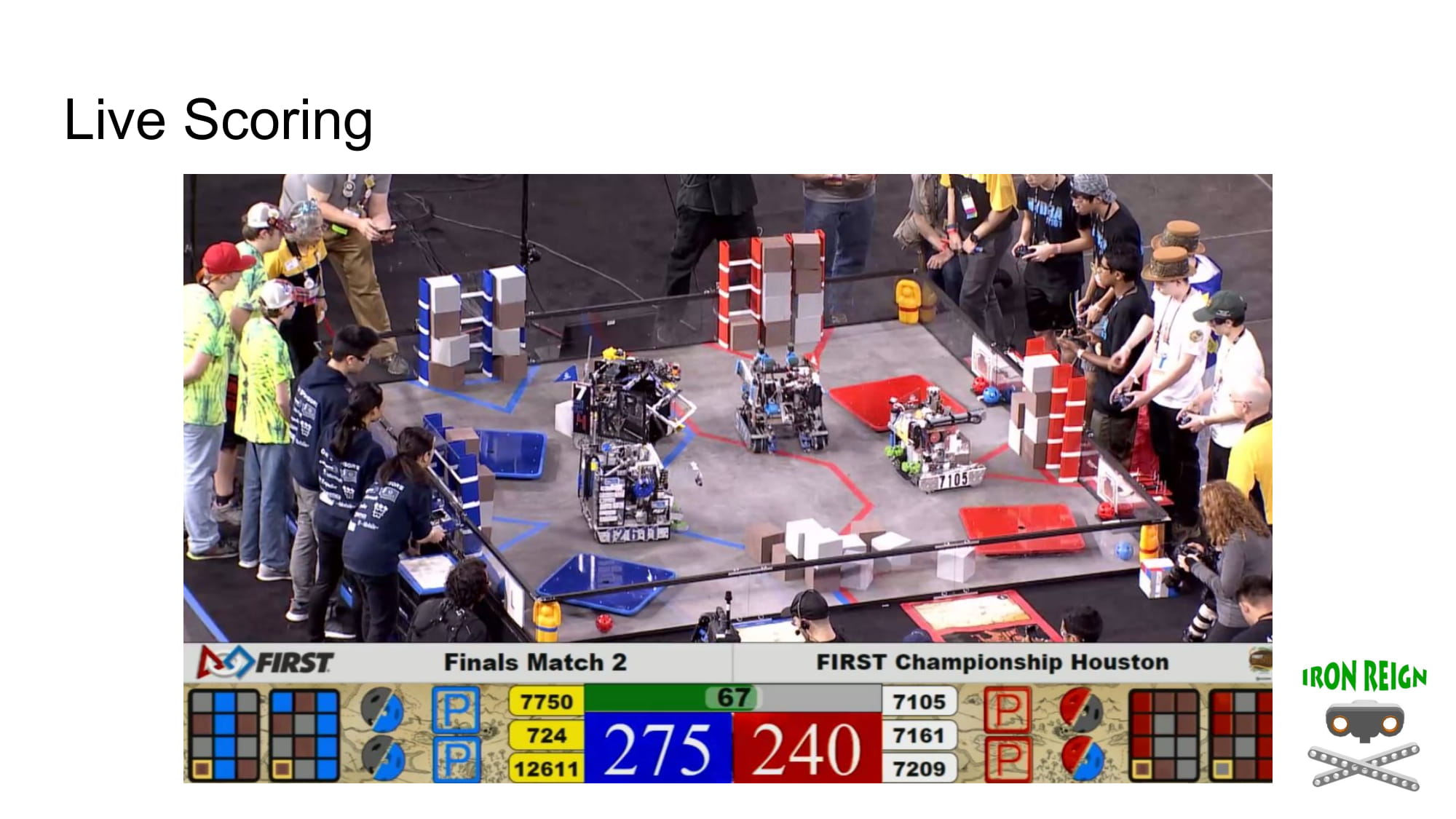

Finals 2

Finals 2

Finals 2

Finals 2

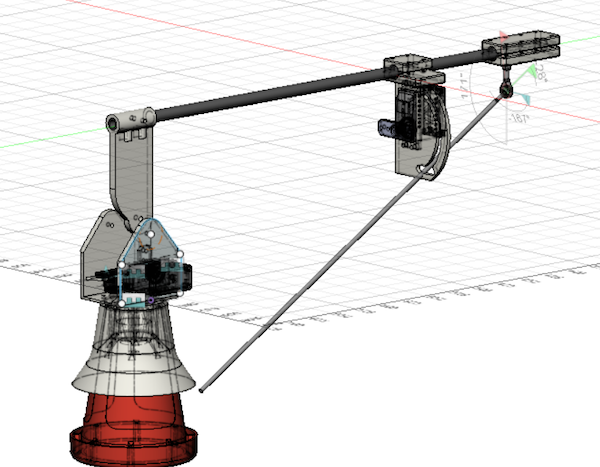

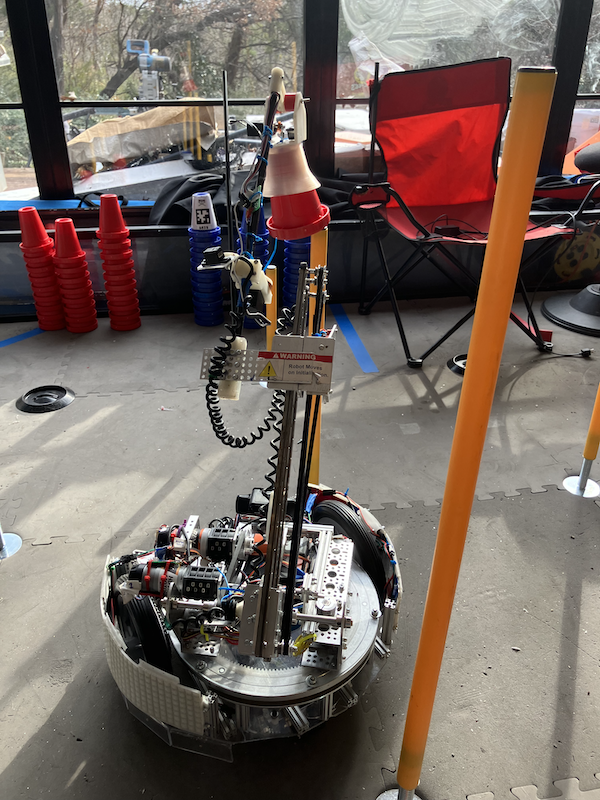

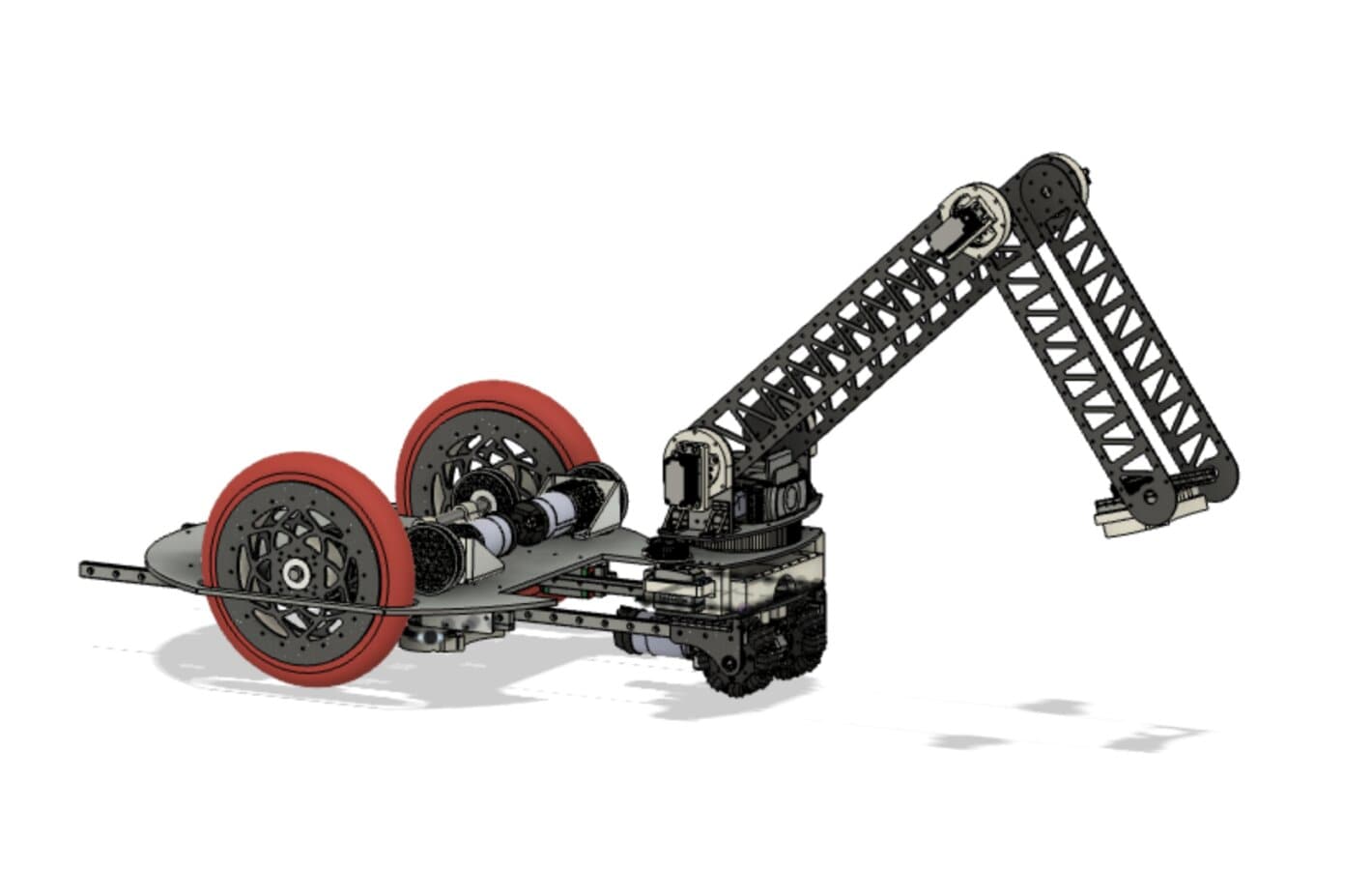

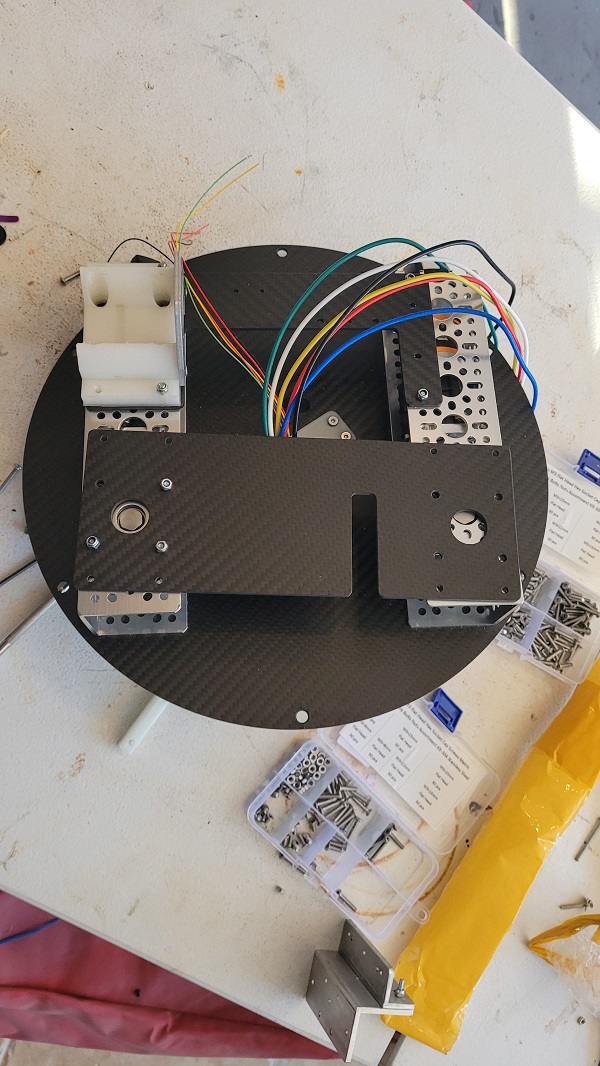

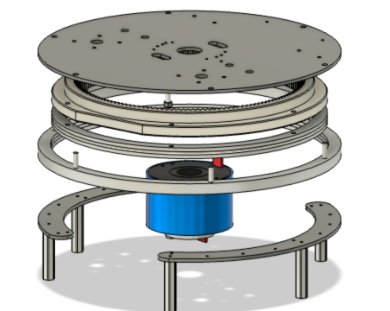

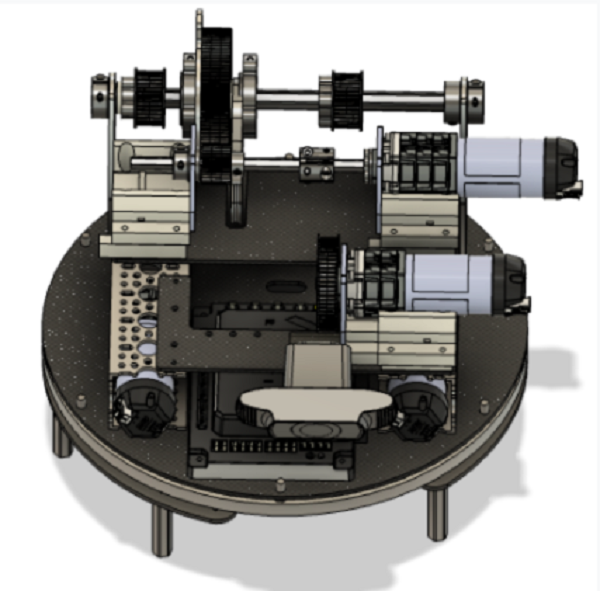

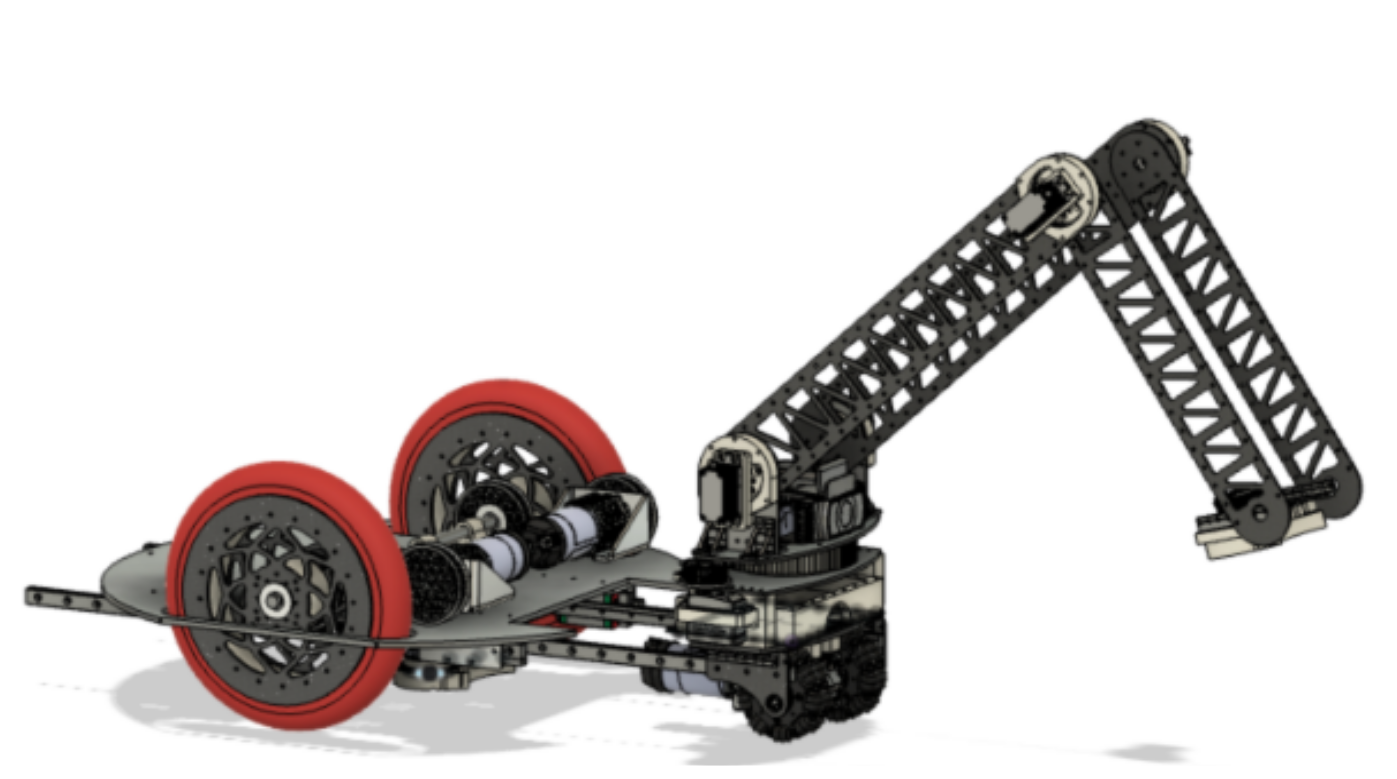

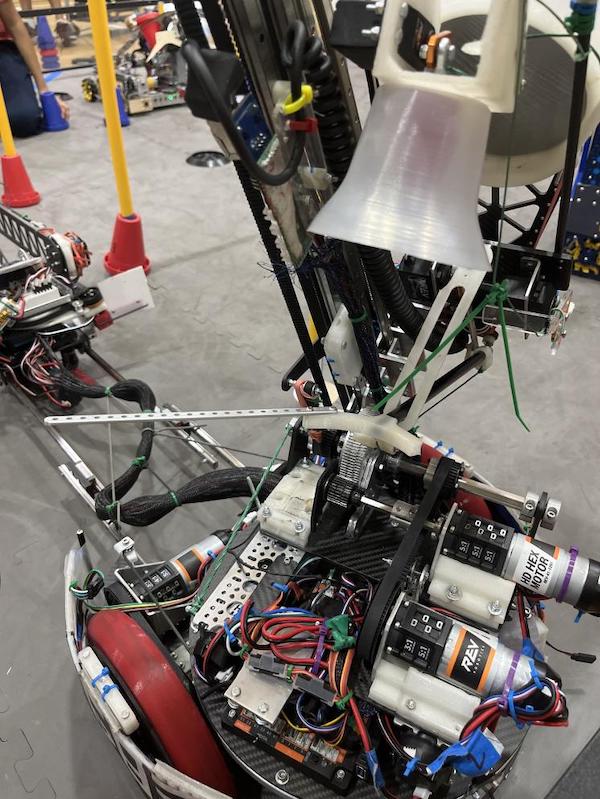

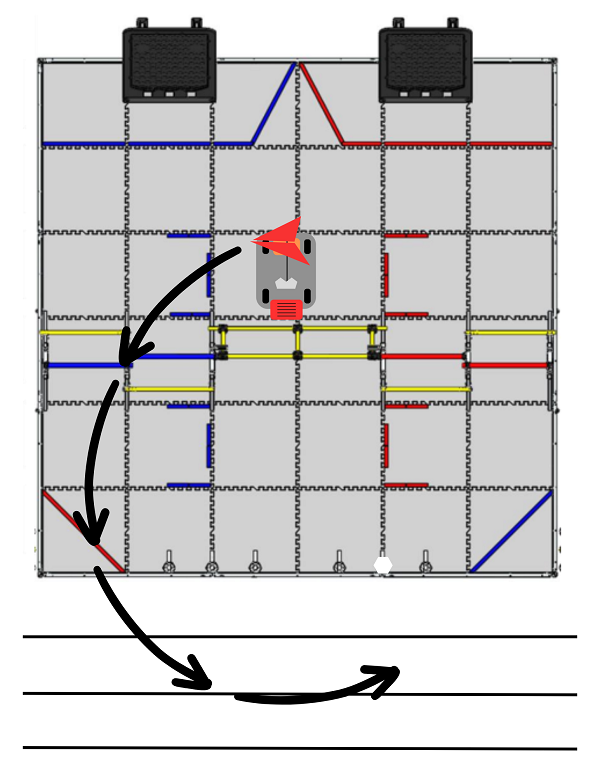

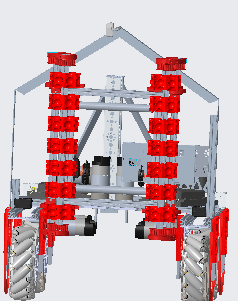

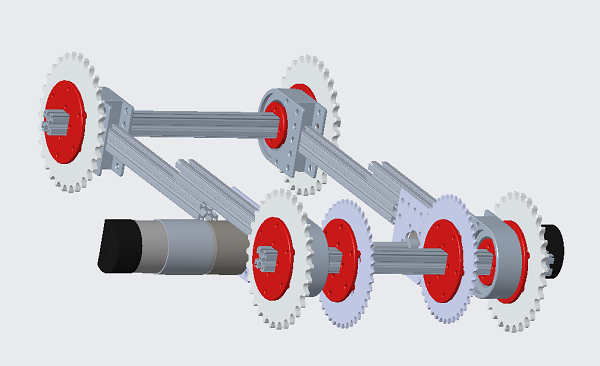

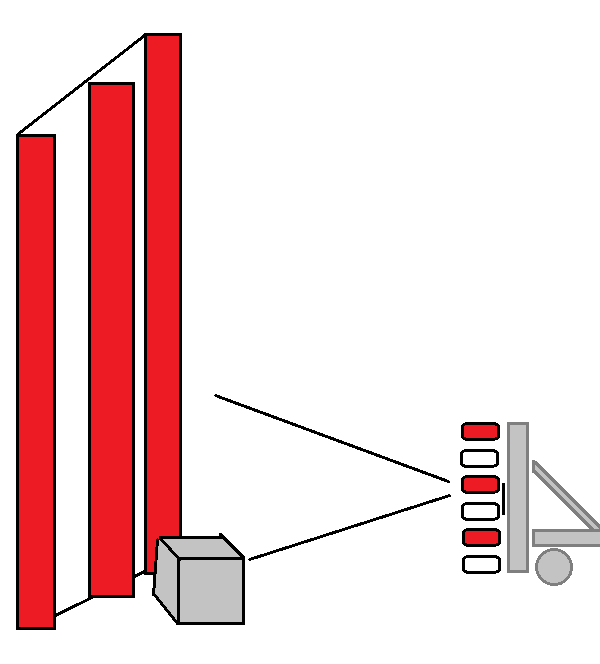

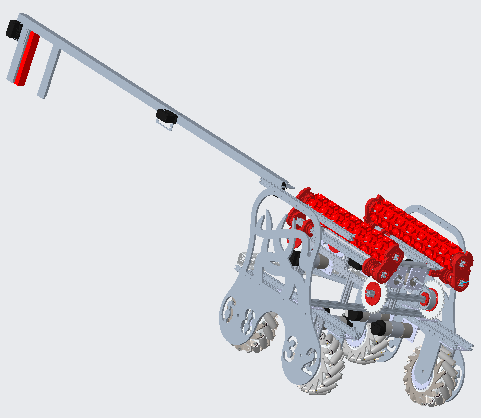

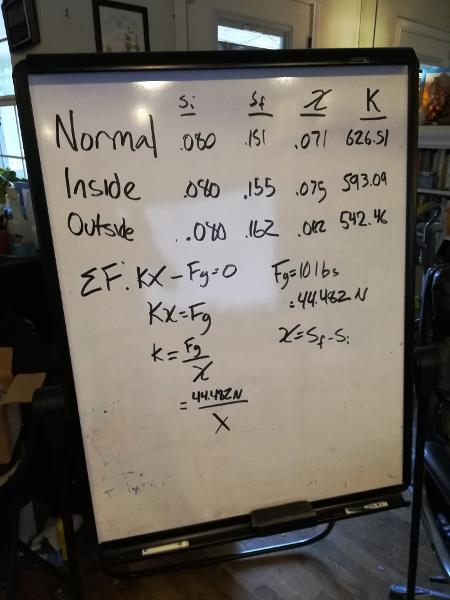

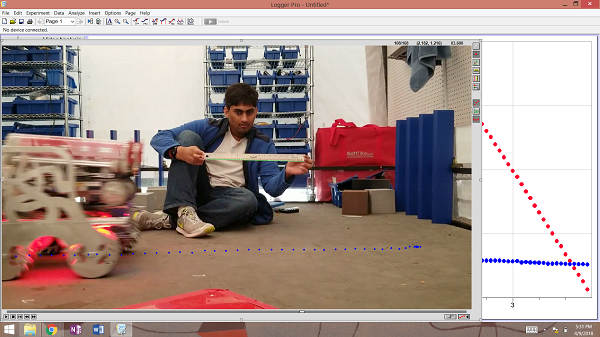

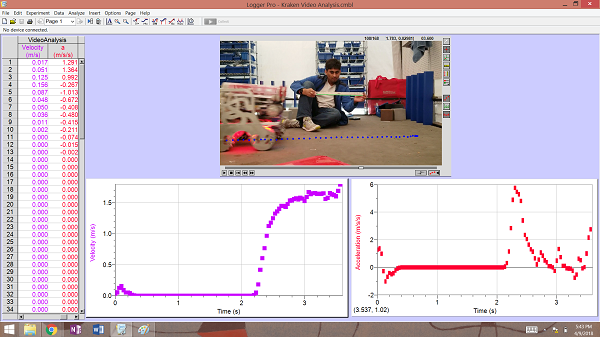

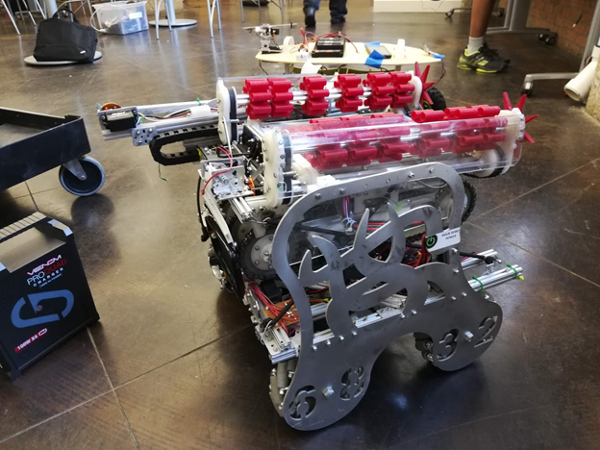

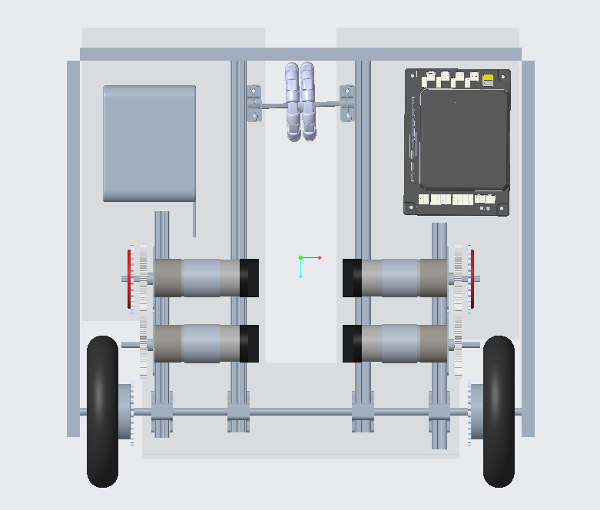

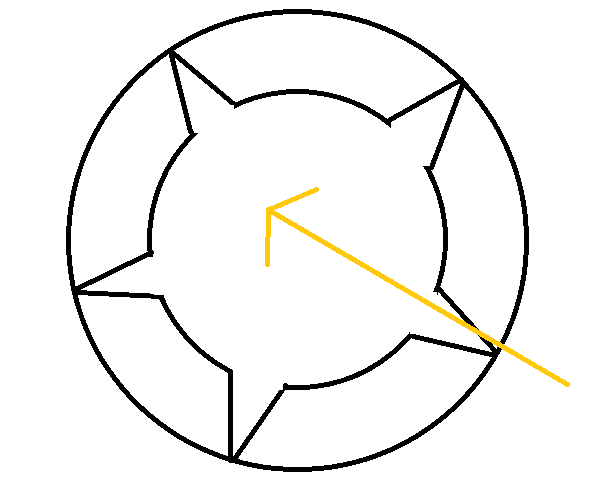

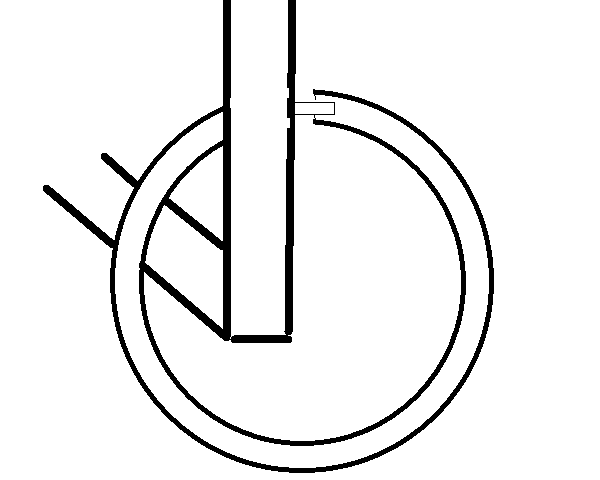

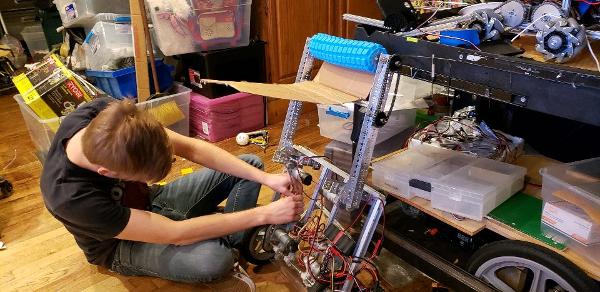

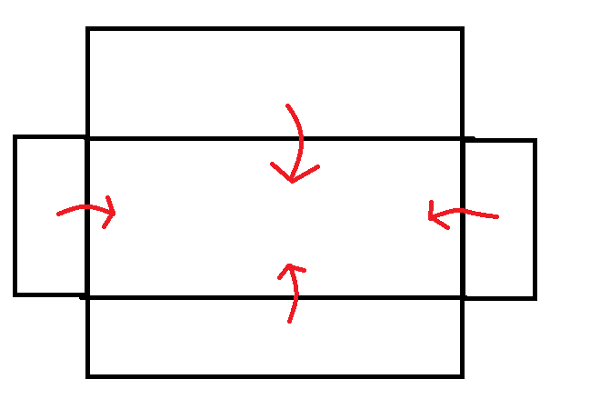

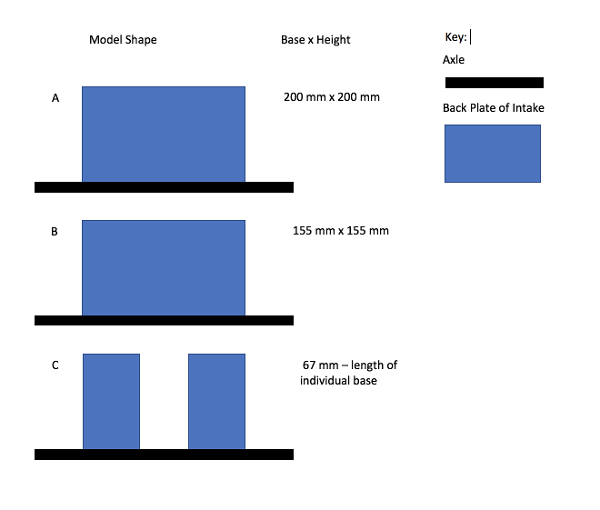

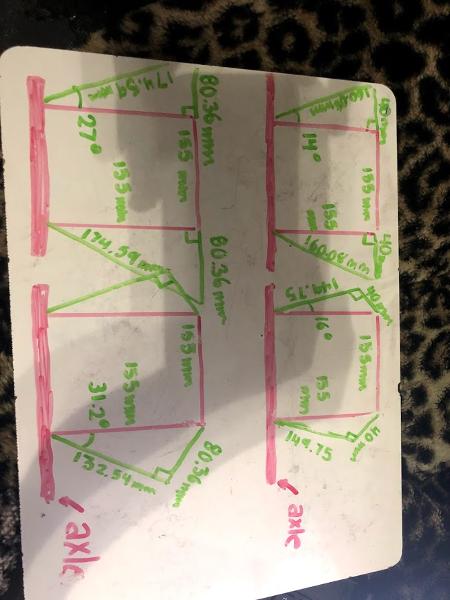

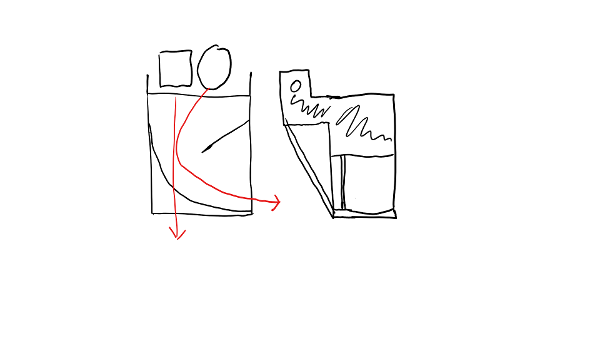

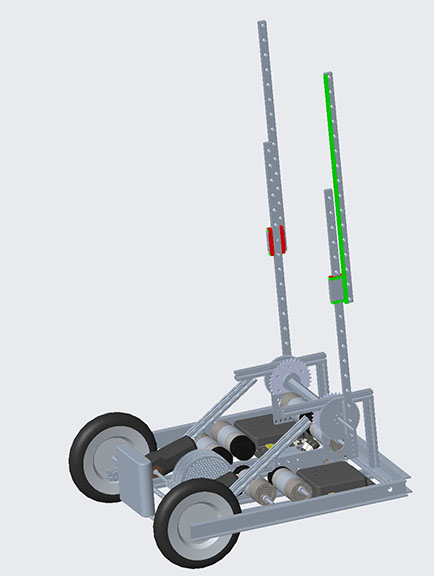

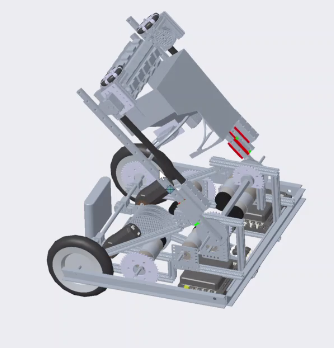

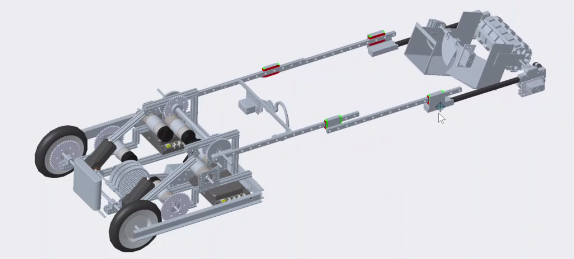

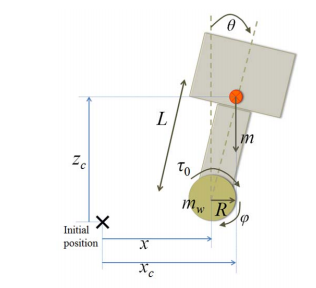

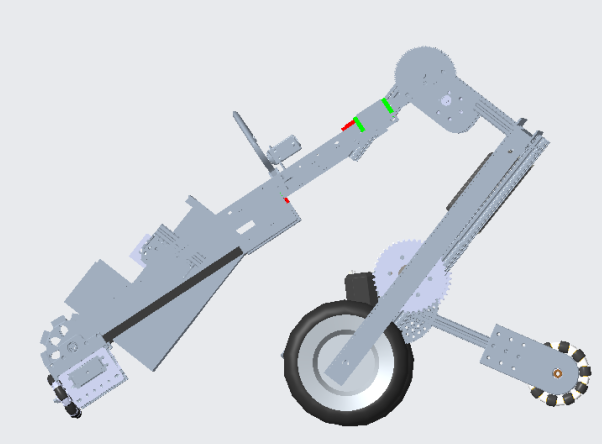

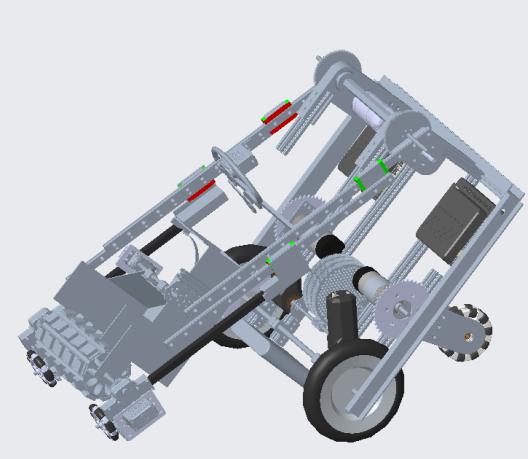

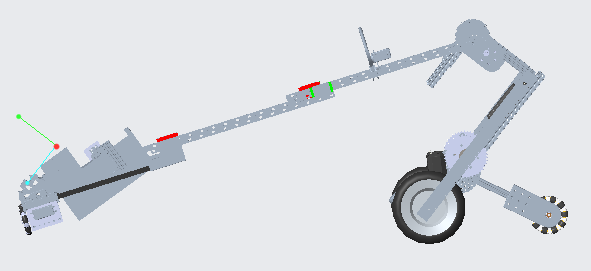

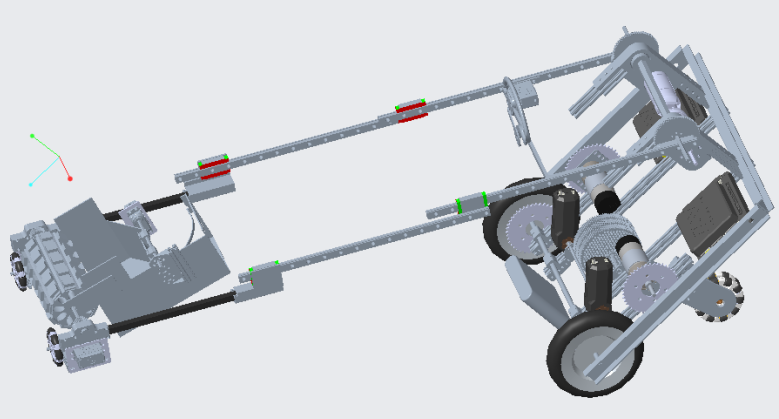

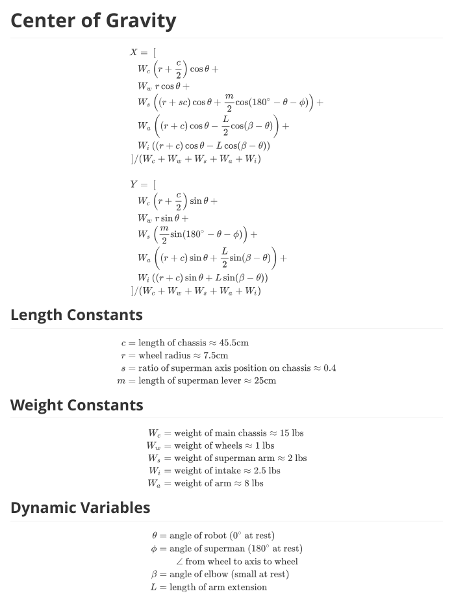

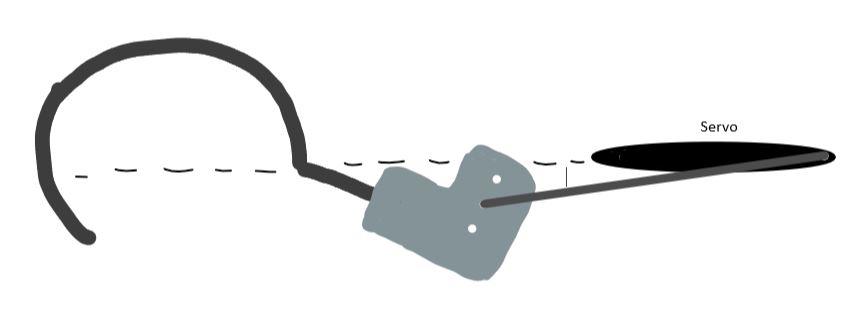

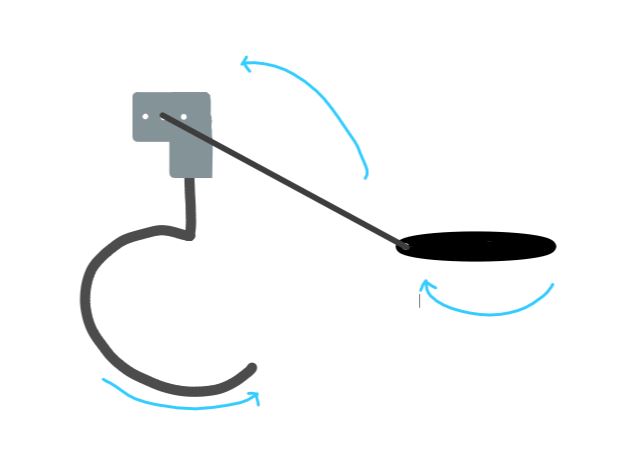

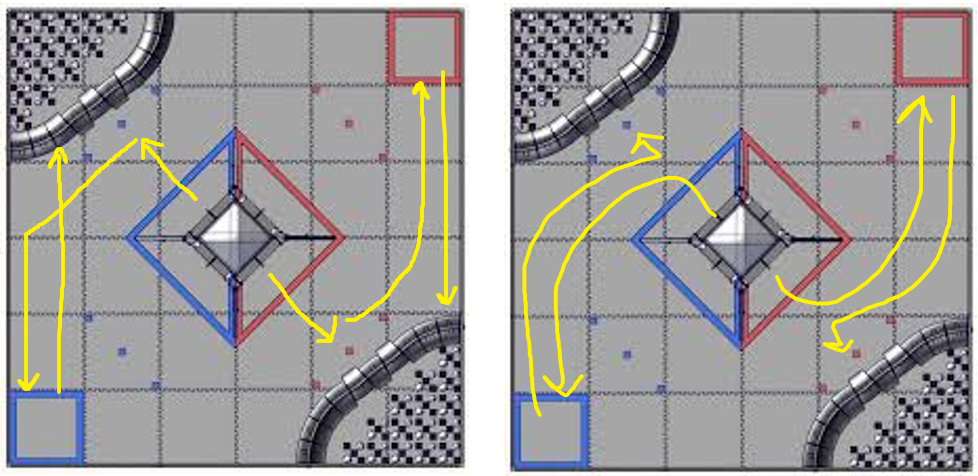

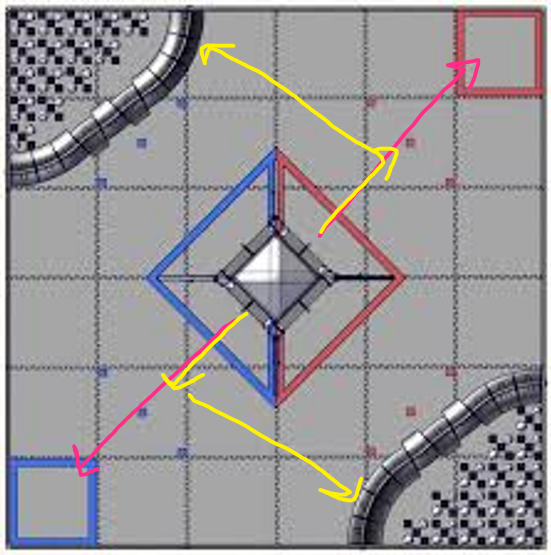

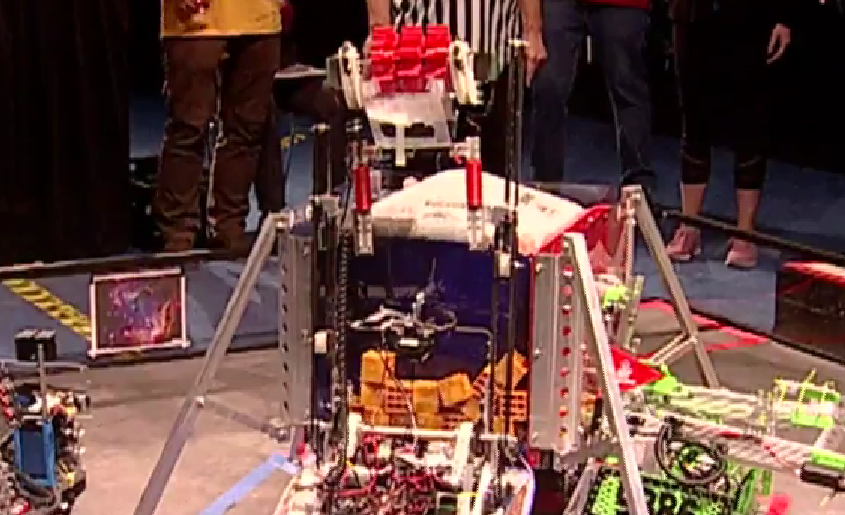

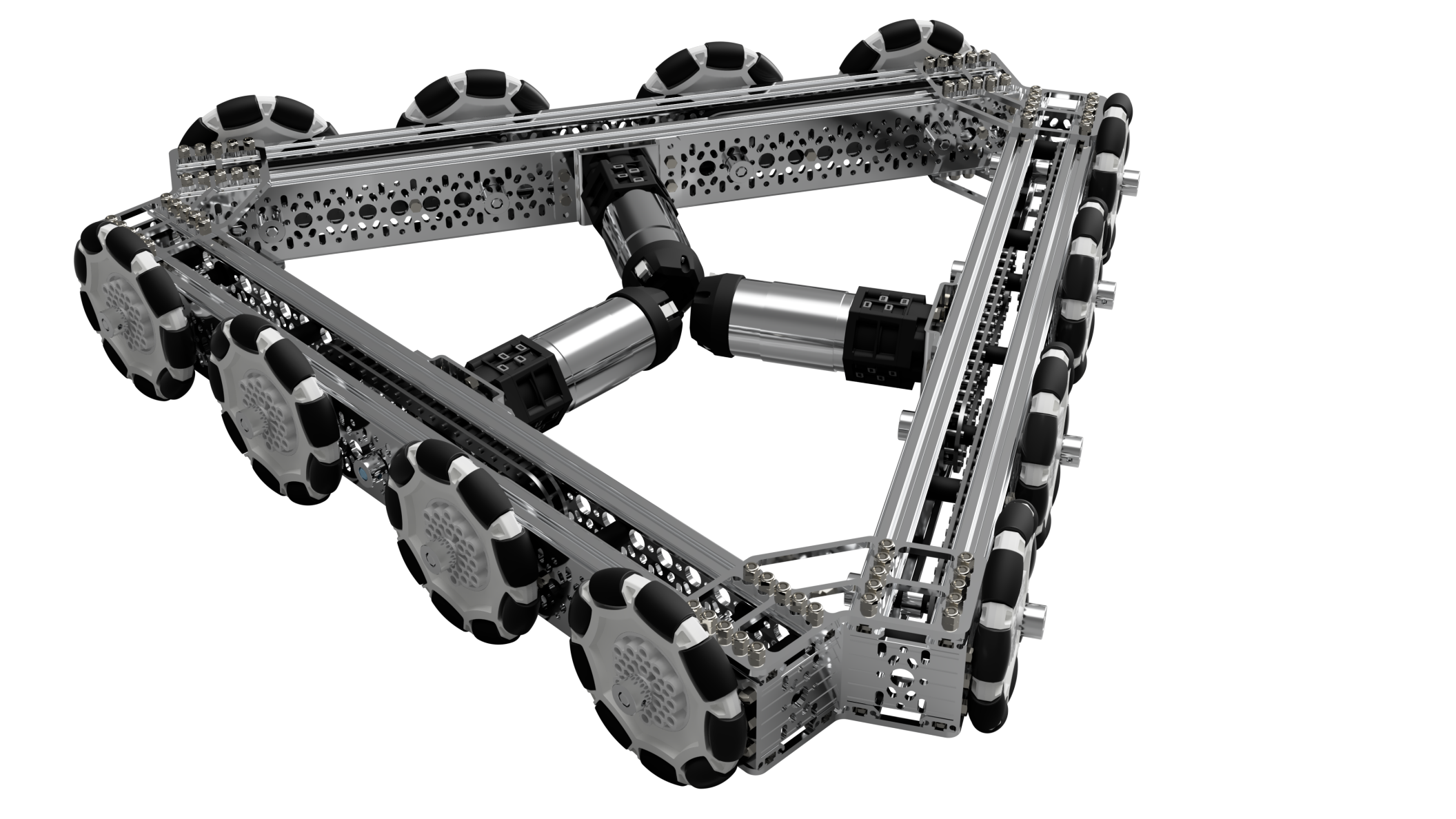

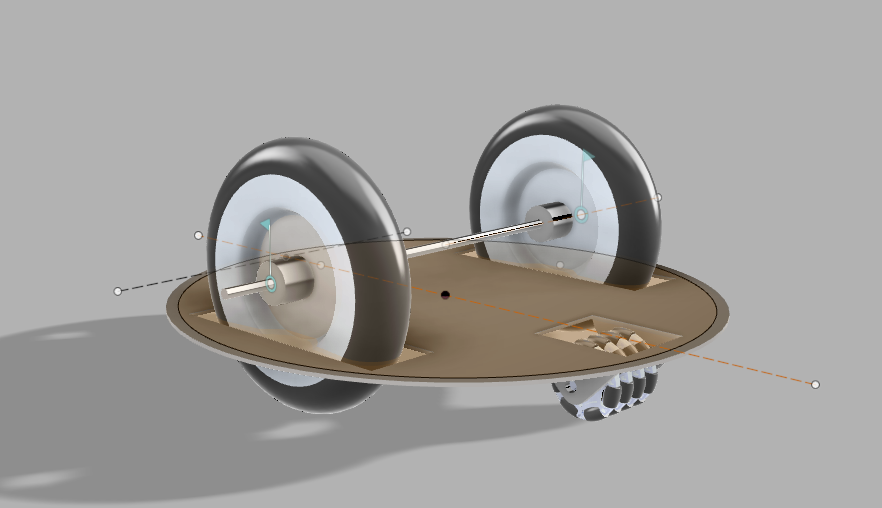

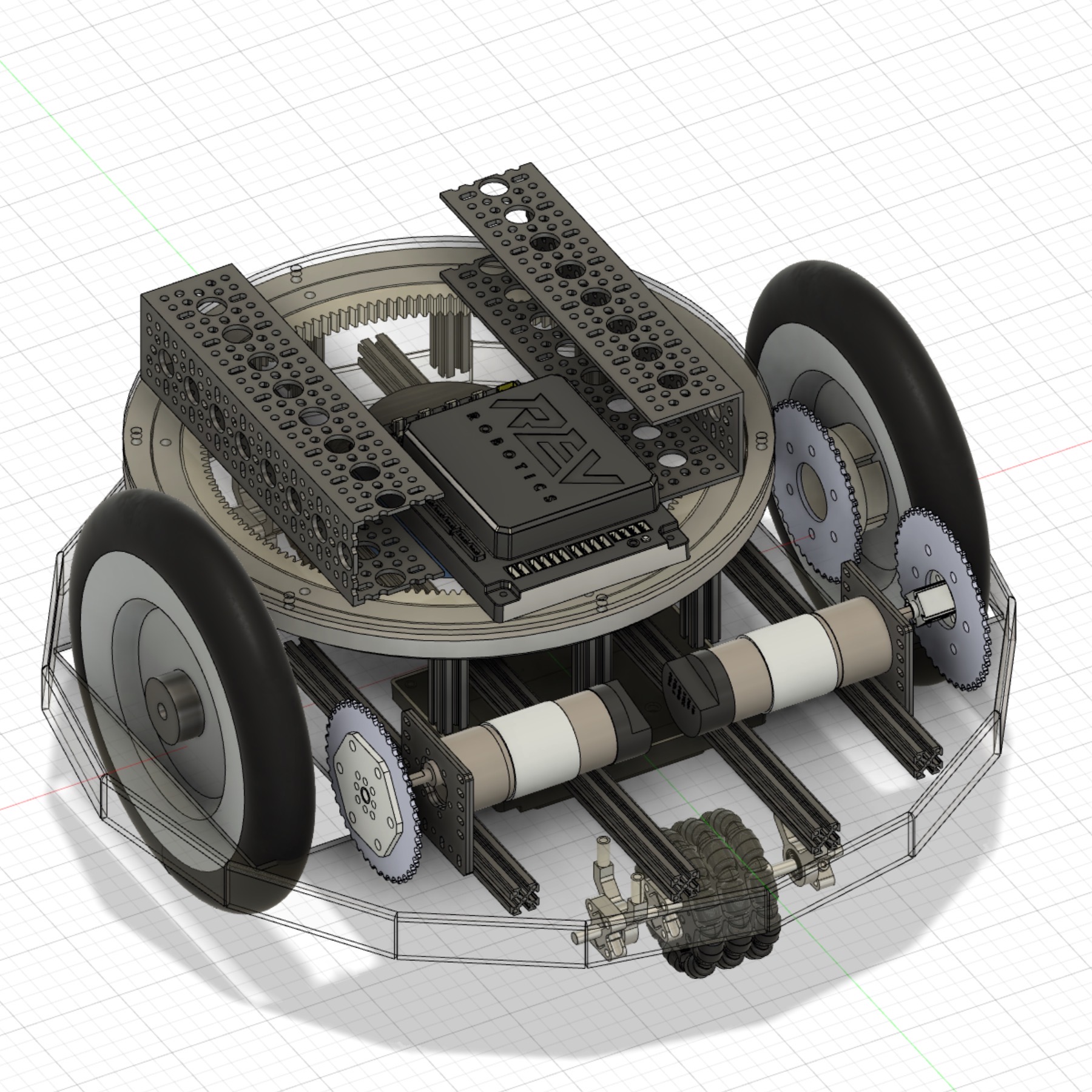

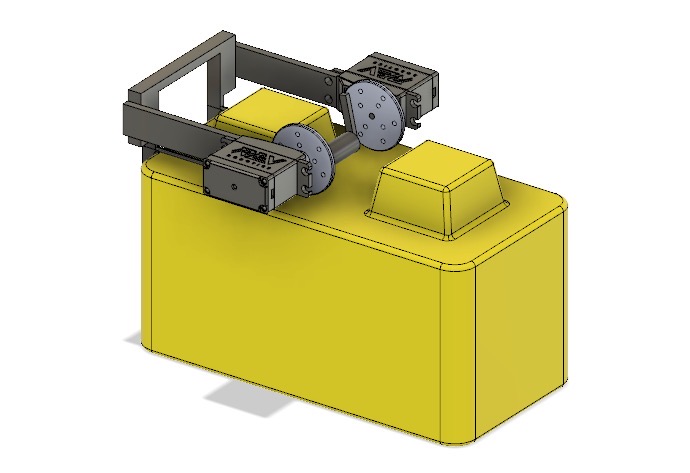

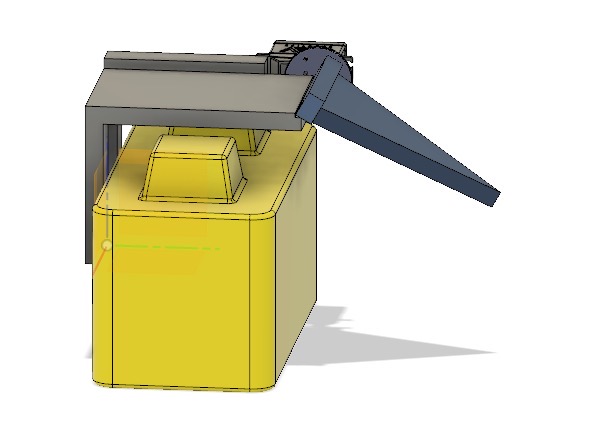

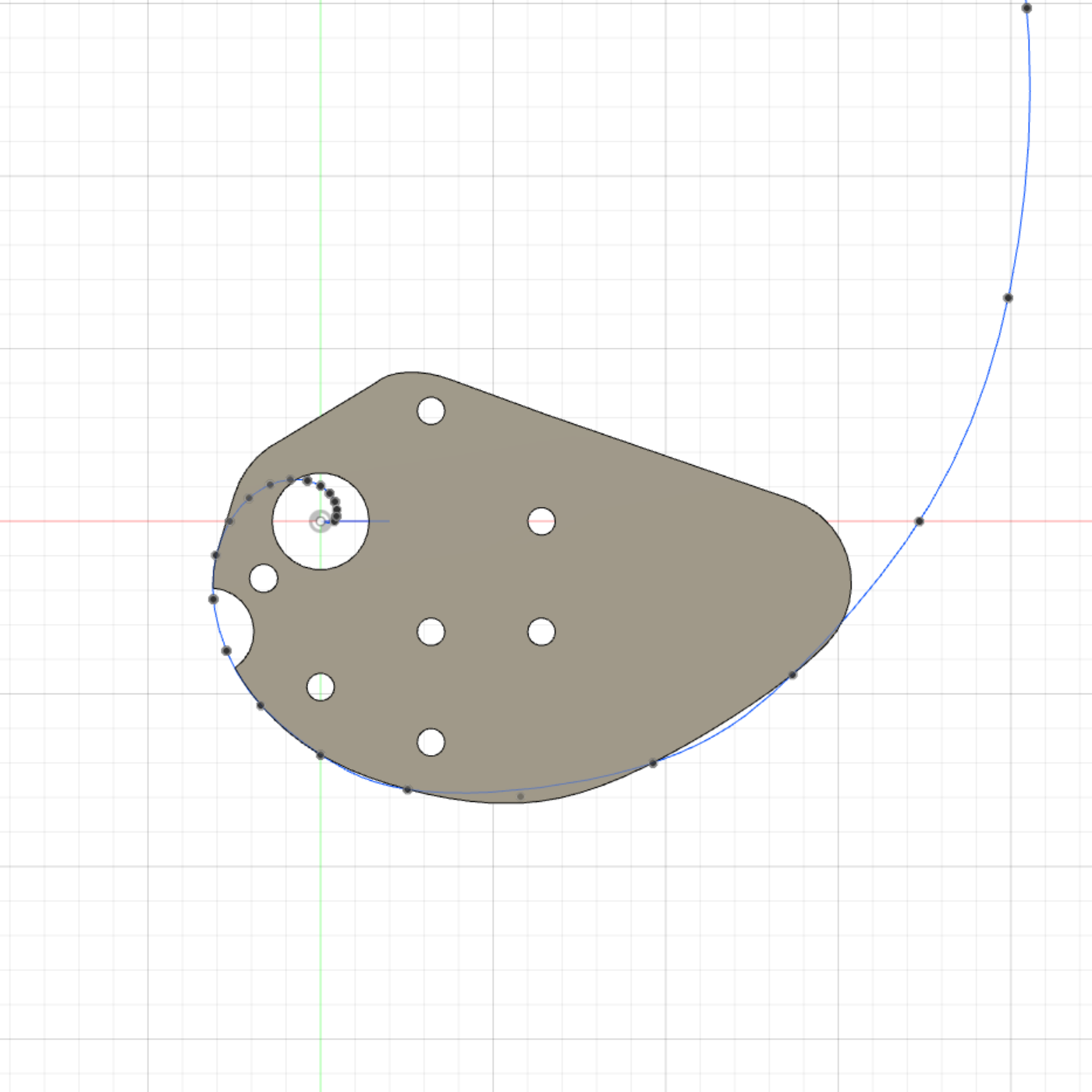

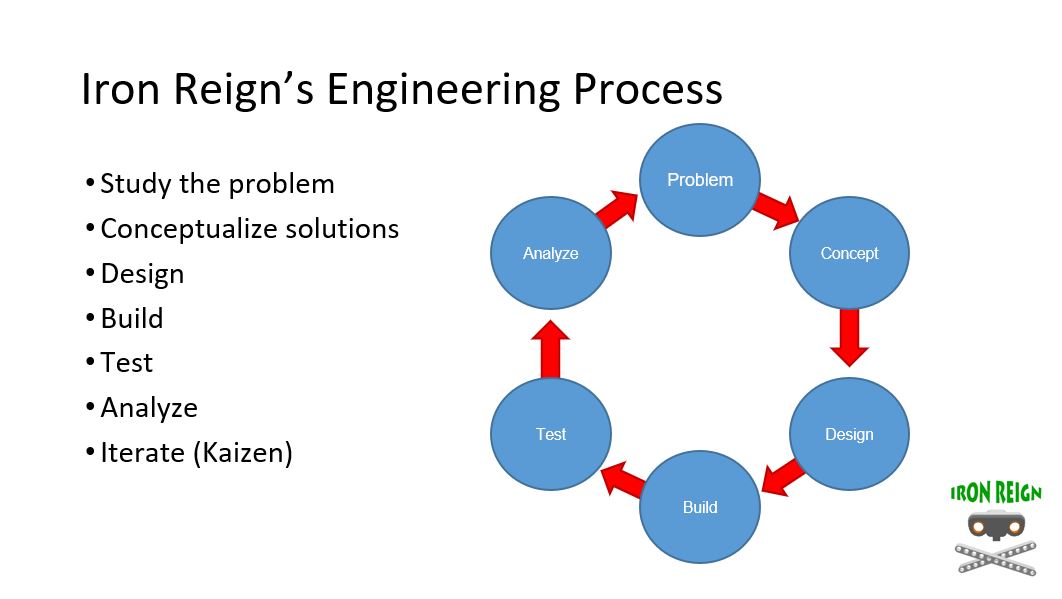

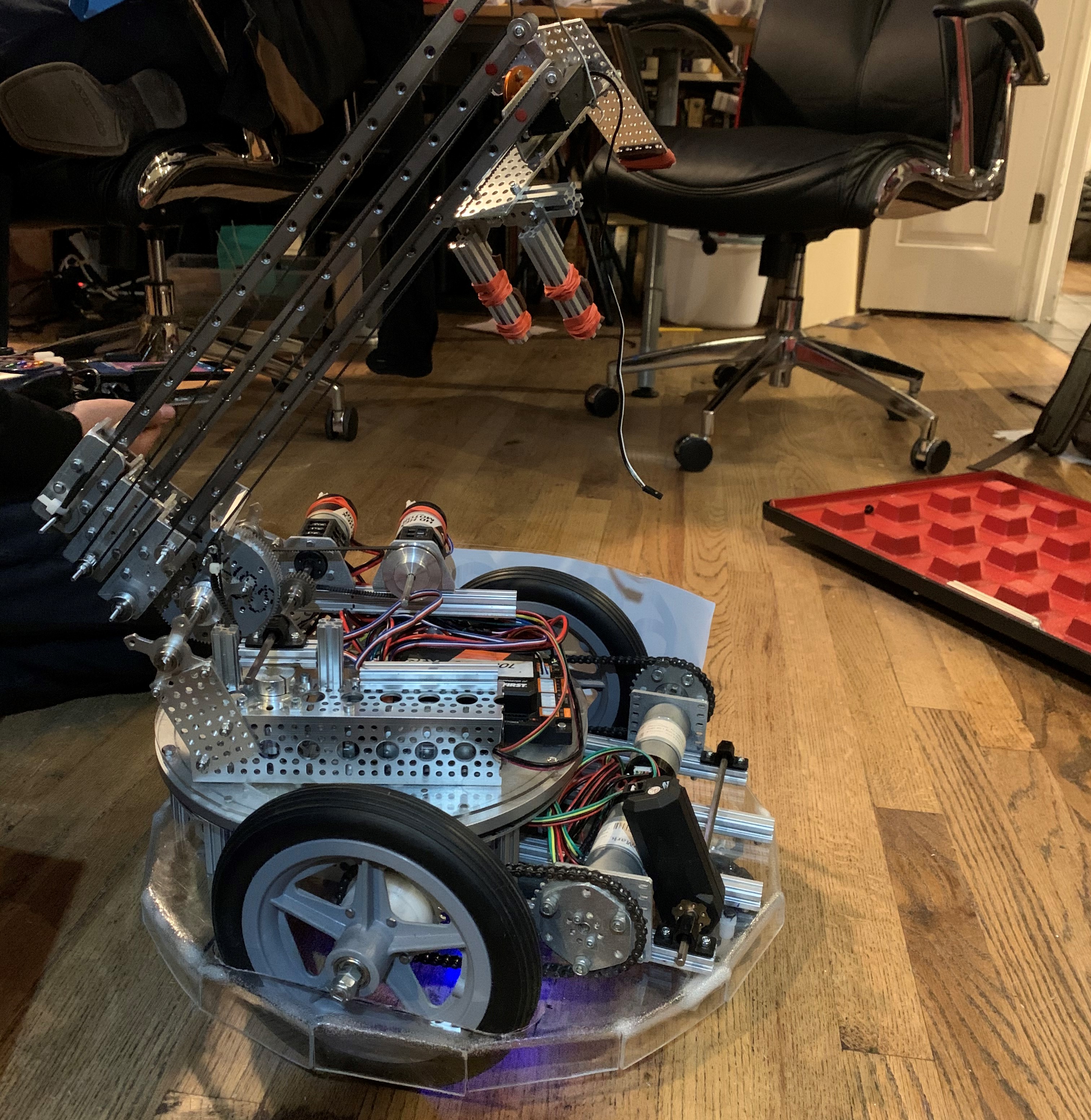

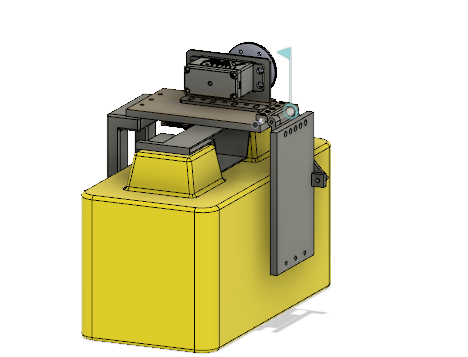

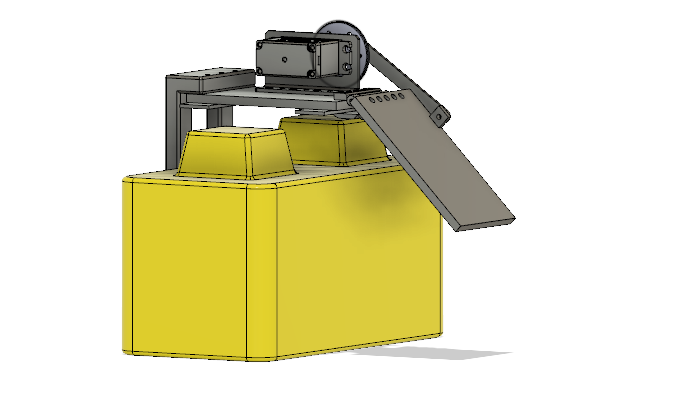

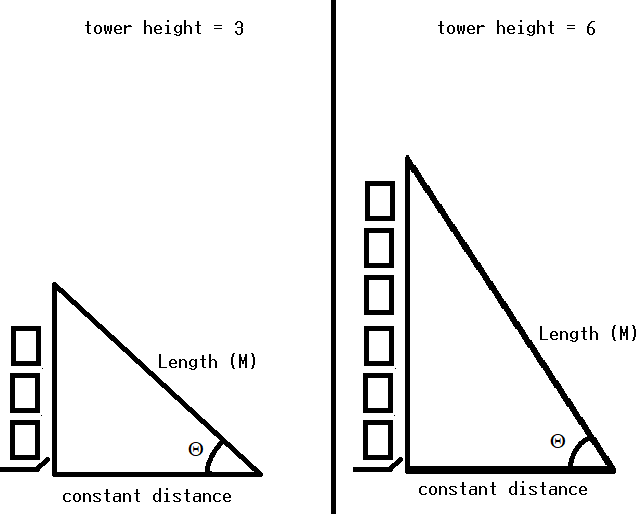

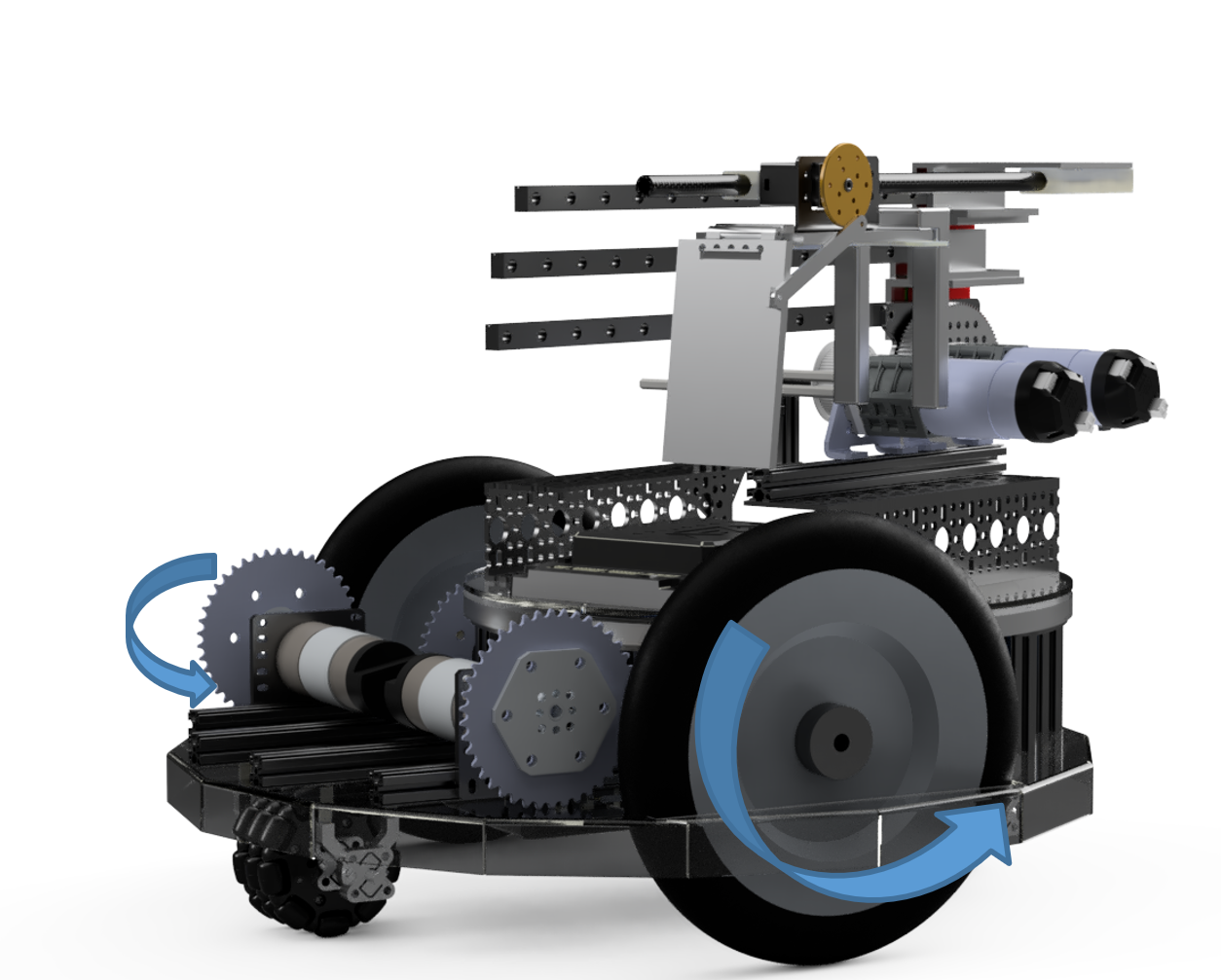

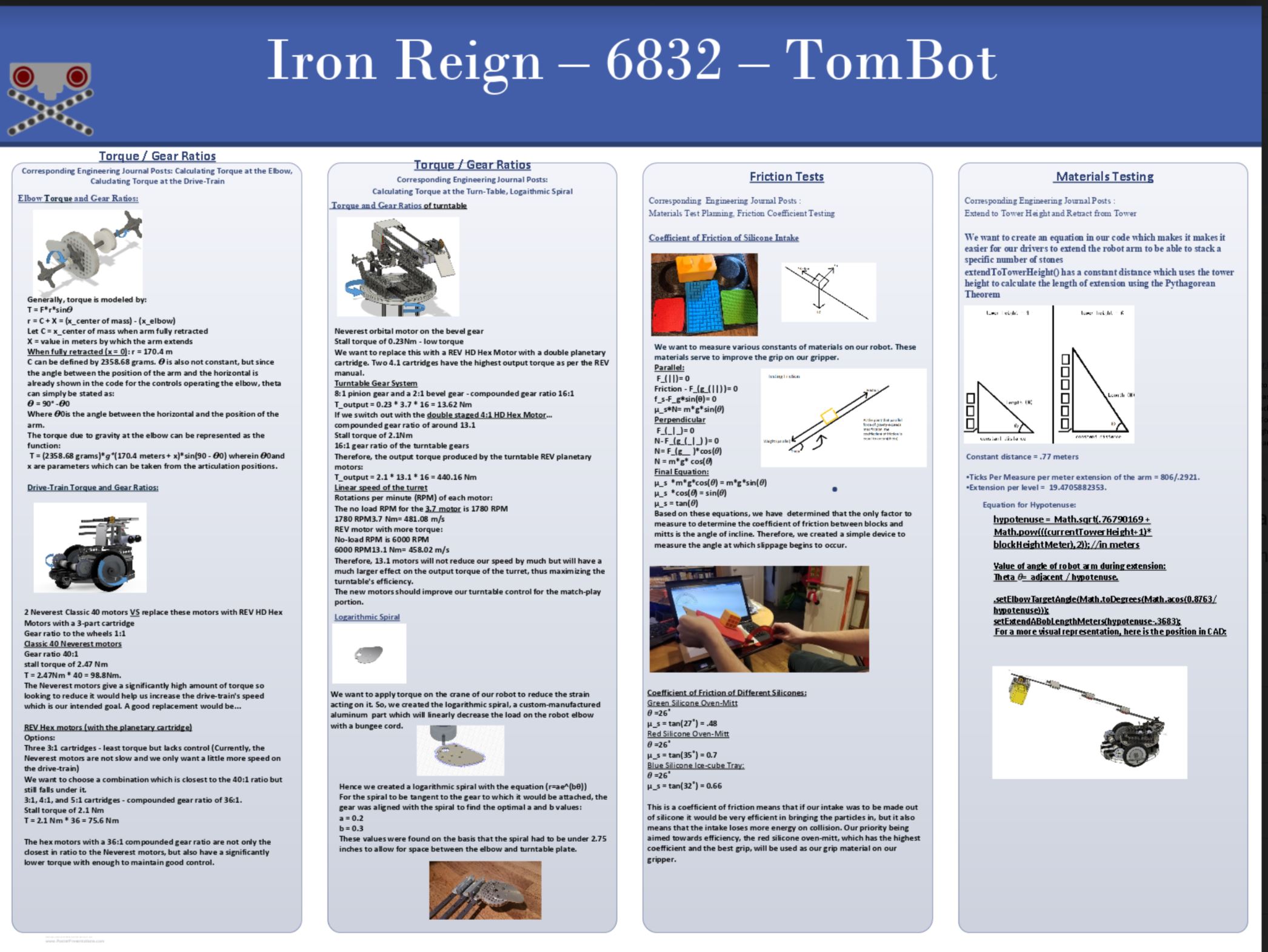

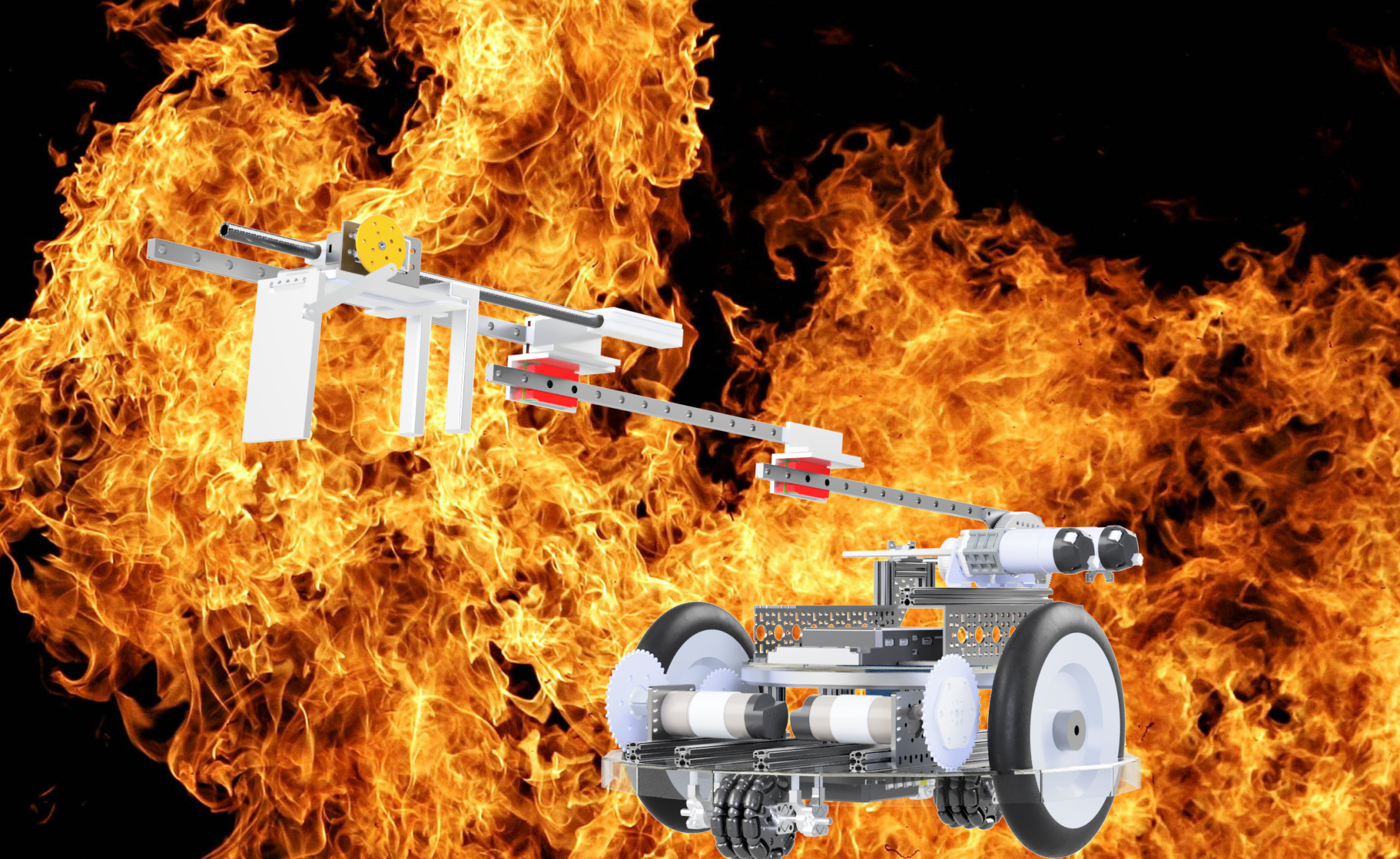

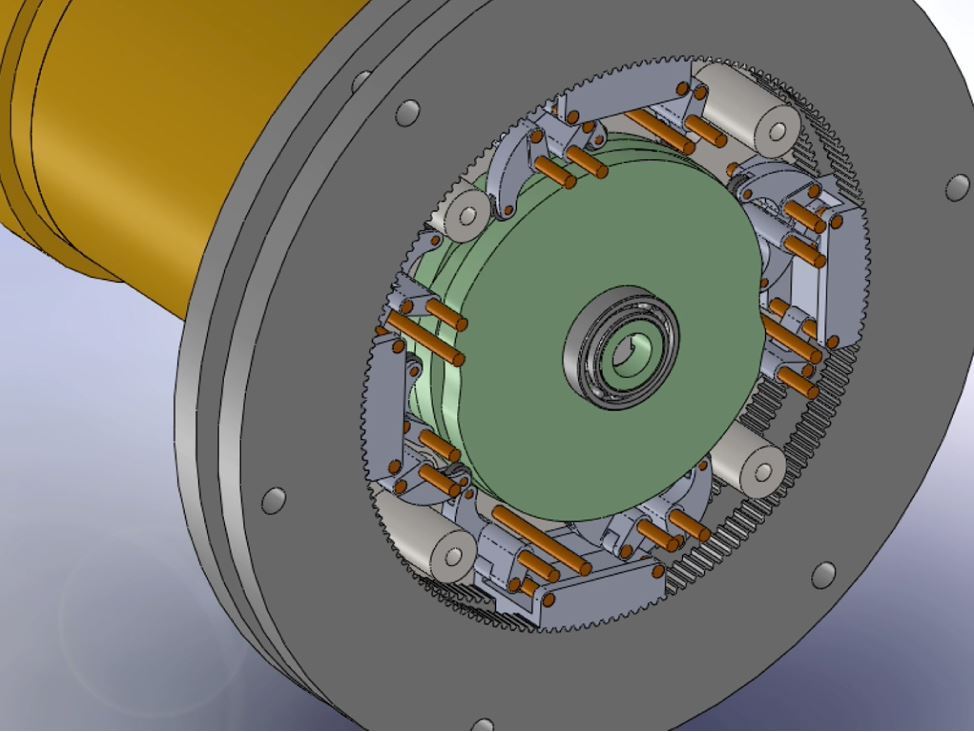

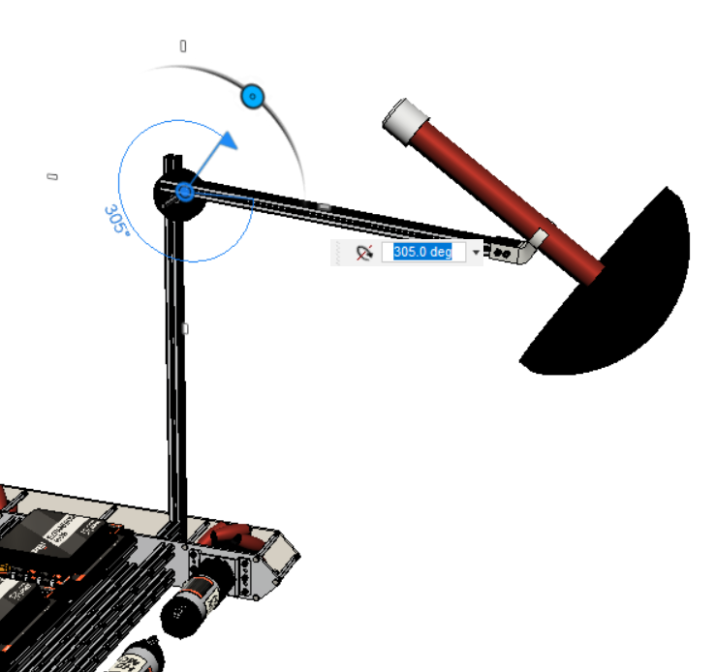

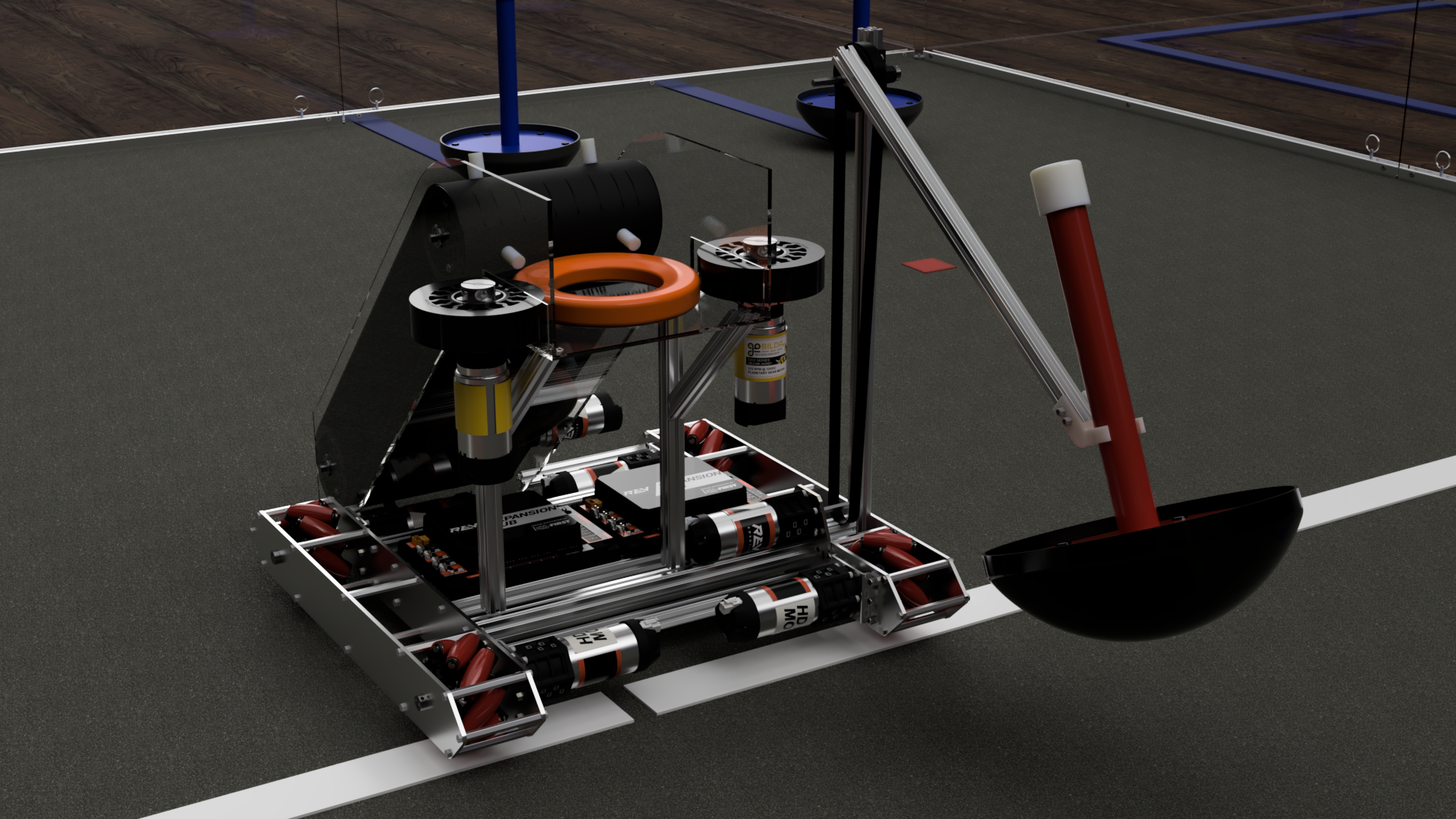

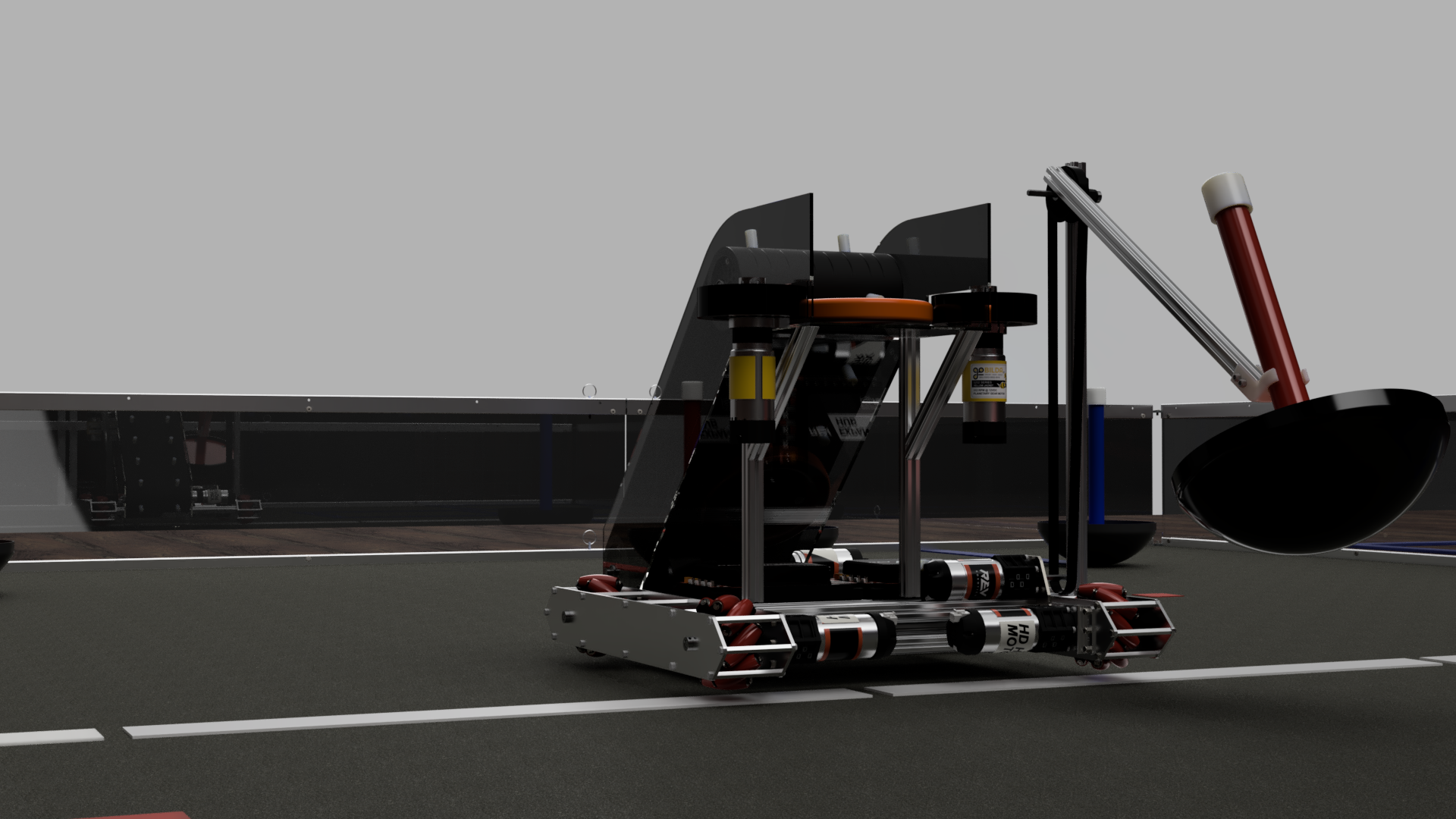

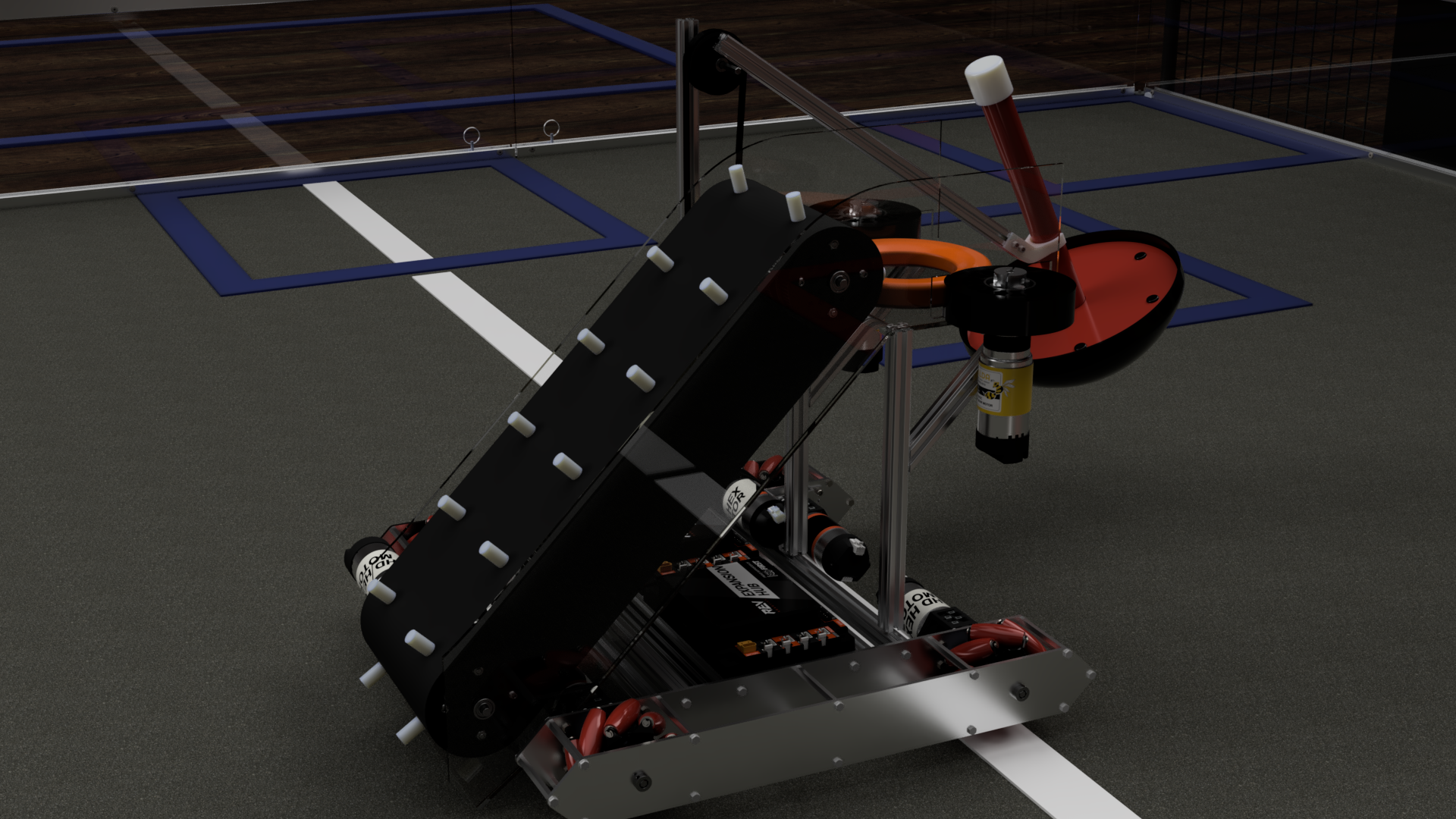

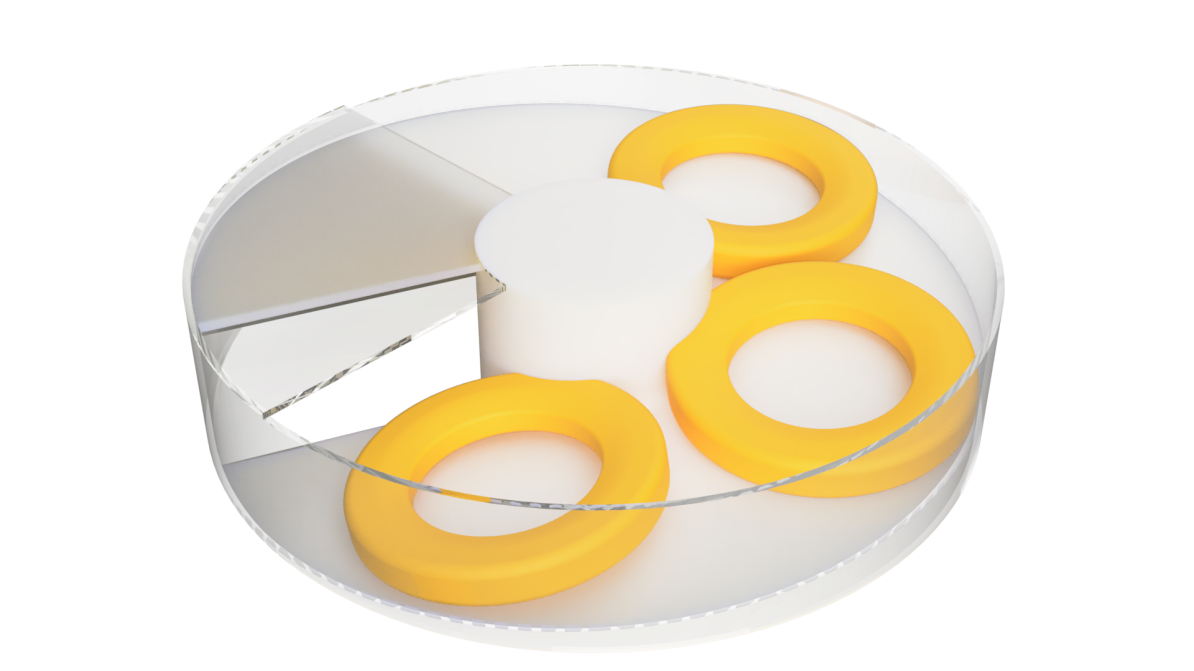

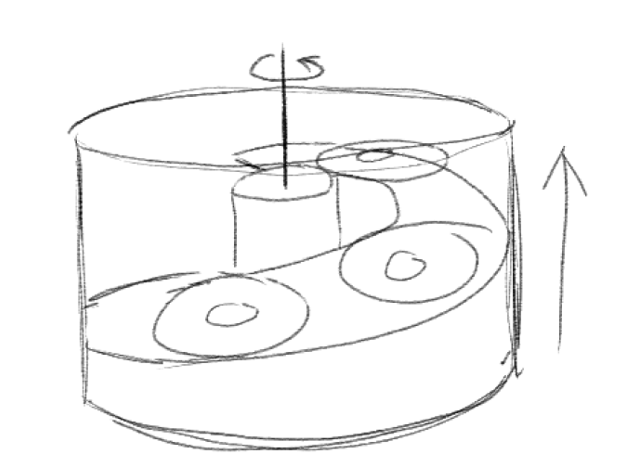

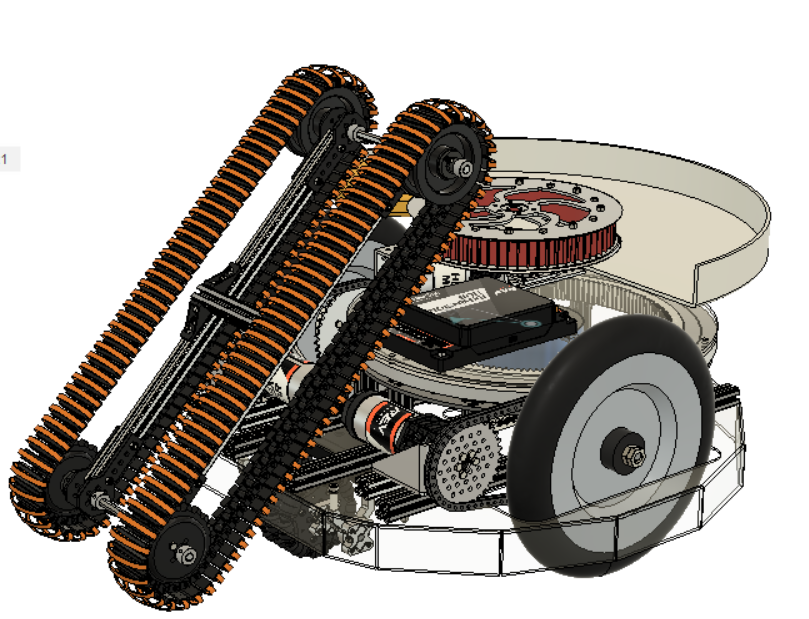

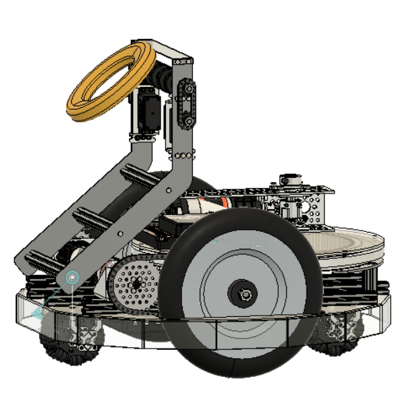

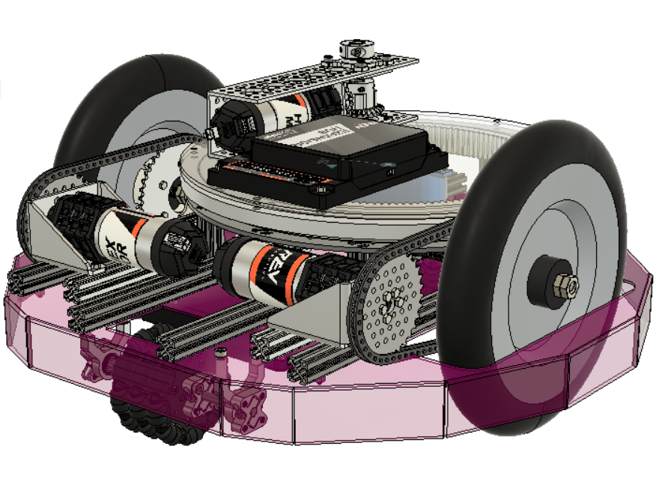

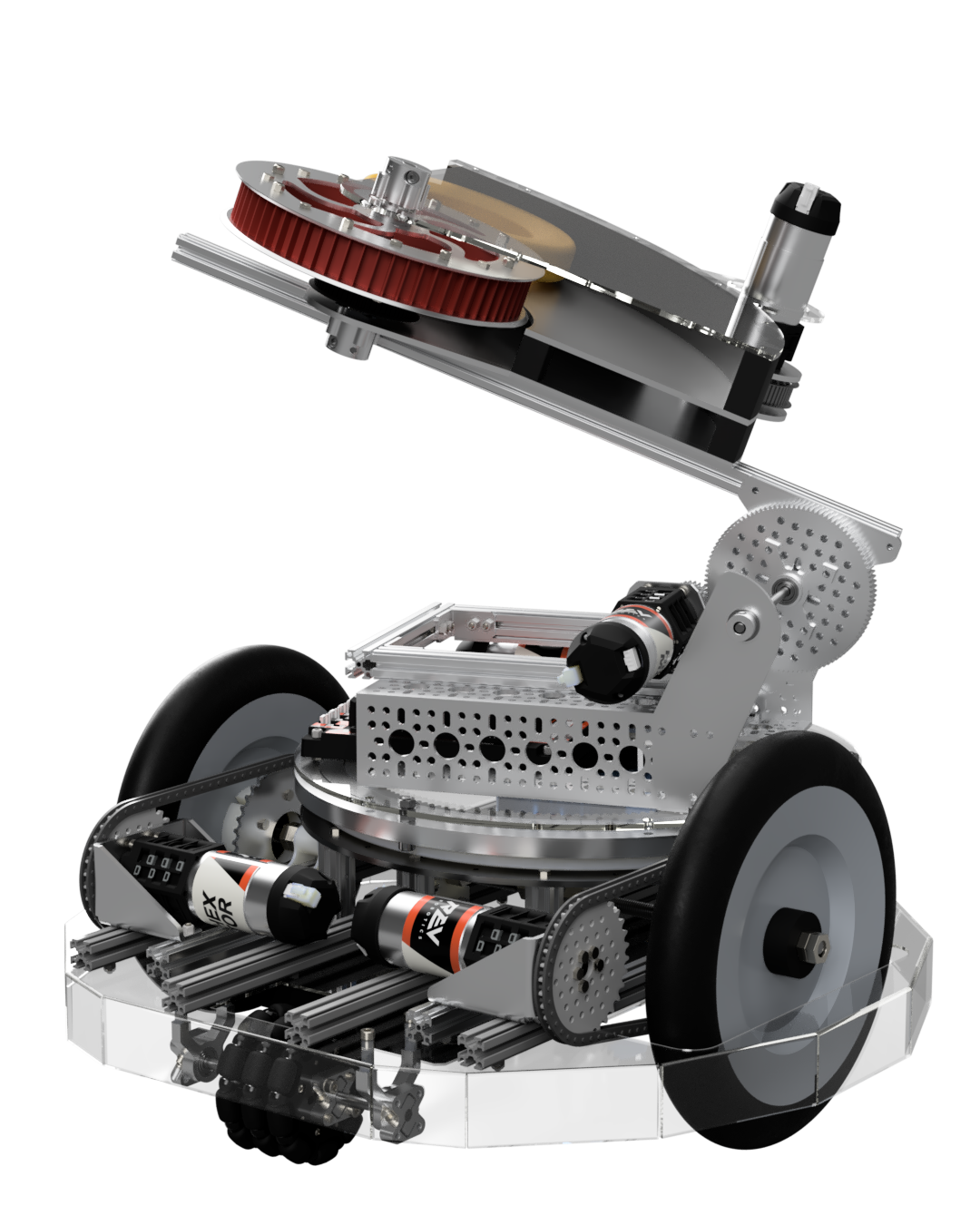

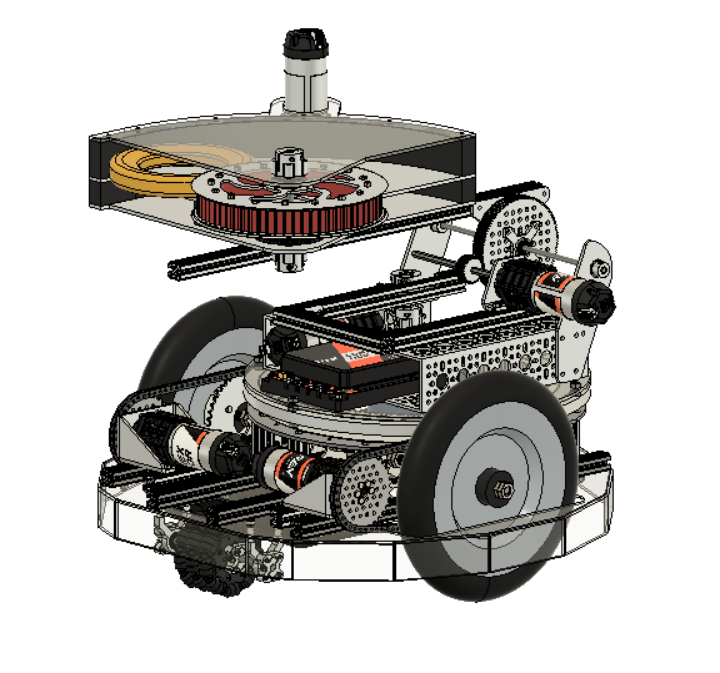

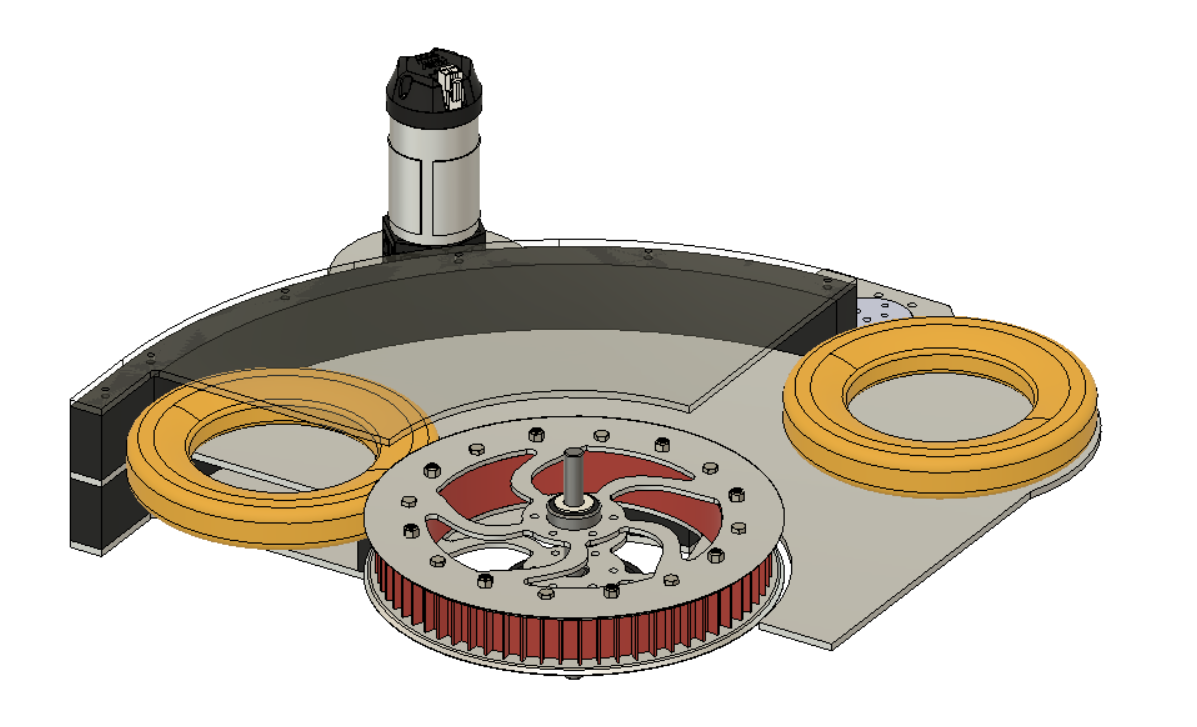

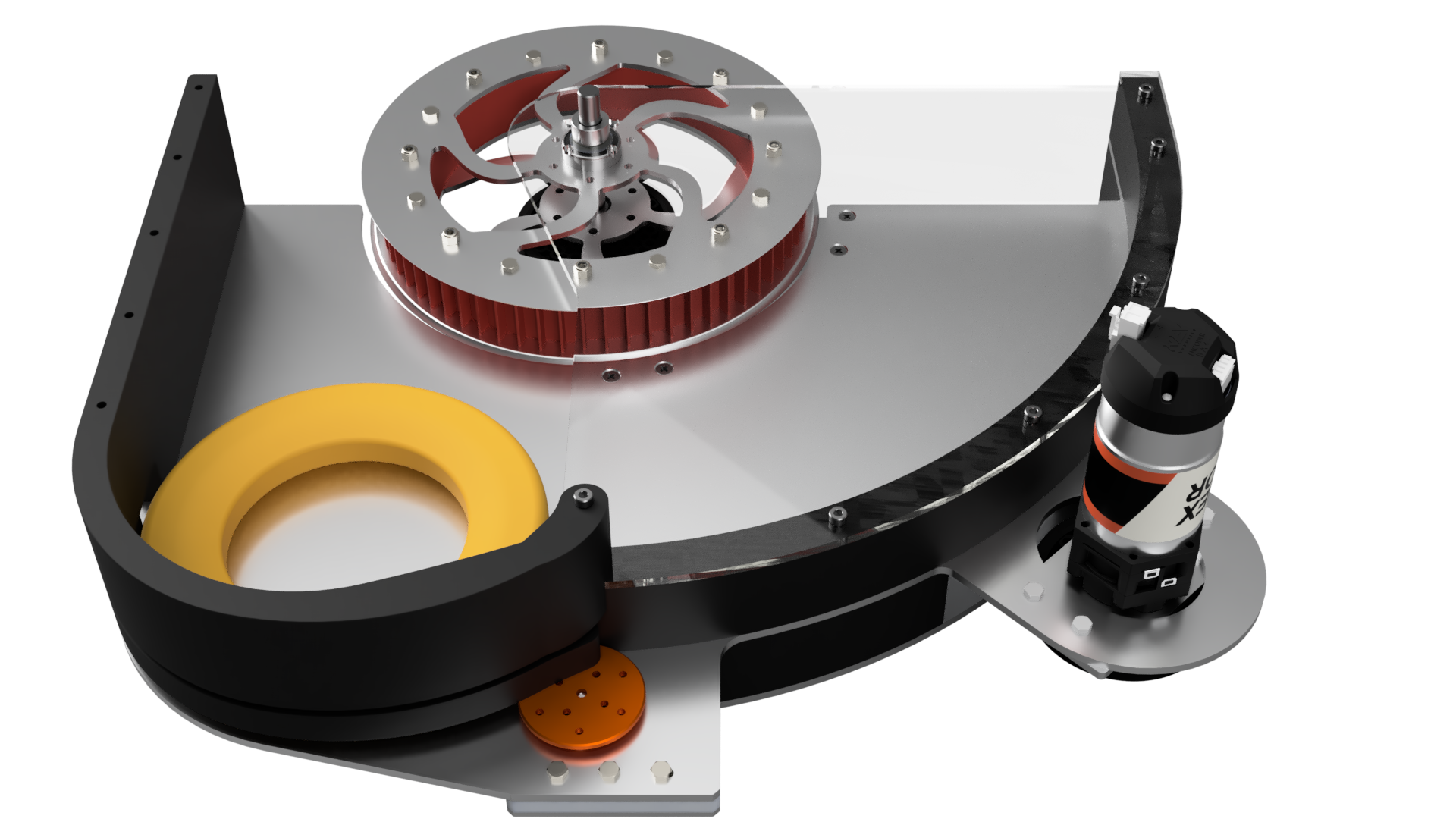

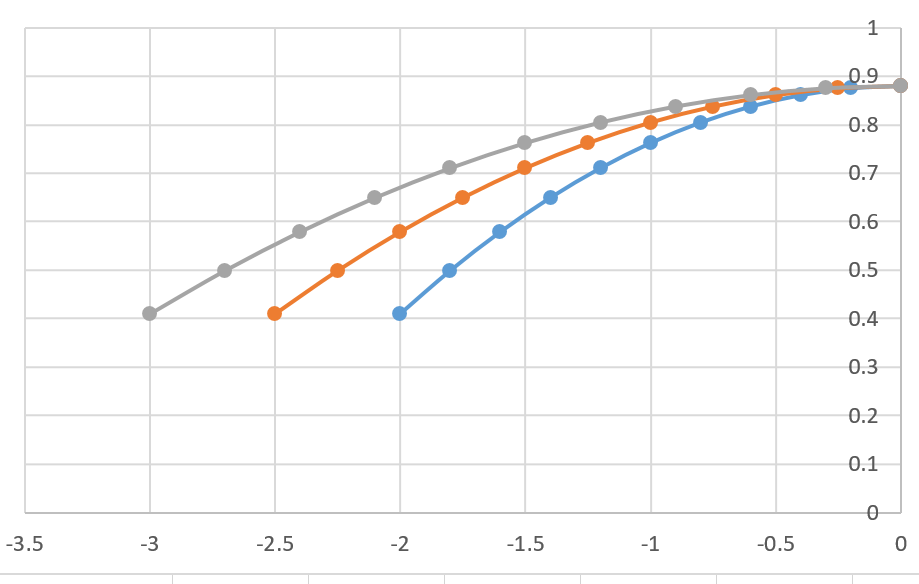

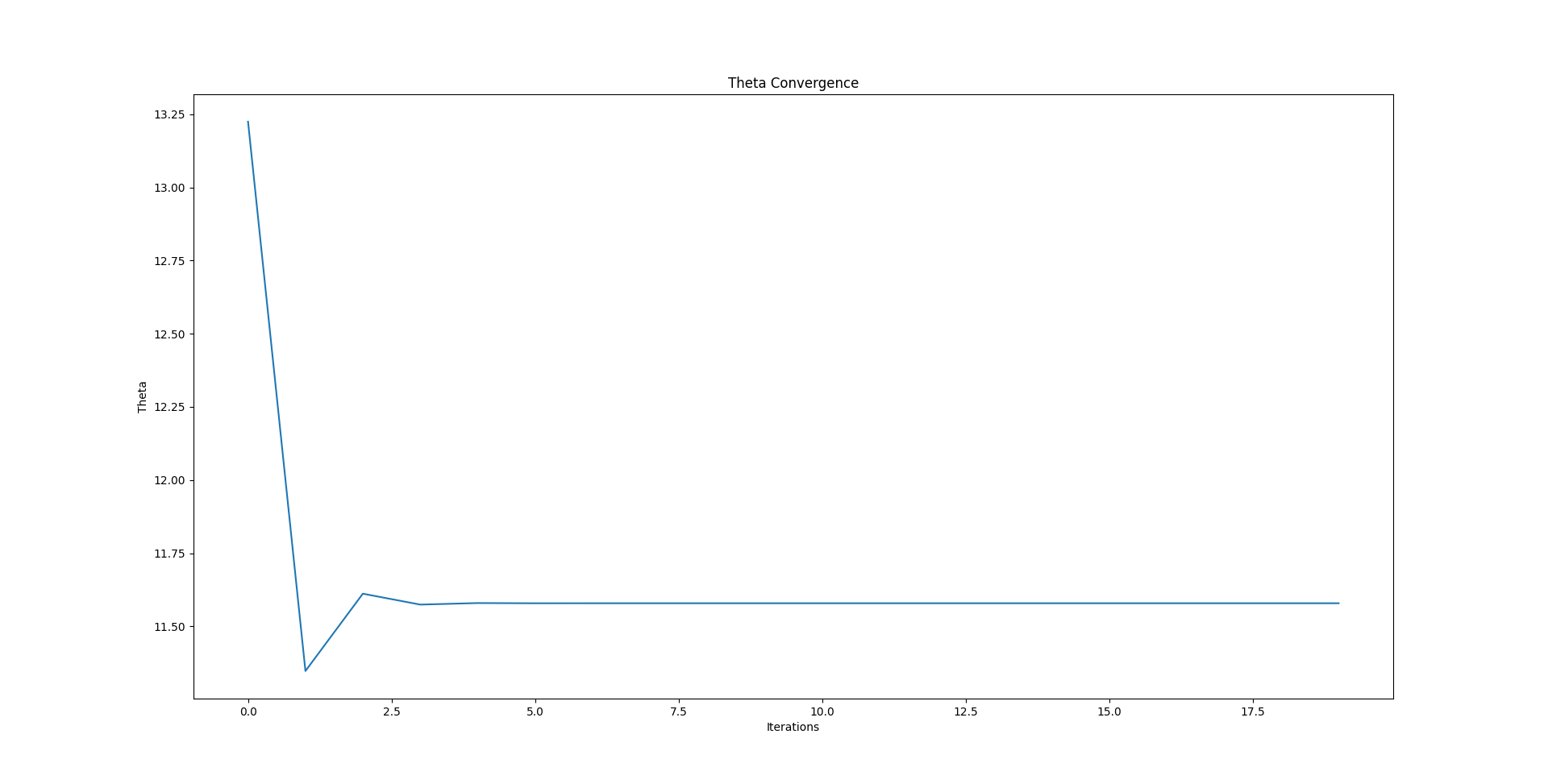

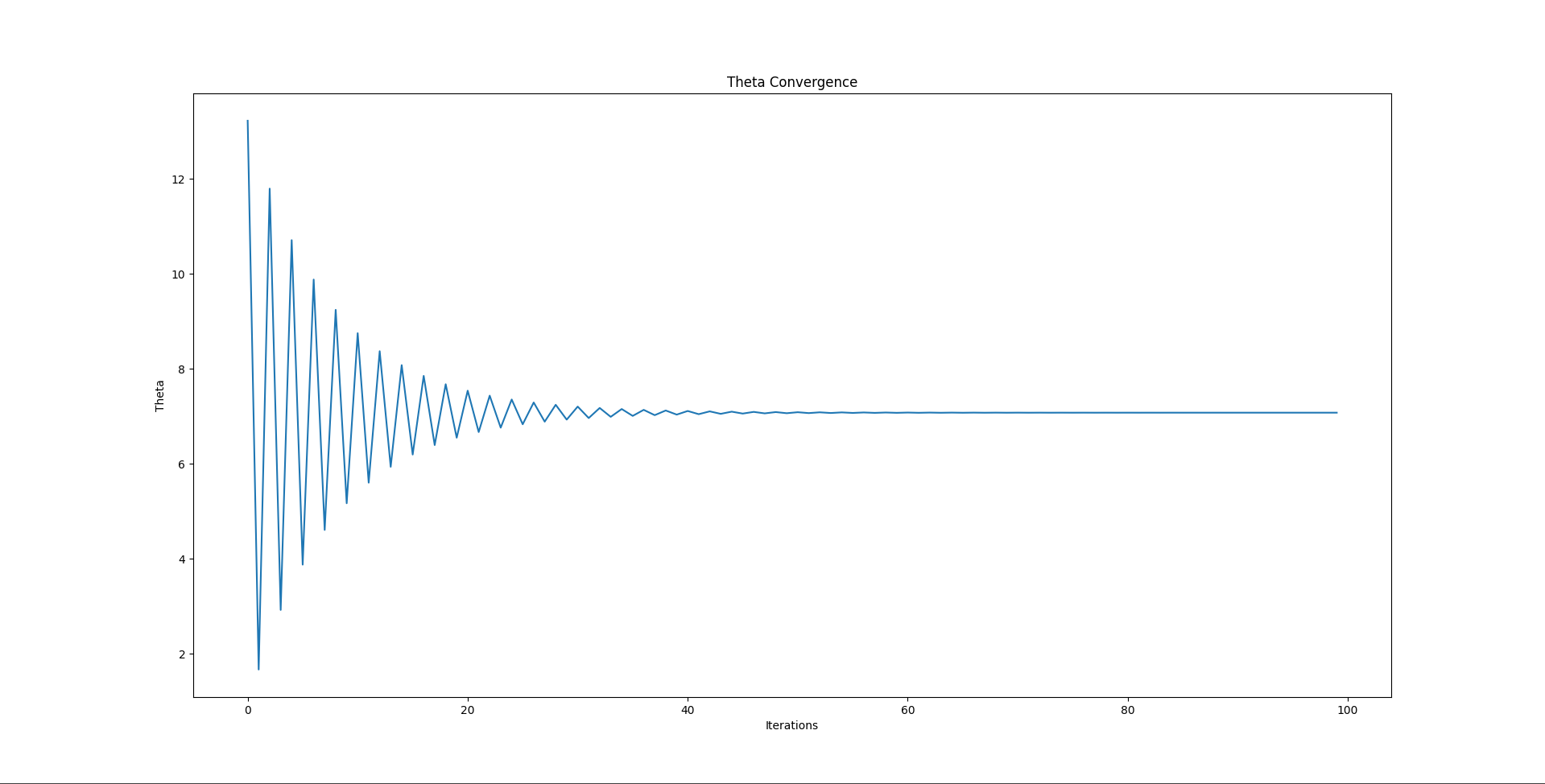

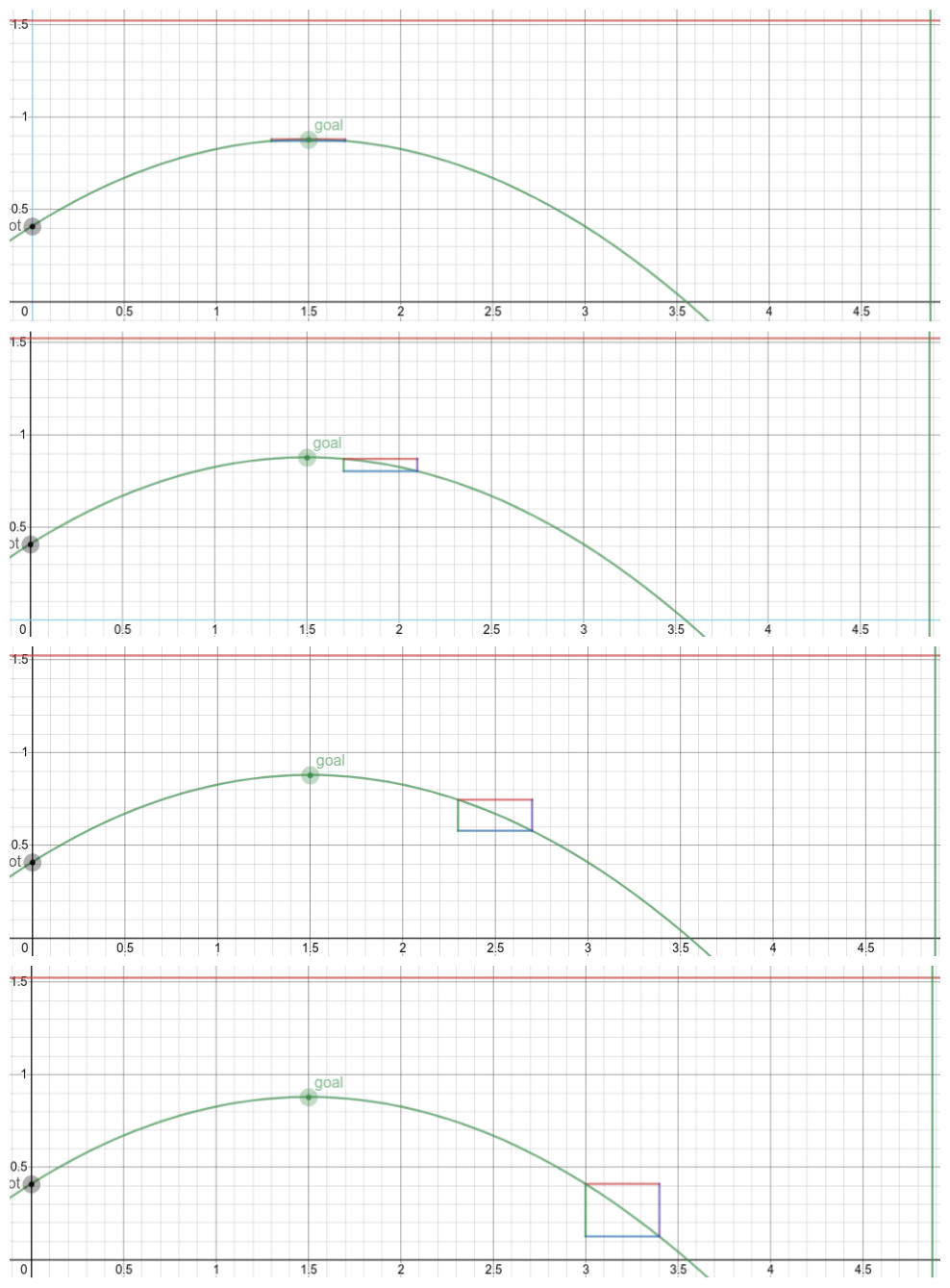

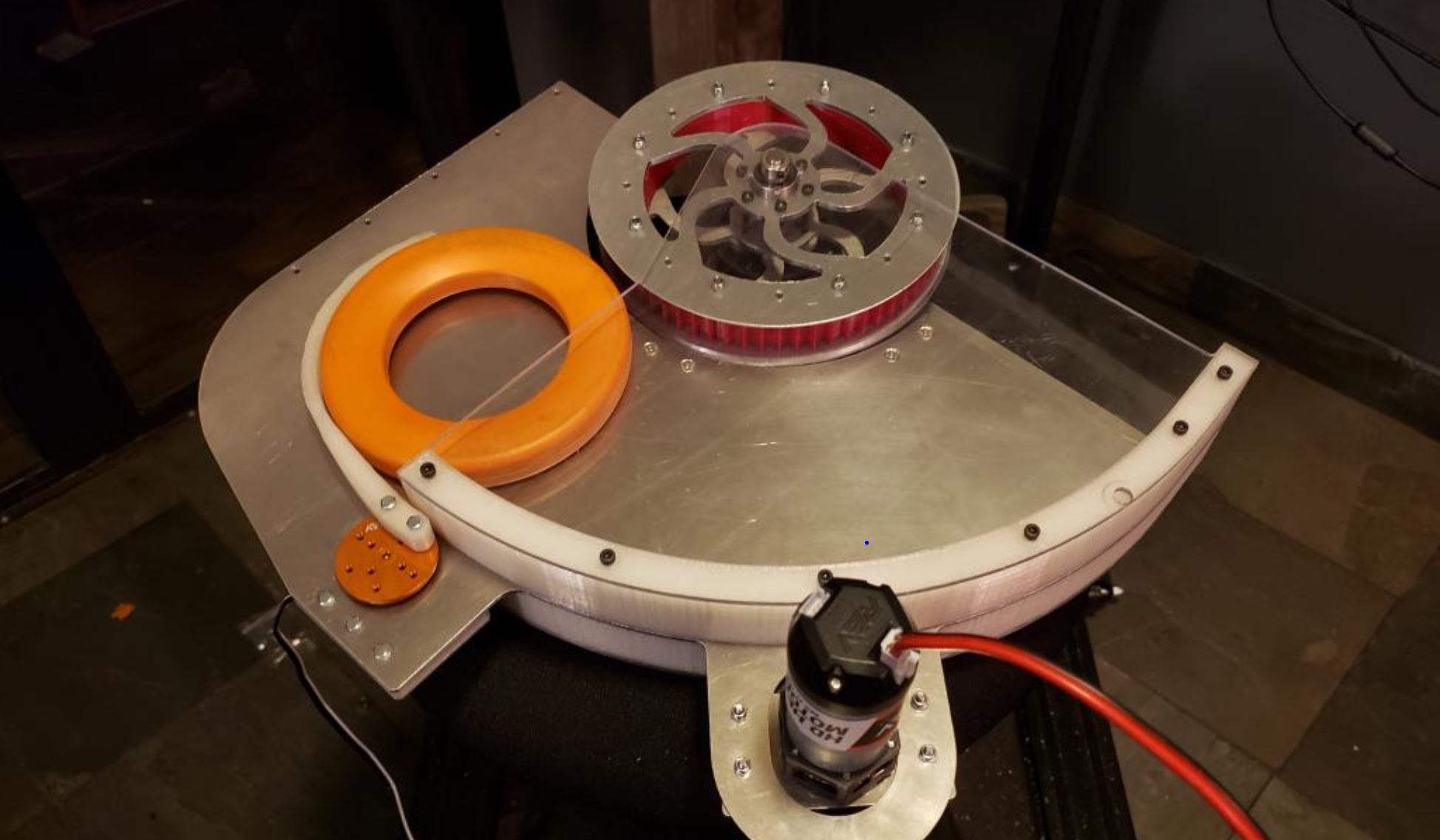

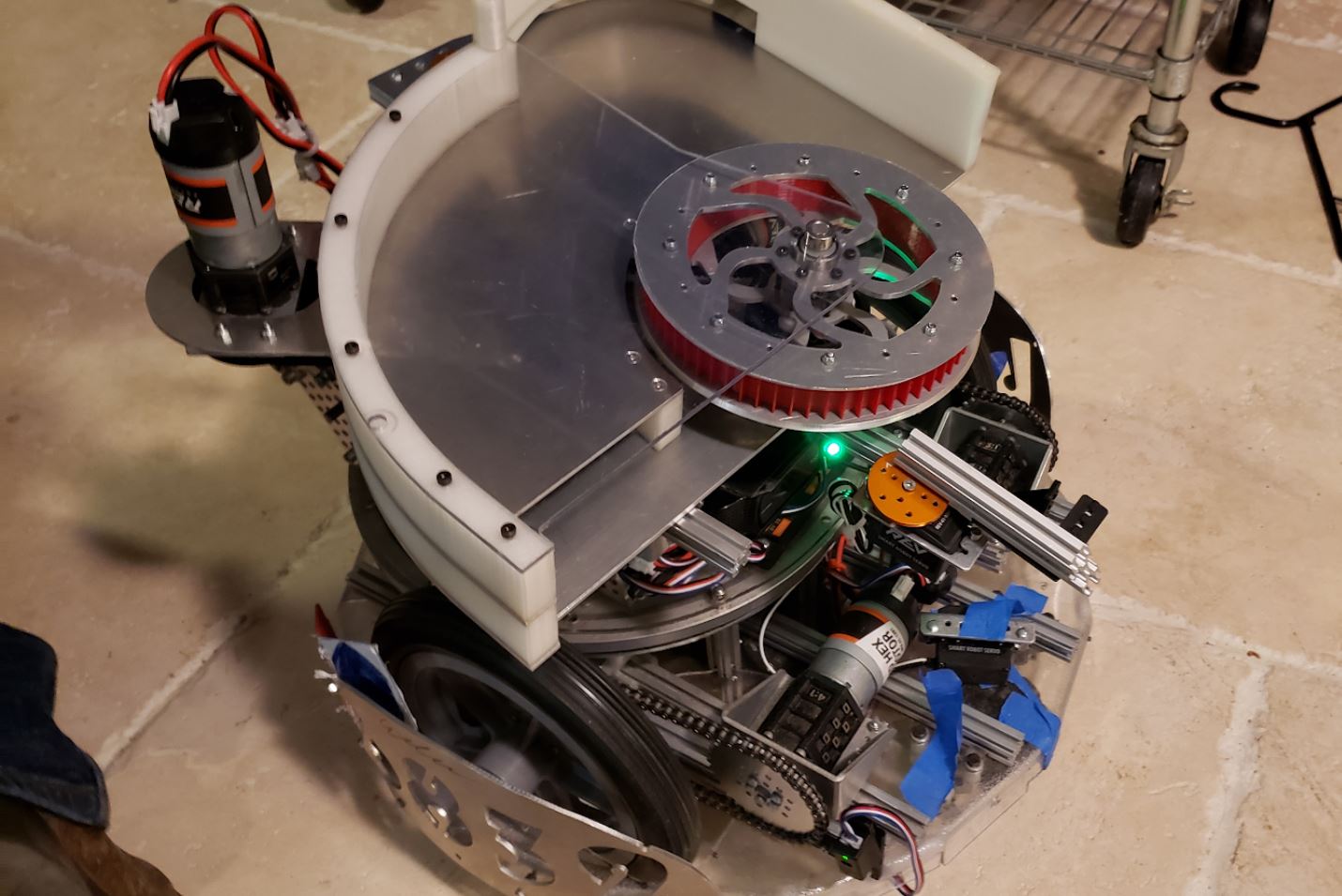

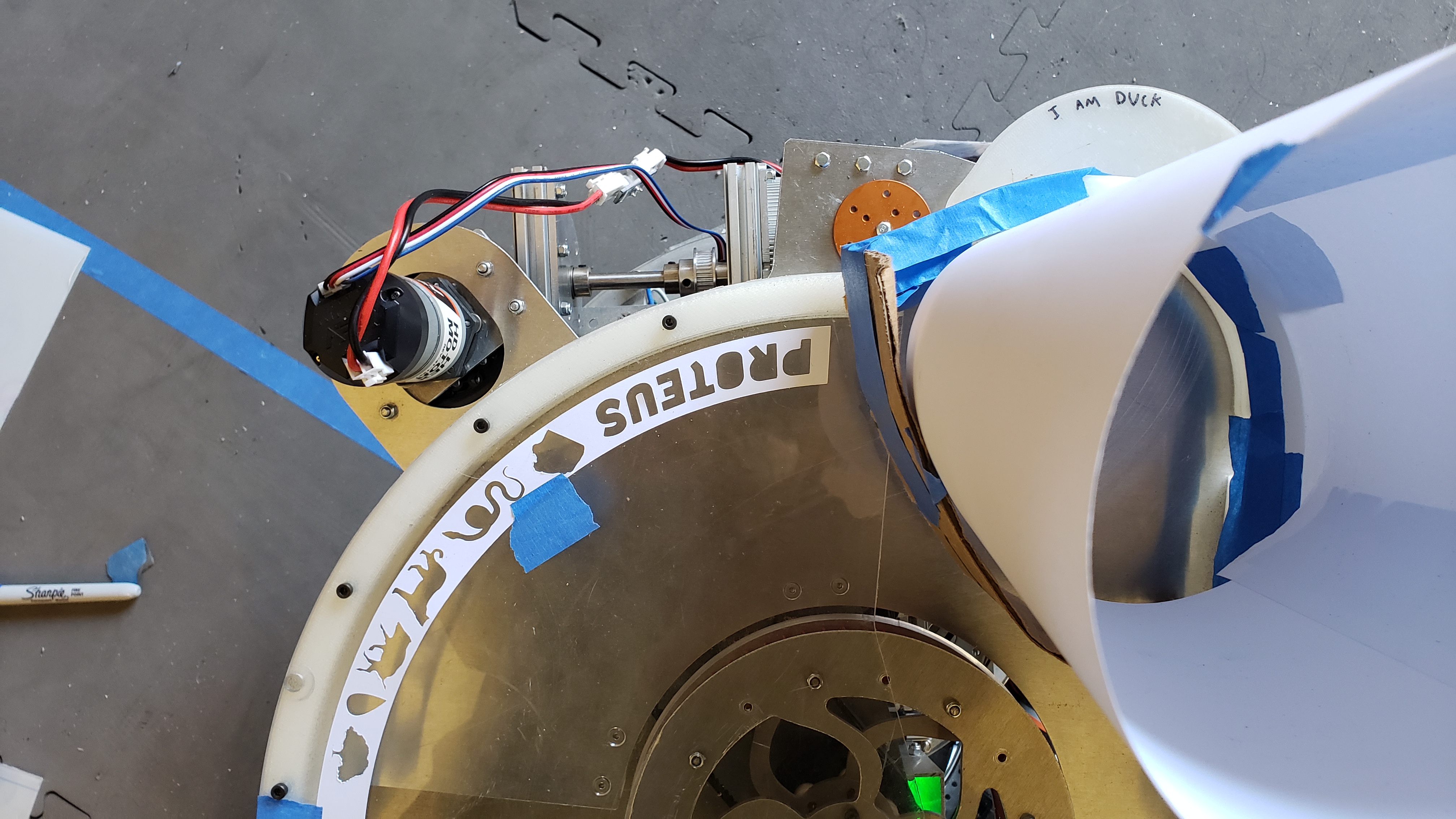

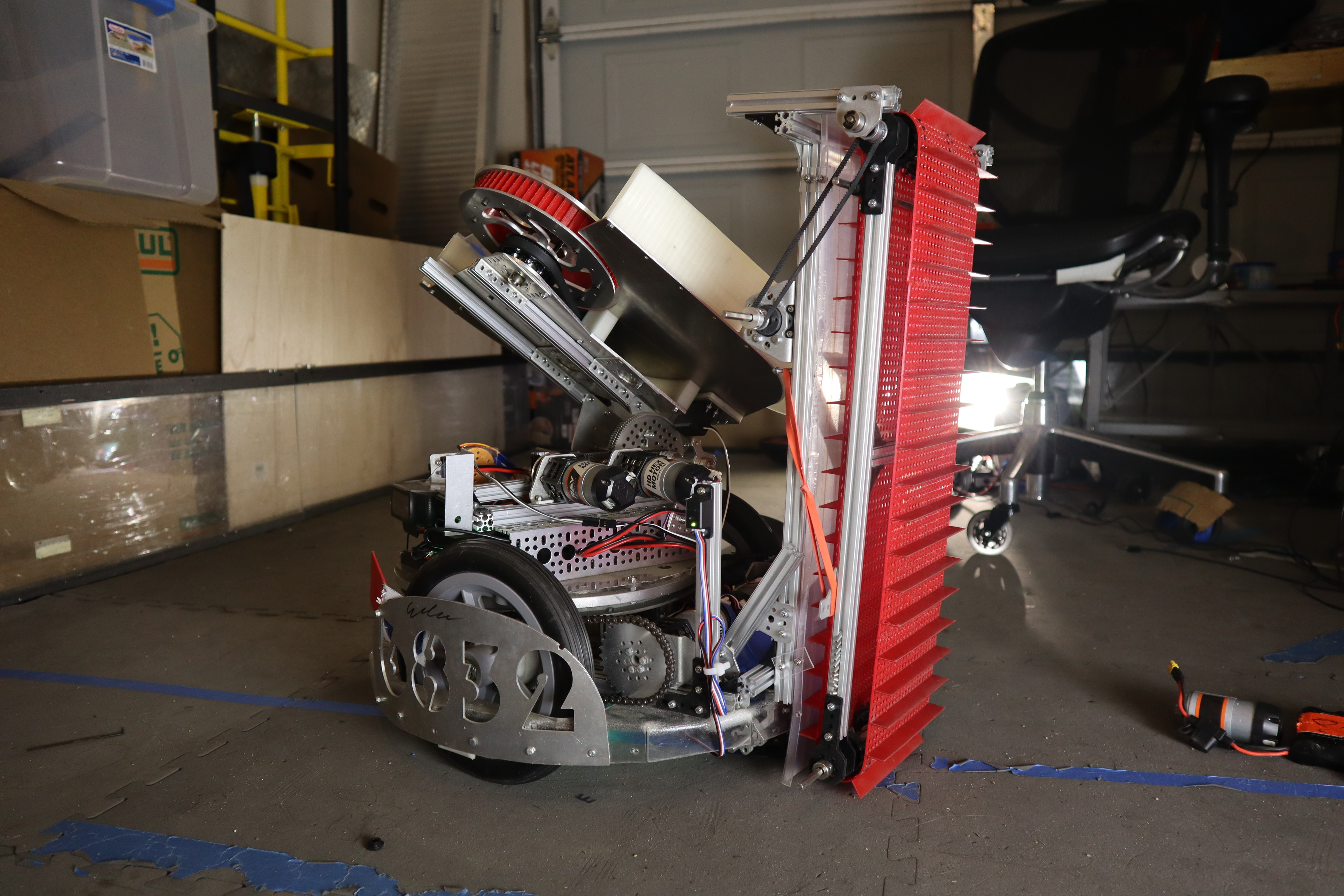

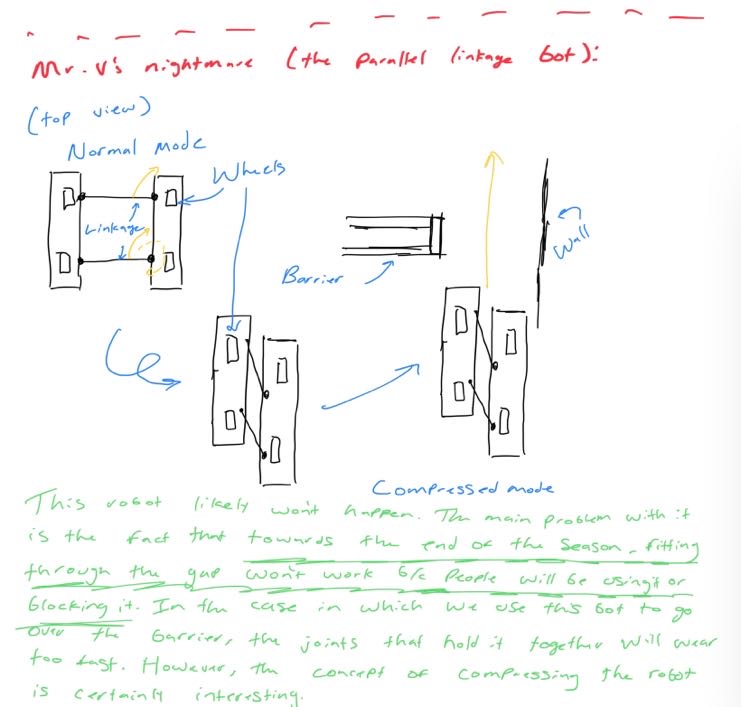

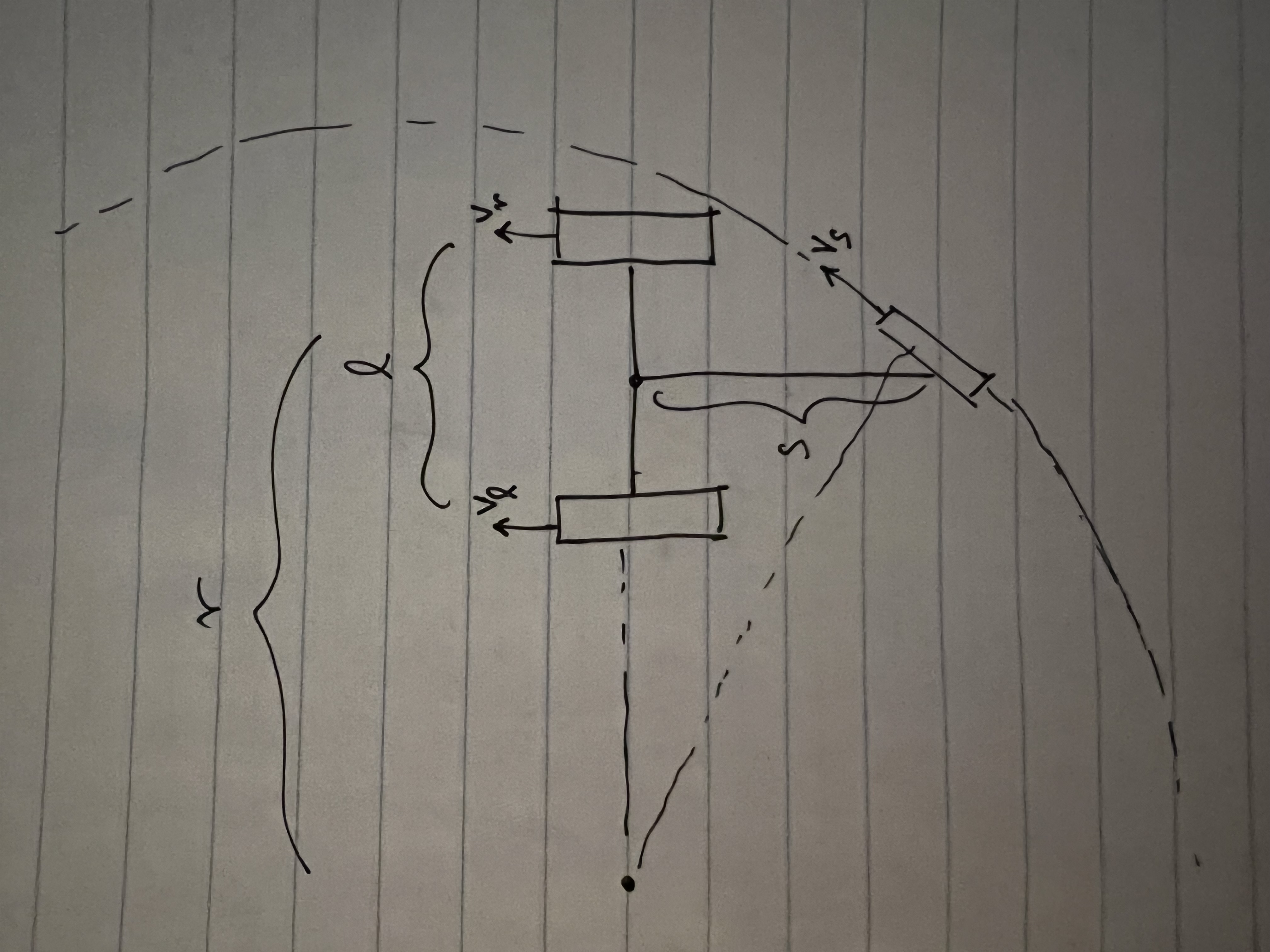

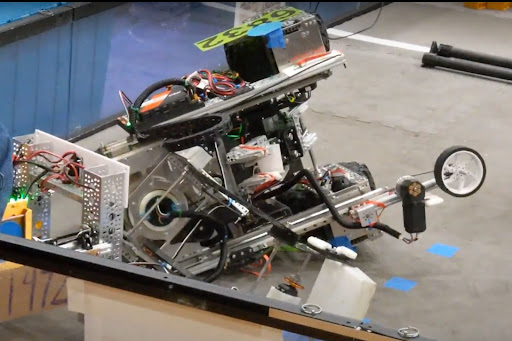

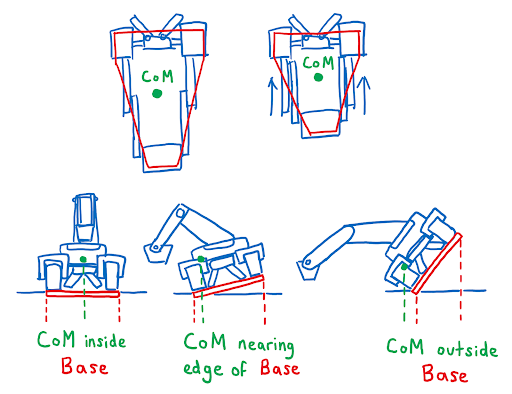

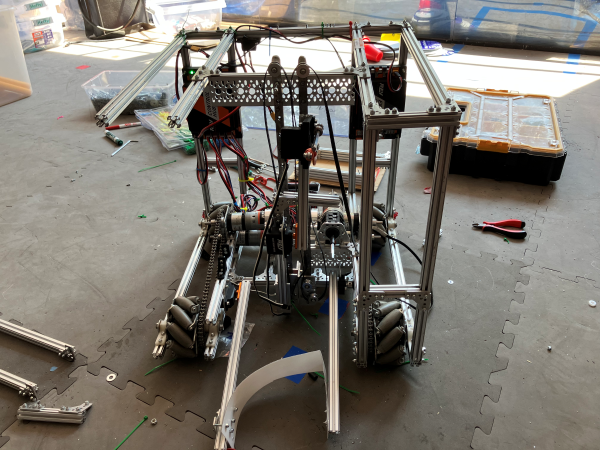

Looking at these diagrams of the robot and its center of mass, we can see how as the crane extends past the base of the robot, the center of mass moves towards the base. Eventually, the center of mass reaches a position outside of the base and the robot falls over. To solve this problem, we would have to either lower the center of mass or limit its fluctuation during movement.

Looking at these diagrams of the robot and its center of mass, we can see how as the crane extends past the base of the robot, the center of mass moves towards the base. Eventually, the center of mass reaches a position outside of the base and the robot falls over. To solve this problem, we would have to either lower the center of mass or limit its fluctuation during movement.

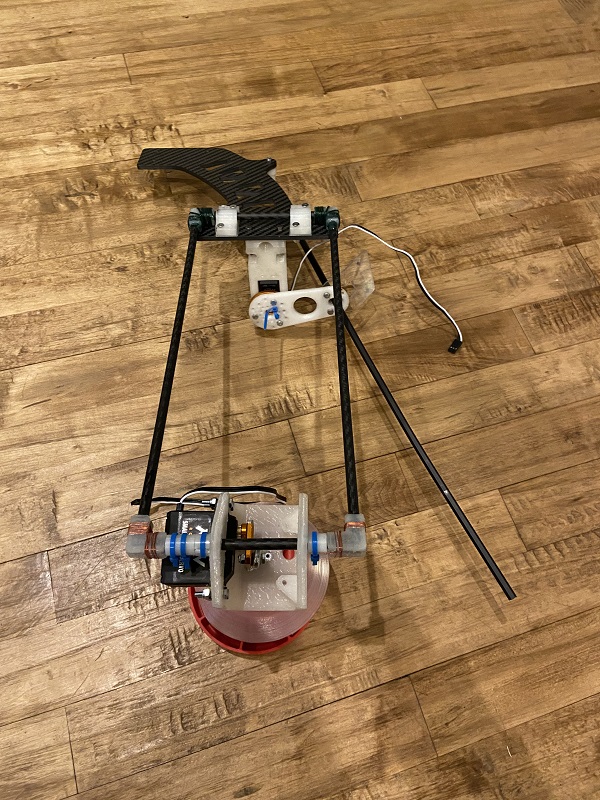

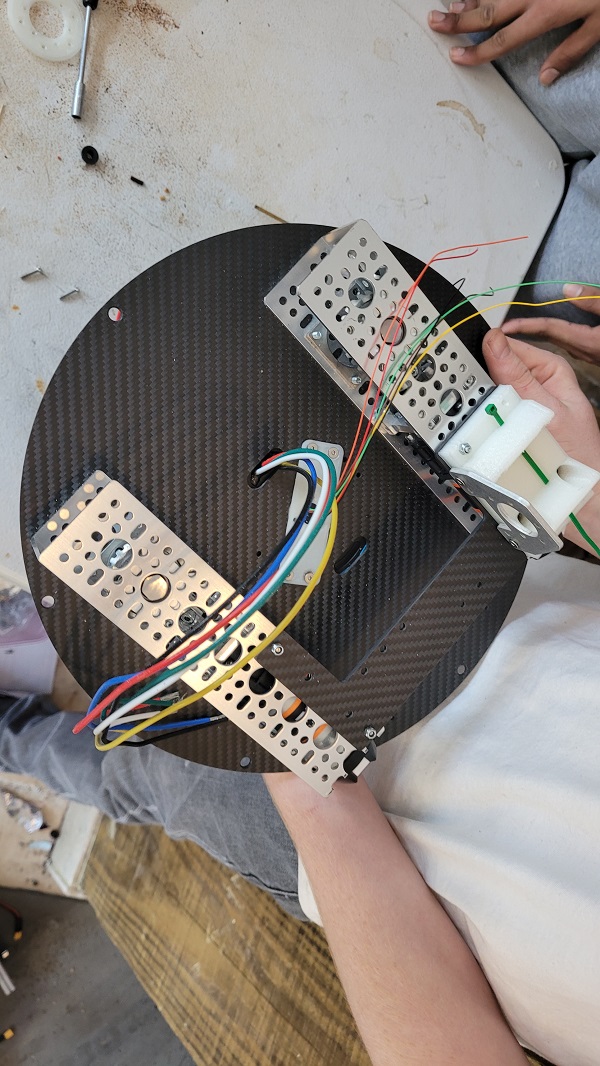

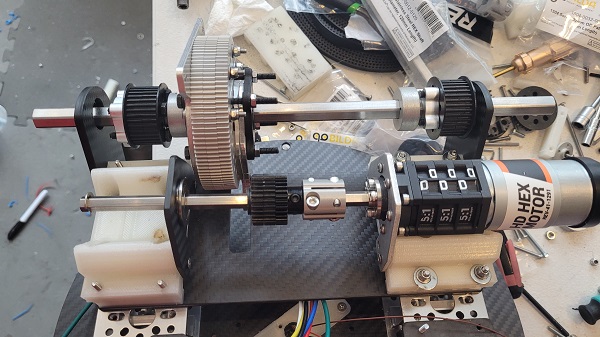

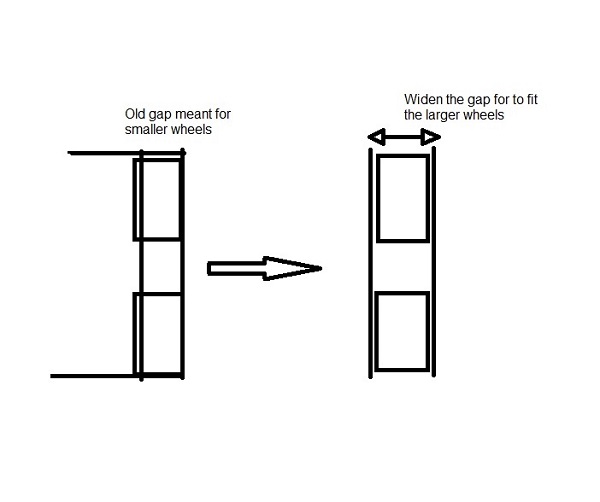

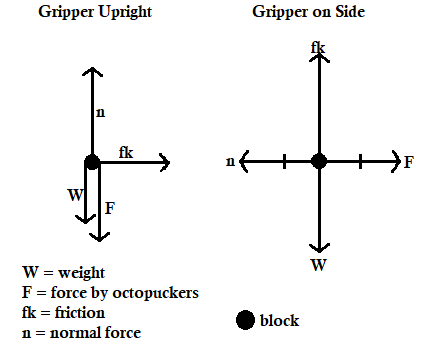

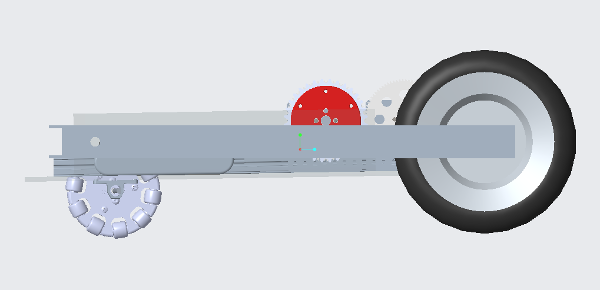

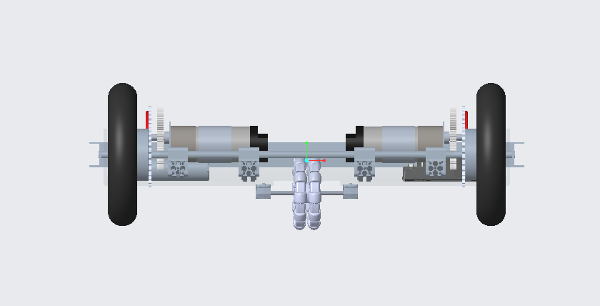

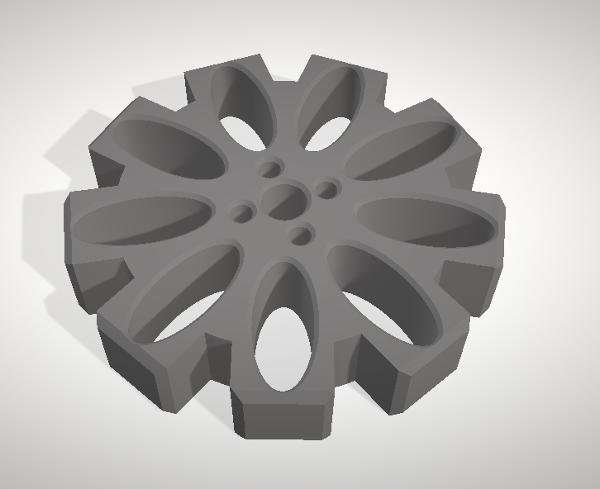

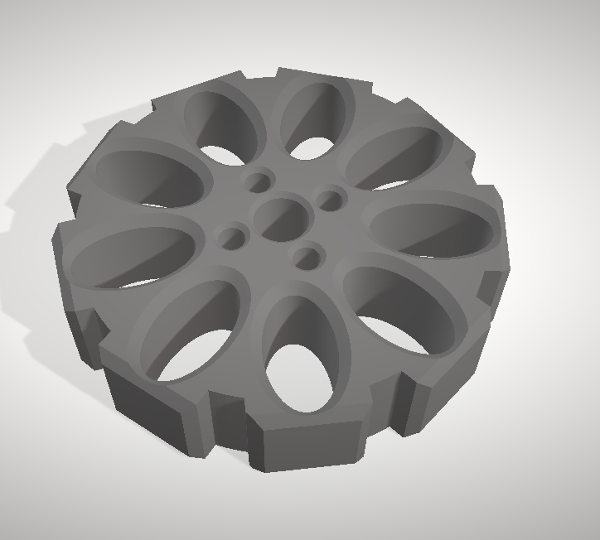

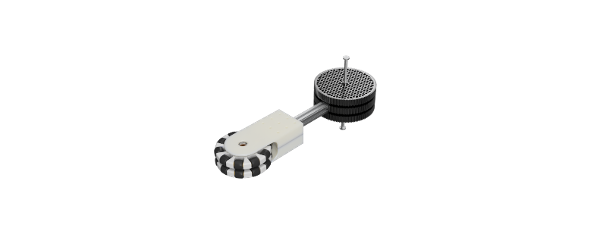

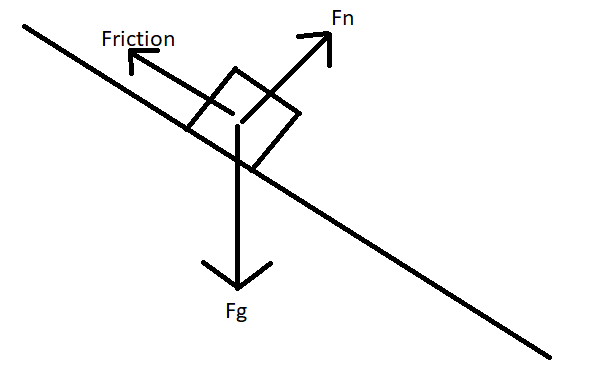

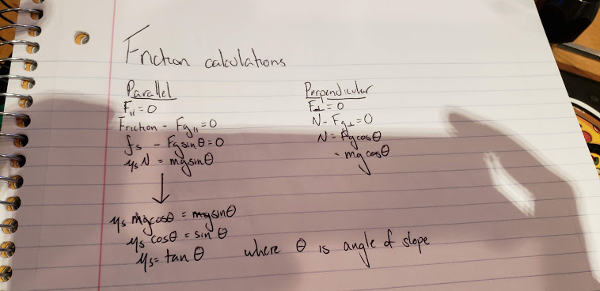

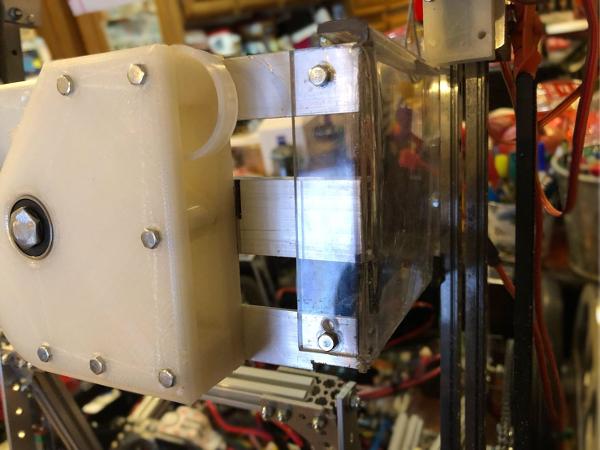

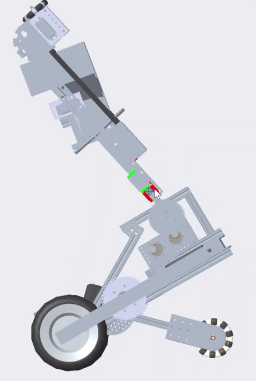

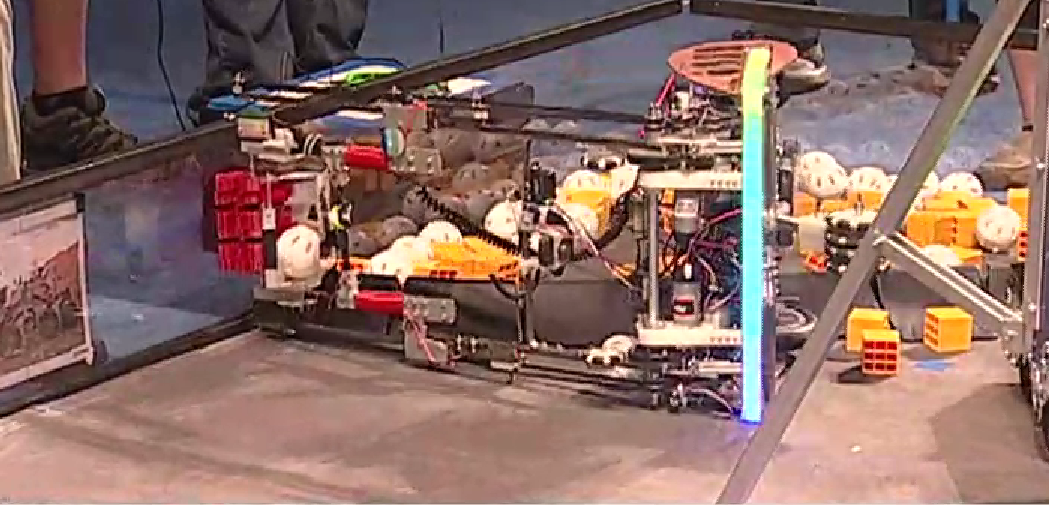

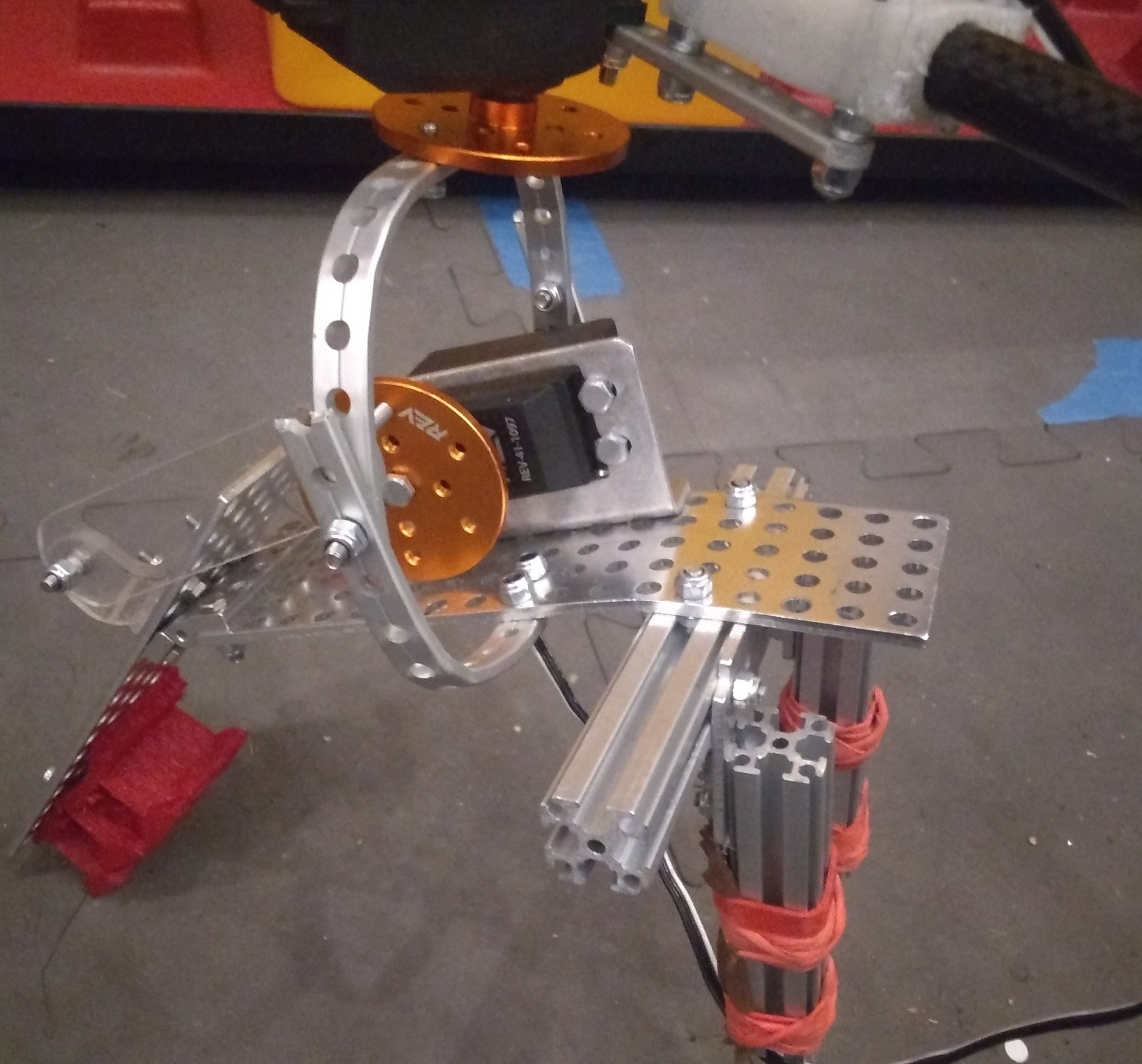

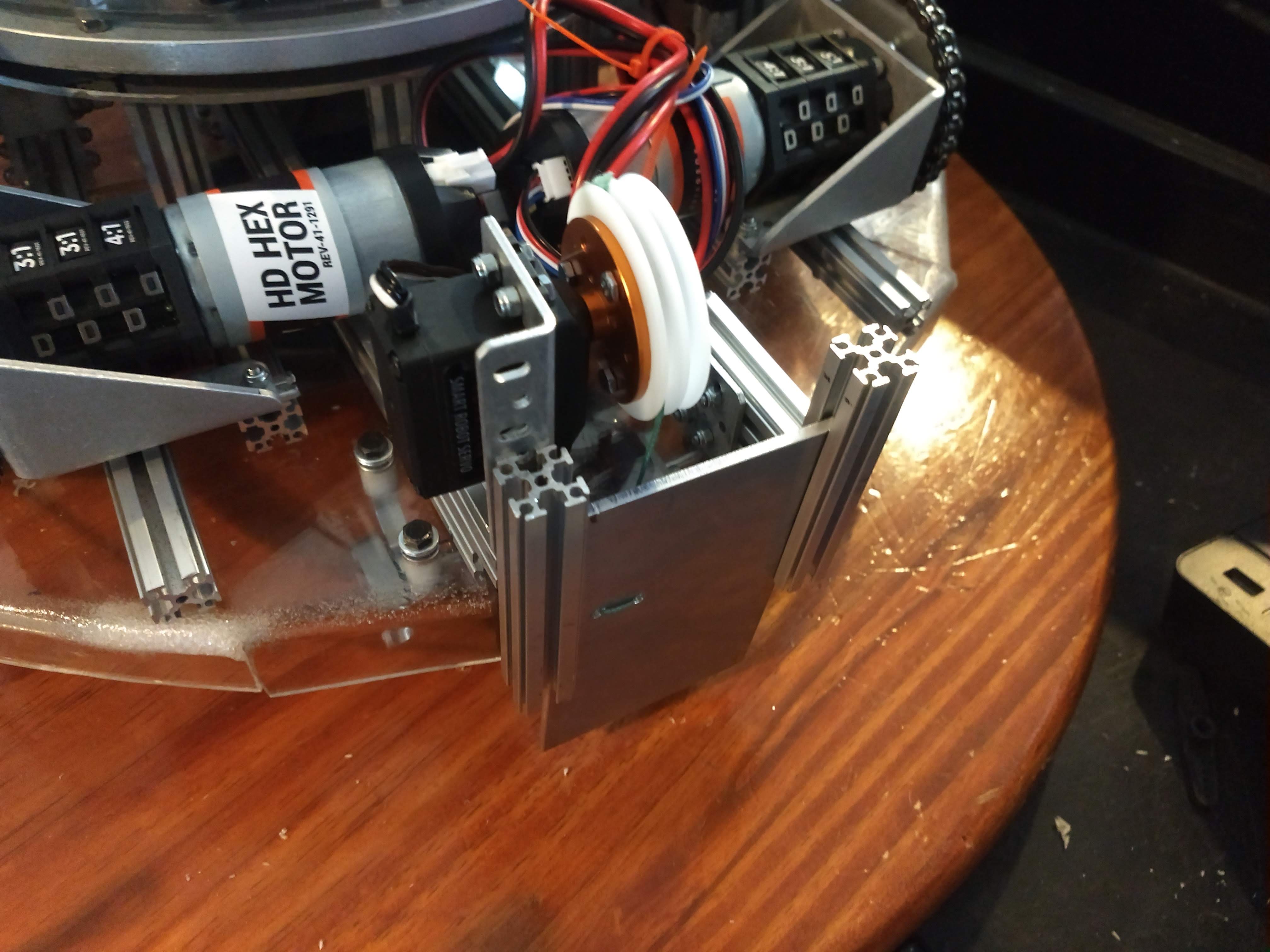

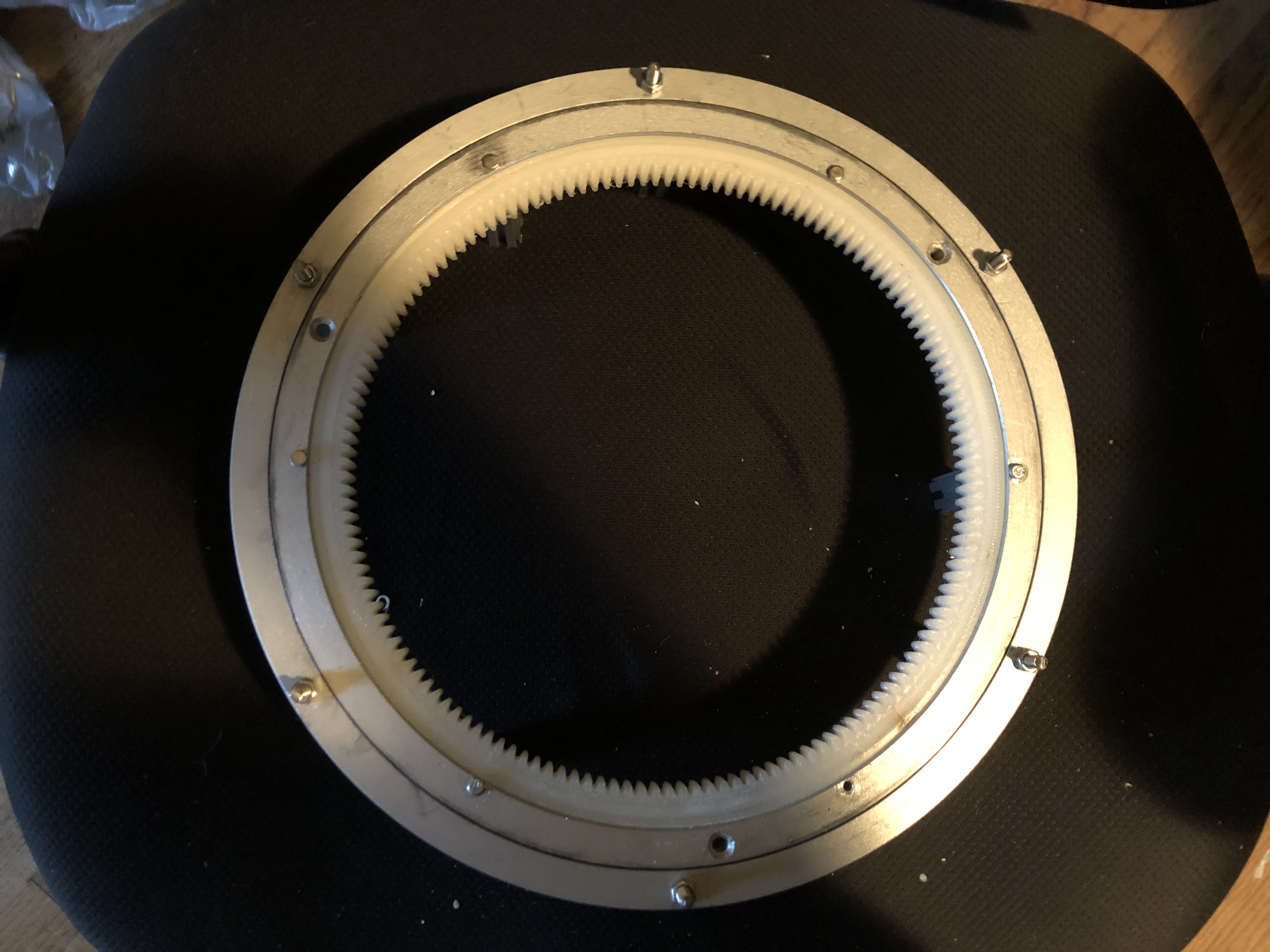

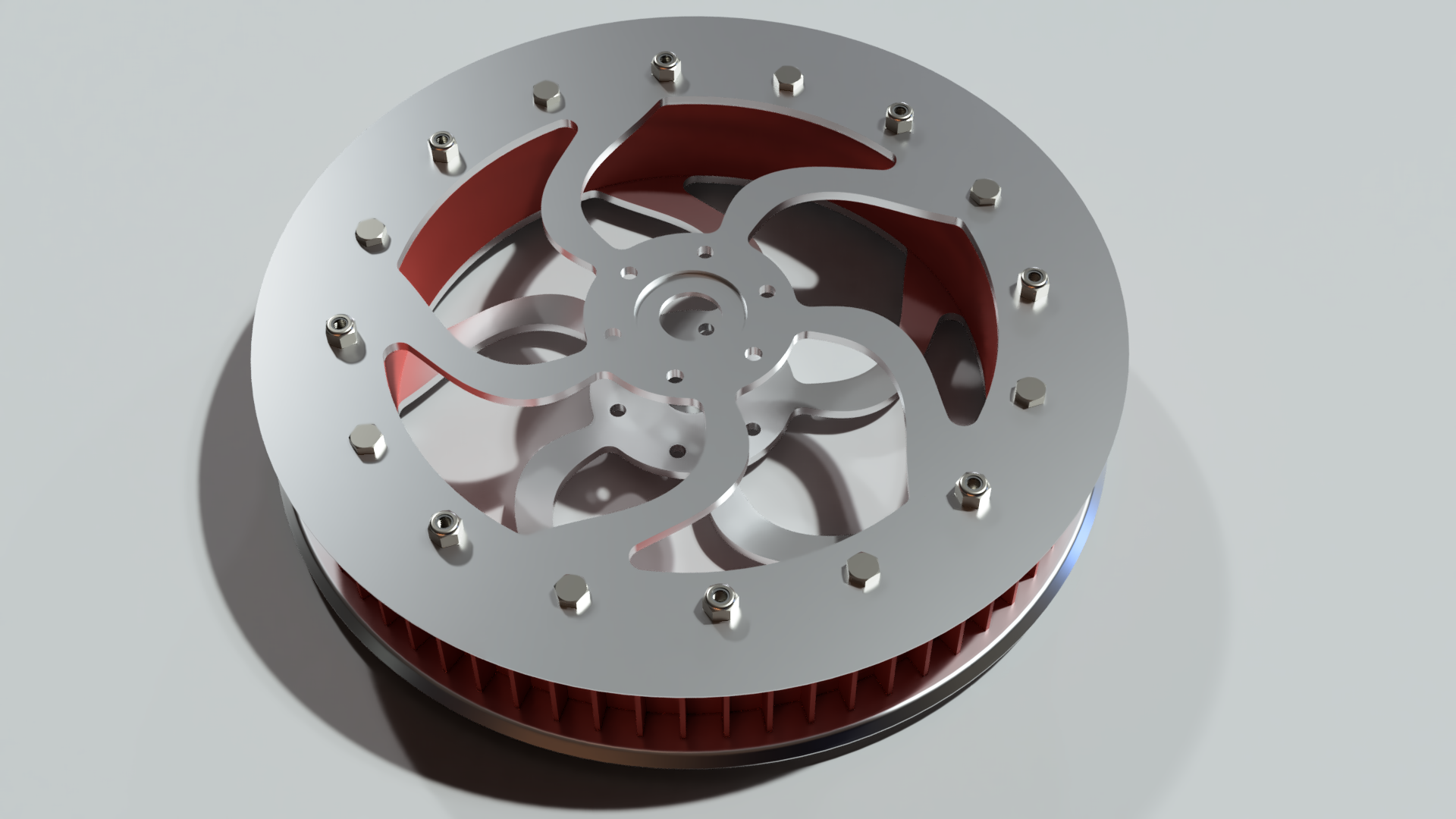

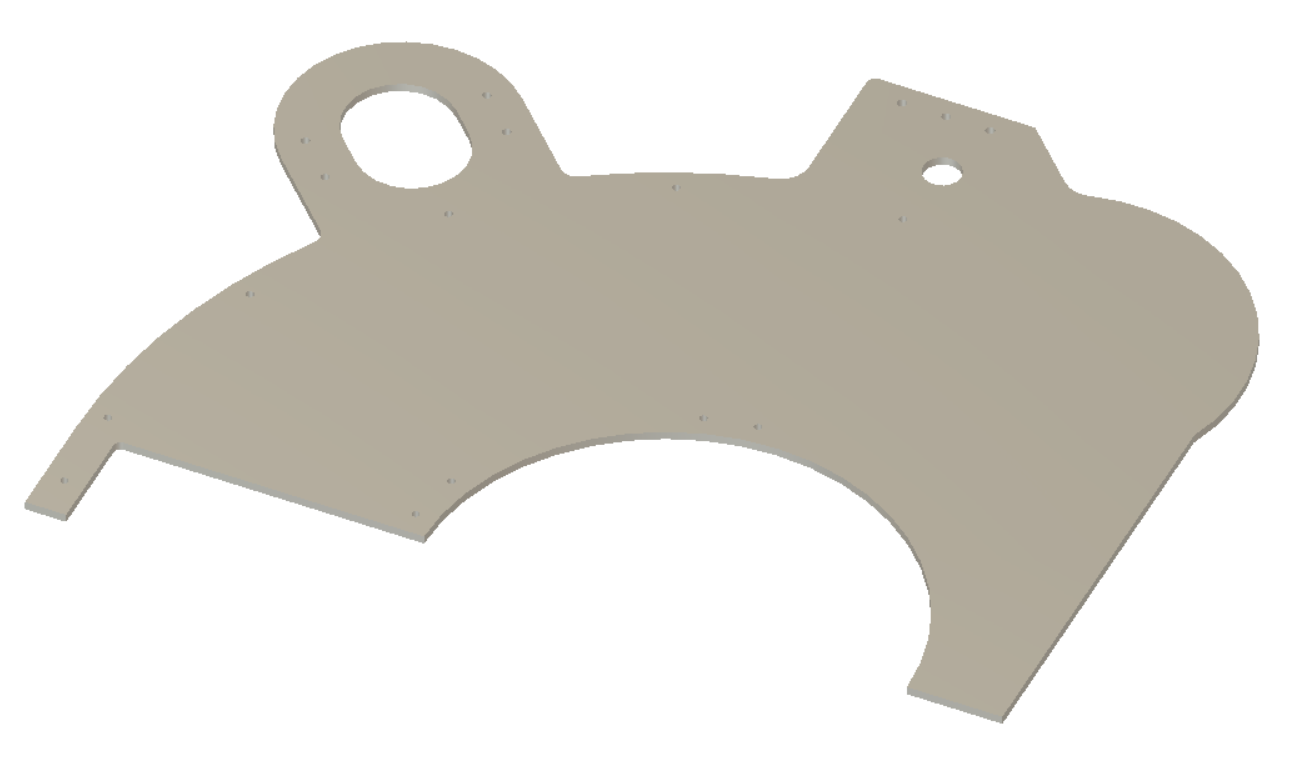

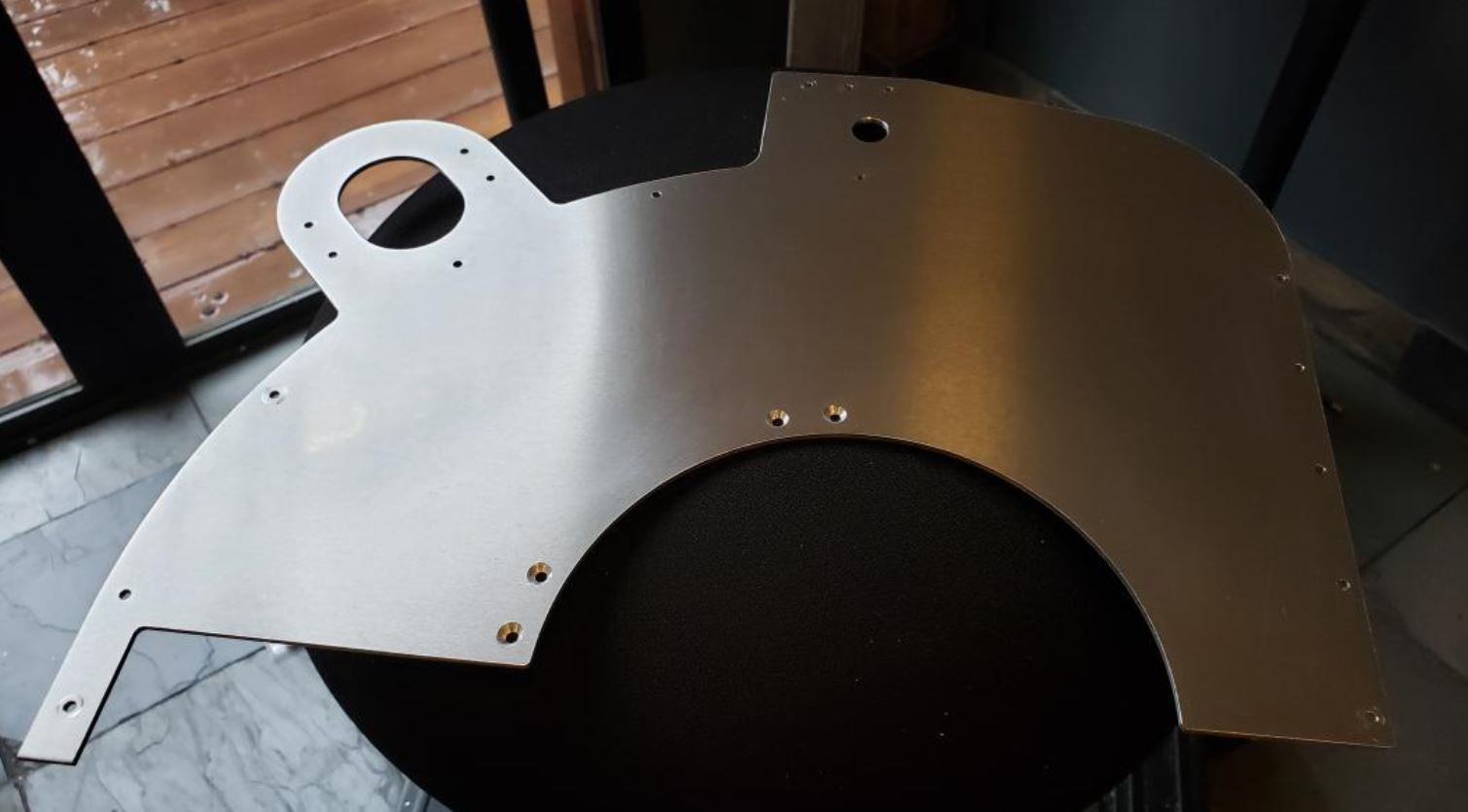

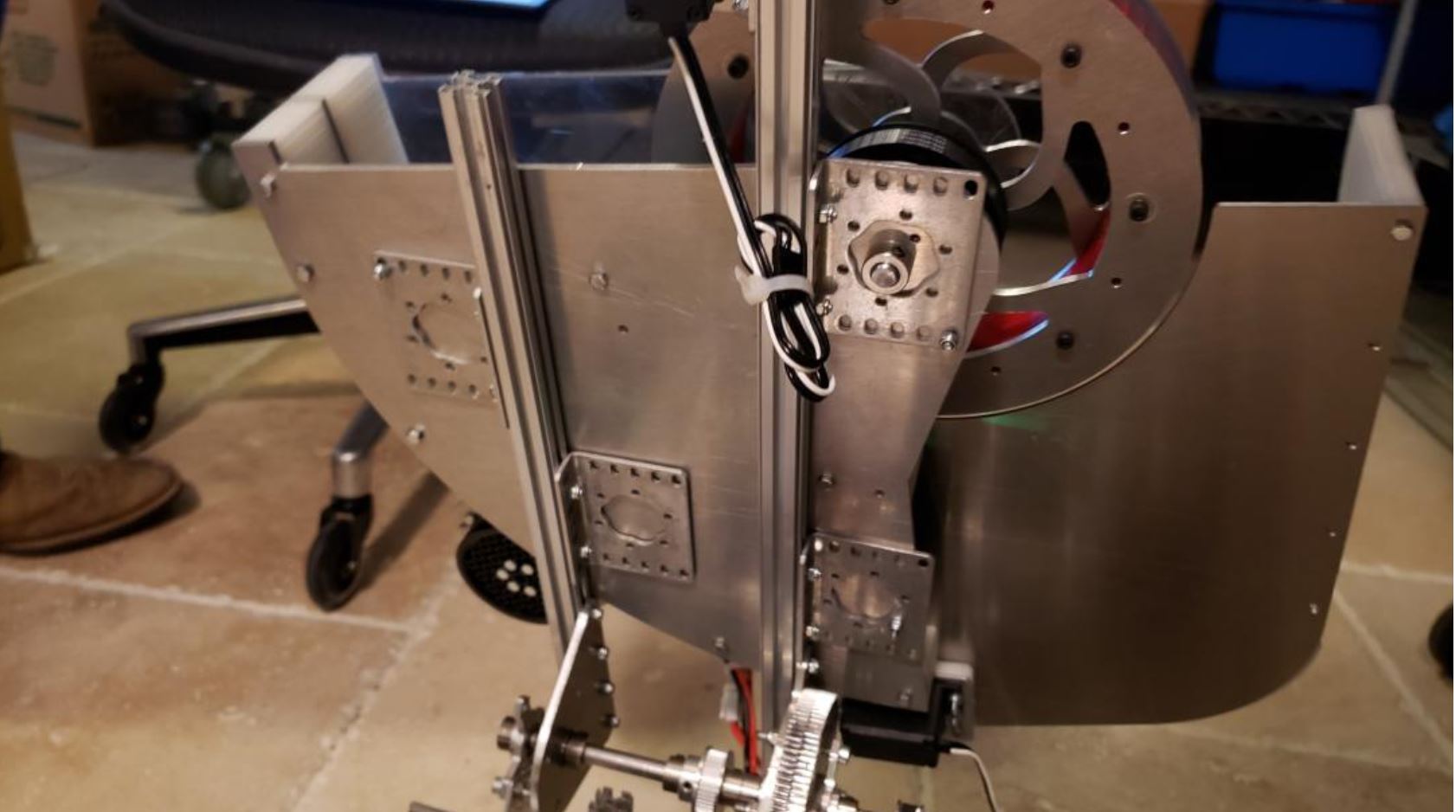

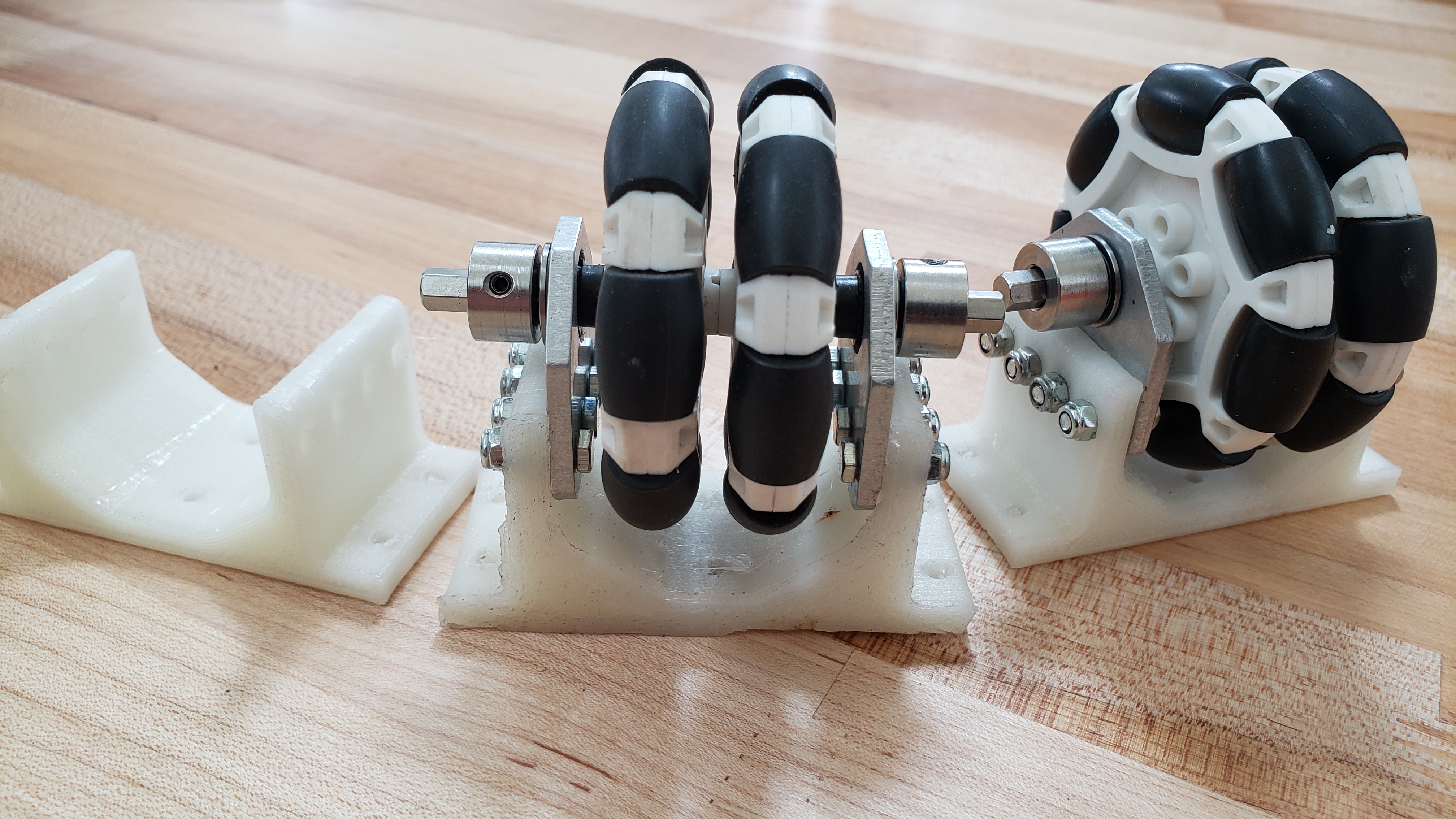

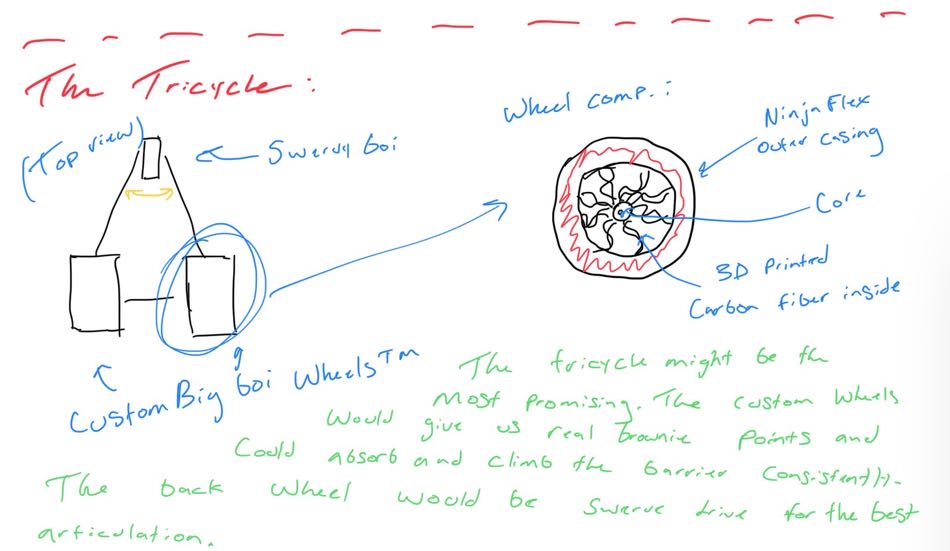

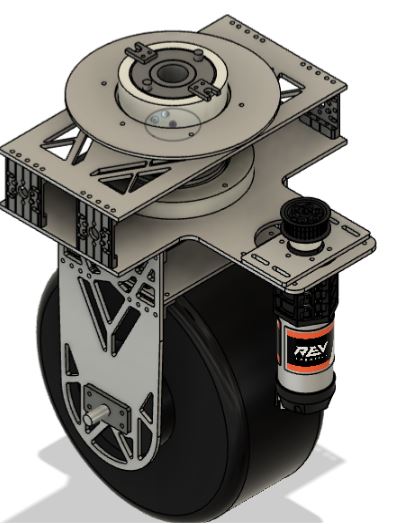

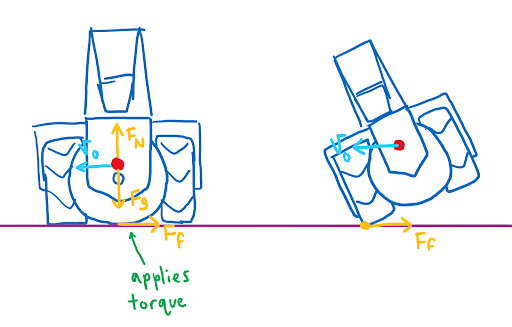

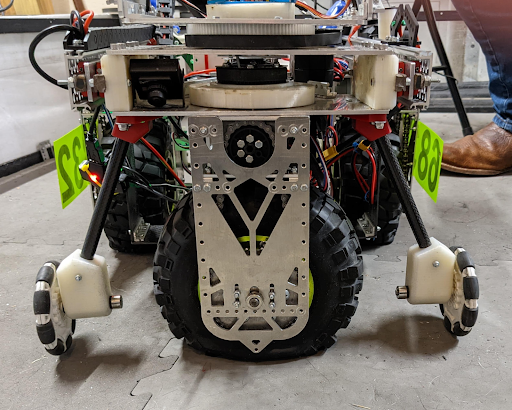

You can see from these free-body diagrams that as we lower the vertical component of the normal force, the overall rotational torque exerted by the swerve module is decreased, which inspired our decisions to lower the center of mass.

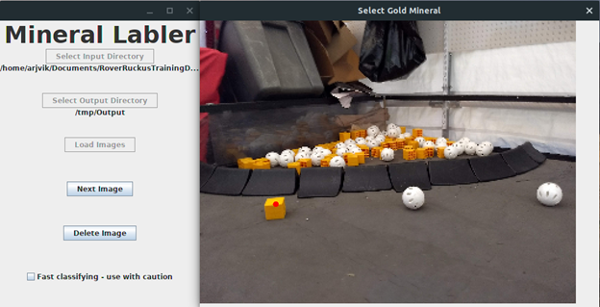

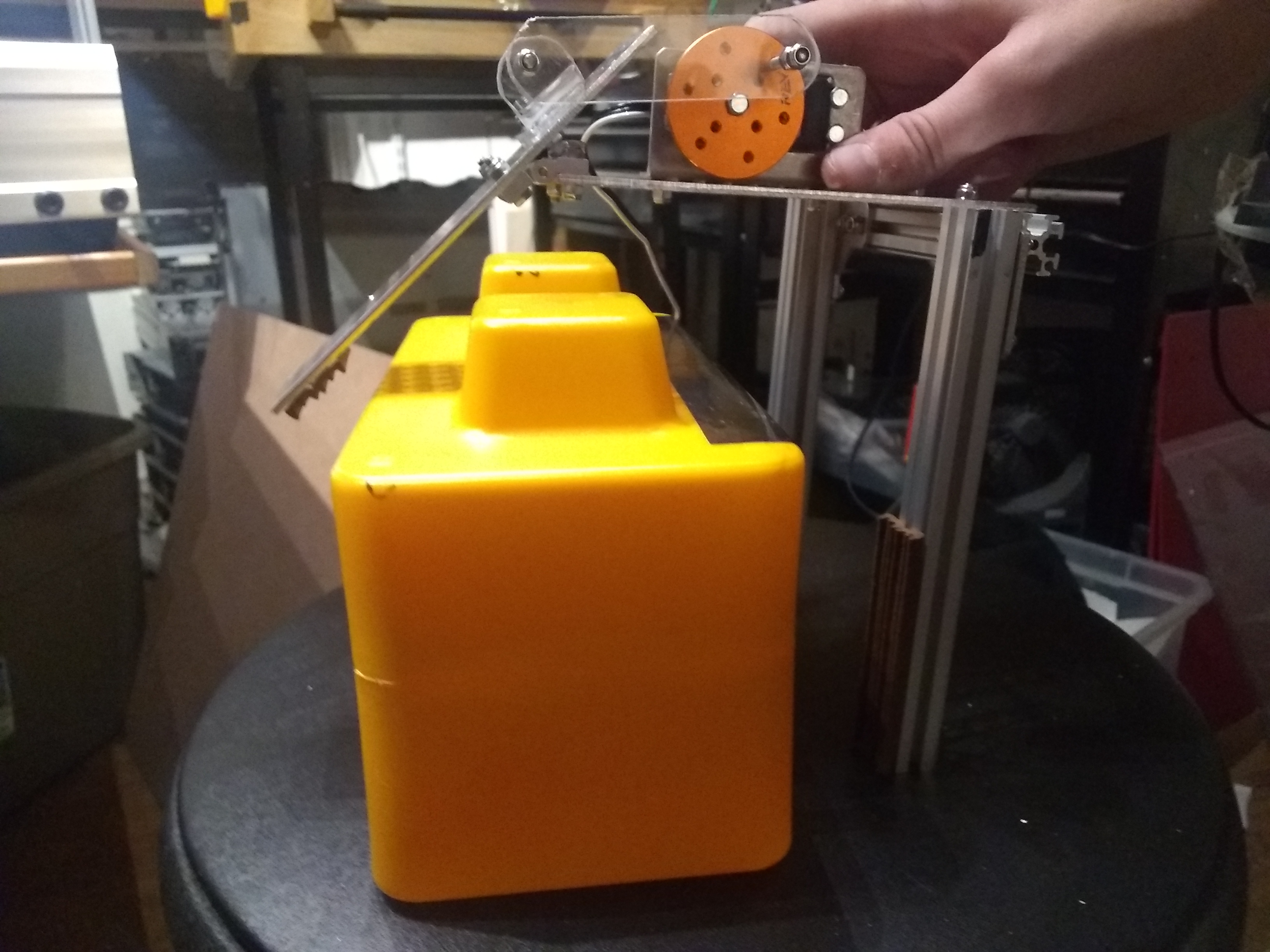

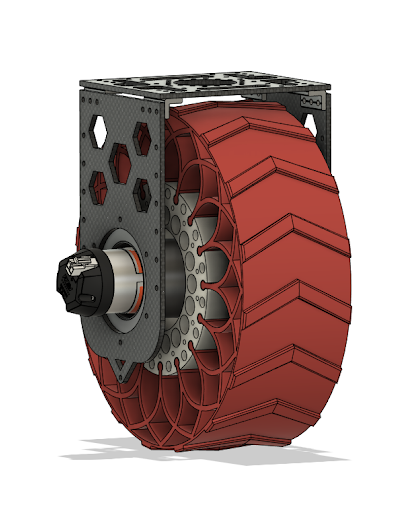

We did this by redesigning our wheel modules and moving the motor further down. Our redesigned wheel modules utilize custom printed "barrier beaters" instead of the rock climbers we used before. These wheels were printed out of ninja flex and nylon and utilized a Gothic Arch design inspired by Monash University's rover wheels. The custom wheel modules used custom carbon-fiber plates and holes in the nylon hub to help reduce weight. Overall, these wheels were excellent at traversing the barriers, weighed less, and the wheel module allowed the motor to drop 5 inches in height. This led to a lower center of mass for the robot.

You can see from these free-body diagrams that as we lower the vertical component of the normal force, the overall rotational torque exerted by the swerve module is decreased, which inspired our decisions to lower the center of mass.

We did this by redesigning our wheel modules and moving the motor further down. Our redesigned wheel modules utilize custom printed "barrier beaters" instead of the rock climbers we used before. These wheels were printed out of ninja flex and nylon and utilized a Gothic Arch design inspired by Monash University's rover wheels. The custom wheel modules used custom carbon-fiber plates and holes in the nylon hub to help reduce weight. Overall, these wheels were excellent at traversing the barriers, weighed less, and the wheel module allowed the motor to drop 5 inches in height. This led to a lower center of mass for the robot.

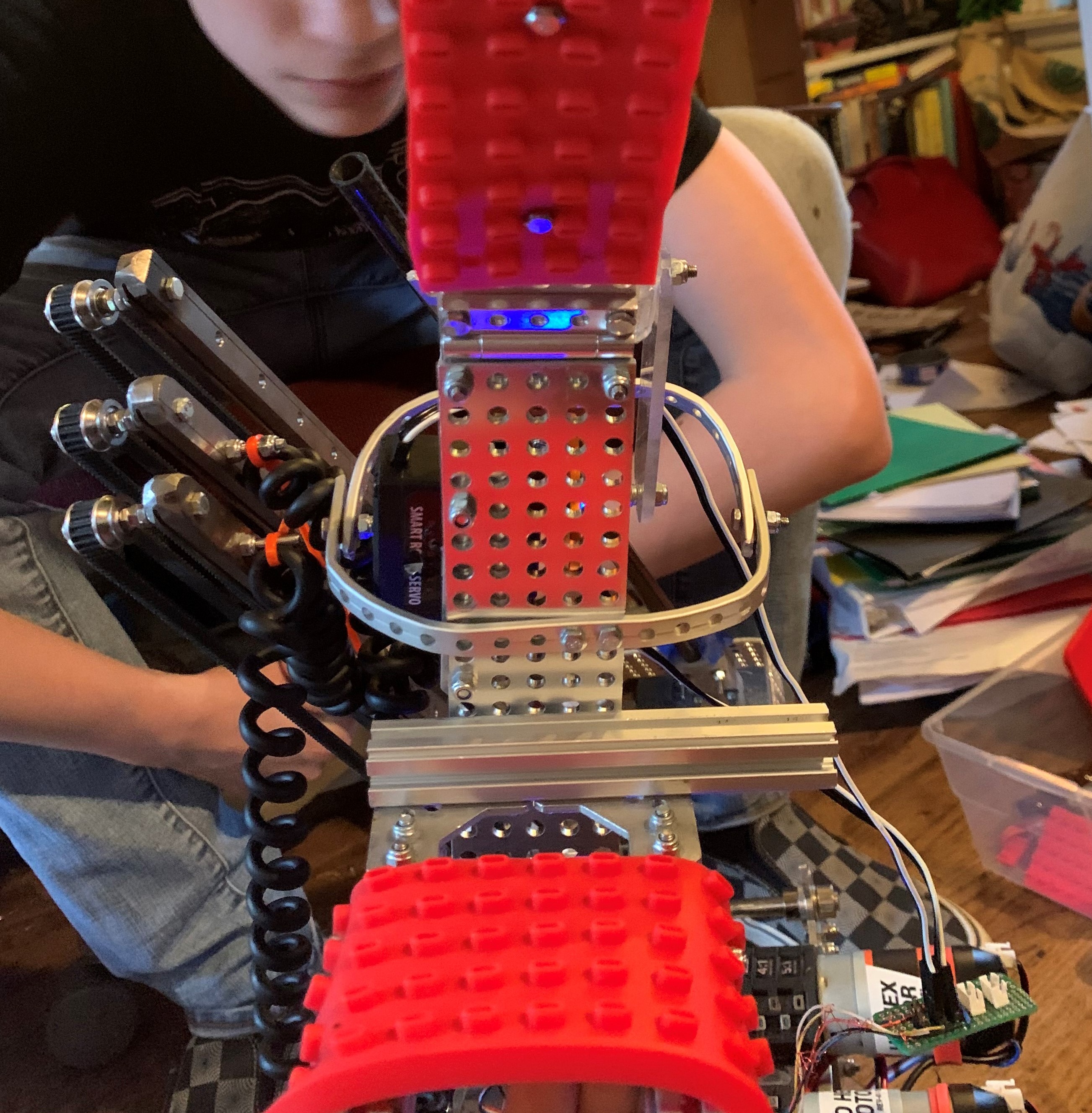

However, in the situation that the crane and robot extension did lead to the center of mass nearing the base, we installed an outrigger system as a preventative measure. An outrigger is essentially a beam that extends from a robot that is used to improve stability. Our outriggers used omni wheels and functioned similarly to training wheels, preventing the robot from tipping over when the crane moves out and extends.

However, in the situation that the crane and robot extension did lead to the center of mass nearing the base, we installed an outrigger system as a preventative measure. An outrigger is essentially a beam that extends from a robot that is used to improve stability. Our outriggers used omni wheels and functioned similarly to training wheels, preventing the robot from tipping over when the crane moves out and extends.

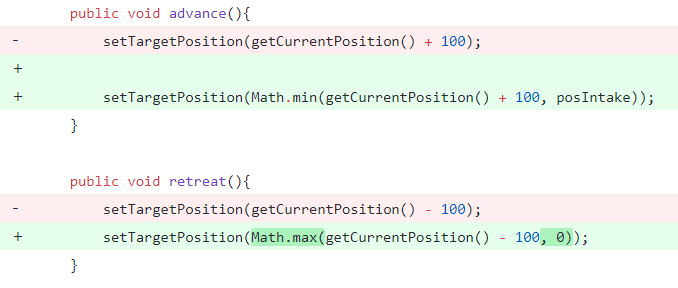

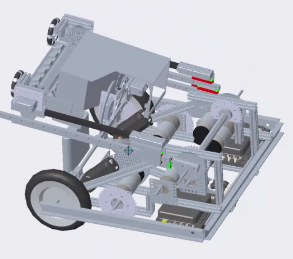

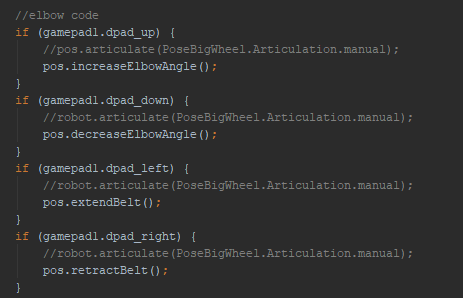

Finally, we implemented some code changes to help deal with this problem, building anti-tipping limiters which allowed for gradual acceleration. This prevented the sudden acceleration mentioned earlier which was a cause of our tipping issue. We also programmed in pre-set arm locations to help keep the center of mass near the wheelbase, making sure that the center of mass never passes the base of the actual robot.

Finally, we implemented some code changes to help deal with this problem, building anti-tipping limiters which allowed for gradual acceleration. This prevented the sudden acceleration mentioned earlier which was a cause of our tipping issue. We also programmed in pre-set arm locations to help keep the center of mass near the wheelbase, making sure that the center of mass never passes the base of the actual robot.

.jpg)

.jpg)